The global air compressor market is experiencing robust growth, driven by increasing demand across automotive, industrial, and commercial sectors. According to a report by Mordor Intelligence, the air compressor market is projected to grow at a CAGR of over 5.1% from 2023 to 2028, fueled by rising requirements for efficient pneumatic systems in commercial vehicles and manufacturing automation. A key segment within this market is WABCO-certified air compressors—critical components in commercial vehicle braking systems, valued for their reliability and compliance with stringent safety standards. As the heavy-duty truck and trailer industry expands, particularly in emerging economies, demand for high-performance, WABCO-compatible air compressors has intensified. This growing need underscores the importance of manufacturers who meet rigorous OEM specifications and deliver consistent quality. Below are the top four WABCO air compressor manufacturers leading innovation and market share in this specialized domain.

Top 4 Wabco Air Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 WABCO Compressors – OE Quality Counts

Domain Est. 1996

Website: aftermarket.zf.com

Key Highlights: Like all its other components, WABCO’s OE quality aftermarket compressors are designed to offer the safest drive, and best performance possible. Designed in ……

#2 WABCO Truck Parts

Domain Est. 2018

Website: partswabco.com

Key Highlights: Genuine Wabco Parts Online Shop – Get high quality and durable Wabco truck & trailer parts! Find them quickly in our website and order now….

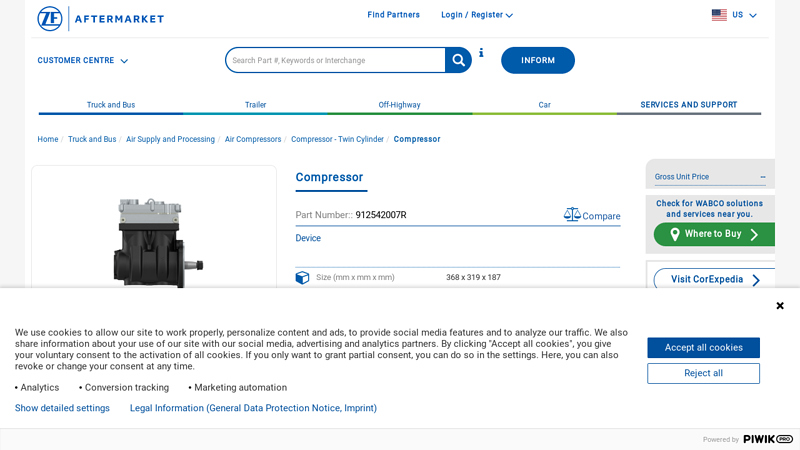

#3 Compressor

Domain Est. 2019

Website: wabco-customercentre.com

Key Highlights: Features and Benefits ; Brand. ZF REMAN – WABCO ; Part type. Remanufactured ; Product category. Device ; Calculated Volume (dm³). 21.95 ; Cooling. Water….

#4 WABCO News Brake

Domain Est. 2019 | Founded: 2010

Website: wabco-solutioncentre.com

Key Highlights: WABCO Remanufactured Air Compressors. Established in 2010, WABCO Reman Solutions specializes in remanufacturing electronic and mechatronic ……

Expert Sourcing Insights for Wabco Air Compressor

H2: 2026 Market Trends for Wabco Air Compressor

The global market for commercial vehicle components, including air compressors, is poised for significant transformation by 2026, driven by technological innovation, regulatory changes, and evolving transportation demands. As a leading provider of braking and air management systems, Wabco (now part of ZF Friedrichshafen following its 2020 acquisition) continues to play a pivotal role in shaping the future of commercial vehicle efficiency and safety. Here are the key market trends influencing Wabco air compressors in 2026:

-

Electrification of Commercial Vehicles

The shift toward electric trucks and buses is accelerating, with major markets like North America, Europe, and China implementing aggressive decarbonization targets. Traditional engine-driven air compressors are being replaced or supplemented with electric air compressors (eAir) that operate independently of the internal combustion engine. In 2026, Wabco’s eAir compressor solutions are expected to see increased adoption, particularly in battery-electric and hydrogen fuel-cell vehicles where consistent air supply is essential for braking, suspension, and door operation. -

