The global agricultural machinery market, driven by rising demand for efficient livestock farming and crop residue management, is experiencing steady growth, with the hay and forage equipment segment playing an increasingly vital role. According to Mordor Intelligence, the agricultural machinery market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, fueled by mechanization in emerging economies and the need for labor-saving technologies. A key driver within this sector is the increasing adoption of compact, user-friendly equipment such as walk-behind hay balers—particularly among small to mid-sized farms and private landowners. These machines offer an economical and mobile solution for baling hay, straw, and other forages, contributing to reduced waste and improved feed storage. As demand rises, manufacturers are innovating with improved durability, energy efficiency, and ease of operation. Based on market presence, technology adoption, and performance reviews, the following eight companies represent the leading walk-behind hay baler manufacturers shaping the equipment landscape today.

Top 8 Walk Behind Hay Baler Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Small Farm Innovations

Domain Est. 2007

Website: smallfarminnovations.com

Key Highlights: Slider 2.2 Hay Mini Baler. Welcome to Small Farm Innovations! Large To Small, We Cover It All. Hay Mowers · Hay Rakes. Model 100 PTO Adapter. BACK IN STOCK!Missing: walk behind ma…

#2 Hay and Forage Baling Equipment

Domain Est. 1990

Website: deere.com

Key Highlights: Learn more about the features, specifications, product offerings for John Deere balers. Visit today to help decide which baler is right for you….

#3 Vermeer Round Balers for Hay and Silage

Domain Est. 1996

Website: vermeer.com

Key Highlights: Bale high-moisture hay, dry hay, cornstalks or a combination of all with our round hay balers. Explore Vermeer’s lineup of hay and silage balers today.Missing: walk behind…

#4 Roll

Domain Est. 1997

Website: agriculture.newholland.com

Key Highlights: The Roll-Belt design can build the industry’s densest round bales to help lower your operating costs….

#5 Round Balers

Domain Est. 2001

Website: deerequipment.com

Key Highlights: For all of your commercial John Deere new and used agriculture equipment, choose C&B Operations, the Midwest’s premiere John Deere ……

#6 Haymaking Implements

Domain Est. 2002

Website: earthtools.com

Key Highlights: This small scale WALK-BEHIND haying equipment very attractive to small farmers, especially in rough terrain or small field sizes where full size equipment is ……

#7 History

Domain Est. 2006

Website: caebinternational.it

Key Highlights: It is the first and only small round baler powered by walk-behind tractors. MOUNTAINPRESS 550 allows farmers to bale hay also in extreme mountain areas, often ……

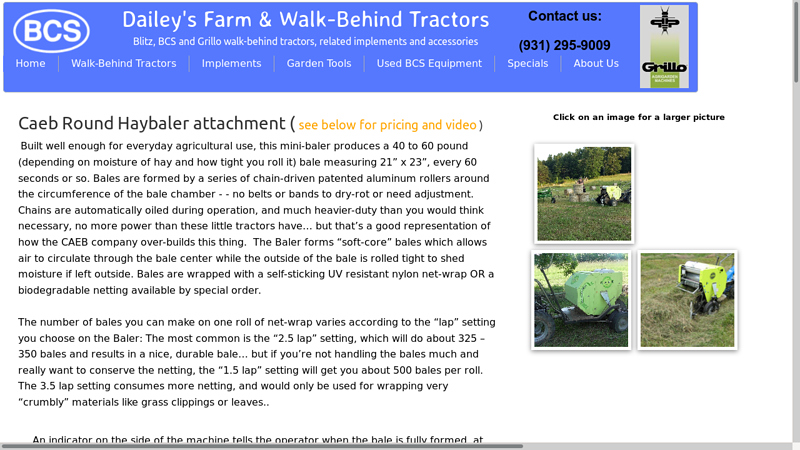

#8 Caeb Hay Baler (round)

Domain Est. 2014

Website: daileysfarmandbcsshop.com

Key Highlights: This mini-baler produces a 40 to 60 pound (depending on moisture of hay and how tight you roll it) bale measuring 21” x 23”, every 60 seconds or so….

