The global automotive camshaft timing control solenoid market is experiencing steady expansion, driven by increasing demand for improved fuel efficiency, reduced emissions, and enhanced engine performance—key priorities in modern pickup trucks like the Ford F-150. According to Grand View Research, the global variable valve timing (VVT) components market was valued at USD 9.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This growth is fueled by stricter emissions regulations and the rising adoption of advanced engine technologies across light-duty vehicles, particularly in North America. As the Ford F-150 continues to dominate the U.S. truck segment, integrating sophisticated variable cam timing systems, demand for high-performance solenoids has surged. This has positioned a select group of manufacturers at the forefront of innovation and supply for OEM and aftermarket solutions. Here are the top six variable cam timing solenoid manufacturers serving the Ford F-150 market, selected based on production scale, technical expertise, market reach, and reliability metrics.

Top 6 Variable Cam Timing Solenoid Ford F150 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

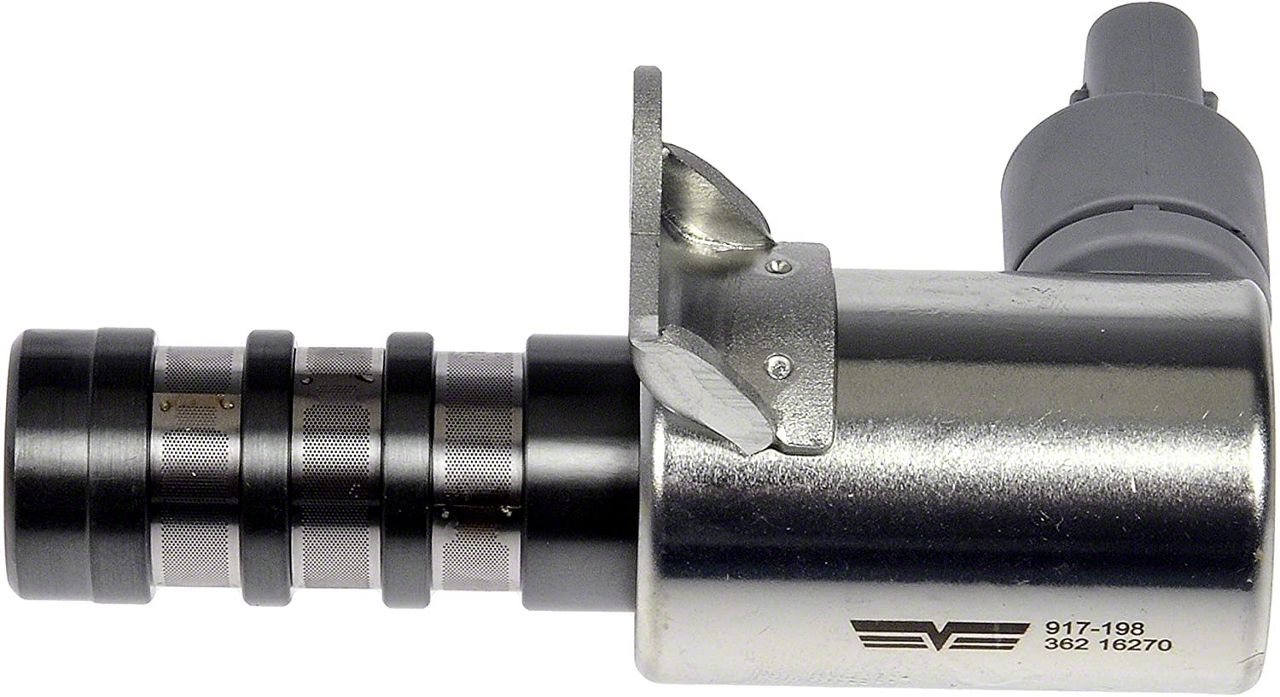

#1 Engine Variable Timing Solenoid 8L3Z

Domain Est. 2013

Website: oemfordpart.com

Key Highlights: Rating 5.0 (2) · 4-day deliveryGenuine OEM Ford Parts Online – Engine Variable Timing Solenoid – Ford Part # 8L3Z-6M280-B – Shop Discount OEM Ford Parts & Ford Accessories Dire…

#2 F

Domain Est. 1998

#3 Ford F

Domain Est. 1999

Website: parts.lakelandford.com

Key Highlights: In stock $12.75 deliveryEngine Variable Valve Timing (VVT) Solenoid. Ford F-150. Genuine Ford Part – HL3Z6M280A (HL3Z-6M280-A). Ships from Lakeland Ford, Lakeland FL….

