The global vibrating feeder market is experiencing robust growth, driven by increasing demand for efficient material handling solutions across industries such as mining, construction, and aggregates. According to Grand View Research, the global vibratory equipment market was valued at USD 2.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects a CAGR of over 6% during the forecast period of 2023–2028, underpinned by rising automation in industrial processes and the need for precision feeding in bulk material operations. As industries prioritize operational efficiency and uptime, the role of high-performance vibrating feeders has become increasingly critical. This growing demand has spurred innovation and competition among manufacturers worldwide. Based on performance, technological advancement, global reach, and customer reviews, here are the top 10 vibrating feeder manufacturers leading the industry in 2024.

Top 10 Vibrating Feeder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

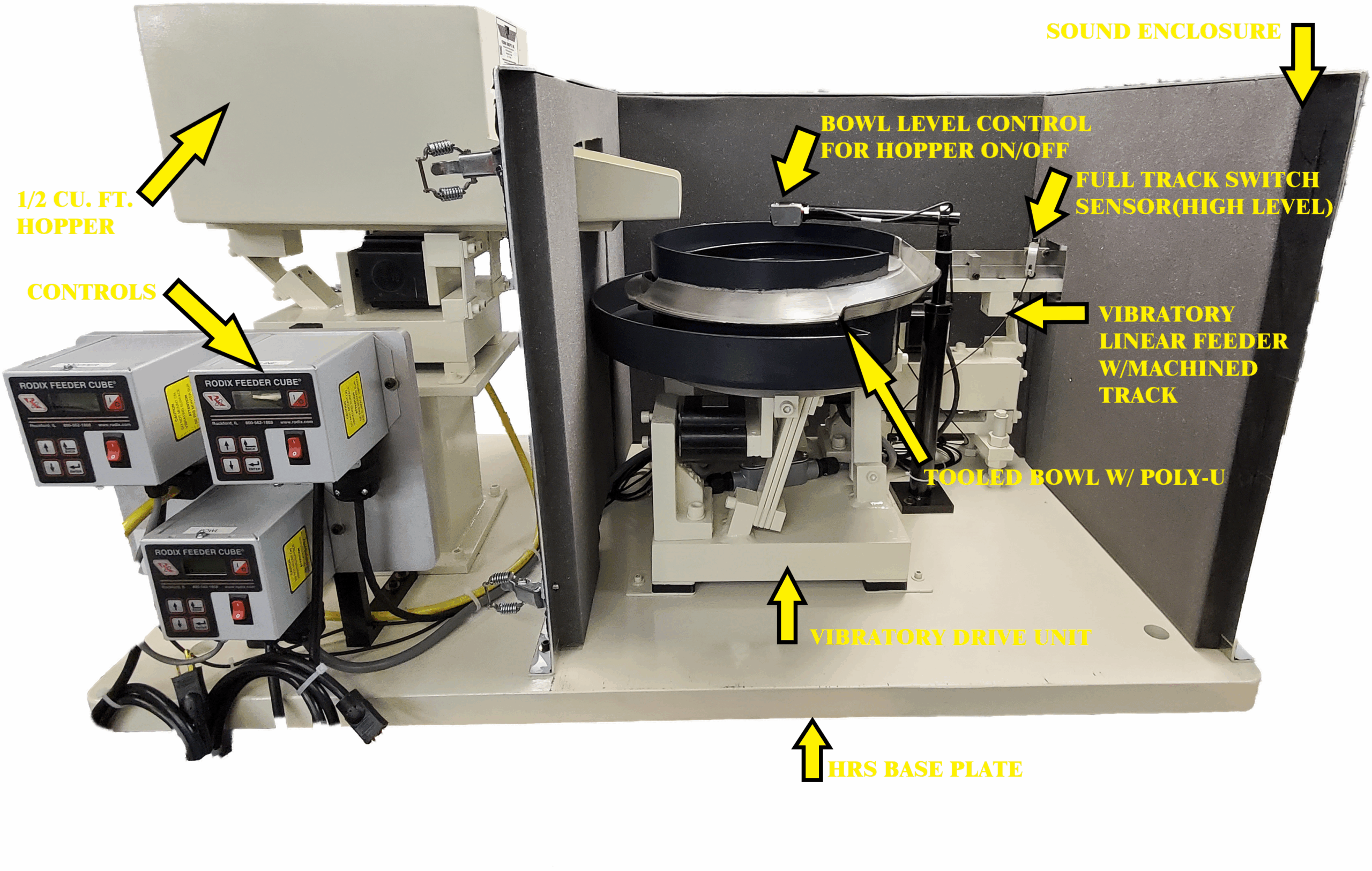

#1 Feeding Concepts Inc.

