The global vane axial fan market is experiencing robust growth, driven by increasing demand across industrial, commercial, and HVAC applications. According to Grand View Research, the global industrial fan market was valued at USD 3.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects steady growth for axial fans, fueled by energy efficiency mandates, rising infrastructure development, and the need for improved ventilation systems in manufacturing and data centers. As industries prioritize performance and compliance with environmental standards, vane axial fans—known for their high-efficiency airflow in confined spaces—have become critical components. This growing demand has elevated the prominence of leading manufacturers who combine engineering excellence with scalable, sustainable solutions. Here, we spotlight the top eight vane axial fan manufacturers shaping the future of airflow technology.

Top 8 Vane Axial Fan Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Vaneaxial Fans

Domain Est. 1996

Website: nyb.com

Key Highlights: Vaneaxial Fans are designed and constructed for high pressure ventilating and industrial process applications requiring the compactness of an axial fan. Uses ……

#2 Vane Acial Fans

Domain Est. 1999

Website: chicagoblower.com

Key Highlights: 34 fans are designed for general industrial, non-VAV applications. Welded steel wheels, heavy gauge housings. Drive adjustment varies volume/pressure….

#3 Vane Axial Ventilating Fans

Domain Est. 1999

Website: fanequipment.com

Key Highlights: Fan Equipment’s ventilating fans are designed for applications requiring higher volume and lower noise output….

#4 VANE AXIAL FANS

Domain Est. 2000

Website: vafmechanical.com

Key Highlights: Specializing in commercial & industrial fan service & repair all brands & types. Electrical systems & infrared inspection….

#5 Vane Axial Fans (AVD, AVB)

Domain Est. 1995

Website: york.com

Key Highlights: For reliable, long-lasting commercial exhaust fan performance, YORK® Vane Axial Fans are the smart choice when efficiency, high volume and compact size matter….

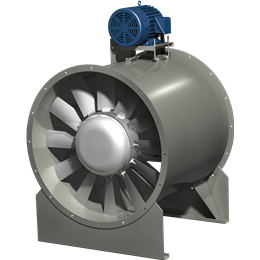

#6 Axial Fans

Domain Est. 1996

Website: aerovent.com

Key Highlights: Vaneaxial Fans are designed for applications where large volumes of air are required at moderate to high pressures. Direct and belt driven models, with fixed ……

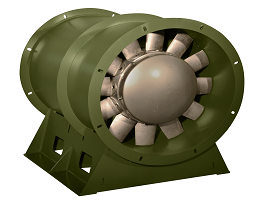

#7 Large Vaneaxial Fans

Domain Est. 1998

Website: rotron.com

Key Highlights: Large Vaneaxial Fans (MAXIAX®) provide high flows against high impedance in a compact axial flow package. They operate at high rotational speeds….

#8 AVD Vaneaxial Fans

Domain Est. 1999

Website: continentalfan.com

Key Highlights: AVD fans are ideal for applications that require high air volume and pressure. These powerful fans are available in diameters from 12” through 60”….

Expert Sourcing Insights for Vane Axial Fan

H2: 2026 Market Trends for Vane Axial Fans

The global vane axial fan market is poised for steady growth through 2026, driven by increasing demand for energy-efficient ventilation systems across industrial, commercial, and infrastructure sectors. These fans, known for their high airflow capacity and directional efficiency, are becoming integral components in HVAC systems, power generation plants, tunnels, and data centers.

Key market trends shaping the vane axial fan industry in 2026 include:

-

Rising Focus on Energy Efficiency and Sustainability

Regulatory standards such as the EU’s Ecodesign Directive and ASHRAE guidelines are pushing manufacturers to develop more energy-efficient fan models. Vane axial fans, with their optimized aerodynamic design and integration of variable frequency drives (VFDs), are increasingly preferred for reducing power consumption. This trend is accelerating adoption in green buildings and industrial facilities aiming for LEED or BREEAM certification. -

