The global vegetable insecticide market is experiencing robust growth, driven by rising vegetable production, increasing demand for high crop yields, and growing concerns over pest resistance. According to Grand View Research, the global agricultural insecticides market was valued at USD 18.9 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030, with vegetable crops representing a significant segment due to their high susceptibility to pests and intensive cultivation practices. Similarly, Mordor Intelligence forecasts a CAGR of approximately 4.8% for the agricultural insecticides market during the forecast period of 2024–2029, citing advancements in bio-based insecticides and integrated pest management (IPM) strategies as key growth catalysts. As food security concerns intensify and commercial vegetable farming scales up worldwide, the demand for effective, sustainable, and targeted insect control solutions continues to rise—placing leading manufacturers at the forefront of innovation and market expansion. Here’s a look at the top 10 vegetable insecticide manufacturers shaping the future of crop protection.

Top 10 Vegetable Insecticide Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Vestaron

Domain Est. 2009

Website: vestaron.com

Key Highlights: Vestaron is leading a revolution in crop protection with new peptide technology. Our insecticides deliver powerful new modes of action to rival traditional ……

#2 Agro Chemicals Manufacturers

Domain Est. 2015

Website: dharmajcrop.com

Key Highlights: We manufacture and sell various formulations of insecticides, fungicide and herbicides, plant growth regulators, micro fertilizers and antibiotics. READ MORE ……

#3 MUSTANG® MAXX INSECTICIDE

Domain Est. 1986

Website: ag.fmc.com

Key Highlights: Mustang® Maxx insecticide offers unique pyrethroid chemistry to effectively control more than 100 pests on 200 crops including corn, soybeans and alfalfa….

#4 Koppert Global

Domain Est. 1995

Website: koppert.com

Key Highlights: We specialize in sustainable solutions for crop protection and natural pollination. Our biological products and services help growers around the world….

#5 Albaugh LLC

Domain Est. 1996

Website: albaugh.com

Key Highlights: Expansive product portfolio that includes herbicides, insecticides, fungicides, and more. Maintaining the Highest Levels of Integrity and Responsibility….

#6 Gowan

Domain Est. 1997

Website: gowanco.com

Key Highlights: The Gowan Group is a global, family-owned agricultural solutions business headquartered in the heart of America’s winter vegetable capital, Yuma, Arizona, USA….

#7 Bonide Trusted since 1926, Everything for Lawn and Garden

Domain Est. 1997

Website: bonide.com

Key Highlights: Organic and synthetic gardening products including weed, insect, disease and animal controls in a variety of formulations and applications to meet any ……

#8 Sevin®

Domain Est. 1998

Website: gardentech.com

Key Highlights: Sevin products are broad-spectrum pesticides. This means they control a wide range of insect pests. However, the number and types of insects ……

#9 Syngenta

Domain Est. 2000

Website: syngenta-us.com

Key Highlights: Syngenta is a leader amongst the US agribusiness companies, with a portfolio including seeds, crop protection and flowers. Explore the ways Syngenta is ……

#10 Suterra

Domain Est. 2001

Website: suterra.com

Key Highlights: Suterra creates healthier environments by reducing the use of conventional insecticides. Our products are used to treat millions of acres each year….

Expert Sourcing Insights for Vegetable Insecticide

H2: 2026 Market Trends for Vegetable Insecticides

The global vegetable insecticide market in 2026 is poised for significant transformation, driven by evolving agricultural practices, regulatory landscapes, and consumer demands. This analysis identifies key trends shaping the market, focusing on innovation, sustainability, and regional dynamics.

1. Dominance of Bio-Based and Organic Insecticides:

By 2026, bio-insecticides—including microbial agents (e.g., Bacillus thuringiensis), botanical extracts (e.g., neem, pyrethrins), and insect pheromones—are projected to experience the highest growth rate. This surge is fueled by rising consumer preference for residue-free vegetables, stricter regulations on synthetic pesticides (e.g., EU’s Green Deal and Farm to Fork Strategy), and increasing organic farming acreage. Major agrochemical companies are expanding their bio-pesticide portfolios through acquisitions and R&D partnerships.

2. Integrated Pest Management (IPM) Adoption:

IPM strategies—combining biological control, cultural practices, monitoring, and targeted chemical use—are becoming standard in commercial vegetable production. In 2026, demand will increasingly favor insecticides compatible with IPM, such as selective insect growth regulators and soft chemicals that preserve beneficial insect populations. Precision agriculture tools (e.g., drones, sensors) will enhance monitoring and reduce unnecessary applications, boosting efficiency and sustainability.