Domain Est. 1997

Website: feedingconcepts.com

Key Highlights: We are a custom vibratory feeder bowl manufacturer. We have a complete line of parts feeders, flex feeders, and vision feeding systems….

#2 Vibratory Feeders & Bowls Manufacturer

Domain Est. 1998

Website: vibratoryfeeders.com

Key Highlights: Vibratory Feeders Inc. manufactures vibratory bowl feeders, automation machines and ancillary components such as supply hoppers and linear power tracks….

#3 Industrial Automation Equipment & Flex Feeders

Domain Est. 1996

Website: feedall.com

Key Highlights: Our Quick Start Guide makes it easy to find the vibrating feeder, bulk feeders, automated conveying system, and more that is ideally suited for your application ……

#4 Automation Devices

Domain Est. 1996

Website: autodev.com

Key Highlights: ADI is a vibratory feeding systems manufacturer with a vast product line of parts feeding and automation equipment serving a variety of industries….

#5 Vibratory Feeder Manufacturers

Domain Est. 2001

Website: vibratory-feeders.com

Key Highlights: Quickly view the top vibratory feeder manufacturers and suppliers in the United States who offer on-site feeder testing and quick delivery at competitive ……

#6 Industry

Domain Est. 2018

Website: vrvibratory.com

Key Highlights: More than 20 years experience in the manufacture of vibratory equipment,including vibratory feeder,vibrating screen,electromagnetic vibrator,etc….

#7 Vibratory Feeders & Conveyors

Domain Est. 1995

Website: eriez.com

Key Highlights: Designed to provide a precise amount of vibration for vibratory feeders, Eriez offers a line of solid state Feeder Controls with state-of-the-art electronics….

#8 Vibratory Feeders

Domain Est. 2000

Website: coperion.com

Key Highlights: Vibratory feeders are ideal for gentle handling of a wide range of bulk solid materials, especially fragile ingredients and problem materials….

#9 About

Domain Est. 2012

Website: hoosierfeeder.com

Key Highlights: Hoosier Feeder started in 2007 with two brothers and a focus on building solid vibratory feeder bowls and backing it up with reliable service….

#10 Bellco Feeders

Domain Est. 2022

Website: bellcofeeders.com

Key Highlights: At Bellco Feeders, we specialize in designing and manufacturing custom vibratory bowl feeding systems, and automated part feeding solutions….

