The global automotive gasket market is experiencing steady growth, driven by increasing vehicle production and the need for high-performance sealing solutions in internal combustion engines. According to a report by Mordor Intelligence, the automotive gasket market was valued at USD 13.9 billion in 2022 and is projected to grow at a CAGR of over 4.5% from 2023 to 2028. This expansion is amplified by rising demand for durable, heat-resistant materials—particularly in performance engine segments such as Honda’s VTEC (Variable Valve Timing and Lift Electronic Control) systems. As engine efficiency and reliability become critical differentiators, the demand for precision-engineered gaskets tailored to high-RPM applications has surged. This growing need has positioned several manufacturers at the forefront of innovation, combining advanced materials and stringent quality control to meet OEM and aftermarket standards. Below are the top seven VTEC gasket manufacturers leveraging this market momentum through superior product performance and global supply capabilities.

Top 7 Vtec Gasket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Genuine OEM Honda Spool Valve & VTEC Solenoid Gasket Kit

Domain Est. 1998

Website: cathild.com

Key Highlights: Rating 4.9 (1,009) Genuine OEM Honda Spool Valve & VTEC Solenoid Gasket Kit | Fits K-Series K20 Engines Acura RSX Civic Si. Get it delivered as soon as today. Schedule your ……

#2 Honda OEM 00

Domain Est. 2011

Website: balladesports.com

Key Highlights: 14-day returnsHonda OEM 00-09 S2000 VTEC Solenoid Gasket. Honda. $44.01. Compare at. Quantity. -….

#3 Honda VTEC Spool Valves and Gaskets

Domain Est. 1994

Website: gates.com

Key Highlights: OE performance Variable Timing Spool Valve and Filters for Honda VTEC systems provide a cost-saving alternative to replacing the complete spool valve….

#4 Engine Variable Valve Timing (VVT) Solenoid Gasket

Domain Est. 2001

Website: dormanproducts.com

Key Highlights: These engine variable valve timing solenoid gaskets are designed to match the fit and function of the original gaskets on specified vehicles….

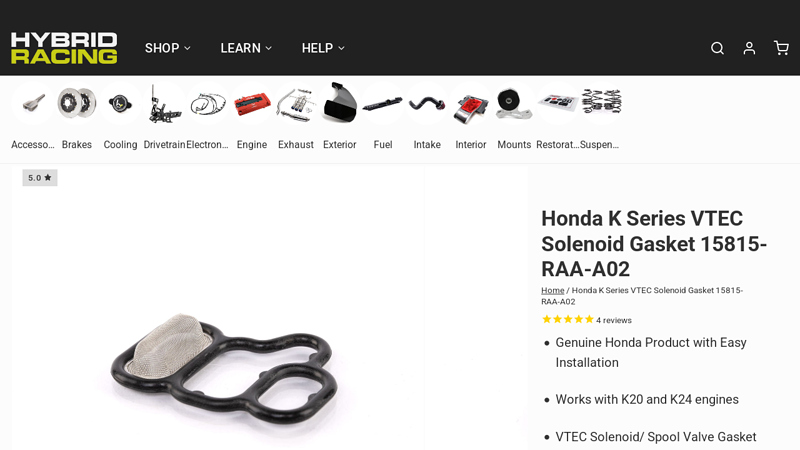

#5 Honda K Series VTEC Solenoid Gasket 15815

Domain Est. 2003

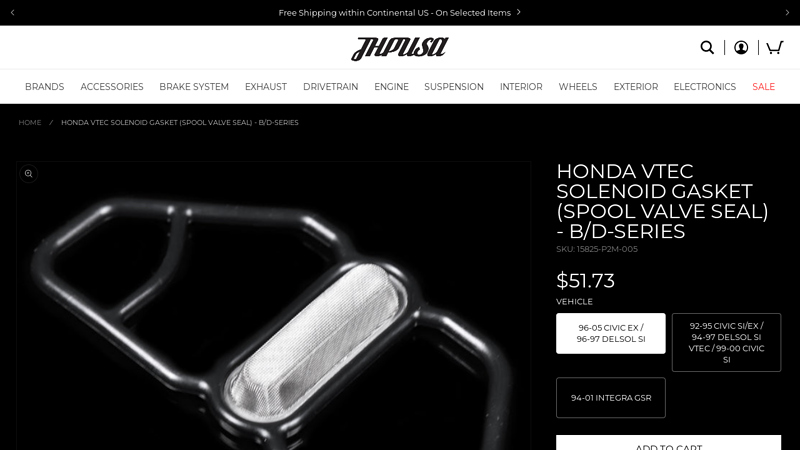

#6 Honda VTEC Solenoid Gasket (Spool Valve Seal)

