The global power tools market, driven by advancements in automation and rising demand across construction, manufacturing, and DIY sectors, is experiencing steady expansion. According to Mordor Intelligence, the global power tools market was valued at USD 42.5 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. A key innovation fueling this growth is the integration of variable speed control in drills, allowing users to adjust rotation speed based on material and application—enhancing precision, efficiency, and tool longevity. This technological edge has become a differentiator among manufacturers competing for market share in both professional and consumer segments. As demand for cordless and smart-enabled tools rises—particularly in emerging economies—leading companies are investing heavily in R&D to improve battery life, ergonomics, and digital integration. In this evolving landscape, variable speed control drills stand out as a critical product category, with the top manufacturers leveraging innovation, brand reputation, and global distribution to maintain competitive advantage. Based on market presence, product performance, and technological leadership, the following ten companies represent the forefront of variable speed control drill manufacturing today.

Top 10 Variable Spped Control Drill Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ABB Drives

Domain Est. 1990

Website: abb.com

Key Highlights: ABB Drives is a global technology leader serving industries, infrastructure and machine builders with world-class variable speed drives, drive systems and ……

#2 Variable

Domain Est. 2001

#3 Deli Drill, Power Drill Manufacturer/Supplier

Domain Est. 2021

Website: delitoolsglobal.com

Key Highlights: The variable-speed trigger controls how fast the drill spins. The harder you press, the faster it goes. Copyright © Deli Group Co.,Ltd….

#4 8 Amp 1/2 in. Heavy

Domain Est. 1995

#5 Step Pulley & Variable Speed Drill Press – Floor and Bench

Domain Est. 1995

Website: jettools.com

Key Highlights: Explore a versatile range of JET step pulley and variable speed drill presses designed for application-specific metalworking, offering sizes and power options…

#6 Drilling Machines

Domain Est. 1996

Website: knuth.com

Key Highlights: Top model of the KB drilling machines with infinitely variable speed adjustment, automatic feed and touchscreen control panel…

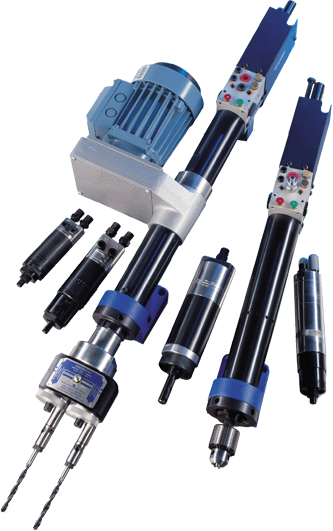

#7 Air Feed Drills

Domain Est. 2000

Website: airmachines.com

Key Highlights: We manufacture quality Pneumatic and Electric Self–Feed Drill Units and Air Motors for production drilling and tapping applications….

#8 Variable Speed Magnetic Drills

Domain Est. 2003

#9 WEG

Domain Est. 2004

Website: weg.net

Key Highlights: WEG provides global solutions for electric motors, variable frequency drives, soft starters, controls, panels, transformers, and generators….

#10 VEVOR Drills & Drivers

Domain Est. 2009

Website: vevor.com

Key Highlights: Free delivery · 30-day returnsVEVOR offers a vast range of drills & drivers. Our drills & drivers are ideal for heavy-duty and DIY tasks. Browse our collection and order now….

Expert Sourcing Insights for Variable Spped Control Drill

H2: 2026 Market Trends for Variable Speed Control Drills

The global market for variable speed control drills is poised for significant transformation by 2026, driven by technological innovation, rising demand across residential and industrial sectors, and increasing emphasis on energy efficiency and precision. As part of the broader power tools industry, variable speed control drills—known for their adaptability in torque and rotational speed—are benefiting from evolving consumer preferences and advancements in motor and battery technologies.