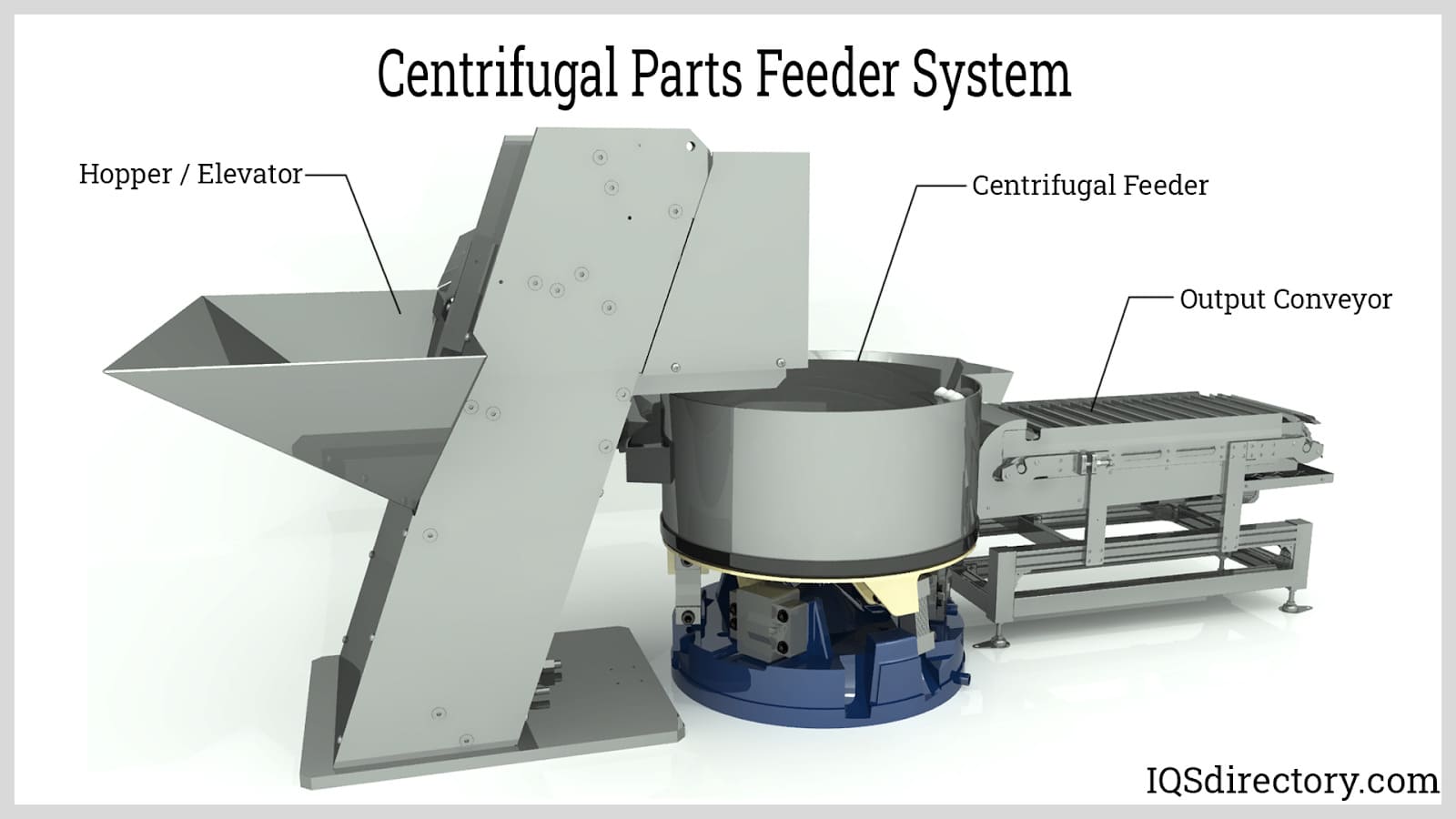

Expert Sourcing Insights for Vibrating Feeder

H2: 2026 Market Trends for Vibrating Feeders

The global vibrating feeder market is poised for significant transformation by 2026, driven by industrial automation, infrastructural development, and evolving material handling demands across key sectors such as mining, construction, and manufacturing. Several strategic trends are expected to shape the market landscape in the coming years.

-

Increased Demand from Mining and Quarrying Industries

The mining and quarrying sectors remain the largest end-users of vibrating feeders, with rising mineral extraction activities—especially in Asia-Pacific and Africa—fueling demand. As governments invest in resource exploration and mineral processing, vibrating feeders will be essential for efficient and continuous material feeding in primary crushing stages. The need for high-capacity, durable feeders capable of handling abrasive materials will drive innovation and market growth. -

Adoption of Smart and Automated Feeding Systems

By 2026, integration with Industry 4.0 technologies will be a defining trend. Manufacturers are increasingly embedding IoT sensors, remote monitoring systems, and predictive maintenance capabilities into vibrating feeders. These smart feeders enable real-time performance tracking, energy optimization, and reduced downtime, appealing to industries seeking operational efficiency and cost savings. -

Growth in Emerging Economies

Countries such as India, Indonesia, Vietnam, and Nigeria are witnessing rapid industrialization and infrastructure expansion. Government initiatives promoting road construction, urban development, and power generation are increasing the demand for aggregates and raw materials, directly boosting the need for reliable feeding equipment. Vibrating feeders tailored for local operating conditions and cost efficiency will gain traction in these markets. -

