The global vehicle roll bar market is experiencing steady expansion, driven by rising demand for enhanced occupant safety across on- and off-road vehicles. According to Mordor Intelligence, the automotive safety systems market—of which roll bars are a critical component—is projected to grow at a CAGR of over 7% from 2024 to 2029, propelled by stricter regulatory standards and increasing consumer awareness. Off-road and recreational vehicle production, in particular, has amplified the need for robust rollover protection systems. Grand View Research further highlights that the global off-highway vehicle market is expected to expand at a CAGR of 6.8% during the same period, directly fueling demand for high-performance roll bars. As safety becomes a non-negotiable feature across agriculture, construction, and automotive sectors, manufacturers are investing in lightweight, high-strength materials and crash-validated designs. This growing market landscape has given rise to a competitive field of innovators and established players, leading to the emergence of the top 10 vehicle roll bar manufacturers shaping industry standards today.

Top 10 Vehicle Roll Bar Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Safety Devices

Domain Est. 2000

Website: safetydevices.com

Key Highlights: Universally accepted as the leading manufacturer of roll cages, we offer a growing range of roll over protection solutions for more than 2,500 vehicles. We ……

#2 AST Roll Cages

Domain Est. 2016

Website: astrollcages.com

Key Highlights: At AST Roll Cages we are manufacturers of roll cages for vehicles and we have the largest catalog in the world! +300 cars, +6000 different designs, ……

#3 All Roll Bars, Cages and Accessories Products

Domain Est. 1998

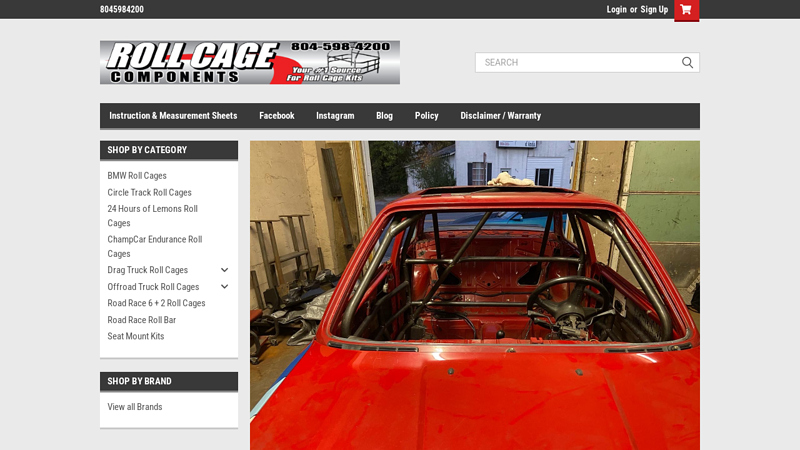

#4 to Roll Cage Components

Domain Est. 2004

Website: rollcagecomponents.com

Key Highlights: Featured Products ; 05-4000 · Road Race Roll Bar Kit · $299.00 ; 05-7305 · BMW E46 Roll Cage Kit · $1,195.00 ; 05-2300 Chevrolet S10 82-93 · Chevrolet 1982-1993 S10 ……

#5 high-performance Bolt-In Roll Bars

Domain Est. 2005

Website: cantrellmotorsport.com

Key Highlights: We manufacture high-performance bolt-in roll bars for sports cars. Cantrell Motorsports in Bellevue WA supplies quality parts for Porsche, Audi, BMW, ……

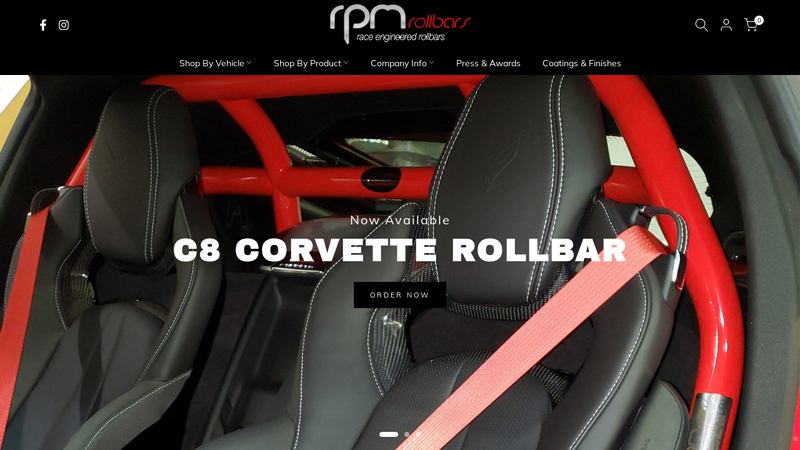

#6 RPM Rollbars

Domain Est. 2010

Website: rpmrollbar.com

Key Highlights: 100% NHRA Legal, 100% welded, and 100% removable roll bars. We also make a SCCA and NASA version of our cages. We guarantee that our rollbars will pass tech or ……

