The global venturi pump market is experiencing steady growth, driven by increasing demand across industries such as water treatment, chemical processing, and oil & gas. According to a report by Mordor Intelligence, the global vacuum pump market—of which venturi pumps are a critical segment—is projected to grow at a CAGR of over 5.2% from 2023 to 2028. This expansion is fueled by the rising need for energy-efficient, maintenance-free pumping solutions in industrial applications. Venturi pumps, known for their simplicity, reliability, and ability to operate without moving parts, are particularly favored in environments requiring corrosion resistance and explosion-proof operation. With growing industrial automation and stricter environmental regulations, the demand for high-performance venturi pumps continues to rise. Based on market presence, technological innovation, and global reach, the following eight manufacturers have emerged as leaders in the design and production of venturi pump systems.

Top 8 Venturi Pump Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Venturi Jet Pumps

Domain Est. 1999

Website: venturipumps.com

Key Highlights: With over 20 years experience in the Power & Process Industry, Venturi Jet Pumps is a leading manufacturer in Venturi Process Equipment….

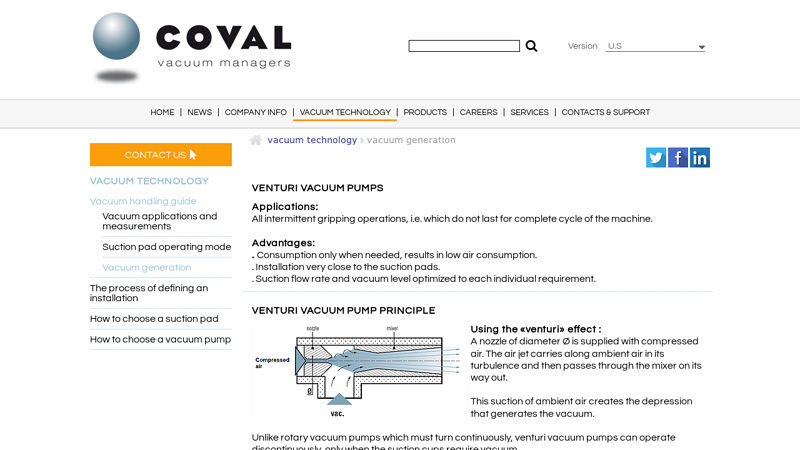

#2 COVAL

Domain Est. 2007

Website: coval-inc.com

Key Highlights: Venturi vacuum pumps are used for all normal vacuum gripping applications. Compact and light, venturis may be installed close to the suction pads….

#3 Venturi Vacuum Pump Manufacturers Suppliers

Domain Est. 2014

Website: vacuumpumpmanufacturers.com

Key Highlights: Discover top venturi vacuum pump suppliers in the USA. Order custom-engineered, user-friendly products online at discounted rates….

#4 EST Venturi Systems: Custom Engineered Venturi Systems

Domain Est. 2020

Website: est-venturisystems.com

Key Highlights: We’re a reliable venturi system manufacturer based out of The Woodlands, TX, but we do business worldwide. We offer a wide range of products to fit our client’ ……

#5 Venturi Pumps

Domain Est. 1995

#6 Venturi Pumps

Domain Est. 1997

Website: updateltd.com

Key Highlights: MULTI VENTURI VACUUM PUMP MODEL 50 MULTI VENTURI VACUUM PUMP MODEL 50. Part Number: VAC-50. Sale Price $730.00 /EACH….

#7 Air Venturi

Domain Est. 2005

Website: airventuri.com

Key Highlights: Discover the power of air with Air Venturi, a leading innovator in high-performance airguns. Shop our collection of PCP air rifles, pistols, pellets, ……

#8 Venturi Supply

Domain Est. 2023

Website: venturisupply.com

Key Highlights: As a united family of companies, Venturi Supply specializes in providing mission-critical pipe, valve and fittings solutions, as well as value-added services….

Expert Sourcing Insights for Venturi Pump

H2: Market Trends for Venturi Pumps in 2026

As of 2026, the global market for Venturi pumps is experiencing steady growth driven by increased demand across industrial, environmental, and healthcare sectors. These simple, reliable, and maintenance-efficient fluid-handling devices are benefiting from technological advancements, sustainability mandates, and a shift toward energy-efficient systems.