3. Regulatory Pressure and Chemical Phase-Outs:

Stringent regulations continue to restrict or ban high-risk synthetic insecticides (e.g., neonicotinoids, chlorpyrifos) due to environmental and health concerns. In 2026, markets in North America and Europe will see reduced reliance on conventional broad-spectrum chemistries, pushing growers toward safer alternatives. This creates opportunities for novel modes of action and low-toxicity formulations but challenges supply chains in regions with limited access to alternatives.

4. Rise of RNA Interference (RNAi) and Next-Gen Technologies:

Emerging technologies like RNAi-based insecticides—offering high target specificity and minimal off-target effects—are expected to gain traction by 2026. Though still in early commercial stages, these products promise sustainable pest control with reduced environmental impact. Investment in biotech solutions is growing, particularly for high-value vegetables like tomatoes, peppers, and leafy greens.

5. Regional Market Diversification:

While North America and Europe lead in adopting sustainable insecticides, Asia-Pacific (especially India and China) will be the fastest-growing market due to increasing vegetable production, urbanization, and food safety awareness. Latin America and Africa present untapped potential, with rising adoption of improved agricultural inputs, though access and affordability remain barriers.

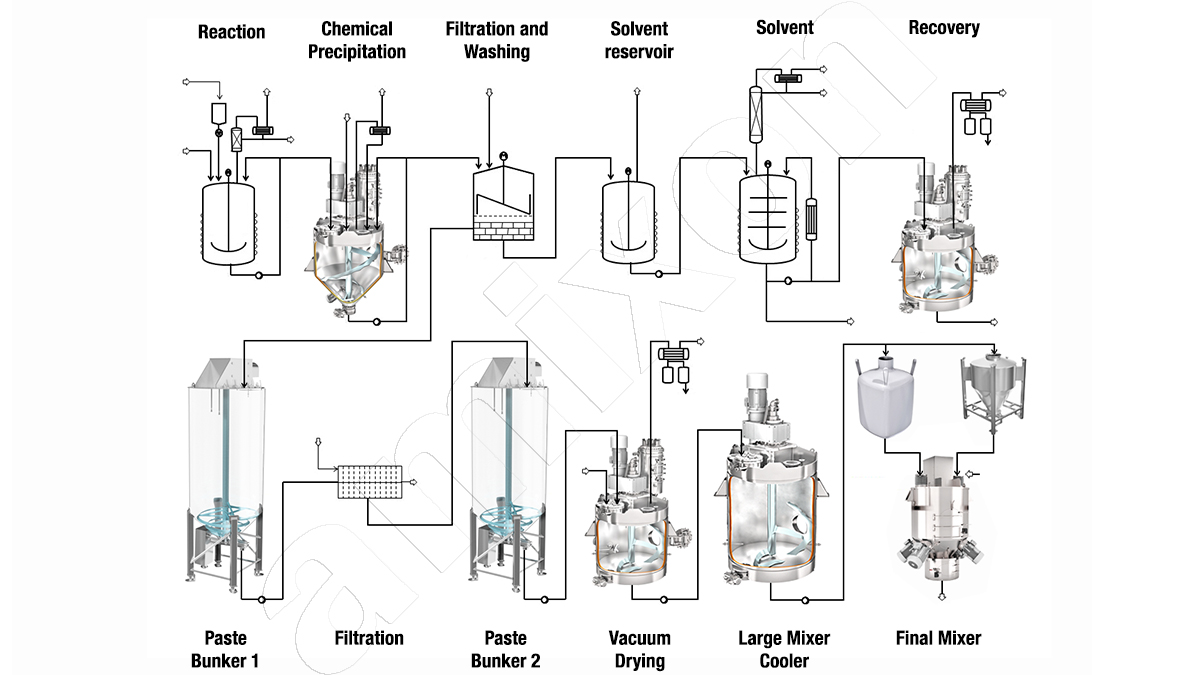

6. Supply Chain and Input Cost Volatility:

Ongoing geopolitical tensions and fluctuating raw material prices (e.g., crude oil derivatives, agricultural feedstocks) continue to impact insecticide production costs. In 2026, manufacturers are expected to focus on supply chain resilience, localized production, and cost-efficient formulations to maintain competitiveness.

Conclusion:

By 2026, the vegetable insecticide market will be increasingly defined by sustainability, innovation, and regulatory compliance. Success will depend on the ability of stakeholders to deliver effective, eco-friendly solutions aligned with global food safety standards and consumer expectations. The shift toward biologicals, digital integration, and next-generation technologies will redefine pest management in vegetable farming worldwide.