#4 Oil Control Valve on a 2013 Ford F

Domain Est. 2012

Website: f150ecoboost.net

Key Highlights: Start by removing both valve covers and replacing all 4 VCT solenoids. Change the oil with a good quality synthetic and a Motorcraft filter. Reset the code and ……

#5 Engine Variable Valve Timing (Vvt) Solenoid

Domain Est. 2015

Website: ford.oempartsonline.com

Key Highlights: In stock Rating 3.0 (2) Engine Variable Valve Timing (Vvt) Solenoid – Ford (HL3Z-6M280-A) · Brand: Ford, Lincoln, Mercury Parts. Lincoln Parts Mercury Parts · SKU: HL3Z-6M280-A ·…

#6 Variable Valve Timing (VVT) Solenoid ( 161631 )for Ford F

Domain Est. 2017

Website: eccppautoparts.com

Key Highlights: Out of stockVariable Valve Timing (VVT) Solenoid ( 161631 )for Ford F-150 · Fitments:2000-2002 Nissan Sentra · Our products come from excellent material suppliers and adopt ……

Expert Sourcing Insights for Variable Cam Timing Solenoid Ford F150

H2: 2026 Market Trends for Variable Cam Timing Solenoid in Ford F-150

As the automotive industry evolves toward increased efficiency, performance optimization, and electrification, the market for components like the Variable Cam Timing (VCT) solenoid in popular models such as the Ford F-150 is expected to undergo significant changes by 2026. The VCT solenoid, a critical part of the engine’s variable valve timing system, plays a vital role in improving fuel economy, reducing emissions, and enhancing engine performance. Below is an analysis of key market trends shaping the demand, technology, and supply chain dynamics for VCT solenoids in the Ford F-150 through 2026.

-

Continued Demand Due to High F-150 Sales Volume

Despite Ford’s expansion into hybrid and electric variants (e.g., the F-150 PowerBoost hybrid and Lightning EV), the majority of F-150s sold through 2026 will still feature internal combustion engines (ICE) or hybrid powertrains that incorporate VCT systems. With the F-150 remaining the best-selling vehicle in the U.S., the aftermarket and OEM demand for VCT solenoids is expected to stay robust. Aging vehicle fleets will further drive replacement demand, especially as VCT solenoids are known wear items susceptible to oil contamination and clogging. -

Shift Toward Higher-Performance and Durable Aftermarket Components

By 2026, consumers and fleet operators are anticipated to favor higher-quality aftermarket VCT solenoids with improved materials and design to mitigate common failure modes. Manufacturers are responding by offering solenoids with enhanced filtration, better seals, and compatibility with modern low-viscosity oils. This trend reflects a growing preference for reliability and longevity, particularly in work-focused F-150 models. -

Integration with Advanced Engine Management Systems

As Ford continues refining its EcoBoost and PowerBoost engine platforms, VCT solenoids will increasingly interface with more sophisticated engine control units (ECUs). By 2026, solenoids may be required to support faster response times, adaptive learning algorithms, and real-time diagnostics. This integration will elevate the technical complexity of solenoids, potentially increasing OEM unit costs and spurring innovation in the aftermarket sector. -

Impact of Electrification on VCT Solenoid Relevance

While full electrification (e.g., F-150 Lightning) eliminates the need for VCT solenoids, hybrid variants like the PowerBoost still utilize gasoline engines with variable cam timing. Given that hybrids are expected to constitute a growing but minority share of F-150 sales through 2026, the VCT solenoid will remain relevant. However, long-term market forecasts suggest a gradual decline in solenoid demand post-2026 as EV adoption accelerates. -

Supply Chain Localization and Resilience

Ongoing supply chain challenges and geopolitical factors are prompting Ford and its suppliers to localize production. By 2026, more VCT solenoids may be manufactured in North America to reduce dependency on overseas components. This shift could improve lead times and support just-in-time manufacturing, benefiting both OEMs and the aftermarket. -

Growth in Predictive Maintenance and Diagnostics

With the proliferation of onboard diagnostics (OBD-II) and connected vehicle technologies, F-150 owners will increasingly receive early warnings about VCT system issues. This shift toward predictive maintenance will likely increase the volume of preemptive solenoid replacements, creating new opportunities for service providers and parts distributors.

