The global vinyl wrap sheets market is experiencing robust growth, driven by increasing demand across automotive, architectural, and commercial sectors. According to a 2023 report by Mordor Intelligence, the market was valued at USD 2.8 billion and is projected to grow at a CAGR of 6.4% from 2023 to 2028, reaching an estimated USD 4.05 billion by 2028. Similarly, Grand View Research reports a CAGR of 6.7% during the forecast period (2023–2030), citing rising consumer preference for vehicle customization and advancements in adhesive and UV-resistant film technologies. With North America and Europe leading adoption due to mature aftermarket automotive industries, and the Asia-Pacific region emerging as a high-growth market, the demand for high-performance vinyl wrap sheets continues to surge. This growing landscape has elevated competition among manufacturers to innovate in durability, color variety, and ease of application—making it essential to identify the top players shaping the industry’s future.

Top 8 Vinyl Wrap Sheets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metro Restyling

Domain Est. 2008

Website: metrorestyling.com

Key Highlights: Free delivery over $99 30-day returnsWe carry the latest and greatest vinyl car wrap and paint protection film technology in a variety of colors, patterns, and finishes….

#2 HEXIS Manufacturer of Sign Vinyl, Digital Printing and Laminates …

Domain Est. 2010

Website: hexis-graphics.com

Key Highlights: HEXIS GRAPHICS is a specialist manufacturer of self-adhesive vinyl films for sign making, vehicle marking and large format digital printing….

#3 3M Vehicle Wraps & Trims

Domain Est. 1988

Website: 3m.com

Key Highlights: Non-printable films used exclusively for covering or wrapping car surfaces….

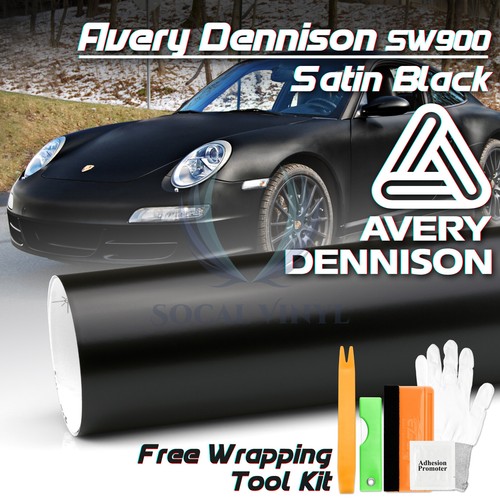

#4 Supreme Wrapping Film™ SW900

Domain Est. 1993

Website: graphics.averydennison.com

Key Highlights: Outstanding durability and performance makes this one of the best vinyl wrap films · Excellent conformability around curves and recesses · Patented Avery Dennison ……

#5 Arlon Graphics

Domain Est. 1996

Website: arlon.com

Key Highlights: Arlon creates innovative materials for visual expression- pressure sensitive cast and calendered vinyl for a variety of applications….

#6 Quality car wraps, vinyl wraps, paint protection films & window films

Domain Est. 2012

#7 Teckwrap USA

Domain Est. 2013

#8 MAXDECAL

Domain Est. 2019

Website: maxdecalsticker.com

Key Highlights: MAXDECAL has been proven to be a reliable supplier for the automotive industry, digital printing materials, signage and decoration vinyls, car wrap film, and ……

Expert Sourcing Insights for Vinyl Wrap Sheets

2026 Market Trends for Vinyl Wrap Sheets

The vinyl wrap sheets market is poised for significant transformation by 2026, driven by advancements in materials, shifting consumer preferences, and expanding applications across industries. This analysis explores key trends shaping the market landscape over the next few years.

Growth in Automotive Customization Demand

One of the primary drivers of the vinyl wrap sheets market is the rising popularity of vehicle customization. By 2026, increasing consumer interest in personalizing cars—both for aesthetic appeal and brand differentiation—will continue to boost demand. The affordability and reversibility of vinyl wraps compared to traditional paint make them an attractive option for car owners and commercial fleets alike. The growth of the aftermarket automotive sector, especially in regions like North America and Europe, will further fuel market expansion.

Advancements in Material Technology

By 2026, manufacturers are expected to introduce next-generation vinyl wrap materials with enhanced durability, UV resistance, and self-healing properties. Innovations such as matte-to-gloss shift films, color-change wraps, and eco-friendly adhesives will cater to a more discerning customer base. Additionally, improved air-release and repositionable technologies will simplify installation, reducing labor costs and expanding the market to DIY users.

Expansion into Non-Automotive Applications

While automotive remains the dominant segment, the use of vinyl wrap sheets is rapidly growing in architecture, interior design, and retail. By 2026, expect increased adoption in wrapping furniture, appliances, walls, and storefronts due to the material’s versatility and cost-effectiveness. The rise of experiential retail and pop-up shops will further drive demand for temporary, high-impact surface transformations.

