The global washing machine market is experiencing steady growth, driven by rising urbanization, increasing disposable incomes, and demand for energy-efficient home appliances. According to Mordor Intelligence, the washing machine market was valued at USD 74.3 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion directly fuels demand for critical components such as drain plugs, which ensure reliable and leak-free operation across various washing machine models. As manufacturers focus on durability, water efficiency, and compliance with environmental standards, the need for high-quality, precision-engineered drain plugs has become paramount. With original equipment manufacturers (OEMs) and after-market suppliers alike emphasizing performance and longevity, sourcing from reliable drain plug manufacturers is essential. Below, we highlight the top eight manufacturers leading innovation and supply in this niche yet vital segment of the home appliance supply chain.

Top 8 Wash Machine Drain Plug Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM Powermate A100721 Washer, Drain Plug

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: Washer, Drain Plug A100721. Manufactured by: Powermate. ERP Number: ERP10039945. Part Number: A100721. Original Equipment Manufacturer ? $4.13. Special Order. 1 ……

#2 Official Washer Parts

Domain Est. 1999

Website: partselect.com

Key Highlights: $12.99 deliveryShop for genuine OEM Washer Parts at PartSelect. Official parts that fit your Washer, same–day shipping, video tutorials, and expert repair help….

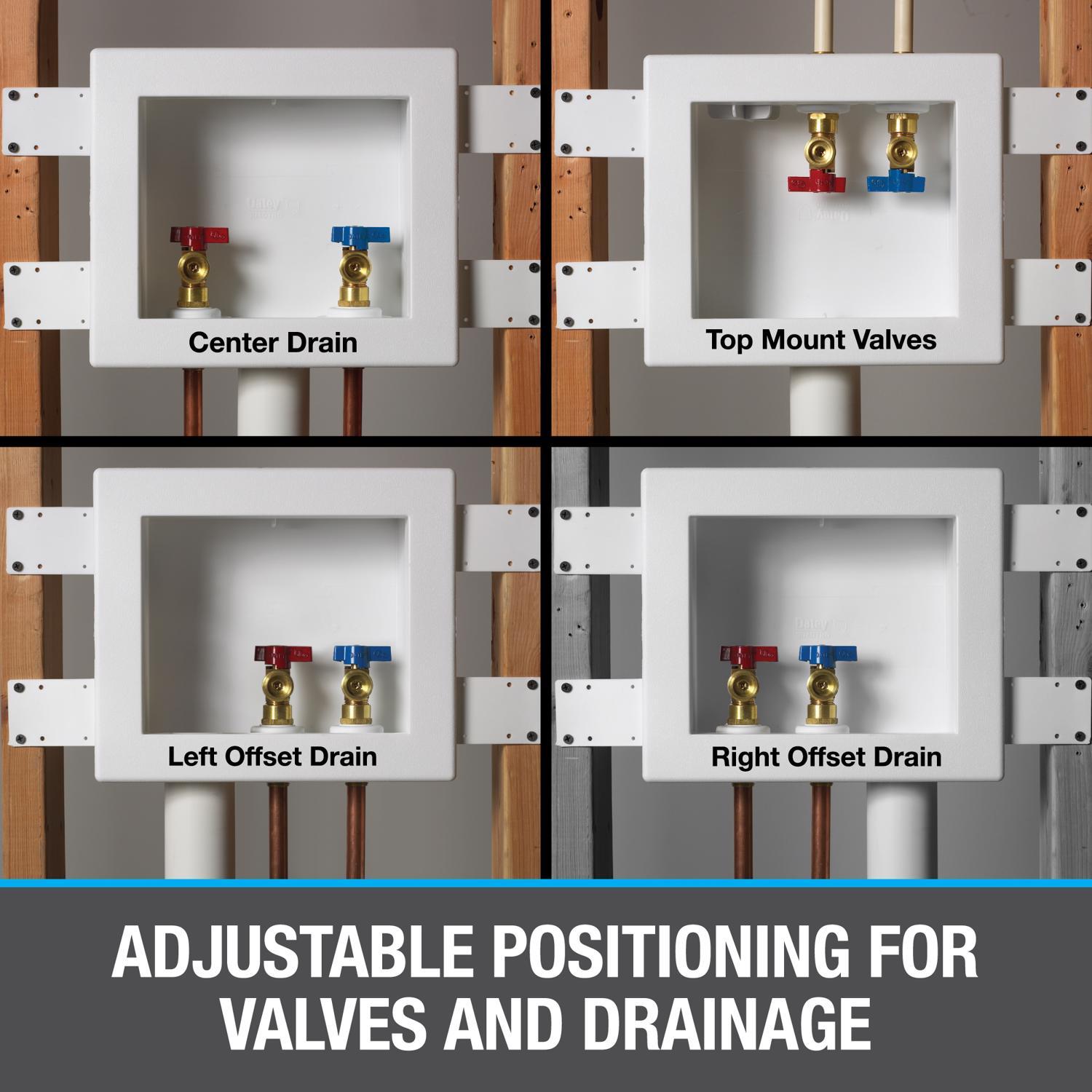

#3 Oatey® Quadtro® 1/4

Domain Est. 1996

Website: oatey.com

Key Highlights: Rating 4.8 (24) The Oatey Quadtro Washing Machine Outlet Box is made for commercial or residential applications where supply valves and waste drains are recessed into the wall….

#4 Washing Machine Outlet Boxes & Valves

Domain Est. 1996

Website: lspproducts.com

Key Highlights: 3/4″ GHT Washing Machine Outlet Box Valves · Condensate Funnel · FireStop™ Washing Machine One Stop Box™ with Hammer Arrester · FireStop™ Washing Machine One Stop ……

#5 washer, drain plug, nylon

Domain Est. 1997

Website: moroso.com

Key Highlights: In stock 5-day deliveryWASHER, DRAIN PLUG, NYLON · High quality washers ensure a leak-free seal · 1/2″ I.D. x 7/8″ O.D. · Fits Moroso Drain Plug Nos. 97000 and 97001 and others….

#6 LG WM2688HNMA Washer Drain Pump Filter Drain Hose Plug

Domain Est. 2004

