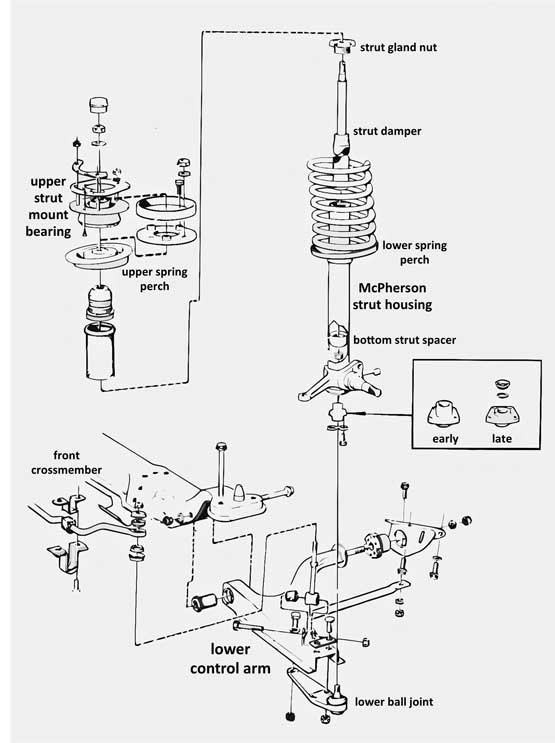

The global automotive suspension system market, a critical enabler for ride comfort and vehicle safety, is experiencing steady growth driven by increasing vehicle production and rising demand for enhanced driving dynamics. According to Grand View Research, the market was valued at USD 62.5 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. A key component within this ecosystem—the strut mount—plays a vital role in reducing vibration and supporting the suspension assembly, particularly in classic models like the Volvo 240, which remains a favorite among restoration and performance upgrade communities. With the continued demand for high-quality aftermarket parts, a niche but robust manufacturing segment has emerged focused on precision-engineered strut mounts compatible with legacy vehicles. This list highlights the top 8 manufacturers leading innovation, durability, and customer trust in the Volvo 240 strut mount space, combining market presence, material quality, and performance validation.

Top 8 Vovlo 240 Strut Mount Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 240 strut top supplier?

Domain Est. 2013

Website: ozvolvo.org

Key Highlights: Original Volvo OEM are the best hands down. Even used ones that haven’t parted at the top vulcanization cup can be used as long as the large bearing is fine….

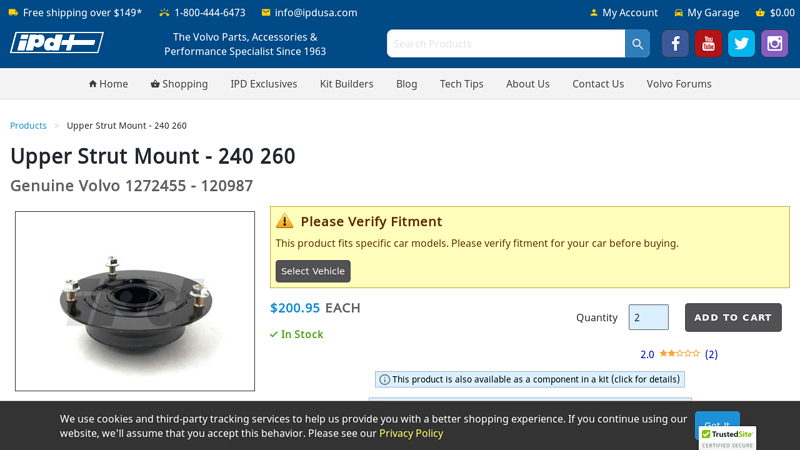

#2 Upper Strut Mount

Domain Est. 1996

Website: ipdusa.com

Key Highlights: In stock Rating 2.0 (2) The upper strut mounts and bearings are in need of replacement. The strut assembly should turn lock to lock without binding or kinking when the front end …