Sustainability and Eco-Conscious Shifts

Environmental concerns will play a larger role in shaping the vinyl wrap market by 2026. Consumers and regulators are pushing for recyclable, biodegradable, or low-VOC (volatile organic compound) materials. Leading manufacturers are expected to invest in sustainable production methods and offer take-back programs for used wraps. Water-based adhesives and PVC-free alternatives may gain traction, especially in eco-sensitive markets like Western Europe.

E-Commerce and Digital Color Sampling

The digital transformation of the industry will accelerate by 2026, with e-commerce platforms offering augmented reality (AR) tools for virtual wrap previews. Customers will be able to visualize designs on their vehicles or surfaces in real time, increasing confidence in online purchases. Online marketplaces will expand globally, improving access to niche and premium wrap products in emerging markets.

Regional Market Dynamics

North America and Europe will remain key markets due to strong automotive cultures and established customization industries. However, the Asia-Pacific region—particularly China, India, and Southeast Asia—is expected to witness the fastest growth, driven by rising disposable incomes and urbanization. Local manufacturing and distribution networks will emerge to meet regional demand.

Conclusion

By 2026, the vinyl wrap sheets market will be defined by innovation, sustainability, and diversification. As technology enhances product performance and digital platforms improve accessibility, vinyl wraps will transition from niche automotive accessories to mainstream decorative and functional solutions across multiple industries. Companies that adapt to these evolving trends will be best positioned for long-term success.

Common Pitfalls When Sourcing Vinyl Wrap Sheets (Quality and Intellectual Property)

Sourcing vinyl wrap sheets can be challenging, especially when balancing cost, quality, and legal compliance. Overlooking key factors can lead to poor performance, customer dissatisfaction, or even legal repercussions. Below are common pitfalls to avoid.

Poor Material Quality and Durability

One of the most frequent issues is receiving vinyl wrap sheets that degrade quickly or fail to adhere properly. Low-quality materials often use inferior adhesives and thin gauge vinyl, resulting in bubbling, peeling, or cracking within months. These wraps may also lack UV resistance, leading to fading or discoloration when exposed to sunlight. Always verify specifications such as thickness (measured in microns), elongation rate, and warranty duration from reputable manufacturers.

Inconsistent Color and Batch Variations

Color mismatch between batches is a significant problem, especially for large or multi-phase projects. Sourcing from suppliers without strict quality control can result in noticeable differences in hue, gloss level, or texture. This undermines the professional finish and may require re-wrapping entire sections. Ensure your supplier guarantees color consistency across production runs and provides batch-specific documentation.

Misrepresentation of Product Specifications

Some suppliers falsely advertise high-performance features such as “air-release technology,” “conformability,” or “10-year durability” without third-party verification. These claims may not hold up under real-world conditions. Always request test reports, certifications (e.g., ISO standards), or independent reviews before committing to bulk orders.

Intellectual Property (IP) and Trademark Infringement

Sourcing counterfeit or imitation branded vinyl wraps—such as knock-offs of 3M, Avery Dennison, or Oracal—poses serious legal risks. These products often mimic branding and packaging but lack performance guarantees. Using or selling such materials can lead to trademark infringement lawsuits, product seizures, and damage to your business reputation. Only purchase from authorized distributors and verify authenticity through official brand channels.

Lack of Compliance with Safety and Environmental Standards

Certain vinyl wraps contain restricted substances like ortho-phthalates or heavy metals, which may violate environmental regulations (e.g., REACH, RoHS). Non-compliant materials can be banned from sale in specific regions or deemed unsafe for indoor applications. Confirm that your supplier provides compliance documentation and uses eco-friendly, non-toxic formulations where required.

Inadequate Technical Support and Application Guidance

Low-cost suppliers may not offer technical data sheets, installation tutorials, or customer support. This can lead to application errors, especially with complex wraps like carbon fiber or matte finishes that require specific tools and techniques. Choose suppliers that provide comprehensive support to ensure successful installations and reduce material waste.

Overlooking Minimum Order Quantities and Lead Times

Some manufacturers impose high minimum order quantities (MOQs) or extended lead times, which can strain cash flow and limit flexibility. Smaller businesses may end up overstocking or facing project delays. Evaluate suppliers based on scalability, inventory availability, and shipping reliability to match your operational needs.

By being aware of these pitfalls—particularly those related to quality inconsistencies and IP risks—you can make informed sourcing decisions that protect your business and deliver superior results to your clients.

Logistics & Compliance Guide for Vinyl Wrap Sheets

Product Classification & HS Codes

Vinyl wrap sheets are typically classified under the Harmonized System (HS) Code 3919.10, which covers self-adhesive plates, sheets, film, foil, tape, and other flat shapes of plastics, non-cellular, of polymers of vinyl chloride, whether or not in rolls. Accurate classification is essential for international shipping, as misclassification can result in customs delays, fines, or incorrect duty assessments. Confirm the correct HS code with local customs authorities or a licensed customs broker, as sub-classifications may vary by country.

