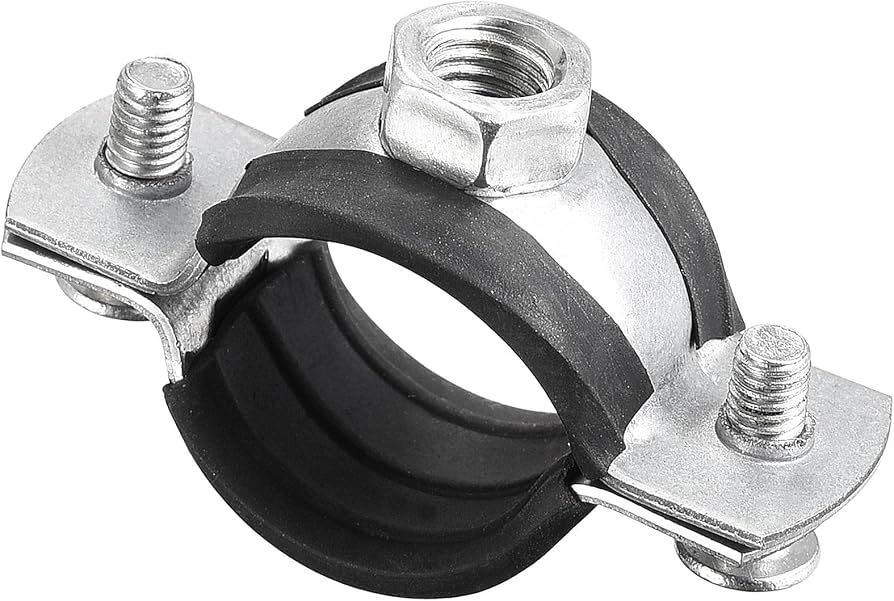

The global pipe clamp market is experiencing steady expansion, driven by increasing infrastructure development, growing industrialization, and rising demand in plumbing, HVAC, and oil & gas sectors. According to Grand View Research, the global pipe support and hanger market size was valued at USD 5.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is further fueled by stringent safety regulations and the need for efficient pipeline systems in both commercial and industrial applications. As demand for reliable, space-saving solutions like wall mount pipe clamps rises, manufacturers are innovating to offer durable, corrosion-resistant, and easy-to-install products. In this evolving landscape, identifying leading suppliers becomes critical for contractors, engineers, and procurement professionals seeking quality and performance. Here, we present the top 10 wall mount pipe clamp manufacturers shaping the industry through innovation, scalability, and global reach.

Top 10 Wall Mount Pipe Clamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Walraven USA

Domain Est. 1999

Website: walraven.com

Key Highlights: Walraven USA is a manufacturer of pipe clamps, pipe hangers, strut accessories & in-wall solutions for the United States market. ✓ The value of smart!…

#2 Pipe mounts & clamps

Domain Est. 1994

Website: andrew.com

Key Highlights: ANDREW® offers a wide array of pipe mounts & clamp sets to augment our structural support product line….

#3 KFWB

Domain Est. 1995

Website: hubbell.com

Key Highlights: 30-day returnsHeavy duty wall mount and/or pipe clamp fitting. Clamps 2″ pipe (2-3/8″ od) thru 2-1/2″ pipe (2-7/8″ od)….

#4 Wall Mount Pipe Clamp & Support – Products

Domain Est. 1996

Website: pipingtech.com

Key Highlights: A wall mount pipe clamp helps to configure universal instrument support systems. A wall mount support can be used alone or with other secondary modules as ……

#5 Bracketing Kits and Accessories

Domain Est. 1996

Website: oatey.com

Key Highlights: Stub-Out Clamps. These clamps fit into both sliding wall brackets and light angled wall brackets effortlessly, with options for CPVC, copper or PEX pipe….

