The global viscoelastic polyurethane foam market is experiencing robust growth, driven by rising demand across bedding, healthcare, and automotive sectors. According to Grand View Research, the global memory foam market size was valued at USD 10.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This expansion is fueled by increasing consumer preference for comfort-oriented products, particularly in mattresses and ergonomic furniture, as well as advancements in foam formulations for enhanced temperature sensitivity and pressure distribution. Mordor Intelligence projects similar momentum, citing urbanization, growing healthcare expenditures, and innovation in sustainable foam production as key market drivers. As demand intensifies, a select group of manufacturers are leading the charge in product development, scalability, and global reach. Below, we spotlight the top 10 viscoelastic polyurethane foam manufacturers shaping the industry’s future through technological innovation and strategic market positioning.

Top 10 Viscoelastic Polyurethane Foam Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Polyurethane Foam Association: Come Learn With PFA!

Domain Est. 1994

Website: pfa.org

Key Highlights: The Polyurethane Foam Association represents FPF manufacturers and suppliers to the industry. PFA funds research on critical industry topics….

#2 Foam Products, Polyurethane Chemicals & Equipment

Domain Est. 2010

Website: fsi.co

Key Highlights: FSI offers a complete line of polyurethane spray foam (SPF) insulation products and application equipment for every construction and industrial application….

#3 Polyurethane Foam

Domain Est. 1993

Website: carpenter.com

Key Highlights: Carpenter produces our own polyol, and offers polyurethane foam in blocks, rolls, and custom specifications….

#4 Viscoelastic Polyurethane Foam

Domain Est. 1996

Website: bergad.com

Key Highlights: We produce all grades of Viscoelastic and high-resilience foams including, but not limited to, Technical grade, Medical grade, Consumer grade, Gel composites, ……

#5 Huntsman Polyurethanes

Domain Est. 1997

Website: huntsman.com

Key Highlights: Huntsman Polyurethanes is a global leader in MDI-based polyurethanes, serving over 3,000 customers in more than 90 countries….

#6 Our materials and material design

Domain Est. 1997

Website: systam.com

Key Highlights: SYST’AM has been the first company in 2009 to offer high end compressed mattresses made of HR and viscoelastic foam, with a fully controlled technological ……

#7 Flexible Foams

Domain Est. 1999

Website: americanexcelsior.com

Key Highlights: Viscool® Visco-Elastic Foams American Excelsior Company takes pride in its history of being an Industry leader and innovator of Flexible Foams products, and we ……

#8 Kayfoam

Domain Est. 1999

Website: kayfoam.com

Key Highlights: Kayfoam is a trusted supplier with over a century of foam innovation. Our passion is developing and manufacturing foams with superior performance and quality ……

#9 Polyurethane Foam

Domain Est. 2012

Website: solutions.covestro.com

Key Highlights: Our extensive range of high-performance polyurethane raw materials offer solutions for flexible, rigid and integral skin foams….

#10 Viscoelastic Slow Recovery Memory Foam

Domain Est. 2020

Website: polyurethanelaboratories.com

Key Highlights: Viscoelastic slow recovery polyurethane memory foam exhibits slow recovery to return to initial form. Low ball rebound. Highly conforming….

Expert Sourcing Insights for Viscoelastic Polyurethane Foam

H2: Market Trends in Viscoelastic Polyurethane Foam (2026 Outlook)

The global viscoelastic polyurethane foam (VEPF) market is poised for steady growth through 2026, driven by increasing demand across healthcare, automotive, and consumer goods sectors. Key trends shaping the market include advancements in material science, rising consumer focus on comfort and ergonomics, and a growing emphasis on sustainability.