Key market trends shaping the Venturi pump industry in 2026 include:

-

Growing Emphasis on Energy Efficiency and Sustainability

With global regulations tightening around energy consumption and carbon emissions, industries are increasingly adopting passive pumping technologies like Venturi pumps that require no moving parts and operate using fluid dynamics. Their ability to utilize existing pressure differentials in systems makes them ideal for green engineering applications, especially in water treatment and HVAC systems. -

Expansion in Water and Wastewater Treatment

The water sector remains a dominant driver of Venturi pump adoption. In 2026, rising investments in municipal and industrial wastewater treatment—particularly for aeration and chemical dosing—are boosting demand. Venturi injectors are widely used for ozone and chlorine dosing due to their precision and reliability, supporting compliance with stringent environmental standards. -

Adoption in Oil & Gas and Chemical Processing

The oil and gas industry continues to use Venturi pumps for vacuum creation, gas lifting, and mixing applications in remote or hazardous environments. Their intrinsic safety—lacking motors or seals—reduces explosion risks, making them favorable in explosive atmospheres. Similarly, chemical processing plants value their corrosion resistance when constructed from materials like PVDF or stainless steel. -

Integration with Digital Monitoring and Smart Systems

A notable trend in 2026 is the integration of Venturi pumps with IoT-enabled sensors and control systems. While Venturi pumps themselves are passive, their performance is now being optimized through real-time monitoring of flow rates, pressure differentials, and cavitation levels. This hybrid approach enhances process efficiency in smart manufacturing and water management infrastructures. -

Rising Use in Medical and Laboratory Applications

The healthcare sector is increasingly adopting miniaturized Venturi pumps in medical vacuum systems, dental equipment, and lab automation. Their oil-free operation and low maintenance meet the hygiene and reliability standards required in clinical environments. -

Material Innovation and Customization

Manufacturers are responding to diverse application needs with advanced materials such as PTFE, ceramic composites, and high-grade alloys. Customization for specific flow dynamics and chemical compatibility is becoming a competitive differentiator, especially in niche industrial applications. -

Geographic Shifts and Emerging Markets

While North America and Europe maintain strong market shares due to infrastructure upgrades and environmental regulations, Asia-Pacific—particularly India, China, and Southeast Asia—is witnessing the fastest growth. Rapid urbanization, industrial expansion, and government-led water sanitation programs are key growth catalysts.

In summary, the 2026 Venturi pump market is characterized by resilience, innovation, and cross-sector adaptability. Driven by sustainability goals, digital integration, and expanding industrial needs, Venturi pumps are evolving from simple fluid-handling tools into integral components of efficient, smart, and eco-friendly systems.

Common Pitfalls When Sourcing a Venturi Pump (Focus on Quality and Intellectual Property)

Sourcing a Venturi pump, while seemingly straightforward, involves significant risks related to quality consistency and intellectual property (IP) protection. Overlooking these aspects can lead to performance failures, safety hazards, financial losses, and legal disputes. Here are the key pitfalls to avoid:

1. Compromised Quality Due to Inadequate Material and Manufacturing Standards

Venturi pumps rely on precise geometry and material integrity for efficient operation, especially in demanding industrial, chemical, or medical applications. A major pitfall arises when suppliers cut corners on materials or manufacturing processes.

- Substandard Materials: Using inferior-grade stainless steel, plastics, or elastomers can lead to rapid corrosion, erosion (especially at the throat), or chemical incompatibility. This results in leaks, contamination, reduced lifespan, and potential safety incidents. For example, a pump specified for aggressive acids might fail within weeks if constructed with 304 SS instead of required 316L or Hastelloy.

- Poor Dimensional Accuracy: The Venturi effect is highly sensitive to the exact contours of the converging cone, throat, and diverging diffuser. Inconsistent machining or molding leads to significant deviations from the designed performance curve (flow rate, suction lift, efficiency). Off-spec pumps may fail to achieve required vacuum levels or fluid transfer rates.

- Lack of Quality Control (QC): Suppliers without rigorous QC processes (e.g., dimensional checks, pressure testing, material certification) may deliver pumps with internal burrs, misaligned ports, or hidden flaws undetectable during initial inspection but causing premature failure.

Mitigation: Demand detailed material specifications (including certifications like Mill Test Reports), require adherence to recognized standards (e.g., ASME BPE for hygienic applications), insist on documented QC procedures, and conduct thorough incoming inspections or third-party audits.

2. Intellectual Property (IP) Infringement and Design Copying

Venturi pump design, while based on a fundamental principle, often incorporates proprietary enhancements that constitute valuable IP. Sourcing from unscrupulous suppliers risks IP theft and legal complications.

- Direct Design Copying: Suppliers may reverse-engineer a competitor’s high-performance or patented Venturi pump (e.g., optimized nozzle geometry, specialized mixing chamber, integrated flow control) and sell identical or substantially similar units without license or attribution. This is direct patent or design right infringement.

- Misappropriation of Specifications: Detailed performance curves, CAD models, or proprietary design features shared during the sourcing process for customization can be copied and used to produce competing products without authorization.

- Counterfeit Products: Suppliers might source or produce pumps falsely branded as genuine or meeting specific certifications (e.g., ATEX, FDA), infringing on trademarks and potentially violating safety regulations.

Mitigation:

* Establish Clear IP Agreements: Use robust NDAs (Non-Disclosure Agreements) and IP assignment clauses in contracts before sharing sensitive design data.

* Conduct Supplier Due Diligence: Vet suppliers for history of IP disputes, verify their design origins, and check for existing patents (yours and theirs).

