The global vertical turbine pump market is experiencing robust growth, driven by increasing demand across key sectors such as water and wastewater management, oil and gas, power generation, and industrial processing. According to a report by Mordor Intelligence, the vertical pump market was valued at approximately USD 6.4 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2029. This expansion is fueled by rising urbanization, stricter environmental regulations, and the need for energy-efficient pumping solutions. Additionally, Grand View Research highlights the growing deployment of vertical pumps in municipal water supply systems and groundwater extraction, further propelling market demand—especially in emerging economies. As infrastructure investments rise and industries prioritize reliability and efficiency, vertical pumps have become a cornerstone of fluid handling systems. In this competitive landscape, manufacturers that offer advanced engineering, durable materials, and scalable solutions are leading the charge. Here’s a look at the top 10 vertical pump manufacturers shaping the future of this dynamic market.

Top 10 Vertical Pumps Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Pumps Manufacturer

Domain Est. 1997

Website: gouldspumps.com

Key Highlights: Industrial Pumps Manufacturer for a wide range of markets — including chemical, mining, oil & gas, power generation, pulp and paper, and general industry….

#2 Grundfos USA

Domain Est. 1995

Website: grundfos.com

Key Highlights: The full range supplier of pumps and pump solutions. As a renowned pump manufacturer, Grundfos delivers efficient, reliable, and sustainable solutions all ……

#3 Pumps and pumping systems

Domain Est. 1996

Website: sulzer.com

Key Highlights: As one of the world’s leading pump manufacturers, Sulzer provides a wide range of products for engineered, configured, and standard pumping solutions….

#4 Durability by Design Since 1873

Domain Est. 1996

Website: wilo.com

Key Highlights: American-Marsh Pumps, is a leading manufacturer of centrifugal & positive displacement pumps, electrical motors, mechanical seals and fire protection ……

#5 Industrial Vertical Pumps Products

Domain Est. 1997

Website: flowserve.com

Key Highlights: The range of Flowserve vertical pumps covers wet-pit, double case, submersible, slurry and solid handling, sump and concrete volute ……

#6 Vertical Pumps

Domain Est. 1995

Website: peerlesspump.com

Key Highlights: Peerless Pump manufactures vertical turbine pumps, hydrofoil pumps, axial and mixed flow, in a variety of configurations and materials….

#7 Vertical Pumps

Domain Est. 1997

#8 Vertical Pumps

Domain Est. 1998

Website: finishthompson.com

Key Highlights: Vertical pumps from Finish Thompson are designed to require a smaller footprint than horizontal models. Applications include chemical sumps….

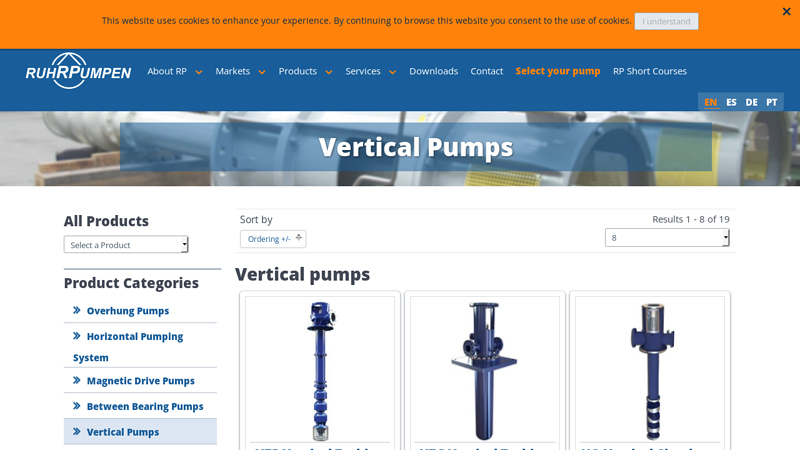

#9 Vertical Centrifugal Pumps, Submersible, Sump, Barge, Cryogenic

Domain Est. 2000

Website: ruhrpumpen.com

Key Highlights: Ruhrpumpen’s range of centrifugal vertical pumps covers submersible, turbine, cryogenic, sump, barge and many more pump models, ……

#10 National Pump Company

Domain Est. 2002

Website: nationalpumpcompany.com

Key Highlights: For 20 years National Pump Company has been a leader in vertical turbine pumps. We serve water, power, municipal, petroleum, and agriculture markets….