Expert Sourcing Insights for Walk Behind Hay Baler

H2: 2026 Market Trends for Walk-Behind Hay Balers

The global market for walk-behind hay balers is poised for steady growth and transformation by 2026, driven by shifts in agricultural practices, technological innovation, and evolving demand in both developed and emerging economies. These compact, cost-effective machines are increasingly favored by small-scale farmers, organic operations, and hobby farms looking for efficient, maneuverable solutions for forage management. Below are the key trends expected to shape the walk-behind hay baler market through 2026:

-

Growing Demand from Smallholder and Part-Time Farmers

The rising number of small-scale and part-time farming operations—especially in North America, Europe, and parts of Asia—is fueling demand for affordable, easy-to-operate equipment. Walk-behind balers offer a lower entry cost compared to large tractor-powered models, making them ideal for limited-acreage operations, equestrian farms, and sustainable agriculture ventures. -

Technological Advancements and Automation

Manufacturers are integrating smart features such as improved bale density sensors, automatic tie mechanisms, and enhanced safety systems. By 2026, expect to see more models with IoT-enabled diagnostics and remote monitoring, allowing operators to track performance and maintenance needs in real time—improving efficiency and uptime. -

Focus on Sustainability and Energy Efficiency

As environmental concerns grow, there is increasing interest in energy-efficient and low-emission machinery. Some manufacturers are exploring electric or hybrid-powered walk-behind balers, aligning with broader trends toward sustainable farming. This innovation is particularly appealing in regions with strong green energy incentives. -

Expansion in Emerging Markets

In countries across Southeast Asia, Sub-Saharan Africa, and Latin America, rising agricultural mechanization and government support for modern farming tools are creating new opportunities. Walk-behind balers are gaining traction due to their adaptability to small fields and uneven terrain, where larger machinery is impractical. -

Integration with Forage Management Systems

Farmers are adopting holistic forage management approaches, integrating balers with mowers, rakes, and wrappers into seamless workflows. Equipment compatibility and modular design will become key selling points by 2026, with manufacturers offering bundled solutions or interoperable accessories. -

Rise of Online Sales and Direct-to-Farmer Distribution

Digital marketplaces and direct e-commerce channels are transforming how farmers purchase equipment. By 2026, expect more manufacturers to leverage online platforms for sales, support, and spare parts distribution, reducing costs and improving accessibility—especially for remote or rural customers. -

Increased Competition and Market Consolidation

The walk-behind hay baler market is seeing entry from new players and diversification by established agricultural machinery brands. This competition is driving innovation and price optimization. At the same time, consolidation among mid-tier manufacturers could occur to achieve economies of scale and global reach.

In conclusion, the 2026 outlook for walk-behind hay balers is positive, supported by technological innovation, a growing base of small-scale producers, and increasing mechanization in developing regions. Companies that prioritize affordability, ease of use, and sustainability are likely to lead the market in the coming years.

Common Pitfalls When Sourcing Walk Behind Hay Balers (Quality and Intellectual Property)

Sourcing walk behind hay balers, especially from overseas or lesser-known manufacturers, can present several challenges related to product quality and intellectual property risks. Being aware of these pitfalls is crucial for making informed procurement decisions and avoiding costly issues down the line.

Poor Build Quality and Substandard Materials

One of the most frequent issues when sourcing walk behind hay balers is encountering units constructed with inferior materials and poor craftsmanship. Low-cost suppliers may use thin-gauge steel, low-grade bearings, or weak welds to cut costs, leading to premature wear, frequent breakdowns, and unsafe operation. These balers may fail under normal field conditions, resulting in downtime and higher total cost of ownership despite a lower initial price.

Inadequate Testing and Lack of Certification

Many sourced balers, particularly from regions with lax manufacturing standards, may not undergo rigorous performance or safety testing. The absence of certifications such as CE, ISO, or compliance with OSHA/ANSI safety standards increases the risk of mechanical failure or operator injury. Without proof of testing, buyers have no assurance that the baler meets minimum safety and durability benchmarks.

Misrepresentation of Technical Specifications

Suppliers may exaggerate or falsify key performance metrics such as bale density, throughput capacity, or compatibility with different crop types. This misrepresentation can lead to the purchase of equipment that underperforms in real-world conditions, failing to meet operational needs and reducing efficiency on the farm.

Copycat Designs and Intellectual Property Infringement

A significant IP-related pitfall is sourcing balers that are direct copies or “knock-offs” of patented designs from established manufacturers. These clones often replicate the appearance and key features of original models but lack the engineering integrity and quality control. Purchasing such equipment may expose buyers to legal risks, especially in markets where intellectual property enforcement is strict, and could damage brand reputation if discovered.

Lack of Genuine Spare Parts and After-Sales Support

Even if a baler initially performs adequately, sourcing spare parts can become a major challenge if the supplier fails to provide a reliable supply chain. Many low-cost manufacturers do not maintain adequate inventories or service networks. This results in extended downtime when repairs are needed. Additionally, copied designs often lack official support channels, making it difficult to obtain authentic replacement components.

Limited Warranty and Accountability

Suppliers of low-quality or IP-infringing balers often offer minimal or non-enforceable warranty terms. If issues arise, buyers may find it difficult to obtain repairs, compensation, or even communication from the supplier. This lack of accountability increases financial risk and diminishes long-term reliability.