One of the dominant trends shaping the 2026 landscape is the integration of smart technology and IoT (Internet of Things) capabilities. Manufacturers are increasingly embedding Bluetooth connectivity, mobile app integration, and real-time performance monitoring into variable speed drills. These features allow users to customize speed settings, track tool usage, and receive maintenance alerts, enhancing both productivity and tool longevity—particularly valuable in professional construction and manufacturing environments.

Another key trend is the shift toward cordless, battery-powered drills with variable speed control. Lithium-ion battery improvements have led to longer runtimes, faster charging, and lighter designs, making cordless models more appealing than ever. By 2026, the cordless segment is projected to dominate the market, supported by growing demand in DIY markets and remote job sites where mobility is essential.

Sustainability and energy efficiency are also influencing product development. Consumers and commercial buyers are prioritizing eco-friendly tools with lower power consumption and longer lifespans. Variable speed control contributes to energy savings by allowing motors to operate at optimal speeds, reducing wear and minimizing power waste—aligning with global sustainability goals and regulatory standards.

Regionally, the Asia-Pacific market is expected to witness the fastest growth due to rapid urbanization, expanding construction activities, and increasing disposable incomes in countries like India and Vietnam. Meanwhile, North America and Europe will continue to lead in innovation, with strong demand from renovation projects, smart home construction, and high-end industrial applications.

Lastly, competition among key players such as Bosch, DeWalt, Makita, and Milwaukee is intensifying, leading to increased R&D investments and product differentiation. By 2026, market leaders are likely to focus on ergonomic designs, enhanced durability, and modular systems that allow seamless integration with other smart tools.

In conclusion, the 2026 market for variable speed control drills will be characterized by smarter, more efficient, and user-centric tools powered by technological advancements and responsive to global construction and sustainability trends.

Common Pitfalls When Sourcing Variable Speed Control Drills (Quality and IP Rating)

Sourcing variable speed control drills, especially for industrial or professional applications, requires careful attention to both quality and Ingress Protection (IP) ratings. Overlooking key aspects can lead to performance issues, safety hazards, and increased long-term costs. Below are common pitfalls to avoid:

1. Prioritizing Cost Over Quality

One of the most frequent mistakes is selecting the lowest-cost option without evaluating build quality. Cheap drills may use inferior motors, gears, and materials that wear out quickly under heavy use, leading to frequent replacements and downtime.

Solution: Assess total cost of ownership, including durability, warranty, and maintenance needs.

2. Ignoring Motor Quality and Speed Consistency

Not all variable speed controls deliver stable performance across the speed range. Low-quality motors may struggle under load, causing speed drops or overheating.

Solution: Test or verify speed consistency under load and ensure the motor is designed for variable speed operation (e.g., electronic speed control with feedback).

3. Overlooking IP Rating for Environment

The Ingress Protection (IP) rating indicates resistance to dust and water. Using a drill with insufficient IP rating in harsh environments (e.g., outdoor, humid, or dusty conditions) can lead to internal damage and failure.

Example Pitfall: Using an IP20-rated drill in a construction site exposed to rain or debris.

Solution: Match the IP rating to the application (e.g., IP54 or higher for outdoor or industrial use).

4. Assuming All “Variable Speed” Drills Are Equal

Some drills offer variable speed in name only, with limited range or poor control. Others may lack torque control, leading to stripped screws or broken bits.

Solution: Check specifications for actual speed range, torque control, and presence of features like soft start or electronic clutch.

5. Failing to Verify Brand Authenticity and Certifications

Counterfeit or unbranded drills often mislabel specifications, including IP ratings and speed ranges. These may lack safety certifications (e.g., CE, UL), posing risks.

Solution: Source from reputable suppliers and verify compliance with regional safety standards.

6. Neglecting Ergonomics and Duty Cycle

Even with good speed control, a poorly designed drill can cause user fatigue. Additionally, continuous use beyond the drill’s duty cycle leads to overheating.

Solution: Evaluate grip design, weight, and thermal protection features. Confirm duty cycle ratings for intended usage.