-

Expansion in Healthcare and Medical Applications

The healthcare sector remains a dominant driver for VEPF demand. By 2026, the use of viscoelastic foam in medical beds, pressure-relief mattresses, wheelchair cushions, and prosthetics is expected to grow significantly. Aging populations in North America, Europe, and parts of Asia-Pacific are increasing the need for long-term care solutions, boosting demand for pressure-distributing foam products. Additionally, post-pandemic healthcare infrastructure investments are accelerating procurement of high-performance medical furnishings. -

Innovation in Sustainable and Bio-Based Foams

Environmental regulations and consumer preferences are pushing manufacturers toward eco-friendly formulations. By 2026, a notable shift toward bio-based polyols and reduced volatile organic compound (VOC) emissions is anticipated. Leading producers are investing in R&D to develop viscoelastic foams using renewable feedstocks such as castor oil or soy-based polyols. Certifications like Cradle to Cradle and GREENGUARD are becoming key differentiators in competitive markets. -

Growth in Automotive and Transportation Interiors

Automakers are increasingly incorporating VEPF into premium seating, headrests, and noise-dampening components to enhance passenger comfort and acoustic performance. The rise of electric vehicles (EVs), which emphasize quiet ride quality and luxury interiors, is amplifying demand. By 2026, Asia-Pacific—particularly China and India—is expected to lead in automotive foam consumption due to expanding EV production and rising vehicle ownership. -

Smart and Responsive Foam Technologies

The integration of smart materials into VEPF is an emerging trend. Thermoresponsive and pressure-sensitive foams that adapt to body temperature and movement are gaining traction in high-end mattresses and seating. Some manufacturers are exploring conductive foams for health monitoring applications, such as embedded sensors that track sleep patterns or posture. These innovations are expected to open new revenue streams by 2026. -

Regional Market Dynamics

North America and Europe will maintain strong market shares due to high healthcare spending and consumer awareness. However, the fastest growth is projected in the Asia-Pacific region, fueled by urbanization, rising disposable incomes, and expanding manufacturing bases. Local production in countries like India and Vietnam is reducing dependency on imports and enabling cost-competitive products. -

Challenges: Raw Material Volatility and Competition

Despite growth, the market faces headwinds from fluctuating prices of key raw materials such as MDI (methylene diphenyl diisocyanate) and polyols. Geopolitical tensions and supply chain disruptions may impact production costs. Additionally, competition from alternative materials like memory foam alternatives and latex continues to pressure pricing and margins.

In summary, the viscoelastic polyurethane foam market in 2026 will be characterized by innovation, sustainability, and geographic diversification. Companies that invest in green chemistry, smart materials, and localized manufacturing are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls Sourcing Viscoelastic Polyurethane Foam (Quality, IP)

Sourcing viscoelastic polyurethane foam (commonly known as memory foam) requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to product failures, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Quality-Related Pitfalls

-

Inconsistent Material Properties

Viscoelastic foam performance hinges on precise density, indentation force deflection (IFD), recovery time, and temperature sensitivity. Sourcing from suppliers without rigorous quality control can result in batch-to-batch variability, leading to inconsistent product performance in applications like mattresses or medical cushions. -

Poor Resilience and Durability

Low-quality foams may degrade quickly, exhibiting issues like permanent indentation (“body impressions”), loss of viscoelastic properties, or crumbling. This is often due to substandard raw materials or improper curing processes during manufacturing. -

Off-Gassing and VOC Emissions

Some foams emit volatile organic compounds (VOCs), causing unpleasant odors and potential health concerns. Sourcing foam without proper emissions certifications (e.g., CertiPUR-US, OEKO-TEX®) risks consumer dissatisfaction and regulatory non-compliance. -

Inaccurate or Misleading Specifications

Suppliers may exaggerate foam characteristics (e.g., density, ILD) or provide incomplete technical data. Without independent testing or third-party verification, buyers may receive material that doesn’t meet published specs. -

Lack of Traceability and Certifications

Failure to source foam with documented compliance to industry standards (e.g., ISO 2439, ASTM D3574) or sustainability certifications (e.g., Greenguard) can hinder market access and damage brand credibility.