Ignoring Regional Adaptability and Regulatory Compliance

Walk behind balers designed for one region may not be suited to different climates, crop types, or regulatory requirements elsewhere. Sourcing without verifying regional compliance—such as noise levels, emission standards, or safety guard requirements—can result in equipment that cannot be legally operated or efficiently used in the target market.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough due diligence: verify supplier credentials, request third-party test reports, inspect build quality firsthand or through trusted agents, and ensure designs do not infringe on existing patents. Investing in reputable suppliers—even at a higher initial cost—often leads to better long-term value, reliability, and legal safety.

Logistics & Compliance Guide for Walk Behind Hay Baler

This guide provides essential information for the safe transportation, handling, regulatory compliance, and operational best practices when using a walk behind hay baler. Proper logistics and adherence to compliance standards ensure efficiency, safety, and legal operation across agricultural settings.

Transportation and Handling

- Secure Transport: Always secure the walk behind hay baler on a trailer or flatbed using heavy-duty tie-down straps (minimum 2,000 lb break strength). Ensure chains or ratchet straps are attached to designated mounting points.

- Weight Distribution: Distribute weight evenly on the transport vehicle. Do not exceed the tow vehicle’s or trailer’s Gross Vehicle Weight Rating (GVWR).

- Clearance and Dimensions: Measure the baler’s height, width, and length before transport. Ensure compliance with local road clearance laws and use caution in narrow lanes or under power lines.

- Flag and Lighting: Attach DOT-compliant slow-moving vehicle (SMV) emblems, reflective tape, and use proper lighting when transporting on public roads.

- Lifting and Loading: Use a forklift with appropriate capacity or a loading ramp with non-slip surface. Never attempt to lift by hand.

Regulatory Compliance

- DOT Regulations (U.S.): If operated on public roads, ensure the baler meets Department of Transportation requirements for width, height, lighting, and signage. Registration may be required in some states for trailed equipment.

- OSHA Standards: Follow OSHA guidelines for workplace safety, particularly when operating near machinery. Keep bystanders, especially children, at a safe distance during operation.

- CE Marking (EU/UK): For European markets, ensure the baler carries a CE mark indicating compliance with EU machinery safety directives (2006/42/EC). Documentation must include a Declaration of Conformity.

- EPA and Emissions: While most walk behind balers are diesel or PTO-powered, verify that engines comply with EPA Tier 4 or equivalent emissions standards if applicable.

Operational Safety and Maintenance

- Operator Training: Only trained and authorized personnel should operate the baler. Review the operator’s manual thoroughly before use.

- PPE Requirements: Operators must wear close-fitting clothing, safety glasses, steel-toed boots, hearing protection, and gloves. Avoid loose items that may get caught in moving parts.

- Pre-Use Inspection: Check belts, chains, bearings, and blades regularly for wear. Ensure all safety guards are in place and properly secured.

- Lubrication and Maintenance: Follow the manufacturer’s schedule for greasing pivot points, oiling chains, and replacing worn components. Keep the baler clean to prevent fire hazards from dry plant material buildup.

Environmental and Field Compliance

- Field Operation Permits: In some regions, large-scale baling operations may require permits, especially near protected habitats or waterways.

- Dust and Noise Control: Operate during daylight hours to minimize noise impact on neighbors. Use water sprays if excessive dust is generated.

- Waste Disposal: Dispose of worn belts, oil, and filters according to local environmental regulations. Recycle metal parts whenever possible.

Documentation and Recordkeeping

- Operator’s Manual: Maintain a copy of the manufacturer’s manual on-site. It contains critical safety warnings, torque specs, and compliance data.

- Maintenance Logs: Keep detailed records of servicing, repairs, and part replacements. Useful for warranty claims and compliance audits.

- Inspection Reports: Conduct and document routine safety inspections, especially before peak harvest seasons.

Emergency Procedures

- Shut-Off Protocol: Know the location and function of all emergency stop mechanisms. Train operators to disengage power immediately in case of jam or injury.

- First Aid and Fire Safety: Keep a first aid kit and a Class ABC fire extinguisher nearby when operating or storing the baler.

By following this logistics and compliance guide, operators and farm managers can ensure safe, legal, and efficient use of walk behind hay balers in agricultural operations. Always consult local regulations and manufacturer recommendations for site-specific requirements.

In conclusion, sourcing a walk-behind hay baler requires careful evaluation of your specific needs, including baling capacity, field conditions, and budget. It is essential to compare different models and brands for durability, ease of use, availability of spare parts, and after-sales support. Choosing a reputable supplier—whether local or international—can significantly impact long-term reliability and operational efficiency. Additionally, considering factors such as warranty, user reviews, and compatibility with existing equipment ensures a sound investment. By conducting thorough research and due diligence, you can source a walk-behind hay baler that enhances productivity, reduces labor costs, and supports sustainable farming practices.