Growing Focus on Energy Efficiency and Sustainability

With rising fuel costs and stricter emissions regulations (such as Euro 7 and EPA Phase 3 in the U.S.), fleet operators are prioritizing energy-efficient components. Wabco’s variable-speed air compressors, which reduce parasitic engine load and improve fuel economy, are gaining traction. These smart compressors adjust output based on system demand, contributing to lower CO₂ emissions and improved total cost of ownership—key selling points in 2026’s sustainability-driven market. -

Integration with Advanced Driver Assistance Systems (ADAS)

By 2026, air compressors are no longer standalone components but integrated parts of vehicle-wide safety ecosystems. Wabco’s air management systems are increasingly interconnected with ADAS and automated braking systems (AEBS), providing reliable air supply for emergency braking scenarios. This integration enhances vehicle safety and supports the progression toward higher levels of automation in commercial fleets. -

Rise in Aftermarket and Predictive Maintenance

The global commercial vehicle aftermarket is expanding, with fleet managers emphasizing uptime and predictive maintenance. Wabco leverages IoT-enabled sensors and cloud-based analytics to monitor air compressor health in real time. In 2026, predictive maintenance solutions help fleets avoid unplanned downtime by forecasting compressor failures before they occur, boosting customer loyalty and aftermarket revenue. -

Expansion in Emerging Markets

While mature markets lead in adopting advanced air compressor technologies, emerging economies in Asia-Pacific, Latin America, and Africa are experiencing growth in commercial vehicle production and infrastructure development. Wabco is adapting its product portfolio to meet cost-sensitive but reliability-focused demands in these regions, offering robust, durable air compressors tailored to harsh operating conditions. -

Consolidation and Innovation under ZF Integration

As part of ZF, Wabco benefits from enhanced R&D capabilities and broader system integration opportunities. By 2026, ZF-Wabco synergy enables the development of holistic commercial vehicle solutions—combining air compressors with transmission, braking, and chassis control systems—positioning the brand as a leader in integrated mobility systems rather than a component supplier alone.

Conclusion:

In 2026, the Wabco air compressor market is shaped by electrification, digitalization, and sustainability. The brand’s strategic evolution under ZF, combined with innovation in electric and smart compressor technologies, positions it strongly in a competitive and rapidly changing industry. Success will depend on continued investment in R&D, global scalability, and alignment with the decarbonization goals of the commercial transportation sector.

H2: Common Pitfalls When Sourcing WABCO Air Compressors (Quality and Intellectual Property)

Sourcing WABCO air compressors—critical components in commercial vehicle braking systems—requires careful consideration to avoid significant risks related to quality and intellectual property (IP). Below are common pitfalls buyers often encounter:

1. Counterfeit or Non-Original Parts

One of the most prevalent issues is the proliferation of counterfeit or imitation WABCO air compressors. These components may appear identical but fail to meet original equipment manufacturer (OEM) specifications. Substandard materials and poor manufacturing processes can lead to premature failure, safety hazards, and increased maintenance costs. Buyers should verify authenticity through authorized distributors and validate part numbers and packaging.

2. Lack of IP Compliance

WABCO holds patents, trademarks, and technical designs that protect its products. Sourcing from unauthorized or third-party manufacturers may involve IP infringement, exposing buyers to legal risks, especially in regulated markets. Using non-licensed replicas not only violates intellectual property rights but may also void warranties and compromise compliance with transportation safety standards.

3. Inconsistent Quality from Unverified Suppliers

Even if a supplier claims to offer “WABCO-compatible” or “replacement” units, the quality can vary drastically. Many aftermarket compressors lack rigorous testing and certification, resulting in inconsistent performance and reliability. Without adherence to WABCO’s ISO and OEM standards, these units can underperform in critical applications.

4. Inadequate Documentation and Traceability

Proper sourcing requires full traceability, including certificates of authenticity, test reports, and compliance documentation. Unreliable suppliers may lack these records, making it difficult to verify product origin or ensure suitability for specific vehicle models. This gap can lead to compliance issues during audits or vehicle inspections.

5. Misleading Marketing and Brand Confusion

Some suppliers use branding or product names that closely resemble WABCO to mislead buyers. Terms like “WABCO style” or “equivalent to WABCO” can create confusion. Buyers must distinguish between genuine WABCO products and look-alikes that do not carry the same performance or safety assurances.