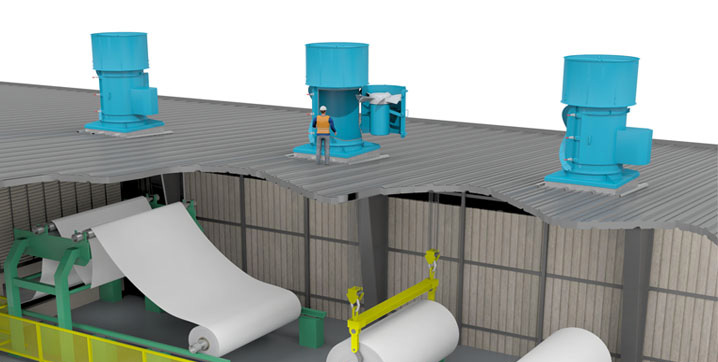

Growth in Infrastructure and Tunnel Ventilation Projects

Expanding urban transit systems, highway tunnels, and underground infrastructure in regions like Asia-Pacific and the Middle East are creating robust demand for high-performance ventilation solutions. Vane axial fans are favored in these applications due to their ability to move large volumes of air under high static pressure conditions, ensuring safety and air quality. -

Adoption of Smart and IoT-Enabled Fans

The integration of IoT sensors and predictive maintenance technologies into vane axial fans is a growing trend. By 2026, smart fans capable of real-time monitoring, remote control, and performance analytics are expected to gain traction, particularly in data centers and manufacturing plants where uptime and thermal management are critical. -

Expansion in the Renewable Energy Sector

Vane axial fans are increasingly used in wind and solar power installations for cooling transformers, inverters, and control cabinets. As renewable energy capacity grows globally, so does the need for reliable thermal management systems, further boosting market demand. -

Regional Market Shifts

Asia-Pacific is expected to dominate the vane axial fan market by 2026, led by rapid industrialization in China, India, and Southeast Asia. North America and Europe will maintain strong demand due to retrofitting of aging infrastructure and stringent ventilation codes. Latin America and Africa show emerging potential, particularly in mining and tunneling applications. -

Material and Design Innovations

Advancements in composite materials and blade design are improving fan efficiency, durability, and noise reduction. Lightweight, corrosion-resistant materials are enabling longer service life in harsh environments, such as chemical plants and coastal installations.

In conclusion, the vane axial fan market in 2026 will be shaped by technological innovation, regulatory pressures, and expanding infrastructure needs. Companies investing in energy-efficient, smart, and application-specific solutions are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls Sourcing Vane Axial Fans: Quality and IP Concerns

When sourcing vane axial fans—commonly used in HVAC systems, industrial ventilation, and cooling applications—buyers often encounter challenges related to product quality and intellectual property (IP) protection. Understanding these pitfalls is essential to avoid performance issues, compliance risks, and legal complications.

Substandard Quality and Performance Inconsistencies

One of the most prevalent issues when sourcing vane axial fans, particularly from low-cost manufacturers, is inconsistent or subpar quality. Poor materials, imprecise blade design, and inadequate balancing can lead to reduced airflow efficiency, excessive noise, and premature motor failure. Buyers may receive units that do not meet specified performance metrics (e.g., static pressure, CFM, or RPM), impacting system performance and energy efficiency. Additionally, inconsistent quality across production batches can disrupt long-term operations and maintenance planning.

Lack of Certification and Compliance

Many suppliers, especially in unregulated markets, provide fans without proper certifications such as CE, UL, or AMCA ratings. This lack of certification raises concerns about safety, reliability, and regulatory compliance, particularly in commercial or industrial installations where standards are strictly enforced. Sourcing non-compliant fans can result in project delays, failed inspections, or liability in the event of equipment failure.

Intellectual Property Infringement Risks

Another critical pitfall involves intellectual property (IP) violations. Some manufacturers replicate patented fan blade designs, housing configurations, or motor technologies without authorization. Purchasing such counterfeit or cloned products exposes buyers to legal risks, especially in regions with strong IP enforcement. Furthermore, using IP-infringing components can damage a company’s reputation and lead to supply chain disruptions if legal action is taken against the supplier.

Inadequate Technical Documentation and Support

Suppliers may offer limited or inaccurate technical documentation, including performance curves, installation guides, or maintenance instructions. This lack of support hinders proper system integration and troubleshooting. Moreover, poor after-sales support and limited warranty coverage can leave buyers vulnerable when issues arise post-installation.

Hidden Costs from Poor Reliability

While low initial pricing may be attractive, poor-quality vane axial fans often result in higher total cost of ownership due to frequent repairs, downtime, and increased energy consumption. Reliability issues such as bearing failures or motor burnout can lead to unplanned maintenance and operational disruptions.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct thorough supplier audits and request product testing data.