Expert Sourcing Insights for Vertical Pumps

H2: 2026 Market Trends for Vertical Pumps

The global vertical pumps market is poised for significant transformation by 2026, driven by technological advancements, increasing demand across key industries, and a heightened focus on energy efficiency and sustainability. As infrastructure development accelerates and water management becomes a critical priority, vertical pumps—known for their space-saving design, high efficiency, and reliability in handling large volumes of liquid—are expected to experience robust growth.

A key trend shaping the 2026 outlook is the rising investment in municipal water and wastewater treatment systems, particularly in emerging economies. Urbanization and stricter environmental regulations are pushing governments and private entities to modernize aging infrastructure, favoring vertical turbine and submersible pumps for deep-well applications and flood control. Additionally, the oil & gas, power generation, and mining sectors continue to adopt advanced vertical pump solutions to improve operational efficiency and reduce maintenance downtime.

Technological integration is another major driver. By 2026, smart pumping systems equipped with IoT-enabled sensors, predictive maintenance capabilities, and remote monitoring are expected to gain widespread adoption. These innovations allow for real-time performance tracking, energy optimization, and reduced lifecycle costs—factors increasingly critical in competitive industrial environments.

Sustainability initiatives are also influencing market dynamics. Manufacturers are focusing on designing energy-efficient pumps that comply with international standards such as MEI (Minimum Energy Efficiency) and ERP (Energy-related Products Directive). The shift toward renewable energy projects, including geothermal and hydroelectric plants, further boosts demand for specialized vertical pumping systems.

Regionally, Asia-Pacific is anticipated to lead market growth due to rapid industrialization and large-scale water infrastructure projects in countries like India and China. Meanwhile, North America and Europe will see steady demand driven by infrastructure renewal programs and stringent environmental compliance requirements.

In summary, the 2026 vertical pumps market will be characterized by digitalization, energy efficiency, and expanding applications across water, industrial, and energy sectors—positioning vertical pumps as essential components in the global push for sustainable and resilient fluid management systems.

Common Pitfalls Sourcing Vertical Pumps (Quality, IP)

Sourcing vertical pumps, especially for critical applications, involves navigating several potential pitfalls related to quality and intellectual property (IP). Overlooking these can lead to performance issues, safety hazards, increased downtime, and legal complications. Below are key areas to watch:

Inadequate Quality Assurance and Certification

One of the most frequent pitfalls is selecting suppliers without rigorous quality control processes. Many low-cost manufacturers may claim compliance with international standards (such as ISO, API 610, or ANSI/HI) but fail to provide verifiable certifications or third-party test reports. This increases the risk of receiving pumps with substandard materials, poor welding, or imprecise machining—leading to premature failure, leaks, or inefficiencies.

Key Red Flags:

– Lack of documented quality management system (e.g., ISO 9001)

– No factory acceptance testing (FAT) or hydrostatic test reports

– Unverified claims of compliance with industry standards

Misrepresentation of IP and Design Ownership

Another major concern is the unauthorized use or cloning of patented pump designs. Some suppliers, particularly in emerging markets, may replicate well-known OEM designs without licensing the IP. While these “copy” pumps may appear identical and cost less, they often lack engineering validation, leading to reliability issues. Purchasing such pumps can expose the buyer to IP infringement risks, especially if used in regulated industries or exported to regions with strong IP enforcement.

Common IP-Related Risks:

– Sourcing pumps that infringe on proprietary hydraulic designs or patented components

– Absence of design documentation or traceability

– Suppliers unable to provide proof of licensed technology or original engineering

Insufficient Material Traceability and Documentation

Vertical pumps used in chemical, water treatment, or oil & gas industries require specific material compatibility (e.g., stainless steel, duplex alloys). A common quality pitfall is receiving components without proper material test reports (MTRs) or with falsified certifications. This compromises corrosion resistance and mechanical integrity, especially in aggressive environments.

Critical Documentation to Request:

– Mill Test Certificates (MTCs) for all wetted parts

– NDT (non-destructive testing) reports for welds and castings

– As-built drawings and design calculations

Overlooking Long-Term Support and Spare Parts Availability

Even with a quality initial product, sourcing from suppliers with weak IP or unclear design ownership often means limited access to spare parts, technical support, or future upgrades. If the supplier lacks genuine engineering capabilities or is merely reverse-engineering products, they may not sustain long-term serviceability.