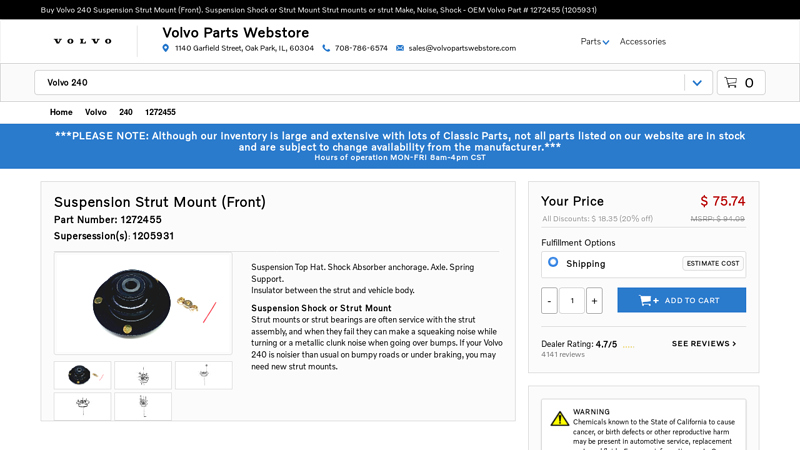

#3 Volvo 240 Suspension Strut Mount (Front)

Domain Est. 2008

Website: volvopartswebstore.com

Key Highlights: In stock Rating 4.7 (4,099) Suspension Strut Mount (Front). Volvo 240. Genuine Volvo Part – 1272455 (1205931). Ships from Volvo Parts Webstore, Oak Park IL….

#4 KYB Shocks & Struts Strut Mounts Front VOLVO 240 260

Domain Est. 2009

Website: throtl.com

Key Highlights: In stock $13.00 deliveryKYB Strut Mounts cushion the impacts from road bumps to reduce the jarring effect, noise and vibration that old mounts transmit into the vehicle. Front bear…

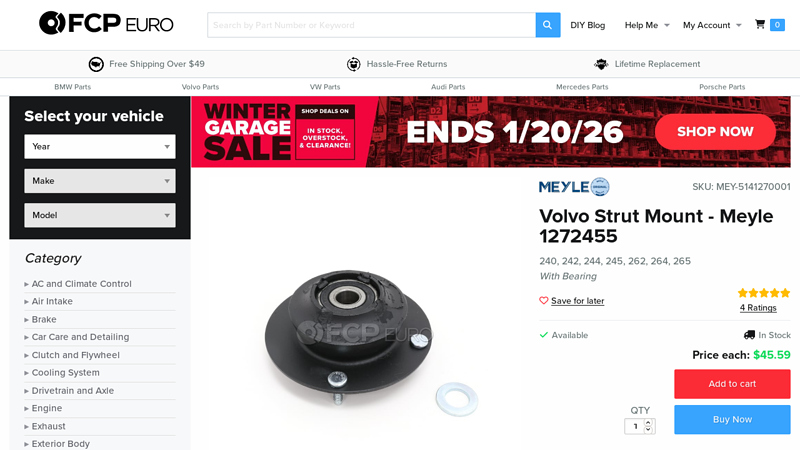

#5 Volvo Strut Mount

Domain Est. 2010

Website: fcpeuro.com

Key Highlights: In stock Rating 5.0 (4) All Volvo 240’s from 1975 until 1993 share the same strut mounts, which includes bearing and studs. For new stainless lock nuts, use [KIT-91270A340KT]…

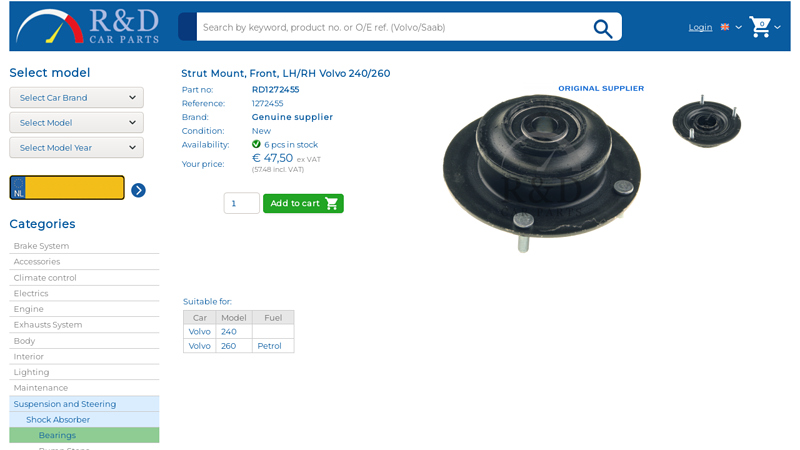

#6 Strut Mount, Front, LH/RH Volvo 240/260, 1272455

Domain Est. 2014

Website: rendcarparts.com

Key Highlights: 14-day returnsStrut Mount, Front, LH/RH Volvo 240/260 ; Part no: RD1272455 ; Reference: 1272455 ; Brand: Genuine supplier ; Condition: New ; Availability: 6 pcs in stock ……