#7 Drain plug, drain filter Washing machines

Domain Est. 2018

#8 DU

Domain Est. 2021

Website: ipsplumbingproducts.com

Key Highlights: Water-Tite DU-ALL™ Dual Drain Washing Machine Outlet Box is a one piece design that speeds up installation vs. using separate drain and valve boxes….

Expert Sourcing Insights for Wash Machine Drain Plug

H2: 2026 Market Trends for Washing Machine Drain Plug

The global market for washing machine drain plugs is expected to witness moderate but steady growth by 2026, driven by advancements in appliance design, rising consumer demand for durability and leak prevention, and increasing urbanization in emerging economies. Key trends shaping the market include:

-

Material Innovation and Durability Focus: Manufacturers are increasingly shifting from traditional rubber and plastic drain plugs to high-performance thermoplastic elastomers (TPE) and silicone-based materials. These materials offer better resistance to heat, corrosion, and wear, aligning with the longer lifespan expectations of modern washing machines.

-

Smart Appliance Integration: As smart washing machines gain popularity, there is a growing emphasis on intelligent drainage systems. While the drain plug itself remains a mechanical component, integration with sensors that detect leaks or blockages is becoming more common. This drives demand for precision-engineered plugs compatible with sensor-equipped housings.

-

Replacement and Aftermarket Demand: The expanding installed base of washing machines—especially in Asia-Pacific and Latin America—fuels demand for replacement drain plugs. Consumers are increasingly opting for OEM-compatible or upgraded aftermarket parts, promoting e-commerce sales through platforms like Amazon and Alibaba.

-

Sustainability and Recyclability: Environmental regulations in Europe and North America are pushing manufacturers to adopt recyclable and eco-friendly materials. Biodegradable elastomers and closed-loop manufacturing processes are emerging as competitive differentiators in the drain plug segment.

-

Regional Market Dynamics:

- Asia-Pacific dominates the market due to high production and consumption of washing machines in China, India, and Southeast Asia.

- North America and Europe show steady demand driven by appliance repair culture and stringent safety standards.

-

Middle East and Africa present growth opportunities due to improving living standards and increased appliance penetration.