6. Supply Chain Vulnerabilities

Sourcing from unauthorized channels—especially through online marketplaces or brokers—increases the risk of receiving stolen, recycled, or refurbished units misrepresented as new. These supply chain gaps undermine quality assurance and may expose fleets to operational downtime and liability.

To avoid these pitfalls, procurement teams should source WABCO air compressors exclusively through authorized distributors or directly from WABCO (now part of Knorr-Bremse), verify product authenticity, and ensure full compliance with IP and quality standards.

Logistics & Compliance Guide for Wabco Air Compressor

Product Identification and Specifications

The Wabco air compressor is a critical component in commercial vehicle braking systems, designed for durability and high performance under demanding conditions. Before shipping or handling, verify the model number, serial number, and technical specifications (e.g., voltage, displacement, mounting type) to ensure compatibility and compliance with customer requirements. Always refer to the manufacturer’s documentation for precise details.

Packaging and Handling Requirements

Wabco air compressors must be shipped in manufacturer-approved packaging to prevent damage during transit. Use original or equivalent protective materials, including foam inserts and sealed cartons. Handle units with care—avoid dropping, tilting, or exposing to excessive vibration. Units should be stored upright in a dry, temperature-controlled environment to prevent internal condensation or corrosion.

Shipping and Transportation

Ensure compliance with domestic and international shipping regulations. For air freight, follow IATA guidelines; for ground transport, adhere to DOT (U.S.) or ADR (Europe) standards as applicable. Clearly label packages with handling instructions such as “Fragile,” “This Side Up,” and “Protect from Moisture.” Include the proper UN number and shipping name if transporting with lubricants or other regulated substances.

Import and Export Compliance

Verify export control classifications (ECCN) under the Export Administration Regulations (EAR) to determine if an export license is required. Wabco compressors may be subject to ITAR or dual-use regulations depending on end-use and destination. Complete accurate commercial invoices, packing lists, and certificates of origin. Screen all parties against denied persons lists (e.g., OFAC, BIS) prior to shipment.

Customs Documentation

Prepare and retain complete customs documentation, including Harmonized System (HS) code (typically 8414.80 for air pumps), country of origin (usually USA, Germany, or India depending on manufacturing site), and declared value. Misclassification or undervaluation may lead to delays, fines, or seizure. Engage a licensed customs broker when necessary.

Environmental and Safety Regulations

Dispose of packaging and used compressors in accordance with local environmental regulations. Used units may contain residual oil or contaminants and should be handled as industrial waste. Comply with REACH (EU) and RoHS directives for restricted substances. Safety data sheets (SDS) must be available for any lubricants shipped with the unit.

Installation and End-Use Compliance

Ensure end-users follow Wabco’s installation guidelines and applicable vehicle safety standards (e.g., FMVSS in the U.S., ECE R121 in Europe). Improper installation may void warranties and create compliance risks. Distributors and service centers must be trained and certified where required by Wabco or regulatory bodies.

Recordkeeping and Audits

Maintain shipping records, compliance certifications, and transaction histories for a minimum of five years. These documents may be required during regulatory audits or investigations. Implement a traceability system to track individual units from production to end-user.

Contact and Support

For compliance questions or logistics support, contact Wabco Customer Service or your regional distribution center. Authorized personnel can provide updated regulatory guidance, technical data, and assistance with customs clearance.

Conclusion for Sourcing WABCO Air Compressor

In conclusion, sourcing WABCO air compressors presents a strategic advantage for ensuring reliable, high-performance air brake systems in commercial vehicles. WABCO’s long-standing reputation for engineering excellence, global support network, and commitment to safety and innovation make it a trusted supplier in the heavy-duty vehicle industry. While the initial procurement cost may be higher compared to alternatives, the long-term benefits—including durability, lower maintenance requirements, energy efficiency, and compliance with international standards—justify the investment.

Careful evaluation of supply chain logistics, authorized distribution channels, and total cost of ownership is essential to maximize value. Partnering with certified WABCO distributors ensures authenticity, access to technical support, and warranty protection. Overall, sourcing WABCO air compressors aligns with goals of operational reliability, regulatory compliance, and enhanced vehicle safety, making it a prudent choice for fleet operators, OEMs, and service providers in the commercial transportation sector.