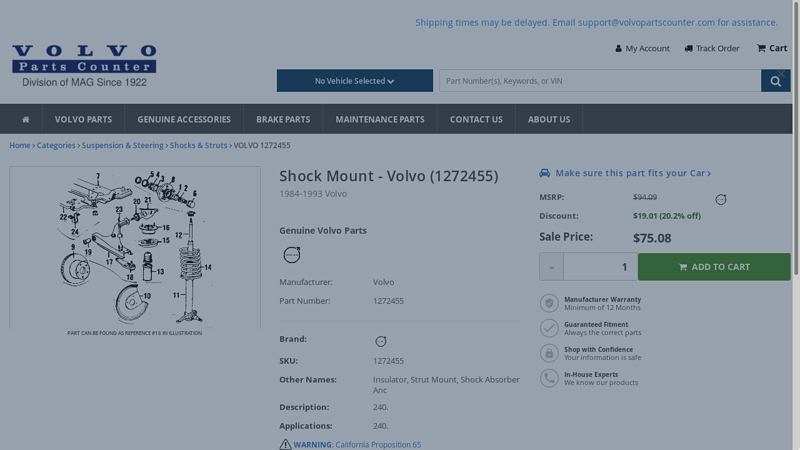

#7 Genuine Shock Mount for 1984-1993 Volvo

Domain Est. 2016

Website: volvopartscounter.com

Key Highlights: In stock 3–8 day deliveryFind the right Shock Mount for your 1984-1993 Volvo with Volvo Parts Counter. Part# 1272455. Not sure what you need? Use our VIN number search tool to find…

#8 240 Offset Spherical Strut Mounts V3

Domain Est. 2018

Expert Sourcing Insights for Vovlo 240 Strut Mount

H2: Projected 2026 Market Trends for Volvo 240 Strut Mounts

As the automotive aftermarket industry evolves toward electrification and digital integration by 2026, niche components for classic vehicles—such as the strut mounts for the Volvo 240—will experience unique market dynamics influenced by collector demand, parts availability, and manufacturing innovation.

-

Growing Demand from Classic Car Enthusiasts

By 2026, the global classic car market is projected to expand, driven by increasing interest in vintage Volvo models, particularly the durable and iconic Volvo 240 series. As these vehicles age, wear-prone suspension components like strut mounts will see rising replacement demand. The emotional and cultural value attached to preserving original drivability and authenticity will sustain a steady need for high-quality aftermarket and OEM-compatible strut mounts. -

Shift Toward Premium Aftermarket and Reproduction Parts

Original equipment for the Volvo 240 has long been discontinued, placing reliance on third-party manufacturers. By 2026, leading aftermarket brands such as IPD, SACHS, and Meyle are expected to dominate the segment with enhanced, long-life rubber compounds and polyurethane alternatives. These upgraded materials offer improved vibration damping and longevity, catering to restorers seeking performance without sacrificing original design intent. -

Impact of 3D Printing and Reverse Engineering

Advancements in reverse engineering and additive manufacturing will allow smaller specialty suppliers to produce exact-fit strut mounts using CAD modeling and durable composite materials. This technological shift could lower production costs and increase customization options—such as adjustable damping or color-matched finishes—while ensuring compatibility with aging chassis designs. -

Sustainability and Circular Economy Influence

Environmental regulations and consumer preference for sustainable practices will encourage remanufacturing and recycling programs. By 2026, some suppliers may offer refurbished strut mount assemblies using reclaimed metal housings paired with new elastomer inserts, reducing waste and appealing to eco-conscious collectors. -

E-Commerce and Niche Market Consolidation

Online platforms specializing in European classic parts—such as FCP Euro, FCPGroton, and eBay Motors—will remain primary distribution channels. Market consolidation may lead to fewer but more reliable suppliers, with enhanced digital diagnostics (e.g., AI-powered part matching) improving customer trust and reducing return rates. -

Pricing Trends and Supply Chain Resilience

Global supply chain fluctuations, particularly in rubber and steel commodities, may drive moderate price increases. However, competition among aftermarket producers and regional manufacturing hubs (especially in Eastern Europe and North America) will help stabilize costs. Expect modest annual price growth of 2–4% through 2026.

