The global demand for precision laboratory equipment continues to rise, driven by expanding pharmaceutical R&D, growing biotechnology sectors, and increasing investments in quality control across industries. According to Mordor Intelligence, the laboratory equipment market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, with volumetric flasks remaining a staple in analytical testing and research applications. As laboratories worldwide prioritize accuracy, durability, and compliance with ISO and ASTM standards, the need for high-quality volumetric glassware has intensified. This surge has elevated the prominence of leading volumetric flask manufacturers who combine innovation, precision engineering, and scalable production. Based on market presence, product quality, global distribution, and adherence to international certifications, the following eight manufacturers stand out in meeting the evolving demands of modern laboratories.

Top 8 Volumentric Flask Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Volumetric Flask Manufacturer

Domain Est. 2022

Website: omsonslabs.com

Key Highlights: Volumetric flasks come in various sizes, ranging from 1 mL to several liters. Omsons manufactures all sizes of volumetric flasks, including 1ml, 2 ml, 5 ml, 10 ……

#2 Volumetric Flasks from Cole

Domain Est. 1994

#3 Volumetric Flasks

Domain Est. 1995

Website: fishersci.com

Key Highlights: Browse a full range of Volumetric Flasks products from leading suppliers. Shop now at Fisher Scientific for all of your scientific needs….

#4 Volumetric Flasks

Domain Est. 1995

Website: thomassci.com

Key Highlights: 1–2 day delivery 30-day returnsVolumetric flasks are essential laboratory glassware designed to withstand high tolerances, ensure precise measurement and accurate volume control….

#5 Volumetric Flasks

Domain Est. 1996

Website: dwk.com

Key Highlights: Our wide selection of volumetric flasks is ideal for accurately measuring liquids. We offer a variety of enhanced performance options and stopper options….

#6 Volumetric Flasks

Domain Est. 1997

Website: globescientific.com

Key Highlights: 6-day delivery 90-day returnsASTM Compliant Designs – Globe Glass lab glassware meets applicable ASTM standards for volume, shape, dimensions, graduation markings, and calibration….

#7 Volumetric Flasks

Domain Est. 2000

Website: savillex.com

Key Highlights: Volumetric flasks are highly transparent, easy to clean, and meet Class A tolerances per DIN EN ISO 1042. Flasks are molded PFA….

#8 What brand?

Domain Est. 2002

Website: sciencemadness.org

Key Highlights: “Volumetric” flask with unknown branding and a new unit for volume “mlln”! … The first flask in question was very poorly calibrated(line volume ……

Expert Sourcing Insights for Volumentric Flask

2026 Market Trends for Volumetric Flask

1. Sustainability and Green Chemistry Driving Material Innovation

By 2026, sustainability will remain a dominant force shaping laboratory supply markets. Regulatory pressure and institutional ESG (Environmental, Social, and Governance) goals will accelerate demand for eco-friendly volumetric flasks. Expect increased adoption of alternative materials such as borosilicate glass with higher recycled content, biodegradable polymers, and reusable or refillable flask systems. Manufacturers will emphasize lifecycle analysis and carbon footprint labeling, with green-certified volumetric glassware gaining preference in academic and pharmaceutical sectors.

2. Digital Integration and Smart Lab Infrastructure Expansion

The proliferation of smart laboratories and Industry 4.0 practices will push volumetric flasks toward digital integration. While the flasks themselves may not become “smart,” their role within connected workflows will grow. RFID tagging or QR codes on flasks will enable traceability, calibration tracking, and inventory management through Laboratory Information Management Systems (LIMS). This trend supports compliance and efficiency, especially in regulated industries like biopharma and clinical research.

3. Customization and Application-Specific Designs

Laboratories are increasingly seeking precision-tailored tools. By 2026, demand will rise for application-optimized volumetric flasks—such as low-adsorption variants for trace analysis, flasks with integrated sensors for real-time monitoring, or designs optimized for automated liquid handlers. Niche markets like nanotechnology and synthetic biology will drive demand for specialized volumes, shapes, and material coatings that reduce contamination and improve accuracy.

4. Supply Chain Resilience and Regional Manufacturing Shifts

Geopolitical instability and past disruptions have prompted reevaluation of supply chains. In 2026, there will be a stronger push toward regional or nearshored production of precision laboratory glassware. North American and European labs will favor suppliers with local manufacturing or robust regional distribution networks to mitigate delays. This trend will benefit domestic producers and encourage investment in automated, high-precision manufacturing facilities.

5. Cost Optimization Amid Budget Constraints

Despite advancements, many academic and public research institutions will operate under tight budgets. This will sustain demand for cost-effective, durable volumetric flasks without compromising accuracy. Reconditioned or recertified glassware, as well as value-tier product lines from major brands, will gain market share. However, total cost of ownership—factoring durability, calibration lifespan, and breakage rates—will become a more important metric than upfront price.