#7 Roll Bars & Harness Bars

Domain Est. 2010

Website: competitionmotorsport.com

Key Highlights: Free delivery over $100 30-day returnsShop race-ready roll bars and harness bars engineered for safety, fitment, and compliance. Strengthen your chassis and secure your harness for…

#8 ChampCar Tech Desk

Domain Est. 2017

Website: champcar.org

Key Highlights: Official channel for ChampCar technical questions, interpretations, and VPI requests. Before you submit a ticket. The Tech Desk is for rules clarifications and ……

#9 Robinson Race Cars

Domain Est. 2019

Website: robinsonracecars.com

Key Highlights: For all your race car engineering needs. Robinson Race Cars offers every kind of engineering and fabrication service necessary to build a complete race car….

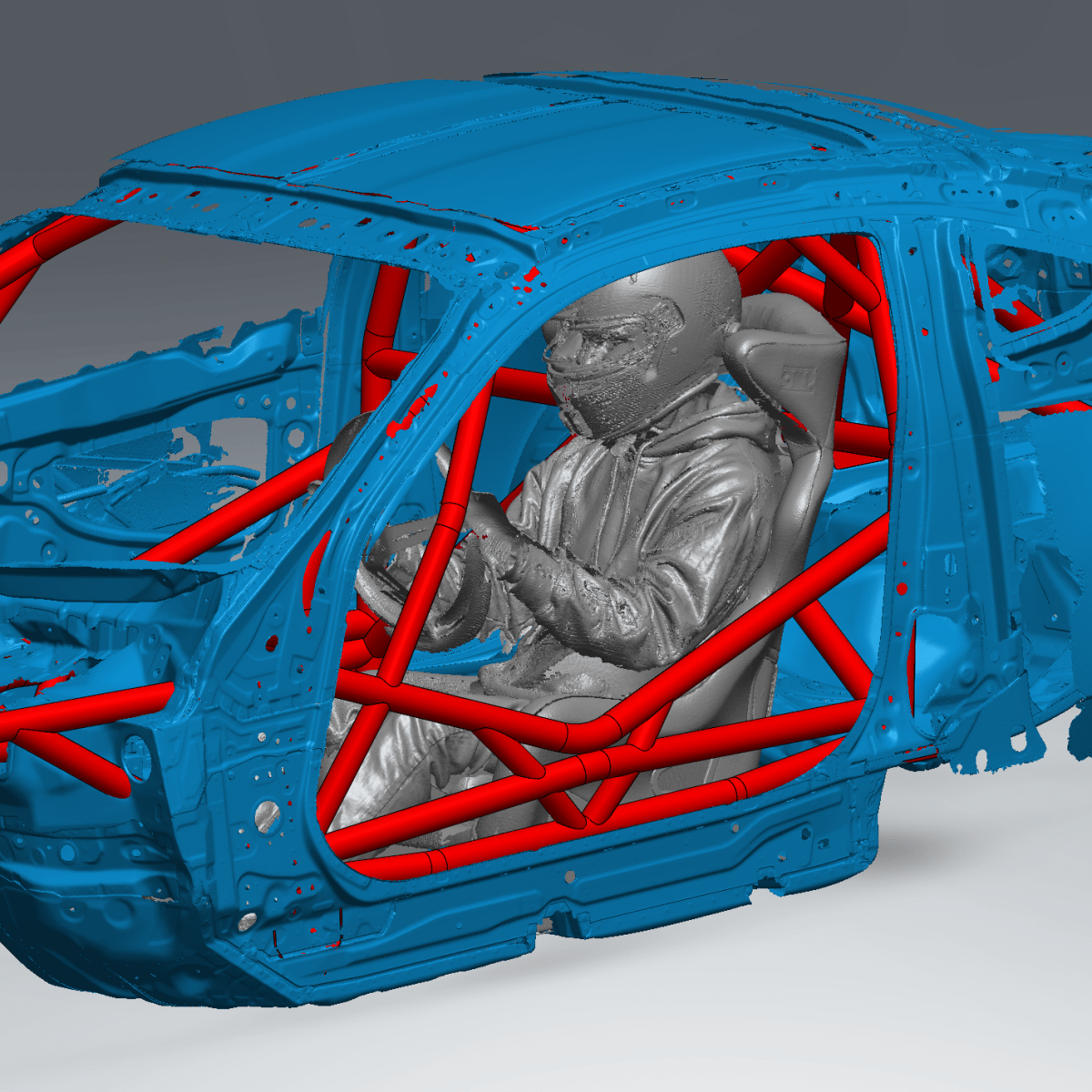

#10 Cagekits.org

Domain Est. 2020

Website: cagekits.org

Key Highlights: All of our roll cages are 3D scanned, CNC-bent, and notched with multiple door bar options. These roll cage kits offer ease of installation and a perfect fit….