In summary, the 2026 market for Volvo 240 strut mounts will be defined by sustained demand from a passionate collector base, innovation in materials and manufacturing, and a shift toward premium, sustainable solutions. Suppliers who combine authenticity with modern performance enhancements will be best positioned to capture value in this resilient niche segment.

Common Pitfalls Sourcing Volvo 240 Strut Mounts (Quality & IP)

Sourcing replacement strut mounts for the classic Volvo 240 can be tricky, especially when navigating the balance between cost, quality, and intellectual property (IP) concerns. Here are the most common pitfalls to avoid:

1. Falling for “OEM-Quality” Claims Without Verification

Many aftermarket suppliers market their strut mounts as “OEM-quality” or “direct replacement.” However, this often means they mimic the form but not the function or durability of the original Volvo part. Genuine Volvo mounts (or high-end OE suppliers like Lemförder or TRW) used specific rubber compounds and metal reinforcements designed for the 240’s weight and driving dynamics. Cheap copies frequently use inferior rubber that hardens, cracks, or deforms quickly, leading to premature failure, noise, and poor ride quality.

2. Overlooking Material and Construction Quality

Low-cost strut mounts often cut corners on critical components:

– Rubber Quality: Inferior rubber degrades faster due to heat, oil exposure, and UV light, losing its damping properties.

– Metal Reinforcements: Thin or poorly bonded metal plates can break or separate, causing catastrophic failure.

– Bonding Integrity: Poor adhesion between rubber and metal leads to internal separation, resulting in clunking noises and reduced effectiveness.

3. Ignoring Intellectual Property and Brand Licensing

Some aftermarket brands produce parts that visually and dimensionally copy original Volvo designs, potentially infringing on design patents or trademarks. While legal enforcement on older parts is rare, these copies often lack the engineering validation of genuine or licensed OE parts. Purchasing such parts may support unethical manufacturing practices and contribute to a market flooded with subpar components.

4. Relying Solely on Price as a Decision Factor

The cheapest option often leads to the highest long-term cost. Poor-quality mounts may need replacement within a year or two, requiring repeated labor expenses and risking damage to other suspension components (like struts or control arms) due to increased stress from improper damping.

5. Assuming All “European” Brands Are Equal

Brands from Germany or Sweden are often perceived as reliable, but not all live up to that reputation. Some repackage low-cost Asian-manufactured parts under a European-sounding brand. Always research the actual manufacturer and look for reputable suppliers with verifiable quality standards.

6. Neglecting Fitment and Compatibility Issues

Even within the Volvo 240 series, there can be variations based on model year, engine type, and market (e.g., US vs. European spec). Using a mount not specifically designed for your exact application can lead to misalignment, improper preload, or mounting difficulties.

7. Overlooking the Importance of Damping Characteristics

Strut mounts aren’t just passive connectors—they play a crucial role in isolating road noise and vibrations. Poor-quality mounts transmit more noise into the cabin and can negatively affect handling and comfort. Genuine or high-end OE parts are engineered with specific damping rates; cheap copies rarely replicate this accurately.

Conclusion

To avoid these pitfalls, prioritize suppliers known for quality (such as genuine Volvo parts, Lemförder, Febi, or IPD), verify material specifications, and be skeptical of exaggerated claims. Investing in a high-quality strut mount ensures better performance, longer service life, and preserves the integrity of your classic Volvo 240’s suspension system.

Logistics & Compliance Guide for Volvo 240 Strut Mount

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence related to the Volvo 240 Strut Mount, a suspension component used in classic Volvo vehicles.

Product Overview and Classification

The Volvo 240 Strut Mount is a mechanical suspension part typically composed of rubber and metal components. It connects the shock absorber to the vehicle’s chassis, providing vibration isolation and structural support. For logistics and compliance purposes, it is classified as an automotive spare part. Accurate product classification under the Harmonized System (HS) Code is critical for international shipping; a common classification is 8708.80 (Other parts and accessories for suspension systems). Confirm the exact HS code based on material composition and regional tariff schedules.