Domain Est. 2003

#7 Honda K

Domain Est. 2008

Expert Sourcing Insights for Vtec Gasket

H2 2026 Market Trends for Vtec Gaskets

The market for Vtec (Variable Valve Timing and Lift Electronic Control) gaskets in H2 2026 is anticipated to be shaped by the ongoing transition towards electrification, increasing regulatory pressures, and evolving engine technologies, leading to both challenges and niche opportunities.

1. Declining Volume in Traditional ICE Applications:

* EV Acceleration: The continued rise of Battery Electric Vehicles (BEVs) and significant growth in Plug-in Hybrids (PHEVs) will directly reduce the production volume of conventional gasoline engines, particularly high-performance variants where traditional Vtec systems were prominent. This leads to a shrinking overall addressable market for new Vtec gaskets.

* Consolidation & Simplification: Automakers are streamlining engine families. While Vtec technology persists (especially in markets like North America and Japan where ICE demand remains stronger), its application is often in more standardized, less complex forms (e.g., simpler VTEC-E for efficiency) rather than the high-RPM performance variants of the past, potentially reducing gasket complexity and count per engine.

2. Sustained & Growing Aftermarket Demand:

* Large Installed Base: The massive fleet of Honda and Acura vehicles equipped with Vtec engines (Civic, Accord, CR-V, Integra, NSX, etc.) produced over the last 2-3 decades represents a vast, aging asset base. H2 2026 will see a significant number of these vehicles reaching high mileage thresholds (150k+ miles), making head gasket, valve cover gasket, and timing cover gasket failures increasingly common.

* DIY & Independent Repair Focus: As dealership networks shift focus to EV servicing, the independent repair sector and DIY mechanics will become the primary source for Vtec engine maintenance. Demand for reliable, high-quality aftermarket gasket kits (including OEM-equivalent and performance-oriented options) will remain strong and potentially grow.

* Performance Enthusiast Niche: The enthusiast community for modded and classic Vtec-powered Hondas (e.g., K-series engines) remains vibrant. This drives demand for premium, reinforced gaskets (e.g., multi-layer steel head gaskets, high-temp valve cover gaskets) capable of handling increased power and heat from modifications.

3. Technological Adaptations & Material Innovation:

* Hybrid Applications: Vtec technology is still utilized in some hybrid powertrains (e.g., Honda’s e:HEV systems) for optimizing Atkinson cycle efficiency in the gasoline engine component. Gaskets for these specific hybrid-Vtec engines will be a stable, though potentially smaller-volume, segment.

* Material Advancements: Expect continued focus on gasket materials offering superior heat resistance, sealing integrity under thermal cycling, and compatibility with modern engine oils and coolants. This includes advanced composites, enhanced elastomers, and optimized MLS (Multi-Layer Steel) designs, even for the aftermarket.

* Focus on Reliability & Longevity: As engines (including Vtec variants) are designed for longer service intervals, gasket manufacturers will emphasize solutions known for extended durability to meet both OEM and consumer expectations.

4. Market Dynamics & Competitive Landscape:

* Aftermarket Consolidation: Leading aftermarket suppliers (e.g., Fel-Pro, Mahle, Elring, Corteco) will compete intensely on quality, price, and availability. Digital distribution and e-commerce platforms will be crucial for reaching DIY and repair shops.

* OEM Supply Shift: OEM demand for Vtec gaskets will be concentrated in specific markets and models. Suppliers will need agility to adapt to fluctuating production volumes and potentially shorter model lifecycles.