-

Consolidation in Appliance Component Supply: Major OEMs are consolidating their supplier base, favoring vendors that offer integrated solutions. This trend benefits large component manufacturers with R&D capabilities, potentially squeezing out smaller players unless they specialize in niche or custom solutions.

In conclusion, the washing machine drain plug market in 2026 will be shaped by material science advancements, sustainability mandates, and the global shift toward durable, efficient home appliances. While the component is small, its role in preventing costly water damage ensures continued relevance and innovation.

Common Pitfalls When Sourcing a Washing Machine Drain Plug (Quality and Intellectual Property)

Sourcing washing machine drain plugs—especially from international suppliers—can expose buyers to several risks related to product quality and intellectual property (IP). Being aware of these pitfalls helps ensure reliable performance, regulatory compliance, and legal safety. Below are key issues to watch for:

Quality-Related Pitfalls

1. Substandard Material Composition

Many low-cost drain plugs are made from inferior rubber, silicone, or plastic that degrade quickly when exposed to heat, water, and detergents. This leads to leaks, warping, or premature failure. Always verify material specifications (e.g., EPDM rubber for durability) and request material test reports.

2. Inconsistent Dimensional Accuracy

Poorly manufactured plugs may not fit standard washing machine drain ports due to inconsistent sizing. This results in improper sealing and potential water damage. Ensure suppliers adhere to OEM specifications and provide detailed CAD drawings or samples for verification.

3. Lack of Durability Testing

Reputable manufacturers conduct pressure, temperature, and cycle testing. Many generic suppliers skip these tests, leading to higher failure rates. Ask for evidence of performance testing (e.g., compression set, aging tests) before placing bulk orders.

4. Inadequate Quality Control Processes

Suppliers without ISO 9001 certification or in-line QC procedures often deliver inconsistent batches. Implement third-party inspections (e.g., pre-shipment inspection) to verify compliance with quality standards.

Intellectual Property (IP) Pitfalls

1. Copying Branded OEM Designs

Some manufacturers produce exact replicas of branded drain plugs (e.g., for Samsung, LG, Whirlpool), infringing on design patents or trademarks. Sourcing these can expose your business to legal action, customs seizures, or reputational damage.

2. Unauthorized Use of Logos and Part Numbers

Suppliers may stamp original equipment manufacturer (OEM) logos or part numbers on generic parts. This constitutes trademark infringement. Ensure all products are clearly labeled as compatible or generic and do not mimic branding.

3. Lack of IP Clearance Documentation

Always request IP indemnification clauses in supplier contracts and confirm that the design does not violate existing patents. Conduct a basic patent search using databases like USPTO or WIPO if launching a proprietary design.

4. Grey Market and Counterfeit Risks

Purchasing through unauthorized distributors increases the risk of counterfeit or diverted genuine parts. Source from audited, direct manufacturers or authorized partners to protect against IP violations and quality issues.

Conclusion

To avoid these pitfalls, conduct thorough supplier due diligence, demand technical and compliance documentation, and prioritize legal safeguards. Investing in quality and IP-safe sourcing protects both your product performance and brand integrity.

Logistics & Compliance Guide for Washing Machine Drain Plug

Product Overview

The washing machine drain plug is a small but essential component designed to seal the drainage outlet of washing machines, preventing water leakage during operation and enabling controlled drainage when required. It is typically composed of rubber, silicone, or thermoplastic elastomer (TPE) materials, often with a plastic or metal fastening mechanism.

Regulatory Compliance

International Standards & Certifications

-

RoHS (Restriction of Hazardous Substances Directive – EU)

Ensure the drain plug complies with EU RoHS 2011/65/EU, restricting the use of lead, mercury, cadmium, hexavalent chromium, PBB, and PBDE in electrical and electronic equipment components. -

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals – EU)

Confirm that all materials used are registered under REACH and do not contain substances of very high concern (SVHCs) above permitted thresholds. -

California Proposition 65 (USA)

Verify that the product does not contain chemicals listed under Prop 65 that require consumer warnings, especially phthalates and certain heavy metals. -

China RoHS (Management Methods for the Restriction of the Use of Hazardous Substances in Electrical and Electronic Products)

Comply with labeling and substance restrictions if exporting to or selling in the Chinese market.