Common Pitfalls Sourcing Vegetable Insecticide (Quality, IP)

Sourcing vegetable insecticides—whether botanical extracts, microbial agents, or other naturally derived products—requires careful attention to both quality assurance and intellectual property (IP) considerations. Overlooking these aspects can lead to product failure, legal disputes, or reputational damage. Below are key pitfalls to avoid:

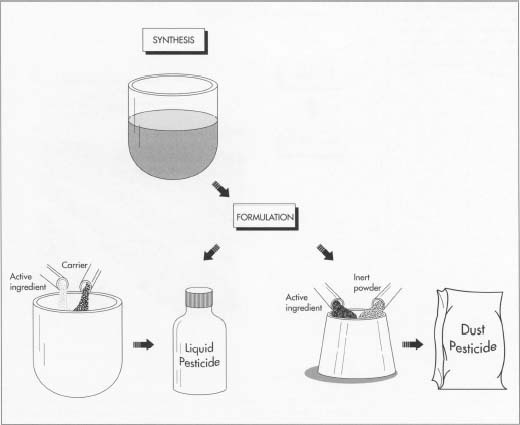

Inadequate Quality Control and Consistency

One of the most frequent challenges in sourcing vegetable insecticides is ensuring consistent quality. Unlike synthetic chemicals, natural products can vary significantly due to growing conditions, extraction methods, and storage. Sourcing without rigorous quality specifications may result in ineffective or unstable formulations. Key issues include:

- Variable Active Ingredient Concentration: Botanical sources (e.g., neem, pyrethrum) often show batch-to-batch variability. Without standardized potency testing (e.g., HPLC for azadirachtin), efficacy cannot be guaranteed.

- Contamination Risks: Poor agricultural practices or improper processing can introduce pesticides, heavy metals, or microbial contaminants.

- Stability and Shelf Life: Natural compounds are often more prone to degradation. Sourcing without stability data may lead to reduced performance over time.

To mitigate these risks, buyers should require certificates of analysis (CoA), conduct third-party testing, and audit manufacturing facilities.

Lack of Traceability and Supply Chain Transparency

Vegetable insecticides rely on raw materials from agricultural sources, making traceability critical. Without transparent supply chains:

- It’s difficult to verify the authenticity of plant species used (e.g., genuine Azadirachta indica vs. substitutes).

- Ethical and sustainability claims (e.g., organic, fair trade) cannot be substantiated.

- Recalls or quality issues are harder to manage due to fragmented sourcing.

Establishing direct relationships with suppliers and demanding full documentation from farm to finished product helps ensure reliability.

Ignoring Intellectual Property Rights

IP is a significant but often overlooked aspect when sourcing natural insecticides. Pitfalls include:

- Infringement on Patented Formulations or Extraction Methods: Even if the active ingredient is natural, specific processes or combinations may be patented. Using such methods without licensing can lead to litigation.

- Misappropriation of Traditional Knowledge: Some botanical insecticides are based on indigenous practices. Sourcing without respecting associated IP or benefit-sharing agreements (e.g., under the Nagoya Protocol) poses legal and ethical risks.

- Weak Protection of Own Innovations: Buyers who develop new formulations based on sourced materials must secure IP rights early to prevent competitors from copying their products.

Conducting freedom-to-operate (FTO) analyses and consulting IP experts before commercialization are essential steps.

Overlooking Regulatory Compliance

Natural does not mean unregulated. Vegetable insecticides must meet national and international standards for registration and use. Common missteps include:

- Assuming “organic” status without certification (e.g., USDA NOP, Ecocert).

- Failing to comply with pesticide registration requirements (e.g., EPA in the U.S., EFSA in the EU).

- Mislabeling claims (e.g., “non-toxic” without proper toxicological data).

Suppliers should provide regulatory dossiers and evidence of compliance to avoid market access issues.

Conclusion

Successfully sourcing vegetable insecticides demands more than finding a low-cost supplier. Emphasizing quality control, supply chain integrity, IP due diligence, and regulatory alignment is essential to avoid costly setbacks and ensure product efficacy and legality in the marketplace.

H2: Logistics & Compliance Guide for Vegetable Insecticides

Proper logistics and compliance management are essential when handling, transporting, storing, and applying vegetable insecticides. Adhering to regulations ensures environmental safety, protects human health, and maintains legal compliance across the supply chain. This guide outlines key considerations for managing vegetable insecticides from production to application.

1. Regulatory Compliance

-

Product Registration:

Ensure the insecticide is registered with the appropriate national regulatory body (e.g., EPA in the U.S., EFSA in the EU, PMRA in Canada). Registration confirms the product is safe and effective for use on edible vegetables. -

Label Compliance:

Follow all label instructions strictly, including application rates, pre-harvest intervals (PHI), personal protective equipment (PPE), and crop-specific usage. Deviating from the label may result in legal penalties and crop contamination. -

Maximum Residue Limits (MRLs):

Comply with MRLs established by importing and exporting countries. Exceeding MRLs can lead to shipment rejections and trade disruptions. -

Organic Certification (if applicable):

For organic farming, only use insecticides approved by certifying bodies such as the USDA National Organic Program (NOP) or EU Organic Regulation. Verify product eligibility before use.