Best Practices to Avoid Pitfalls:

– Partner with reputable manufacturers who own or license their designs

– Require full documentation, including test reports and design validation

– Audit suppliers’ quality systems and manufacturing facilities

– Include IP indemnity clauses in procurement contracts

By proactively addressing these quality and IP concerns, organizations can ensure reliable pump performance, regulatory compliance, and protection against legal and operational risks.

Logistics & Compliance Guide for Vertical Pumps

Product Identification and Specifications

Ensure accurate identification of vertical pump models, including manufacturer, model number, flow rate, head, materials of construction (e.g., cast iron, stainless steel), motor specifications, and any applicable standards (e.g., API 610, ANSI/ASME B73.3). This information is essential for compliance, proper handling, and customs documentation.

Packaging and Handling Requirements

Use robust, weather-resistant packaging with secure crating to protect vertical pumps during transit. Include lifting points clearly marked on the crate or pump base. Always lift using designated lifting lugs—never use the motor or piping connections. Protect pump shafts and seals from damage during handling and transport.

Transportation and Shipping

Ship vertical pumps in an upright position to prevent internal component misalignment or seal damage. Secure loads to prevent movement during transit. For international shipments, comply with IMDG Code (if applicable), IATA regulations (for air freight), and regional transport safety standards. Provide detailed shipping manifests and packing lists.

Import/Export Compliance

Verify compliance with international trade regulations, including export controls (e.g., EAR or ITAR, if applicable), country-specific import restrictions, and required certifications (e.g., CE, UKCA, CRN). Ensure Harmonized System (HS) codes are correctly classified for customs clearance. Maintain documentation such as commercial invoices, certificates of origin, and test reports.

Regulatory and Industry Standards

Confirm adherence to relevant standards such as:

– API 610 (Centrifugal Pumps for Petroleum, Petrochemical, and Natural Gas Industries)

– ANSI/ASME B73.3 (Specification for Vertical Inline Pumps)

– ISO 5199 (Technical specifications for thermoplastics and metallic pumps)

– ATEX/IECEx (for pumps used in explosive atmospheres)

Environmental and Safety Compliance

Ensure pumps meet environmental regulations such as EPA, REACH, and RoHS, particularly concerning materials and coatings. Provide Material Safety Data Sheets (MSDS/SDS) for any lubricants or hydraulic fluids included. Follow OSHA or local safety regulations during installation and handling.

Documentation and Traceability

Maintain comprehensive documentation including test certificates (e.g., hydrostatic, performance), material certifications (e.g., MTRs), quality control records, and compliance declarations. Ensure full traceability of components for regulatory audits and warranty claims.

Installation and On-Site Compliance

Follow manufacturer’s installation guidelines to ensure safe and compliant operation. Verify that site conditions (e.g., foundation, alignment, piping support) meet design specifications. Conduct pre-commissioning inspections and ensure all safety guards and electrical grounding are properly installed per local codes (e.g., NEC, IEC).

Conclusion for Sourcing Vertical Turbine Pumps

After a comprehensive evaluation of technical requirements, supplier capabilities, and total cost of ownership, the sourcing of vertical turbine pumps should be guided by a strategic approach that balances performance, reliability, and lifecycle costs. Vertical pumps are critical in applications requiring high head, deep sump installations, or large-volume water transfer, such as in municipal water supply, industrial processing, and power generation.

Key considerations in the sourcing decision include pump efficiency, material compatibility with the fluid handled, manufacturer reputation, service and support availability, and compliance with relevant industry standards (e.g., API, ANSI, HI). Engaging suppliers with proven experience, strong technical support, and demonstrated after-sales service ensures long-term operational reliability.

Additionally, incorporating lifecycle cost analysis—rather than focusing solely on initial purchase price—leads to more sustainable and cost-effective outcomes. Preferred suppliers should offer customization options, energy-efficient designs, and robust warranties.

In conclusion, successful sourcing of vertical pumps hinges on a well-structured procurement strategy that prioritizes technical fit, long-term value, and vendor partnership. Selecting the right pump from a reputable supplier will ensure optimal performance, reduced downtime, and lower maintenance costs over the equipment’s operational life.