Material Safety & Environmental Compliance

-

FDA/NSF Compliance (if applicable)

Although typically not required for non-potable water components, if the plug contacts water that could affect human consumption (e.g., in commercial laundry near food facilities), NSF 51 or FDA 21 CFR 177.2600 may apply. -

Recyclability & Waste Compliance

Ensure packaging and product materials are labeled for recyclability and comply with WEEE (Waste Electrical and Electronic Equipment) directives where applicable.

Packaging & Labeling Requirements

Packaging Standards

- Use protective packaging to prevent deformation of rubber or silicone components during shipping.

- Include desiccant packs if moisture-sensitive materials are used.

- Minimize packaging size and materials to align with sustainability goals (e.g., ISO 14001).

Labeling

- Clearly mark product part number, material type (e.g., “TPE”), and country of manufacture.

- Include compliance labels: RoHS, REACH, and any regional certifications.

- Add multilingual instructions if shipping to non-English-speaking markets.

Shipping & Logistics

International Shipping Considerations

-

HS Code Classification

Classify under appropriate Harmonized System (HS) code. Example: 8481.80 (other taps, cocks, valves) or 8482.99 (parts of appliances), depending on design. Confirm with local customs authority. -

Incoterms

Define responsibilities using standard Incoterms (e.g., FOB, EXW, or DDP) to clarify shipping, insurance, and customs clearance duties. -

Temperature & Humidity Sensitivity

Avoid extreme temperatures during transit, as rubber and elastomers may degrade or deform under high heat or freezing conditions.

Documentation

- Commercial Invoice

- Packing List

- Certificate of Conformity (CoC) for RoHS, REACH, etc.

- Material Safety Data Sheet (MSDS/SDS), if requested

- Bill of Lading or Air Waybill

Import/Export Regulations

EU Market

- Ensure CE marking is not applied unless the entire washing machine (not just the plug) is being certified. The drain plug itself does not require CE but must comply with underlying directives.

- Notify EU REACH SVHC if substance content exceeds 0.1% by weight.

North America (USA/Canada)

- No specific federal certification required for standalone drain plugs.

- Comply with U.S. Customs and Border Protection (CBP) import rules and provide accurate tariff classification.

- In Canada, ensure compliance with the Canadian Environmental Protection Act (CEPA).

Other Regions

- UKCA Marking (UK): Required for UK market post-Brexit; apply if selling in Great Britain.

- KOSHA (Korea) and PSE (Japan): Generally not applicable unless part of a larger appliance submission.

- ANVISA (Brazil): Not typically required, but verify local INMETRO standards if bundled with major appliances.

Quality Assurance & Traceability

- Implement batch tracking for raw materials and finished goods.

- Conduct regular third-party testing for material compliance (e.g., SGS, TÜV).

- Maintain a technical file documenting compliance efforts for audit readiness.

Sustainability & End-of-Life

- Design for disassembly and recyclability.

- Avoid mixed-material construction that complicates recycling.

- Provide disposal guidance in product documentation.

This guide ensures that the washing machine drain plug meets global logistics and compliance requirements, minimizing risk during international distribution and enhancing market access.

Conclusion: Sourcing Washing Machine Drain Plug

Sourcing a washing machine drain plug requires careful consideration of compatibility, material quality, and supplier reliability. It is essential to identify the specific make and model of the washing machine to ensure the correct fit and functionality, as drain plugs vary in size, thread type, and design across different brands. Opting for OEM (original equipment manufacturer) parts ensures authenticity and long-term durability, while reputable third-party suppliers may offer cost-effective alternatives without compromising quality.

Additionally, evaluating suppliers based on customer reviews, product warranties, and availability of technical support can significantly reduce downtime and maintenance costs. Environmental factors such as resistance to corrosion and water-tight sealing should also be considered to ensure leak-free operation.

In summary, successful sourcing involves a balance between cost-efficiency, product compatibility, and supplier trustworthiness. A well-sourced drain plug not only maintains the efficiency and safety of the washing machine but also contributes to the overall reliability and longevity of the appliance.