Import/Export Regulations

When shipping vinyl wrap sheets internationally, compliance with import and export regulations is mandatory. Exporters must verify licensing requirements, especially when shipping to countries with strict environmental or chemical regulations. Some regions may require pre-shipment inspections or conformity assessments. Importers should ensure that the product meets destination country standards, including labeling and safety requirements. Always maintain accurate commercial invoices, packing lists, and certificates of origin to facilitate customs clearance.

Packaging & Handling Requirements

Vinyl wrap sheets must be securely packaged to prevent damage during transit. Rolls should be protected with end caps and outer wrapping (e.g., plastic film or cardboard sleeves) to prevent edge damage, moisture, and dust. Store and ship rolls vertically when possible to avoid deformation. Handle with care to prevent creasing, kinking, or adhesive contamination. Clearly label packages with handling instructions such as “This Way Up,” “Fragile,” and “Protect from Moisture.”

Transportation & Storage Conditions

Vinyl wrap sheets should be transported in dry, temperature-controlled environments. Avoid exposure to extreme heat (above 35°C/95°F) or cold (below 0°C/32°F), which can affect the adhesive properties and dimensional stability. During storage, keep rolls in a clean, dry area away from direct sunlight and sources of UV radiation. Ideal storage conditions are between 15–25°C (59–77°F) with low humidity. Rolls should be stored vertically to prevent warping.

Regulatory Compliance (REACH, RoHS, CPSIA)

Vinyl wrap sheets may be subject to chemical and safety regulations depending on the market:

– REACH (EU): Ensure compliance with registration, evaluation, authorization, and restriction of chemicals. Confirm that the product does not contain substances of very high concern (SVHCs) above threshold levels.

– RoHS (EU): While primarily for electronics, some decorative wraps used in electronic enclosures may need to comply with restrictions on hazardous substances like lead, cadmium, and phthalates.

– CPSIA (USA): If the vinyl wrap is used on children’s products, it must comply with lead and phthalate limits. Even if not directly regulated, providing test reports may be required by retailers.

Always request material safety data sheets (MSDS/SDS) and compliance certificates from suppliers.

Labeling & Documentation

Proper labeling is critical for compliance and traceability. Each roll or package should include: product name, batch/lot number, manufacturing date, roll dimensions, material composition, and manufacturer details. For international shipments, include safety warnings and language-specific labels if required. Documentation should consist of safety data sheets (SDS), compliance statements, and any third-party test reports (e.g., for fire resistance or phthalate content).

Environmental & Disposal Regulations

Vinyl wraps are typically made from polyvinyl chloride (PVC), which has environmental implications. Be aware of local regulations regarding PVC disposal and recycling. Some regions restrict the incineration of PVC due to dioxin emissions. Encourage end-users to follow local waste management guidelines. Consider offering recycling programs or take-back initiatives to support sustainability goals and enhance compliance with extended producer responsibility (EPR) laws in certain jurisdictions.

Customs Clearance & Duties

Prepare for customs clearance by ensuring all documentation is accurate and complete. Duties and taxes vary by country and may be influenced by free trade agreements. Use an experienced freight forwarder or customs broker familiar with plastic sheet goods. Provide detailed product descriptions, including adhesive type (e.g., solvent-free, acrylic), substrate composition, and intended use (e.g., automotive, signage), as this can affect duty rates and regulatory scrutiny.

Quality Control & Traceability

Implement a quality control process to verify that incoming and outgoing vinyl wrap sheets meet specifications. Maintain batch traceability through lot numbering and record-keeping to support recalls or compliance audits. Conduct periodic testing for adhesive strength, color consistency, and dimensional accuracy. Document all QC procedures and results as part of your compliance portfolio.

Conclusion for Sourcing Vinyl Wrap Sheets:

Sourcing high-quality vinyl wrap sheets is a critical step in ensuring the success and longevity of any vehicle or surface customization project. After evaluating various suppliers, material types, and market options, it is clear that selecting the right vinyl involves balancing durability, color and finish variety, ease of installation, and cost-effectiveness. Reputable manufacturers such as 3M, Avery Dennison, and Arlon offer reliable performance and warranties, making them preferred choices in the industry. Additionally, considering factors like air-release technology, conformability, and UV resistance can significantly impact the final result.

Direct sourcing from authorized distributors or established online platforms ensures authenticity and access to technical support, while bulk purchasing can reduce long-term costs for professional installers. Ultimately, investing time in researching and partnering with trustworthy suppliers not only enhances product quality but also improves customer satisfaction and business reputation. In the evolving vinyl wrap market, consistent attention to material innovation and supplier reliability is key to maintaining a competitive edge.