Intellectual Property (IP)-Related Pitfalls

-

Infringement of Patented Formulations or Processes

Many advanced viscoelastic foams are protected by patents covering specific chemical formulations, additives (e.g., gel infusion, phase-change materials), or manufacturing methods. Sourcing foam from suppliers using patented technology without a license exposes buyers to infringement lawsuits. -

Unverified Supplier Claims of “Generic” or “Non-Infringing” Foam

Suppliers may claim their foam avoids IP issues, but without access to freedom-to-operate (FTO) analyses or legal opinions, these assurances can be misleading. Due diligence is essential to confirm the foam does not infringe active patents. -

Lack of IP Warranty or Indemnification

Contracts that fail to include supplier warranties against IP infringement leave the buyer liable for third-party claims. Always ensure agreements include indemnification clauses for IP-related risks. -

Reverse Engineering Risks

Attempting to replicate high-performance foam based on a competitor’s product may inadvertently infringe design or utility patents. Proper IP landscaping and legal counsel are critical before developing or sourcing similar materials. -

Ambiguous Ownership of Custom Formulations

When collaborating with a supplier to develop a proprietary foam blend, unclear contracts may result in disputes over IP ownership. Define rights to formulations, trade secrets, and improvements in writing prior to development.

By proactively addressing these quality and IP pitfalls—through rigorous supplier vetting, independent testing, legal due diligence, and clear contractual terms—organizations can mitigate risks and ensure reliable, compliant sourcing of viscoelastic polyurethane foam.