7. Inadequate After-Sales Support and Spare Parts Availability

Low-cost drills may come from suppliers with no local service or spare parts, increasing downtime when repairs are needed.

Solution: Choose brands with established service networks and available replacement components.

By addressing these pitfalls during procurement, buyers can ensure reliable performance, safety, and longevity of variable speed control drills in their operations.

Logistics & Compliance Guide for Variable Speed Control Drill

Product Classification & Regulatory Compliance

Ensure the variable speed control drill complies with relevant safety and electromagnetic compatibility (EMC) standards. In the European Union, the drill must meet the requirements of the Machinery Directive (2006/42/EC), Low Voltage Directive (2014/35/EU), and EMC Directive (2014/30/EU), and carry the CE marking. In the United States, compliance with OSHA standards and FCC Part 15 for electromagnetic interference is required. Confirm that all components, including the motor and speed control circuitry, are certified by recognized testing laboratories (e.g., UL, CSA, or TÜV).

Packaging & Labeling Requirements

Package the drill securely to prevent damage during transit, using anti-vibration materials and robust outer cartons. Include required labels on both the product and packaging: safety warnings, voltage and power specifications, CE/FCC marks, serial number, and manufacturer information. Labels must be durable and legible in the local language(s) of the destination market. Include multilingual user manuals and safety instructions inside the packaging.

Import/Export Documentation

Prepare accurate customs documentation, including commercial invoice, packing list, bill of lading or air waybill, and certificate of origin. For exports to regulated markets, include a Declaration of Conformity (DoC) verifying compliance with regional standards. If shipping lithium-ion batteries (for cordless models), comply with IATA Dangerous Goods Regulations, including proper UN38.3 testing certification and packaging.

Transportation & Handling

Use freight carriers experienced in handling power tools and electrical equipment. For air transport of cordless drills with batteries, follow IATA guidelines for lithium battery shipment (e.g., state of charge ≤30%, protected from short circuits). For sea freight, ensure containers are sealed and protected from moisture. Clearly mark packages as “Fragile” and “This Side Up” to prevent mishandling.

Storage & Inventory Management

Store drills in a dry, temperature-controlled environment to protect electronic components and battery life (if applicable). Maintain separation between tools and incompatible materials (e.g., chemicals or moisture sources). Rotate stock using FIFO (First In, First Out) to minimize obsolescence and ensure compliance with warranty periods.

Environmental & Disposal Compliance

Adhere to WEEE (Waste Electrical and Electronic Equipment) Directive requirements in applicable regions. Provide end-of-life take-back options and label products with the crossed-out wheeled bin symbol. Ensure that packaging materials are recyclable and minimize plastic use to comply with local environmental regulations.

Training & Safety Compliance

Provide training for warehouse and logistics personnel on safe handling procedures, including proper lifting techniques and battery safety. Ensure all staff are familiar with MSDS (Material Safety Data Sheets) for any included lubricants or batteries. Maintain records of compliance training and safety audits.

Recordkeeping & Traceability

Maintain detailed records of product batches, serial numbers, compliance certifications, and shipping documentation for a minimum of five years. This supports traceability in case of recalls or audits and ensures ongoing regulatory compliance across jurisdictions.

Conclusion:

In conclusion, sourcing a variable speed control drill offers significant advantages in terms of precision, versatility, and efficiency across a wide range of drilling applications. Whether for professional use or DIY projects, the ability to adjust the drill’s speed ensures optimal performance on different materials—from delicate wood and plastic to tough metal and masonry. When sourcing such a tool, it is essential to consider factors such as power source (corded vs. cordless), battery life, torque settings, ergonomics, brand reliability, and cost-effectiveness. Additionally, evaluating supplier credibility, warranty options, and user reviews helps ensure a sound investment. By selecting a high-quality variable speed drill from a reputable source, users can enhance their productivity, achieve better results, and extend the tool’s lifespan, making it a valuable addition to any toolkit.