Focus on Energy Efficiency and Sustainability

Environmental regulations and rising energy costs are compelling manufacturers to develop energy-efficient vibrating feeders. Electromagnetic and variable-frequency drive (VFD) models are gaining popularity due to their precise control and lower power consumption. Additionally, equipment made from recyclable materials and designed for longer lifecycles will align with global sustainability goals. -

Product Customization and Modular Designs

As end-user requirements become more specialized, manufacturers are shifting toward modular and customizable vibrating feeder solutions. Customizations include variable amplitude control, corrosion-resistant coatings, and compatibility with different conveyor systems. This trend enables clients to adapt feeders to specific material types, throughput needs, and spatial constraints. -

Competitive Landscape and Strategic Collaborations

The market is expected to witness increased consolidation, with key players forming joint ventures, expanding production facilities, and acquiring regional suppliers to strengthen their global footprint. Companies like FLSmidth, Metso Outotec, and Sandvik are expected to lead innovation, while regional manufacturers will compete on pricing and after-sales service.

In conclusion, the 2026 vibrating feeder market will be shaped by technological advancement, regional development, and sustainability imperatives. Stakeholders who invest in smart technologies, expand into emerging markets, and offer tailored solutions will be best positioned to capitalize on the growing demand across industrial sectors.

Common Pitfalls Sourcing Vibrating Feeders: Quality and IP Concerns

When sourcing vibrating feeders, overlooking critical quality and intellectual property (IP) factors can lead to operational failures, safety risks, and legal complications. Here are key pitfalls to avoid:

Overlooking Build Quality and Material Specifications

Choosing a vibrating feeder based solely on price often results in subpar materials and construction. Low-grade steel, inadequate corrosion protection, or poor weld integrity can lead to premature wear, structural failure, or contamination in sensitive applications (e.g., food, pharmaceuticals). Always verify material certifications (e.g., 304/316 stainless steel) and demand test reports for durability and load capacity.

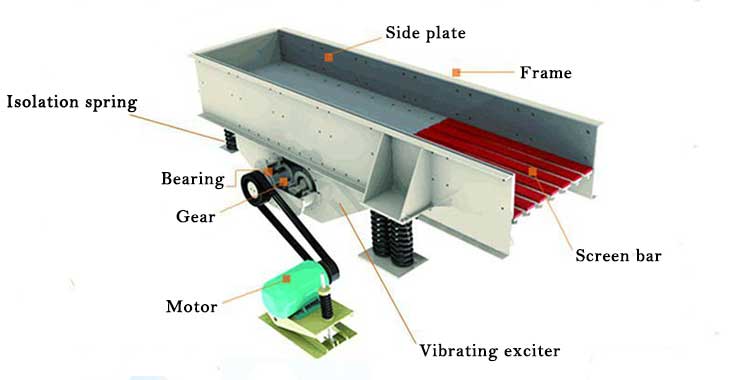

Ignoring Vibration Mechanism Design and Reliability

The core performance of a vibrating feeder depends on its drive mechanism—electromagnetic, motor-driven, or pneumatic. Poorly engineered systems may cause inconsistent feed rates, excessive noise, or mechanical breakdown. Ensure the design includes proper isolation, durable bearings, and sealed components to prevent dust or moisture ingress, especially in harsh environments.

Failing to Verify IP Protection and Legal Compliance

Sourcing from manufacturers without proper intellectual property rights can expose buyers to legal risks. Counterfeit or cloned designs may infringe on patents, leading to shipment seizures or litigation. Always request documentation proving original design ownership and compliance with international standards (e.g., CE, UL, ATEX for hazardous areas).

Underestimating Environmental and Ingress Protection (IP) Ratings

The IP rating (e.g., IP65, IP69K) defines protection against dust and water. Selecting a feeder with insufficient IP rating for the operating environment—such as washdown zones or outdoor installations—can result in motor failure or safety hazards. Confirm the IP rating matches your environmental conditions and verify it with third-party test reports.

Skipping Factory Acceptance Testing (FAT) and Quality Audits

Relying solely on supplier claims without on-site inspection or testing increases the risk of receiving defective units. Conduct Factory Acceptance Testing to evaluate vibration performance, material flow, noise levels, and safety features. For high-volume or mission-critical applications, perform quality audits of the manufacturer’s production facility.