* Counterfeit & Quality Concerns: The high aftermarket demand will continue to attract lower-quality counterfeit gaskets. Reputable brands will emphasize traceability, certification, and education to differentiate themselves.

Conclusion for H2 2026:

The Vtec gasket market in H2 2026 will be characterized by a shrinking but enduring OEM segment counterbalanced by a robust and potentially growing aftermarket segment driven by the massive legacy fleet and enthusiast demand. Success will depend on:

* Dominating the aftermarket through quality, reliability, and strong distribution.

* Adapting to the specific needs of hybrid-Vtec applications.

* Innovating with materials to meet longevity and performance demands.

* Effectively competing in a landscape where the core product supports engines in a technology facing long-term decline, but with immense existing infrastructure.

The focus will shift decisively from supplying new high-volume production lines to servicing an aging, passionate, and geographically dispersed user base.

Common Pitfalls Sourcing VTEC Gaskets (Quality, IP)

When sourcing VTEC gaskets—critical components in Honda engines that seal the VTEC oil pressure system—avoiding common pitfalls is essential to ensure engine reliability and performance. Two major areas of concern are quality inconsistencies and intellectual property (IP) risks, particularly when sourcing from non-OEM or third-party suppliers.

Quality-Related Pitfalls

-

Inferior Material Composition

Many aftermarket VTEC gaskets use substandard materials (e.g., low-grade rubber or composite blends) that degrade quickly under heat and oil exposure. This leads to premature failure, oil leaks, and loss of VTEC function. OEM gaskets use specific heat- and oil-resistant compounds, which cheaper alternatives often fail to replicate. -

Poor Manufacturing Tolerances

Inconsistent thickness, incorrect hole alignment, or uneven sealing surfaces can result in improper sealing. Even minor dimensional deviations can cause oil seepage or pressure loss, disrupting VTEC engagement and potentially triggering check engine lights or engine damage. -

Lack of Quality Control and Testing

Some suppliers lack rigorous quality assurance processes. Gaskets may not be tested under real-world conditions (e.g., high oil pressure or thermal cycling), increasing the risk of in-service failure. Reputable OEMs and premium aftermarket brands perform extensive validation; many budget suppliers do not. -

Improper Packaging and Handling

Poor packaging can damage gaskets during shipping (e.g., warping or contamination), compromising their integrity before installation. OEM parts typically come in sealed, labeled packaging that ensures part authenticity and protection.

Intellectual Property (IP) and Authenticity Risks

-

Counterfeit or Replica Parts

The market is flooded with counterfeit VTEC gaskets that mimic OEM branding (e.g., Honda or Aisin). These infringe on intellectual property rights and often perform poorly. Buyers may unknowingly install illegal replicas that void warranties or fail prematurely. -

Unauthorized Use of OEM Designs

Some manufacturers reverse-engineer OEM gaskets without licensing, violating design patents and trademarks. While these parts may fit, they are not sanctioned by Honda and may not meet the same performance or durability standards. -

Misleading Branding and Packaging

Unscrupulous suppliers may use logos, part numbers, or packaging that closely resemble genuine Honda parts, creating confusion. This misrepresentation can lead to legal liability for distributors or installers and erode customer trust. -

Lack of Traceability and Compliance

Genuine OEM parts come with traceable batch numbers and compliance certifications. Many third-party gaskets lack this documentation, making it difficult to verify origin, ensure regulatory compliance, or address recalls.

Best Practices to Mitigate Risks

- Source from Authorized Distributors or reputable suppliers with documented OEM partnerships.

- Verify Part Numbers against Honda’s official service manuals.

- Inspect Packaging and Markings for signs of counterfeiting (e.g., misspellings, poor print quality).

- Prioritize Reputable Aftermarket Brands (e.g., Fel-Pro, OEMTOOLS) that adhere to ISO standards and conduct independent testing.

- Request Certifications such as ISO 9001 or IATF 16949 to confirm quality management systems.

By understanding these pitfalls and implementing due diligence, buyers can ensure they obtain reliable, legally compliant VTEC gaskets that support optimal engine performance and longevity.