#6 Pipe Supports, Brackets & Hanging Systems

Domain Est. 1996

Website: gripple.com

Key Highlights: Gripple pipe clamps deliver universal solutions which replace more than 13 different pipe ring sizes, and significantly reduce your component count. When ……

#7 Clamps and Clips

Domain Est. 2001

Website: nvent.com

Key Highlights: Easy to install, tool-free conduit support that provides stabilitiy and secureness. Provides the proper spacing to facilitate electrical box alignment….

#8 Clamp Set Wall Mount

Domain Est. 2003

#9 Pipe clamps for wall mounting

Domain Est. 2018

Website: jacob-group.com

Key Highlights: Pipe clamps for wall mounting from JACOB pipework systems. Our standard range includes more than 8500 items. Discover our products today!…

#10 Pipe Hangers & Supports

Domain Est. 2020

Website: asc-es.com

Key Highlights: The HBS Series provides a longer mounting surface with strut lengths up to 46-3/8”. Standard strut mount pipe clamps are used to secure the pipes….

Expert Sourcing Insights for Wall Mount Pipe Clamp

H2: 2026 Market Trends for Wall Mount Pipe Clamps

The wall mount pipe clamp market in 2026 is poised for steady growth, driven by underlying industrial and infrastructure development, while also adapting to evolving technological, regulatory, and sustainability demands. Key trends shaping the market include:

1. Sustained Growth in Construction & Industrial Infrastructure:

Global investments in commercial buildings, industrial facilities, water treatment plants, and HVAC (Heating, Ventilation, and Air Conditioning) systems remain strong, particularly in emerging economies and regions renewing aging infrastructure. This continued construction activity directly fuels demand for reliable pipe support systems, keeping wall mount clamps essential across plumbing, fire protection, and mechanical installations.

2. Heightened Focus on Safety and Regulatory Compliance:

Stricter building codes and safety regulations—especially concerning fire suppression systems and seismic resilience—are pushing demand for high-performance, code-compliant clamps. Manufacturers are increasingly emphasizing certifications (e.g., UL, FM Global, ICC-ES) and engineering validation to meet these standards, influencing product design and material selection.

3. Shift Towards Corrosion-Resistant and Sustainable Materials:

Galvanized steel remains dominant, but demand for stainless steel and engineered polymers is rising, especially in harsh environments (marine, chemical, food processing) and applications requiring long-term durability with minimal maintenance. Additionally, recyclability and lower environmental impact are becoming purchase criteria, encouraging manufacturers to adopt greener production processes and materials.

4. Integration with Smart Building and BIM Technologies:

While the clamp itself is a passive component, its role in smart infrastructure is growing. Compatibility with Building Information Modeling (BIM) allows for precise pre-planning and clash detection during design, reducing installation errors and costs. In smart facilities, reliable pipe support systems are foundational for the stability of connected sensors and monitoring equipment in plumbing and HVAC networks.

5. Supply Chain Resilience and Regional Manufacturing:

Ongoing global supply chain volatility is prompting companies to diversify sourcing and consider nearshoring or regional manufacturing. This trend may boost local production in key markets like North America and Europe, reducing lead times and exposure to geopolitical disruptions, while also supporting sustainability goals through reduced transportation emissions.

6. Demand for Modular and Adjustable Solutions:

Installers increasingly favor clamps with modular designs, quick-install features, and adjustable sizing to accommodate variable pipe diameters and retrofit applications. These user-friendly designs reduce labor time and costs, making them attractive in both new construction and maintenance projects.

In summary, the 2026 wall mount pipe clamp market is characterized by stable demand driven by infrastructure growth, tempered by a shift toward higher-performance, compliant, and sustainable products. Innovation is less about radical redesign and more about material advancement, regulatory alignment, and integration within modern construction workflows.