6. Regulatory Harmonization and Quality Standards

Global regulatory alignment, particularly in pharmaceuticals (e.g., adherence to USP, EP, and ISO standards), will reinforce the need for certified volumetric flasks. By 2026, compliance with ISO 1042 and ISO 4787 will be non-negotiable in regulated environments. Manufacturers will invest in stricter quality control and digital certification to meet audit demands, supporting trust in measurement accuracy critical for product development and regulatory submissions.

Conclusion

By 2026, the volumetric flask market will evolve beyond basic functionality, shaped by sustainability mandates, digital connectivity, and specialized applications. While remaining a fundamental tool in laboratories, its design, materials, and integration will reflect broader trends in scientific innovation and operational efficiency. Manufacturers who embrace customization, traceability, and environmental responsibility will lead the market.

Common Pitfalls When Sourcing Volumetric Flasks (Quality and Intellectual Property)

Sourcing volumetric flasks—especially for laboratories requiring high precision—can present several challenges related to quality assurance and intellectual property (IP) protection. Being aware of these pitfalls helps ensure reliable results and legal compliance.

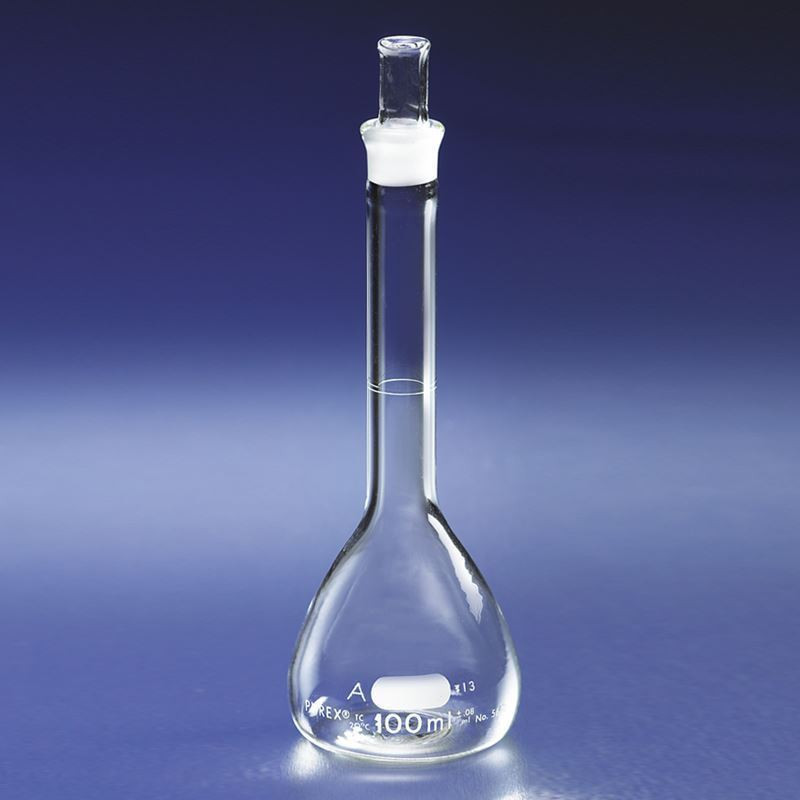

Poor Quality Control and Inaccurate Calibration

One of the most critical pitfalls is purchasing volumetric flasks that lack proper calibration or are manufactured to substandard tolerances. Low-cost suppliers, particularly from regions with lax regulatory oversight, may offer flasks that do not meet ISO or ASTM standards. Such flasks can have inaccurate volume markings, poor bore consistency, or non-uniform wall thickness, leading to volumetric inaccuracies in experiments. Always verify that flasks are certified as Class A or Class B and come with a calibration certificate traceable to national standards.

Use of Substandard Materials

Volumetric flasks are typically made from borosilicate glass (e.g., 3.3 coefficient expansion) to resist thermal shock and chemical corrosion. Sourcing flasks made from lower-grade glass or plastic alternatives can compromise durability and chemical compatibility. Inferior materials may leach contaminants or deform under temperature changes, affecting both measurement accuracy and sample integrity.

Lack of Traceability and Documentation

Reliable sourcing requires full traceability, including batch numbers, manufacturing dates, and quality control records. Some suppliers, especially those operating through third-party marketplaces, fail to provide adequate documentation. Without proper traceability, it becomes difficult to validate quality or respond to audits—particularly in regulated industries like pharmaceuticals or environmental testing.