Neglecting After-Sales Support and Spare Parts Availability

Even high-quality feeders require maintenance. Sourcing from suppliers with limited technical support or unavailable spare parts can lead to extended downtime. Confirm the availability of spare components, technical documentation, and responsive customer service before finalizing procurement.

By addressing these quality and IP-related pitfalls early, buyers can ensure reliable, compliant, and long-lasting vibrating feeder performance.

Logistics & Compliance Guide for Vibrating Feeder

This guide outlines key considerations for the safe and compliant logistics operations related to vibrating feeders, from transportation to installation and operation. Adhering to these guidelines ensures regulatory compliance, operational efficiency, and personnel safety.

Transportation and Handling

Ensure proper packaging and secure loading of the vibrating feeder to prevent damage during transit. Use lifting points specified in the manufacturer’s documentation and avoid slinging cables around critical components such as motors or springs. For oversized units, coordinate with freight carriers experienced in handling industrial machinery and obtain necessary permits for over-dimensional loads if required. Maintain documentation including bills of lading, packing lists, and shipping manifests for traceability.

Import/Export Regulations

Verify compliance with international trade regulations when shipping vibrating feeders across borders. Prepare accurate Harmonized System (HS) codes—typically under heading 8474 (machines for sorting, screening, separating, washing, crushing, grinding, mixing, or kneading earth, stone, ore, or other solid minerals)—and confirm country-specific import requirements. Include certificates of origin, commercial invoices, and ensure adherence to sanctions and export control laws (e.g., EAR in the U.S.). For units with integrated motors, evaluate dual-use implications and power specifications for regional compatibility.

Installation and Site Compliance

Before installation, confirm that the receiving site complies with local building, electrical, and occupational safety codes. Ensure mounting surfaces can support dynamic loads generated by the feeder’s vibration. Electrical connections must meet regional standards (e.g., NEC in the U.S., IEC in Europe), including proper grounding and protection against overcurrent. Use licensed personnel for wiring, and verify that explosion-proof or hazardous location certifications (e.g., ATEX, IECEx) are in place if the feeder operates in classified environments.

Environmental and Safety Regulations

Operate the vibrating feeder in accordance with environmental protection standards, particularly regarding noise and dust emissions. Install noise-dampening enclosures or barriers if sound levels exceed permissible limits (e.g., OSHA or EU Directive 2003/10/EC). Implement dust control measures such as shrouding or integrated dust extraction to comply with air quality regulations (e.g., EPA or EU Industrial Emissions Directive). Conduct regular risk assessments and ensure emergency stop mechanisms are accessible and functional.

Maintenance and Operational Documentation

Maintain comprehensive records of maintenance, inspections, and repairs as required by local regulations and industry standards. Keep user manuals, safety data sheets (SDS) for lubricants or coatings, and equipment certification documents on file. Train operators and maintenance staff on safe handling procedures, lockout/tagout (LOTO) protocols, and vibration exposure limits per OSHA or EU-OSHA guidelines. Schedule routine checks of springs, bolts, and drive mechanisms to prevent failure and ensure continued compliance.

Disposal and End-of-Life

At end-of-life, dispose of the vibrating feeder in compliance with local waste management and environmental laws. Recycle metal components through certified facilities and handle electrical parts and motors according to WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Properly document disposal activities to demonstrate regulatory compliance and support sustainability reporting.

Conclusion for Sourcing a Vibrating Feeder

In conclusion, sourcing a vibrating feeder requires a comprehensive evaluation of operational requirements, material characteristics, environmental conditions, and long-term maintenance needs. Selecting the right vibrating feeder ensures improved efficiency, consistent material flow, reduced downtime, and enhanced productivity in material handling processes. Key considerations such as feed rate, amplitude, power requirements, construction material, and supplier reliability play a critical role in making an informed decision. By partnering with reputable suppliers who offer quality-built equipment, technical support, and after-sales service, organizations can achieve optimal performance and a strong return on investment. Ultimately, a well-sourced vibrating feeder contributes significantly to the reliability and effectiveness of the overall processing system.