Expert Sourcing Insights for Vehicle Roll Bar

H2: 2026 Market Trends for Vehicle Roll Bars

The global vehicle roll bar market is poised for steady growth by 2026, driven by increasing safety regulations, rising off-road and recreational vehicle adoption, and growing consumer awareness. Key trends shaping the market include:

1. Regulatory Push and Safety Standards: Governments worldwide are tightening vehicle safety mandates, particularly for utility, agricultural, and off-road vehicles. Mandates for Rollover Protective Structures (ROPS) in construction, mining, and farming equipment in regions like North America and Europe will continue to be a primary growth driver. Expect increased enforcement and expanded scope of regulations, pushing OEMs to integrate roll bars as standard equipment.

2. Growth in Off-Road and Recreational Vehicle (ORV/UTV/ATV) Markets: The booming popularity of utility task vehicles (UTVs), side-by-sides, and off-road trucks—especially in North America and Europe—fuels demand for aftermarket and OEM roll bars. Consumers in these segments prioritize safety during high-speed or rough-terrain driving, making roll bars a critical accessory. Customization and performance enhancements will drive aftermarket sales.

3. Material Innovation and Lightweighting: To meet fuel efficiency and performance goals, manufacturers are shifting toward high-strength, lightweight materials such as advanced high-strength steel (AHSS) and aluminum alloys. Some premium and racing applications may explore carbon fiber composites, though cost remains a barrier to mass adoption. This trend supports durability without compromising vehicle dynamics.

4. Integration with Advanced Safety Systems: By 2026, roll bars are increasingly being designed as part of holistic vehicle safety architectures. Integration with airbag systems, roll angle sensors, and electronic stability control (ESC) enhances overall occupant protection during rollover events. OEMs are focusing on structural synergy between roll bars and the vehicle frame for optimized crash performance.

5. Expansion in Emerging Markets: Rapid industrialization and infrastructure development in Asia-Pacific (especially India and Southeast Asia) and Latin America are increasing demand for commercial and agricultural vehicles equipped with ROPS. Local manufacturing and cost-effective roll bar solutions will be key to capturing this growing segment.

6. Aftermarket Customization and Aesthetics: Beyond safety, roll bars are becoming a style statement in the automotive aftermarket. Consumers seek customizable finishes (powder coating, chrome), integrated lighting, and multi-functional designs (e.g., mounting points for cameras or winches). This trend is particularly strong in the U.S. truck and SUV aftermarket.

7. Focus on Cost-Effective and Modular Designs: As competition intensifies, suppliers are developing modular roll bar systems that can be adapted across vehicle platforms, reducing production costs. This benefits both OEMs and the aftermarket, enabling scalable solutions for diverse vehicle types.

Conclusion:

By 2026, the vehicle roll bar market will be characterized by stronger regulatory influence, technological integration, and diversification across industrial, agricultural, and recreational sectors. Innovation in materials and design, coupled with rising safety consciousness, will sustain market expansion, with North America and Asia-Pacific leading in adoption and production.

Common Pitfalls When Sourcing Vehicle Roll Bars: Quality and Intellectual Property Risks

Sourcing vehicle roll bars—especially for off-road, racing, or aftermarket applications—requires careful attention to both quality standards and intellectual property (IP) compliance. Failure to address these areas can lead to safety hazards, legal liabilities, and reputational damage. Below are key pitfalls to avoid.

Quality-Related Pitfalls

1. Inadequate Material Specifications

A common mistake is sourcing roll bars made from substandard or unverified materials. Low-grade steel or aluminum may not meet the required strength-to-weight ratio, compromising occupant safety during a rollover. Always verify material certifications (e.g., ASTM, ISO) and ensure the supplier provides mill test reports.

2. Poor Welding and Fabrication Practices

Weak or inconsistent welds are a leading cause of roll bar failure. Suppliers may cut costs by using unqualified welders or automated processes without proper inspection. Ensure compliance with welding standards (e.g., AWS D1.1) and require destructive or non-destructive testing (NDT) records.