Conclusion:

The market for Variable Cam Timing solenoids in the Ford F-150 is poised for sustained demand through 2026, driven by strong ICE and hybrid sales, high vehicle longevity, and evolving performance expectations. While electrification presents a long-term challenge, technological advancements, supply chain adaptations, and aftermarket innovation will ensure the VCT solenoid remains a critical component in Ford’s flagship pickup for the near future.

H2: Common Pitfalls When Sourcing a Variable Cam Timing Solenoid for Ford F150 (Quality and IP Concerns)

When replacing the Variable Cam Timing (VCT) solenoid in a Ford F150, many vehicle owners and technicians encounter pitfalls related to part quality and intellectual property (IP) issues. Selecting the wrong solenoid can lead to persistent engine performance issues, costly rework, and even damage to the engine. Below are key challenges to avoid:

1. Poor Aftermarket Quality and Counterfeit Parts

One of the most common issues is purchasing low-quality aftermarket solenoids that mimic OEM design but use inferior materials. These parts may fail prematurely due to weak internal coils, substandard seals, or improper filtering. Counterfeit solenoids often lack proper calibration and can trigger fault codes such as P0011, P0021, or P0073. Always verify the manufacturer reputation and look for certifications like ISO or IATF 16949.

2. Lack of Genuine OEM or Licensed Components

Some suppliers market parts as “OEM-equivalent” without proper licensing from Ford. This raises IP concerns, as the VCT solenoid design is protected intellectual property. Using non-licensed components may void warranties and expose buyers to legal or compliance risks, especially in commercial or fleet applications. Ensure the part number matches Ford’s specifications (e.g., Motorcraft FL2Z-6G269-A) and is sourced from an authorized distributor.

3. Incompatible Part Numbers and Model-Year Mismatches

The F150 has used different VCT solenoid designs across model years (e.g., 2004–2014 5.4L vs. 2011–2014 3.5L EcoBoost). Using an incorrect solenoid due to inaccurate cross-referencing leads to fitment and performance issues. Always confirm compatibility using the VIN or consult Ford’s service database.

4. Missing Software Calibration or Programming Requirements

Modern F150 engines require proper ECM calibration when replacing VCT components. Some aftermarket solenoids are not programmed to work with Ford’s adaptive timing strategies, leading to rough idling, poor fuel economy, or check engine lights. Genuine or properly licensed parts often include updated calibration data; generic parts do not.

5. Inadequate Testing and Validation

Many aftermarket solenoids are not subjected to the same durability and thermal testing as OEM units. This increases the risk of failure under real-world conditions, especially in high-heat environments or heavy towing scenarios. Look for suppliers that provide test data or field performance history.

To avoid these pitfalls, source VCT solenoids from reputable suppliers, verify part authenticity, and prioritize OEM or licensed aftermarket brands like Motorcraft, Ford Genuine Parts, or reputable licensed manufacturers such as Delphi or Denso. Always inspect packaging and part markings for signs of tampering or inconsistencies that may indicate counterfeit goods.

Logistics & Compliance Guide for Variable Cam Timing Solenoid – Ford F150

Product Overview

The Variable Cam Timing (VCT) Solenoid is a critical engine management component in Ford F150 trucks equipped with variable valve timing systems. It controls oil flow to the camshaft phaser, enabling dynamic adjustment of cam timing for improved fuel efficiency, performance, and emissions control. This guide outlines logistics handling, transportation, storage, and regulatory compliance considerations for the VCT Solenoid in North American and global supply chains.

Logistics Handling & Packaging

Packaging Requirements

- The VCT Solenoid must be shipped in manufacturer-approved, sealed anti-static packaging to prevent electrostatic discharge (ESD) damage.