* Protect Core IP: Patent unique design features. Avoid sharing complete, high-fidelity design data unless absolutely necessary and legally protected.

* Verify Authenticity: Source from authorized distributors or directly from known manufacturers. Scrutinize certifications and markings.

Failure to address these quality and IP pitfalls can result in unreliable equipment, costly downtime, safety risks, product recalls, and damaging legal battles. Proactive due diligence, clear contractual safeguards, and stringent quality requirements are essential when sourcing Venturi pumps.

H2: Logistics & Compliance Guide for Venturi Pump

Handling, transporting, and deploying a Venturi Pump—especially in regulated or industrial environments—requires strict adherence to logistics protocols and compliance standards. This guide outlines key considerations under the H2 framework (Handling, Hazards, and Harmonization) to ensure safe, efficient, and compliant operations.

1. Handling (H2 – Handling)

1.1. Packaging & Transport Preparation

– Ensure the Venturi Pump is securely packaged in shock-resistant, moisture-proof materials.

– Use original manufacturer crates or equivalent protective packaging to prevent mechanical damage.

– Label packages with “Fragile,” “This Side Up,” and handling instructions.

– Confirm compatibility with transport modes (road, air, sea) based on pump material (e.g., stainless steel, PVC, PTFE).

1.2. Storage Conditions

– Store in a dry, temperature-controlled environment (typically 5°C to 40°C).

– Avoid exposure to direct sunlight, corrosive chemicals, or high humidity.

– Keep pumps on pallets or racks to prevent floor contact and contamination.

1.3. Installation & Deployment

– Follow manufacturer’s installation manual strictly.

– Ensure proper alignment with connected piping and avoid stress on inlet/outlet ports.

– Use protective caps until ready for installation to prevent debris ingress.

2. Hazards (H2 – Hazards)

2.1. Material Compatibility & Fluid Hazards

– Confirm the Venturi Pump’s material (e.g., 316 stainless steel, PVDF) is compatible with the fluid being handled (e.g., acids, solvents, water).

– Refer to chemical resistance charts from the manufacturer.

– Never use with fluids outside the approved range—risk of degradation, leaks, or failure.

2.2. Pressure & Vacuum Safety

– Operate only within the specified suction lift, discharge pressure, and motive fluid pressure ranges.

– Install pressure relief valves and vacuum breakers where required.

– Inspect for leaks, erosion, or cavitation during operation.

2.3. Personnel Safety

– Use appropriate PPE (gloves, goggles, face shield) during maintenance or when handling hazardous fluids.

– Lockout/Tagout (LOTO) procedures must be followed during servicing.

– Avoid exposure to high-velocity motive fluid (e.g., steam, compressed air) under pressure.

3. Harmonization (H2 – Harmonization)

3.1. Regulatory Compliance

– Ensure the Venturi Pump meets relevant international standards:

– ISO 9001: Quality management for manufacturing.

– ISO 14001: Environmental management (if applicable).

– ATEX/IECEx: Required if used in explosive atmospheres.

– FDA 21 CFR: If used in food, beverage, or pharmaceutical applications.

– PED (Pressure Equipment Directive 2014/68/EU): For EU markets involving pressure systems.

3.2. Documentation & Traceability

– Maintain Certificate of Conformity (CoC), Material Test Reports (MTR), and calibration records.

– Keep user manuals, safety data sheets (SDS), and installation certificates on file.

– Ensure serial number tracking for warranty and recall purposes.

3.3. Import/Export & Customs Compliance

– Verify HS Code (e.g., 8413.70 for liquid pumps) for customs classification.

– Comply with export control regulations (e.g., ECCN if dual-use technology).

– Provide accurate commercial invoices, packing lists, and origin declarations.

– Check destination country restrictions (e.g., REACH, RoHS, local environmental laws).

Conclusion

Adhering to the H2 Logistics & Compliance framework—Handling, Hazards, and Harmonization—ensures the Venturi Pump is safely transported, installed, and operated in full compliance with global standards. Always consult the manufacturer’s technical documentation and engage certified professionals for installation and maintenance in regulated environments.

Conclusion for Sourcing Venturi Pumps:

After a thorough evaluation of technical requirements, performance needs, and supplier capabilities, sourcing a Venturi pump presents a reliable and cost-effective solution for applications requiring fluid movement or vacuum generation without moving parts. The simplicity of design, low maintenance, and ability to operate using existing pressure differentials make Venturi pumps ideal for industrial, chemical, wastewater, and process applications.

Key considerations in the sourcing decision include material compatibility with the process fluid, required flow rates, operating pressure conditions, and overall system efficiency. It is essential to partner with reputable suppliers offering proven designs, compliance with industry standards, and technical support to ensure optimal integration and long-term performance.

In conclusion, the Venturi pump is a robust and efficient choice for specific fluid handling needs. Strategic sourcing focused on quality, application suitability, and supplier reliability will ensure successful implementation and operational effectiveness.