3. Lack of Crash Testing and Certification

Many sourced roll bars lack validation through recognized safety standards (e.g., FIA, SFI, or OEM specifications). Relying on untested designs increases liability risk. Confirm that the product has undergone dynamic and static load testing and carries relevant certifications.

4. Inconsistent Tolerances and Fitment Issues

Poor dimensional control can result in roll bars that do not align properly with vehicle mounting points, leading to stress concentrations or installation difficulties. Require detailed CAD compatibility checks and first-article inspections before full-scale procurement.

5. Inadequate Corrosion Protection

Roll bars exposed to harsh environments must have proper surface treatments (e.g., powder coating, galvanization). Sourcing products without durable finishes can result in premature rust and structural degradation.

Intellectual Property-Related Pitfalls

1. Sourcing Counterfeit or Reverse-Engineered Designs

Some suppliers offer roll bars that closely mimic patented OEM or aftermarket designs. Using such products exposes the buyer to IP infringement claims. Conduct due diligence to confirm the supplier owns the design or has proper licensing.

2. Unclear Design Ownership and Licensing

When co-developing or customizing roll bars, failure to define IP ownership in contracts can lead to disputes. Ensure agreements clearly state who owns tooling, CAD files, and design modifications.

3. Use of Proprietary Mounting Systems or Brackets

Even if the roll bar itself is generic, copying patented mounting solutions can infringe IP rights. Review technical drawings for potential overlap with existing patents, especially for integrated safety systems or quick-release mechanisms.

4. Lack of IP Warranty from Supplier

Many suppliers do not provide IP indemnification. Without a contractual guarantee that the product doesn’t infringe third-party rights, the buyer may bear legal and financial responsibility in case of a lawsuit.

5. Sourcing from Regions with Weak IP Enforcement

Procuring from countries with lax IP regulations increases the risk of unintentionally acquiring infringing products. Prioritize suppliers with transparent design origins and verifiable compliance documentation.

Mitigation Strategies

- Conduct factory audits to assess quality control and design processes.

- Require full traceability of materials and weld procedures.

- Engage legal counsel to perform IP clearance searches before procurement.

- Include IP indemnification clauses in supplier contracts.

- Source from certified manufacturers with a track record in automotive safety components.

By addressing these quality and IP pitfalls proactively, organizations can ensure the safety, legality, and long-term reliability of their vehicle roll bar supply chain.

Logistics & Compliance Guide for Vehicle Roll Bar

Overview

This guide provides essential information on the logistics and compliance requirements for the shipment, handling, installation, and certification of vehicle roll bars. Adherence to these guidelines ensures safety, regulatory compliance, and efficient operations across supply chain and end-use phases.

Regulatory Compliance

FMVSS and DOT Standards (USA)

Roll bars intended for use in the United States must comply with applicable Federal Motor Vehicle Safety Standards (FMVSS), particularly FMVSS 216 (Roof Crush Resistance) and FMVSS 225 (Child Restraint Anchorage Systems), where applicable. While roll bars are often considered aftermarket equipment, they must not interfere with original equipment manufacturer (OEM) safety systems. The Department of Transportation (DOT) does not typically certify aftermarket roll bars, but manufacturers may need to self-certify compliance with relevant standards.

ECE Regulations (Europe)

In Europe, roll bars must comply with United Nations Economic Commission for Europe (UNECE) regulations, including Regulation No. 66 (Strength of Superstructures of Large Passenger Vehicles). For off-road or specialty vehicles, compliance with ECE R144 (Roll-Over Protection Structures for Off-Road Motor Vehicles) may be required. Certification through an approved body (e.g., TÜV, DEKRA) is necessary for legal installation and use.

ADR Compliance (Australia)

In Australia, roll bars must meet the requirements of the Australian Design Rules (ADR), particularly ADR 46/01 for roll-over protection for light vehicles. Certification via an accredited testing facility and submission to the Department of Infrastructure, Transport, Regional Development, Communications and the Arts is mandatory for compliance.

CSA & Transport Canada (Canada)

In Canada, roll bars must adhere to the Motor Vehicle Safety Regulations (MVSR) under the Canada Motor Vehicle Safety Standards (CMVSS), which often mirror U.S. FMVSS. Certification and documentation are required for import and installation, and modifications must not compromise OEM safety features.

Certification & Documentation

Manufacturer Certification

All roll bars must be accompanied by a certificate of compliance from the manufacturer stating adherence to relevant safety standards. This includes load testing results, material specifications, and installation instructions.