Common Pitfalls Sourcing Wall Mount Pipe Clamp (Quality, IP)

Sourcing wall mount pipe clamps—especially when specific quality standards or Ingress Protection (IP) ratings are required—can present several challenges. Overlooking these pitfalls can lead to equipment failure, safety hazards, or non-compliance. Here are key issues to watch for:

Overlooking Material Quality and Corrosion Resistance

Many suppliers offer pipe clamps made from inferior materials such as low-grade steel or poorly coated metals. Without proper corrosion resistance (e.g., galvanized, stainless steel, or powder-coated finishes), clamps degrade quickly in humid or outdoor environments, compromising structural integrity. Always verify material specifications and request test reports or certifications.

Assuming IP Rating Without Verification

Ingress Protection (IP) ratings are critical for outdoor or industrial installations where dust and moisture are concerns. A common mistake is assuming a clamp is IP-rated based on appearance or marketing claims. Suppliers may not provide valid IP certification, or the rating may apply only to the enclosure—not the entire mounting system. Always request third-party test documentation to confirm the IP rating.

Inadequate Load Capacity and Structural Design

Sourcing clamps without verifying load-bearing specifications can result in system failure. Some low-cost clamps are not engineered for heavy-duty applications or seismic zones. Ensure clamps meet required mechanical standards (e.g., EN, ASTM) and are suitable for pipe size, weight, and environmental stress.

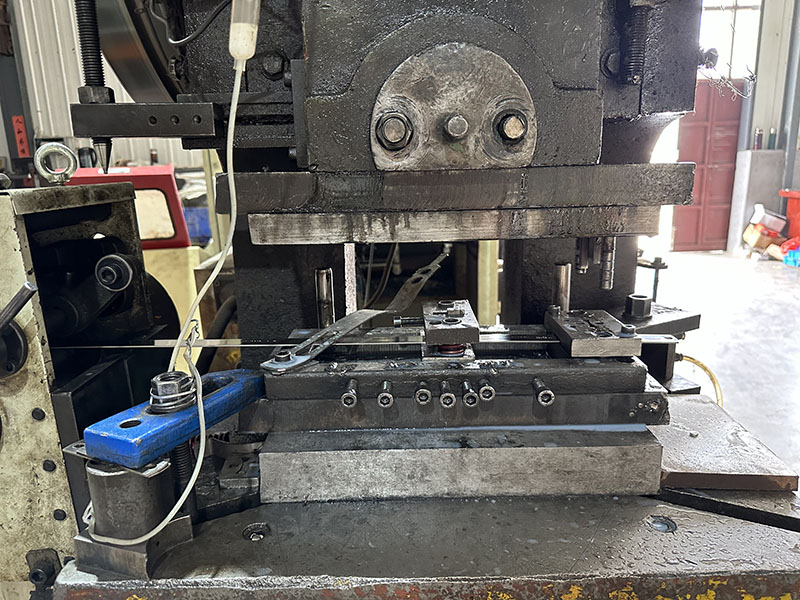

Poor Manufacturing Tolerances and Fit

Substandard manufacturing leads to inconsistent clamp dimensions, improper threading, or misaligned mounting holes. This results in difficult installation, uneven stress distribution, and potential leaks or pipe damage. Request samples before bulk ordering to assess fit and finish.

Lack of Compliance with Regional Standards

Pipe clamps may need to comply with regional regulations (e.g., UL, CE, RoHS). Sourcing from non-compliant manufacturers risks project delays, failed inspections, or legal liability. Confirm that products meet local building codes and safety standards.

Inconsistent Quality from Low-Cost Suppliers

While cost-saving is a priority, extremely low-priced clamps often come from suppliers with inconsistent quality control. Batch-to-batch variations can undermine reliability. Prefer suppliers with established quality management systems (e.g., ISO 9001) and a track record of consistent output.

Insufficient Documentation and Traceability

Reliable sourcing requires full product traceability, including material certificates, test reports, and IP validation. Many suppliers fail to provide these documents, making it difficult to ensure compliance or troubleshoot issues. Always include documentation requirements in procurement contracts.