Logistics & Compliance Guide for Viscoelastic Polyurethane Foam

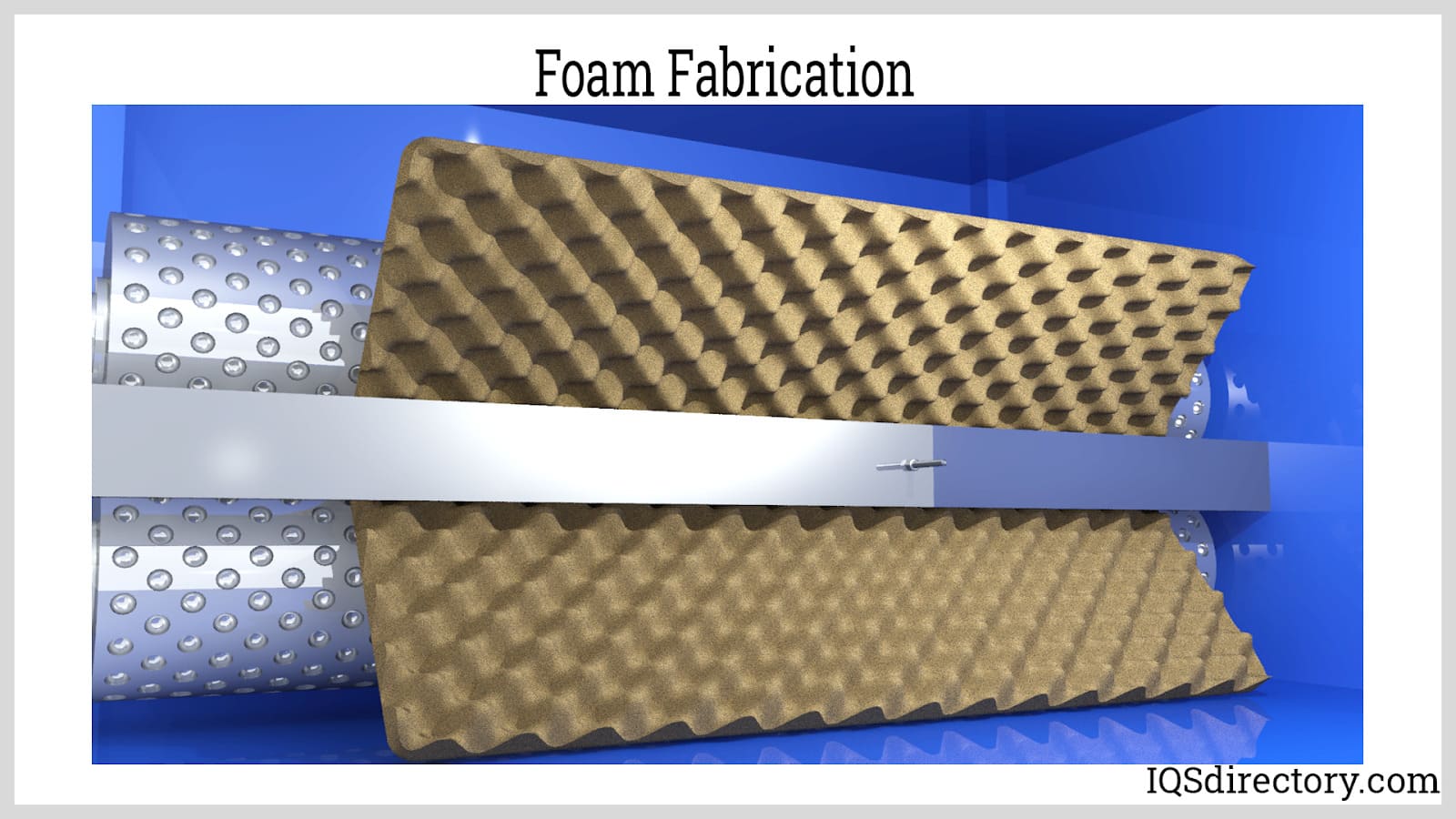

Overview of Viscoelastic Polyurethane Foam

Viscoelastic Polyurethane Foam (commonly known as memory foam) is a temperature-sensitive, open-cell foam widely used in mattresses, cushions, medical devices, and packaging. Due to its chemical composition and physical properties, it is subject to specific logistics and regulatory compliance requirements. This guide outlines key considerations for the safe and compliant handling, transportation, storage, and regulatory adherence when managing this material.

Regulatory Classification and Documentation

Viscoelastic Polyurethane Foam is typically classified as a non-hazardous solid under most international transport regulations when in finished form. However, compliance documentation must be maintained to confirm safety and origin. Required documentation includes:

– Safety Data Sheet (SDS): Must be provided by the manufacturer in accordance with GHS (Globally Harmonized System) standards. The SDS should cover composition, handling, storage, and disposal.

– Certificate of Conformity (CoC): Confirms compliance with relevant standards such as ISO 9001, Oeko-Tex Standard 100 (for consumer products), or medical-grade certifications (e.g., ISO 13485) if applicable.

– REACH and RoHS Compliance: In the EU, ensure the foam does not contain SVHCs (Substances of Very High Concern) above threshold levels. For electronics or consumer goods, RoHS restrictions on certain hazardous substances must be verified.

– TSCA Compliance (USA): Confirm that all chemical components are listed on the U.S. Toxic Substances Control Act (TSCA) Inventory.

Transportation and Packaging Requirements

Proper packaging and transport methods are essential to maintain foam integrity and meet carrier standards.

– Packaging: Use moisture-resistant wrapping (e.g., polyethylene film) to prevent water absorption. Vacuum packaging may be used to reduce volume for shipping efficiency.

– Stacking and Load Securing: Avoid excessive compression during transport; use pallets and edge protectors. Secure loads to prevent shifting, which could damage foam structure.

– Mode-Specific Regulations:

– Road & Rail (ADR/RID): Generally non-hazardous; no ADR classification required for finished foam.

– Air (IATA): Classified as “Not Restricted” when non-flammable and properly packed. Confirm with IATA Dangerous Goods Regulations (DGR) Section 2.

– Sea (IMDG Code): Subject to general cargo rules; no special marine pollutant designation for standard viscoelastic foam.

– Labeling: Include product name, batch number, handling instructions (e.g., “Do Not Puncture,” “Keep Dry”), and supplier information.