- Individual units should be protected with foam or molded plastic inserts inside sturdy corrugated cardboard boxes.

- Outer packaging must display handling icons indicating “Fragile,” “Do Not Stack,” and “Protect from Moisture.”

Labeling & Barcoding

- Each package must include a standardized barcode (GS1-128) containing:

- OEM Part Number (e.g., FT5Z-6C297-A, FO5Z-6C297-BA, depending on model year)

- Manufacture Date

- Batch/Serial Number

- Country of Origin

- Labels must be durable, weather-resistant, and comply with ANSI/ISO labeling standards.

Shipping & Transportation

- Ground freight via temperature-controlled, enclosed trailers is recommended to avoid exposure to extreme heat, cold, or humidity.

- Avoid air freight unless expedited delivery is required; if used, ensure cargo compartments are climate-controlled.

- Maximum stack height: 5 standard cartons per pallet to prevent bottom-unit compression.

- Use slip sheets or pallets meeting ISO 6780 standards for unit load compatibility.

Storage Conditions

Environmental Controls

- Store in a clean, dry warehouse environment with temperatures between 40°F and 80°F (4°C to 27°C).

- Relative humidity must not exceed 60% to prevent internal corrosion or coil damage.

- Keep away from direct sunlight, solvents, oils, and electromagnetic sources.

Shelf Life & Rotation

- Maximum recommended shelf life: 24 months from manufacture date.

- Implement FIFO (First In, First Out) inventory rotation practices.

- Conduct quarterly stock audits to identify expired or damaged stock.

Regulatory & Compliance Requirements

Environmental Regulations

- Comply with EPA and Environment Canada regulations regarding hazardous materials. The solenoid contains no regulated hazardous substances under RoHS (Restriction of Hazardous Substances) Directive 2011/65/EU.

- Confirm REACH (EC 1907/2006) compliance for chemical substances used in manufacturing.

- Waste disposal must follow local electronic waste (e-waste) protocols if the unit is non-repairable.

Import/Export Compliance

- Harmonized System (HS) Code: 8481.80.65 (Valves for engines, automotive parts).

- For U.S. imports: Comply with CBP regulations; ensure proper documentation (Commercial Invoice, Packing List, Bill of Lading).

- For exports: Adhere to U.S. Department of Commerce Export Administration Regulations (EAR); no license required for most destinations under ECCN 9A991.d.

Automotive Industry Standards

- Must meet OEM specifications set by Ford Motor Company (WSS-M86D1-A1 for solenoid performance and durability).

- Conform to ISO/TS 16949 (now IATF 16949) quality management standards for automotive components.

- Packaging and labeling must follow AIAG (Automotive Industry Action Group) standards.

Aftermarket & Warranty Compliance

Warranty Handling

- Core return programs must be supported where applicable; used solenoids should be returned in original packaging with proof of purchase.

- Warranty claims require documentation linking part number, VIN, and installation date.

Counterfeit Prevention

- Use tamper-evident packaging and authenticate parts via Ford’s OEM verification portal.

- Distributors must be authorized Ford parts suppliers to maintain compliance.

Conclusion

Proper logistics and compliance procedures ensure the integrity, performance, and traceability of the Variable Cam Timing Solenoid in the Ford F150 supply chain. Adherence to packaging, handling, environmental, and regulatory standards minimizes risk, supports warranty validity, and maintains alignment with Ford’s quality expectations.

In conclusion, sourcing a variable cam timing (VCT) solenoid for a Ford F-150 requires careful consideration of vehicle-specific details such as model year, engine size (e.g., 3.5L V6, 5.0L V8), and engine generation. Using OEM or high-quality aftermarket parts ensures reliability and compatibility, helping to maintain optimal engine performance, fuel efficiency, and emissions control. It is essential to verify the part number and consult service manuals or trusted suppliers to avoid purchasing incorrect components. Additionally, proper installation and, if necessary, resetting adaptation values using a diagnostic tool can prevent recurring issues. By taking a thorough and informed approach, vehicle owners and technicians can effectively address VCT solenoid problems and restore the engine’s variable valve timing functionality for long-term performance.