Counterfeit or Misbranded Products

Reputable brands such as BrandTech, VWR, or Corning are frequently counterfeited. Purchasing from unauthorized distributors increases the risk of receiving fake or rebranded products that do not meet original specifications. Counterfeit flasks may mimic branding and packaging but lack the precision and durability of authentic equipment.

Intellectual Property (IP) Risks in Custom Designs

When sourcing custom-designed volumetric flasks (e.g., unique graduations, specialized ports, or proprietary fittings), there is a risk of IP infringement if the design resembles patented features from established manufacturers. Additionally, without clear contractual agreements, the supplier may claim ownership of design modifications or reuse the design for other clients, compromising competitive advantage.

Inadequate Supplier Vetting and Compliance

Failing to vet suppliers thoroughly can expose organizations to legal and operational risks. Suppliers may not comply with international trade laws, environmental regulations (e.g., REACH, RoHS), or export control requirements. This is especially relevant when sourcing from offshore manufacturers where oversight is limited.

Conclusion

To avoid these pitfalls, always source volumetric flasks from reputable, accredited suppliers. Demand certification, material specifications, and calibration documentation. For custom designs, ensure IP rights are clearly defined in contracts and conduct due diligence to confirm originality and compliance. Prioritizing quality and legal safeguards protects both experimental accuracy and organizational integrity.

Logistics & Compliance Guide for Volumetric Flask

This guide outlines the essential logistics and compliance considerations for the safe handling, storage, transportation, and regulatory adherence related to volumetric flasks used in laboratory settings.

Storage and Handling

Volumetric flasks should be stored in a clean, dry environment protected from dust, direct sunlight, and extreme temperatures. Store upright on stable shelving to prevent tipping or breakage. Avoid stacking to minimize the risk of chipping or cracking the narrow necks. Always handle with care—use both hands when transporting, especially when filled. Ensure caps or stoppers are securely fastened during storage to prevent contamination or evaporation.

Transportation

When transporting volumetric flasks, particularly when containing liquids, use padded containers or rack systems designed for glassware to prevent movement and breakage. Flasks should be placed in secondary containment (e.g., plastic trays) to contain spills. If transporting off-site, comply with relevant hazardous materials regulations if the contents are classified as dangerous goods. Empty flasks should be cleaned and dried prior to shipment to avoid residue buildup or microbial growth.

Cleaning and Maintenance

Clean volumetric flasks promptly after use with appropriate solvents or detergents, followed by thorough rinsing with deionized water. Avoid abrasive scrubbing tools that could scratch or alter the flask’s calibration. Inspect regularly for cracks, chips, or etching—any damaged flask should be removed from service. Never subject volumetric flasks to rapid temperature changes, as thermal shock can cause breakage.

Calibration and Traceability

Ensure volumetric flasks are calibrated according to ISO 1042 or ASTM E288 standards, depending on regional or organizational requirements. Maintain calibration records with traceability to national or international standards (e.g., NIST). Recalibrate periodically or after any event that may affect accuracy (e.g., cleaning with strong bases, physical damage). Label flasks with calibration dates and next due dates where applicable.

Regulatory Compliance

Adhere to laboratory safety standards such as OSHA (Occupational Safety and Health Administration), GLP (Good Laboratory Practice), and ISO/IEC 17025 where applicable. Ensure proper labeling of contents when in use, following GHS (Globally Harmonized System) standards if hazardous chemicals are involved. Institutions must comply with local environmental regulations regarding disposal of chemical residues and broken glassware.

Training and Documentation

Personnel using volumetric flasks must receive training on proper handling, measurement techniques, and safety procedures. Document all training, calibration, maintenance, and incidents involving volumetric glassware. Establish standard operating procedures (SOPs) for the use and care of volumetric flasks within the laboratory.

Disposal

Dispose of broken or irreparably damaged volumetric flasks as chemical-contaminated glass waste in accordance with local waste disposal regulations. Intact but retired flasks may be recycled through specialized glass recycling programs if uncontaminated. Never dispose of flasks containing chemical residues in regular trash.

Conclusion for Sourcing Volumetric Flask:

In conclusion, sourcing volumetric flasks requires careful consideration of accuracy, material quality, compliance with international standards (such as ISO or ASTM), and supplier reliability. Choosing the right volumetric flasks is essential for ensuring precise and reproducible measurements in laboratory settings, particularly in analytical chemistry, quality control, and research applications. It is recommended to procure from certified suppliers who provide traceable calibration and proper documentation. Additionally, factors such as volume range, durability, and resistance to chemicals should align with the intended use. By evaluating these aspects, organizations can ensure the accuracy of their measurements, maintain regulatory compliance, and enhance the overall integrity of their laboratory operations.