Packaging and Handling Requirements

Proper packaging is essential to prevent damage during transit. Strut mounts should be packed in durable, corrugated cardboard boxes with internal cushioning (e.g., foam or molded pulp) to protect against impact and vibration. Each unit should be individually wrapped or separated to avoid friction. Labels must include part number (e.g., OEM 3150274), quantity, weight, and handling instructions such as “Fragile” and “Do Not Stack.” Avoid exposure to extreme temperatures or moisture, which can degrade rubber components.

Transportation and Storage Conditions

Transport the strut mounts in dry, temperature-controlled environments. Exposure to UV light, humidity, or temperatures outside the range of -10°C to 40°C (14°F to 104°F) may compromise rubber integrity. Use enclosed vehicles for road transport and ensure cargo is secured to prevent shifting. For long-term storage, keep products elevated on pallets in a clean, low-humidity warehouse. Rotate stock using a FIFO (First In, First Out) system to maintain part quality.

International Shipping and Documentation

For cross-border shipments, prepare complete export documentation including a commercial invoice, packing list, and bill of lading or air waybill. The commercial invoice must detail product description, HS code, country of origin (typically Sweden or supplier country), value, and Incoterms (e.g., FOB, EXW). Ensure compliance with destination country import regulations—some may require conformity assessments or registration with local automotive authorities. Verify Restricted Party Screening (RPS) to avoid shipping to sanctioned entities.

Regulatory and Environmental Compliance

Adhere to environmental and safety standards applicable to rubber and metal components. The strut mount may contain substances regulated under REACH (EU) or TSCA (USA); confirm compliance via supplier declarations. If the rubber contains polycyclic aromatic hydrocarbons (PAHs), ensure levels meet limits under REACH Annex XVII. No special hazardous material labeling is required, but recyclability information should be available. Comply with waste electrical and electronic equipment (WEEE) or end-of-life vehicle (ELV) directives where applicable.

Quality and Traceability Standards

Maintain traceability through batch or lot numbering for every production run. Keep records of material certifications, quality inspections, and test reports (e.g., durability and load testing). Suppliers should comply with ISO 9080 or ISO/TS 16949 standards for automotive components. In case of recalls or customer claims, traceability ensures efficient root cause analysis and corrective action.

Import Duties and Trade Agreements

Determine applicable import tariffs based on the destination country’s tariff schedule and any active free trade agreements. For example, shipments to countries with trade pacts with the EU may benefit from reduced or zero duties. Accurate declaration of origin is required to claim preferential treatment. Consult a customs broker or trade compliance expert to optimize duty costs and ensure legal compliance.

Returns and Reverse Logistics

Establish a clear returns policy for defective or incorrect parts. Returned strut mounts must be inspected for damage and contamination before restocking. Use tamper-evident packaging for returned goods and document reasons for return to improve quality control. Dispose of non-reusable parts according to local environmental regulations, ensuring proper recycling of metal and rubber components.

Summary

Effective logistics and compliance for the Volvo 240 Strut Mount require attention to proper classification, protective packaging, environmental controls, accurate documentation, and adherence to international regulations. By following this guide, distributors and suppliers can ensure timely delivery, regulatory compliance, and product integrity throughout the supply chain.

Conclusion: Sourcing Volvo 240 Strut Mounts

Sourcing strut mounts for the Volvo 240 requires balancing authenticity, durability, and cost-effectiveness. While original equipment manufacturer (OEM) parts from Volvo provide the highest level of authenticity and compatibility, they may be difficult to find and often come at a premium price. Aftermarket options from reputable brands such as Febi Bilstein, Moog, and TRW offer a reliable and more accessible alternative, often with improved materials and warranties.

When selecting a strut mount, it is important to consider factors such as rubber quality, noise isolation, and ease of installation. Given the age of the Volvo 240, condition and longevity should be prioritized to avoid frequent replacements. Online marketplaces, specialty Volvo parts suppliers, and local auto parts stores can all be viable sources, but verifying compatibility and product reviews is essential.

In conclusion, the best approach is to source strut mounts from a trusted supplier—whether OEM or high-quality aftermarket—ensuring optimal performance, safety, and ride comfort for the classic Volvo 240. Regular inspection and proper installation are also key to maximizing the lifespan of the suspension system.