– Verify certifications and compliance with industry standards.

– Engage legal counsel to assess IP risks, especially when sourcing proprietary designs.

– Prioritize suppliers with proven track records, strong warranties, and responsive technical support.

By proactively addressing quality and IP concerns, organizations can ensure reliable performance, regulatory compliance, and long-term cost efficiency when sourcing vane axial fans.

Logistics & Compliance Guide for Vane Axial Fan

This guide outlines key logistics considerations and compliance requirements for the transport, handling, and operation of vane axial fans. Adherence to these guidelines ensures safety, regulatory compliance, and optimal product performance.

Product Classification & Handling

Vane axial fans are typically classified as industrial machinery or components. They should be handled with care to avoid damage to blades, bearings, and structural components. Always use appropriate lifting equipment (e.g., forklifts, cranes with slings) attached to designated lifting points. Never lift by the fan blades or motor. Store in a dry, indoor environment, protected from moisture, dust, and extreme temperatures.

Packaging & Transportation

Ensure fans are securely packaged in robust wooden crates or palletized with corner protectors and weather-resistant wrapping. Confirm that all moving parts are immobilized during transit to prevent internal damage. For international shipments, use packaging that complies with ISPM 15 standards for wood materials. Label packages clearly with handling instructions (e.g., “Fragile,” “This Side Up”) and include shipping documentation with product details and destination information.

Import/Export Compliance

Verify export control regulations based on the country of origin and destination. Vane axial fans may be subject to dual-use export controls under frameworks such as the Wassenaar Arrangement or national regulations (e.g., EAR in the U.S.). Check Harmonized System (HS) codes—common classifications include 8414.59 for axial fans. Ensure all export documentation (commercial invoice, packing list, bill of lading, and export declaration) is accurate and complete. Obtain necessary export licenses if required.

Safety & Operational Compliance

Vane axial fans must comply with relevant safety standards in the destination market. Common certifications include:

– UL/CSA (North America): For electrical safety and performance.

– CE Marking (European Union): Compliance with Machinery Directive (2006/42/EC) and Low Voltage Directive (2014/35/EU).

– IEC 60034 series: International standards for rotating electrical machines, including efficiency and testing.

– AMCA Certification: Ensures performance ratings for airflow and efficiency are independently verified (especially in HVAC applications).

Ensure fans are installed and operated in accordance with local electrical, mechanical, and building codes. Provide end-users with operation and maintenance manuals in the appropriate language.

Environmental & Energy Regulations

Comply with energy efficiency regulations such as:

– ERP Directive (EU): Sets ecodesign requirements for fans.

– DOE Standards (U.S.): Energy conservation standards for commercial and industrial fans.

Confirm that fan motors meet minimum efficiency levels (e.g., IE3 or IE4 as per IEC 60034-30).

Dispose of packaging and obsolete units in accordance with local environmental regulations. Follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions for end-of-life equipment.

Documentation & Recordkeeping

Maintain comprehensive records including:

– Product specifications and test reports

– Certificates of compliance (CE, UL, AMCA, etc.)

– Export documentation and customs filings

– Safety data sheets (if applicable for lubricants or coatings)

Retain records for a minimum of five years or as required by jurisdiction.

Adhering to this logistics and compliance guide ensures legal shipment, safe handling, and regulatory conformity for vane axial fans across global markets.

Conclusion for Sourcing Vane Axial Fan

In conclusion, sourcing a vane axial fan requires a comprehensive evaluation of application requirements, performance specifications, operational environment, and supplier reliability. Vane axial fans are ideal for applications demanding high airflow at moderate pressures, offering energy efficiency, reliability, and directional flow control due to their guide vanes. When selecting a supplier, factors such as build quality, material compatibility, energy efficiency ratings, noise levels, and compliance with industry standards (e.g., AMCA, ISO) must be carefully assessed.

Additionally, considering total cost of ownership—factoring in energy consumption, maintenance needs, and expected lifespan—ensures long-term operational efficiency. Partnering with reputable manufacturers or suppliers who provide technical support, warranties, and customization options further enhances system performance and reliability.

Ultimately, a well-informed sourcing decision for a vane axial fan ensures optimal airflow management, improved system efficiency, and sustained performance across industrial, commercial, or HVAC applications.