Storage Conditions and Shelf Life

To preserve material properties, follow these storage guidelines:

– Temperature: Store between 10°C and 30°C (50°F–86°F). Avoid prolonged exposure to extreme heat (>50°C) or cold (<0°C), which may degrade foam structure.

– Humidity: Maintain relative humidity below 70% to prevent moisture absorption and microbial growth.

– Ventilation: Store in well-ventilated areas to avoid odor buildup from off-gassing.

– Light Exposure: Limit UV exposure to prevent surface degradation. Use opaque or covered storage.

– Shelf Life: Typically 3–5 years when stored properly. Rotate stock using FIFO (First In, First Out) principles.

Environmental and Disposal Compliance

End-of-life handling must align with local environmental regulations:

– Recycling: Polyurethane foam can be mechanically recycled into rebonded foam or chemically broken down. Facilities must be certified under local waste frameworks (e.g., WEEE in EU).

– Landfill Disposal: Permitted in most jurisdictions but discouraged due to low biodegradability. Document disposal through licensed waste handlers.

– Incineration: Must comply with emissions standards (e.g., EU Directive 2010/75/EU on Industrial Emissions). Energy recovery is acceptable if conducted in approved facilities.

– Hazardous Waste Determination: Conduct waste characterization if foam is contaminated (e.g., with flame retardants or adhesives). Some additives may trigger hazardous waste classification.

Occupational Health and Safety (OHS)

Ensure worker safety during handling and processing:

– Ventilation: Use local exhaust ventilation when cutting or machining foam to control dust and fumes.

– PPE Requirements: Provide gloves, safety glasses, and respiratory protection (e.g., N95 masks) when generating dust or vapors.

– Fire Safety: While viscoelastic foam is typically treated with flame retardants, it is combustible. Store away from ignition sources and comply with local fire codes (e.g., NFPA 921).

– First Aid Measures: Refer to SDS for exposure response (e.g., eye contact, inhalation).

Import/Export Considerations

International shipments require attention to:

– Customs Tariff Codes: Use accurate HS codes (e.g., 3921.13 for foamed plastics in sheets or blocks).

– Country-Specific Regulations:

– USA: FDA compliance may be needed for medical or food-contact applications.

– EU: CE marking may apply if part of a medical device or furniture product.

– China: CCC certification may be required for certain end products.

– Documentation: Include commercial invoice, packing list, bill of lading, and any required permits or certificates.

Conclusion

Proper logistics and compliance management for Viscoelastic Polyurethane Foam ensures regulatory adherence, product quality, and supply chain efficiency. Always consult the latest regulatory updates, maintain accurate documentation, and partner with certified suppliers and carriers to mitigate risks.

Conclusion for Sourcing Viscoelastic Polyurethane Foam

Sourcing viscoelastic polyurethane foam requires a strategic approach that balances material quality, performance requirements, cost-efficiency, and supplier reliability. This specialized foam, known for its pressure sensitivity, energy absorption, and temperature responsiveness, is critical in applications ranging from medical devices and seating to packaging and noise insulation.

After evaluating market suppliers, technical specifications, and sustainability considerations, it is evident that selecting the right source involves thorough due diligence. Key factors such as foam density, rebound resilience, compression set, and certifications (e.g., ISO, REACH, UL) must align with intended application standards. Additionally, prioritizing suppliers with consistent quality control, scalability, and transparent supply chains ensures long-term reliability.

Sustainability is increasingly influential, with growing demand for low-emission, recyclable, or bio-based formulations. Therefore, sourcing strategies should also consider environmental impact and regulatory compliance, especially in regions with strict emission standards.

In conclusion, successful sourcing of viscoelastic polyurethane foam hinges on a holistic assessment of technical needs, supplier capabilities, and sustainability goals. Establishing strong partnerships with qualified manufacturers, possibly including regional suppliers to mitigate logistical risks, will support consistent product performance and supply chain resilience.