2. Storage Requirements

-

Secure Storage Facilities:

Store insecticides in locked, dry, cool, and well-ventilated areas away from food, feed, fertilizers, and seeds. -

Temperature Control:

Maintain storage temperatures within manufacturer specifications (typically 40°F–90°F / 4°C–32°C) to preserve efficacy. -

Spill Containment:

Use spill trays or secondary containment systems to prevent environmental contamination in case of leaks. -

Proper Labeling:

All containers must be clearly labeled with product name, active ingredients, expiration date, and hazard symbols.

3. Transportation Guidelines

-

Hazard Classification:

Classify insecticides according to international transport regulations (e.g., UN classification, IMDG for sea, ADR for road in Europe). Many insecticides are classified as hazardous materials (Class 6.1 – Toxic Substances). -

Packaging Standards:

Use UN-certified, leak-proof containers that meet regulatory packaging requirements. Ensure closures are secure and tamper-evident. -

Documentation:

Provide Safety Data Sheets (SDS), transport declarations, and shipping manifests. Include emergency response information. -

Vehicle Requirements:

Vehicles must be suitable for hazardous goods, equipped with spill kits, fire extinguishers, and proper signage (e.g., “Dangerous Goods” placards).

4. Handling and Application

-

Personal Protective Equipment (PPE):

Operators must wear appropriate PPE (e.g., gloves, goggles, respirators, coveralls) as specified on the label. -

Calibration and Equipment:

Use properly calibrated sprayers and equipment to ensure accurate dosing and minimize drift or over-application. -

Application Timing:

Apply insecticides according to label-recommended timing, weather conditions, and pest life cycles. Avoid application during high winds or near bloom periods to protect pollinators. -

Buffer Zones:

Maintain required buffer zones near water bodies, residential areas, and non-target crops to reduce environmental impact.

5. Recordkeeping and Traceability

- Maintain detailed records of:

- Product purchase and inventory

- Application dates, rates, and fields treated

- Worker training and PPE usage

- Spray equipment maintenance

-

Harvest dates relative to last application (to ensure PHI compliance)

-

Records must be retained for a minimum of 2–3 years, depending on jurisdiction.

6. Disposal and Waste Management

-

Container Handling:

Triple-rinse empty containers and recycle through approved programs (e.g., ChemClear, Ag Container Recycling Council). -

Leftover Product:

Do not pour unused insecticide down drains or onto soil. Contact hazardous waste disposal services or participate in local take-back programs. -

Spill Response:

Train staff in spill response procedures. Use absorbent materials and contain spills immediately. Report major spills to environmental authorities as required.

7. International Trade Considerations

-

Import/Export Permits:

Verify if permits are needed for cross-border movement, especially for restricted or scheduled substances. -

Customs Documentation:

Include product registration numbers, certificates of analysis, and compliance statements with shipments. -

Country-Specific Regulations:

Research destination country requirements (e.g., EU’s Directive 2092/2013 for organic produce, Japan’s Positive List System).

8. Training and Certification

-

Ensure all personnel involved in handling, transporting, or applying insecticides are trained and certified according to local regulations (e.g., EPA Worker Protection Standard, CDA in Canada).

-

Conduct regular refresher training on safety, compliance, and emergency response.

Conclusion

Effective logistics and compliance management for vegetable insecticides safeguard public health, the environment, and market access. By adhering to regulatory standards, maintaining proper documentation, and implementing best practices in storage, transport, and application, stakeholders can ensure safe and legal use of these essential agricultural inputs.

Always consult local, national, and international authorities for the most current requirements.

In conclusion, sourcing vegetable-based insecticides offers a sustainable, eco-friendly, and health-conscious alternative to synthetic chemical pesticides. These natural solutions, derived from plant extracts such as neem, garlic, chili, and pyrethrum, effectively manage pest populations while minimizing harmful impacts on the environment, non-target organisms, and human health. By prioritizing locally available, organic, and responsibly produced botanical insecticides, farmers and gardeners can support integrated pest management (IPM) practices, reduce chemical residues in food, and promote biodiversity. Furthermore, investing in the research, standardization, and widespread adoption of vegetable insecticides can contribute to resilient agricultural systems and long-term food security. Ultimately, sourcing vegetable-based insecticides aligns with the growing global demand for safer, greener, and more sustainable farming practices.