Installation Certification

Installation by a certified technician may be required in certain jurisdictions. A signed installation certificate should be provided, confirming proper fitment, structural integrity, and compliance with manufacturer guidelines.

Vehicle Modifications Log

Any installation of a roll bar must be recorded in the vehicle’s modification log. This is essential for insurance purposes, roadworthiness inspections, and resale value.

Packaging & Handling

Protective Packaging

Roll bars should be shipped in sturdy, protective packaging to prevent deformation or surface damage during transit. Use foam padding, corner protectors, and wooden crates for large or heavy units.

Labeling Requirements

Each package must be clearly labeled with:

– Product name and part number

– Weight and dimensions

– “Fragile” and “This Side Up” indicators

– Handling instructions (e.g., “Do Not Stack”)

Storage Conditions

Store roll bars in a dry, indoor environment, free from moisture and corrosive agents. Keep off the ground using pallets and avoid exposure to extreme temperatures.

Shipping & Transportation

Domestic Shipping

Use freight carriers experienced in handling automotive components. Ensure roll bars are securely fastened in trucks to prevent shifting. For oversized items, coordinate with carriers for appropriate vehicle types (e.g., flatbeds).

International Shipping

Comply with international shipping regulations (e.g., IMDG for sea freight, IATA for air). Include a commercial invoice, packing list, and certificate of origin. Verify import duties and customs clearance requirements for the destination country.

Hazardous Materials Consideration

Standard roll bars are not classified as hazardous, but coatings or finishes (e.g., certain paints or galvanization treatments) may require declaration if they contain regulated substances.

Import & Export Compliance

HS Codes

Use the correct Harmonized System (HS) code for customs declarations. Typical classifications include:

– 8708.29 – Other parts and accessories for bodies (vehicles)

– 7308.90 – Structures and parts of structures, of iron or steel

Verify exact code based on material and design with local customs authorities.

Import Duties & Tariffs

Check applicable tariffs in the destination country. Free trade agreements (e.g., USMCA, CETA) may reduce or eliminate duties for qualifying goods.

Export Controls

Ensure roll bars are not subject to export restrictions. Most automotive parts are not controlled, but verify with the relevant government body (e.g., BIS in the U.S.).

Installation & Safety Protocols

Qualified Installation

Roll bars must be installed by trained personnel using manufacturer-approved hardware and procedures. Improper installation compromises structural integrity and may void compliance.

Welding & Structural Integrity

If welding is required, it must be performed by a certified welder using appropriate techniques (e.g., MIG/TIG) and materials. Post-weld inspections and stress testing are recommended.

Post-Installation Inspection

After installation, conduct a thorough inspection to verify alignment, weld quality, and clearance with seatbelts, airbags, and other safety systems.

Maintenance & Inspection

Regular Inspections

Inspect roll bars periodically for signs of corrosion, cracking, or impact damage, especially in off-road or high-use environments.

Recertification

In commercial or racing applications, periodic recertification may be required, typically every 1–2 years, depending on usage and jurisdiction.

Environmental & Disposal Compliance

Material Disposal

At end-of-life, roll bars (typically steel or aluminum) should be recycled through certified metal recyclers. Follow local environmental regulations for disposal of coatings or treated metals.

RoHS & REACH Compliance

Ensure materials used in manufacturing comply with EU directives on hazardous substances (RoHS) and chemical registration (REACH), especially for export into Europe.

Conclusion

Proper logistics and compliance management for vehicle roll bars ensures safety, legal conformity, and operational efficiency. Always consult local regulations and work with certified partners throughout the supply chain—from manufacturing to installation.

Conclusion for Sourcing Vehicle Roll Bar:

After a comprehensive evaluation of suppliers, product specifications, cost structures, and quality standards, the sourcing of vehicle roll bars has been strategically finalized to ensure optimal performance, safety compliance, and cost-efficiency. The selected supplier demonstrates consistent adherence to industry regulations (such as ISO and FMVSS standards), offers durable materials (typically high-strength steel or chromoly alloy), and provides reliable lead times and after-sales support. Additionally, factors such as customization capability, weld integrity, and crash-test certifications were critical in the decision-making process.

This sourcing strategy not only enhances vehicle safety for driver and passenger protection in rollover scenarios but also aligns with operational requirements and budgetary constraints. Ongoing supplier performance monitoring and periodic quality audits will be implemented to maintain long-term reliability and continuous improvement in the supply chain. Overall, the successful sourcing of roll bars supports enhanced vehicle safety standards and reinforces organizational commitment to quality and compliance.