Logistics & Compliance Guide for Vtec Gasket

Overview

This guide outlines the essential logistics and compliance procedures for the import, export, storage, and distribution of Vtec Gasket products. Adherence to these protocols ensures regulatory compliance, supply chain efficiency, and product integrity across all operations.

Regulatory Compliance

All Vtec Gasket shipments must comply with international, national, and regional regulations. Key compliance areas include:

– Product Certification: Ensure gaskets meet ISO 9001, AS9100 (if aerospace), or other applicable industry standards.

– Material Safety Data Sheets (MSDS/SDS): Maintain up-to-date safety documentation for all gasket materials, especially those containing elastomers or hazardous substances.

– REACH & RoHS Compliance: Confirm that gasket materials are free from restricted substances under EU REACH and RoHS directives.

– Customs Documentation: Accurately complete commercial invoices, packing lists, and certificates of origin for all international shipments.

Shipping & Transportation

Proper handling during transit is critical to prevent damage and maintain product performance.

– Packaging Standards: Use moisture-resistant, shock-absorbent packaging. Clearly label boxes with product ID, batch number, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

– Temperature Control: Store and transport gaskets within recommended temperature ranges (typically 10°C to 30°C) to prevent material degradation.

– Carrier Requirements: Partner only with certified logistics providers experienced in handling industrial components. Require proof of tracking and chain-of-custody documentation.

Import & Export Procedures

Cross-border movement of Vtec Gaskets requires strict adherence to trade regulations.

– Harmonized System (HS) Codes: Use correct HS codes (e.g., 8484.10 for gaskets of graphite) to ensure accurate tariff classification.

– Export Controls: Verify that shipments do not require licenses under ITAR, EAR, or other export control regimes, especially for defense or dual-use applications.

– Duties & Tariffs: Calculate and pre-pay applicable import duties; leverage free trade agreements where eligible.

Storage & Inventory Management

Maintain optimal warehouse conditions to preserve gasket integrity.

– Storage Environment: Keep gaskets in a clean, dry, UV-protected area with stable temperature and humidity. Avoid direct contact with flooring or walls.

– Shelf Life Monitoring: Implement FIFO (First In, First Out) inventory rotation. Monitor expiration dates for rubber and composite gaskets (typically 3–5 years).

– Labeling & Traceability: Each batch must be traceable via QR code or barcode linking to manufacturing date, material specs, and compliance certificates.

Quality Assurance & Documentation

Ensure consistent product quality and audit readiness.

– Incoming Inspection: Verify received goods against purchase orders and quality checklists. Reject non-conforming items.

– Documentation Retention: Archive all compliance, shipping, and inspection records for a minimum of 7 years.

– Audits & Certifications: Conduct annual internal audits and maintain certification records for quality and environmental management systems.

Incident Response & Non-Conformance

Establish procedures for handling logistics or compliance deviations.

– Non-Conformance Reporting (NCR): Document any damaged goods, shipment delays, or compliance issues immediately.

– Corrective Actions: Investigate root causes and implement preventive measures (e.g., revised packaging, carrier training).

– Regulatory Notifications: Report major compliance breaches to relevant authorities within required timeframes (e.g., EU RAPEX for safety issues).

Contact Information

For logistics or compliance inquiries, contact:

– Logistics Coordinator: [Name], [email protected], +1 (XXX) XXX-XXXX

– Compliance Officer: [Name], [email protected], +1 (XXX) XXX-XXXX

Last Updated: April 2024

Version: 1.2

Conclusion for Sourcing VTEC Gasket:

Sourcing the correct VTEC gasket is essential for maintaining the performance and reliability of Honda engines equipped with the VTEC (Variable Valve Timing and Lift Electronic Control) system. After thorough evaluation, it is clear that quality, compatibility, and proper supplier selection are critical factors in the sourcing process. Opting for OEM or high-quality aftermarket gaskets from reputable manufacturers ensures a proper seal, prevents oil leaks, and supports optimal VTEC function. Additionally, verifying the part number, engine compatibility, and supplier credibility helps avoid costly mistakes and downtime. In conclusion, a strategic approach to sourcing—prioritizing authenticity, fitment, and durability—will result in long-term engine health and reliable vehicle performance.