By addressing these common pitfalls early, buyers can ensure they source wall mount pipe clamps that deliver long-term performance, safety, and compliance—especially in demanding environments where quality and IP protection are non-negotiable.

Logistics & Compliance Guide for Wall Mount Pipe Clamp

Product Overview

Wall Mount Pipe Clamps are mechanical fasteners designed to secure pipes to walls or structural surfaces, commonly used in plumbing, HVAC, and industrial applications. Ensuring proper logistics handling and compliance with relevant standards is essential for safety, performance, and regulatory adherence.

Packaging & Labeling Requirements

- Packaging: Use durable, moisture-resistant packaging (e.g., corrugated cardboard boxes or shrink-wrapped bundles) to prevent damage during transit. Include dividers or spacers to avoid scratching or deformation.

- Labeling: Each package must include: product name, part number, quantity, material type (e.g., galvanized steel, stainless steel), size range, manufacturer name, and country of origin. Include hazard symbols if applicable (e.g., sharp edges).

- Barcoding: Apply standardized barcodes (e.g., UPC or EAN) for inventory and distribution tracking.

Shipping & Transportation

- Mode of Transport: Suitable for road, rail, air, and sea freight. Secure loads with straps or pallets to prevent shifting.

- Stacking: Limit stacking height per packaging specifications to avoid crushing lower units. Use pallets with a weight capacity exceeding the load.

- Environmental Protection: Protect from prolonged exposure to moisture, extreme temperatures, and corrosive environments during transit. Use desiccants in sealed containers if shipping overseas.

Storage Conditions

- Store indoors in a dry, well-ventilated area with controlled temperature (10°C to 30°C).

- Keep off the floor using pallets or shelving to prevent moisture absorption and contamination.

- Separate from chemicals, acids, or salts that may cause corrosion, especially for carbon steel clamps.

Import/Export Compliance

- HS Code: Typically classified under HS 7307.99 (Other tube or pipe fittings, of iron or steel) – verify based on material and design.

- Documentation: Provide commercial invoice, packing list, bill of lading/airway bill, and certificate of origin.

- Regulatory Approvals: Ensure compliance with destination country standards (e.g., CE marking for EU, NSF/ANSI 61 for potable water applications in the U.S.).

- Customs Clearance: Include product specifications, material certifications, and any required test reports (e.g., RoHS, REACH) to facilitate inspection.

Regulatory & Safety Standards

- Material Compliance: Confirm adherence to environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

- Performance Standards: Comply with relevant standards like ASTM F2388 (for pipe clamps in plumbing) or EN 13684 (for pipe supports in Europe).

- Load Ratings: Clearly specify maximum load capacity and installation guidelines to ensure safe use.

Quality Assurance & Documentation

- Maintain traceability through batch/lot numbering and quality control records.

- Provide Material Test Reports (MTRs) or Certificates of Conformance (CoC) upon request.

- Conduct periodic audits of manufacturing and packaging processes to ensure consistency.

Disposal & Environmental Considerations

- Dispose of packaging materials in accordance with local recycling regulations.

- End-of-life metal clamps should be recycled through approved metal recycling facilities. Avoid landfill disposal when possible.

Contact & Support

For compliance inquiries, logistics support, or documentation requests, contact:

[Your Company Name]

Email: [email protected]

Phone: +1 (555) 123-4567

In conclusion, sourcing wall mount pipe clamps requires careful consideration of factors such as material quality, load capacity, corrosion resistance, compatibility with pipe size, and compliance with industry standards. Selecting the right supplier is equally important to ensure reliability, consistency, and timely delivery. By evaluating technical specifications, cost-efficiency, and long-term durability, organizations can make informed procurement decisions that enhance safety, reduce maintenance requirements, and support efficient piping system installations. Ultimately, a strategic sourcing approach ensures optimal performance and value in both residential and industrial applications.