The global vacuum truck market is experiencing steady growth, driven by increasing demand for efficient waste management, municipal cleaning, and industrial maintenance services. According to Mordor Intelligence, the global vacuum truck market was valued at USD 2.7 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. A critical component of these specialized vehicles is the vacuum pump, which determines suction efficiency, reliability, and overall performance. As infrastructure development accelerates and environmental regulations tighten worldwide, the demand for high-performance vacuum pumps has surged. This has led to a competitive landscape among manufacturers specializing in robust and durable vacuum pump systems tailored for vacuum trucks. In this report, we identify and analyze the top 10 vacuum pump manufacturers shaping the industry, evaluating them based on innovation, market share, product range, and customer feedback.

Top 10 Vacuum Truck Vacuum Pump Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

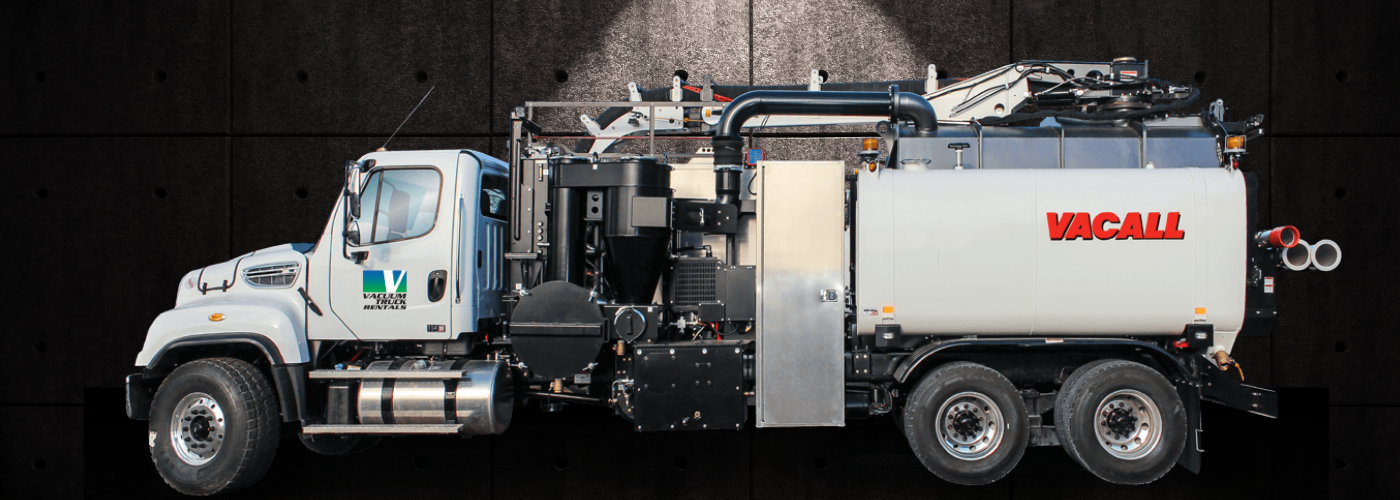

#1 Vacuum Trucks

Domain Est. 2003

Website: koks.com

Key Highlights: Rating 9.1/10 (382) KOKS Group is a manufacturer of vacuum trucks and heavy industrial cleaning equipment. ✓ Innovative & Leading ✓ Safest technology….

#2 Guzzler Industrial Vacuum Trucks

Domain Est. 1996

Website: guzzler.com

Key Highlights: Looking for vacuum truck companies? Guzzler offers industrial vacuum loader trucks, dual-purpose solutions, and more. Contact us today to learn more!…

#3 Truck Blowers & Rotary Vacuum Pumps

Domain Est. 1995

Website: gardnerdenver.com

Key Highlights: We offer a leading range of air-cooled, oil-lubricated industrial vacuum truck pumps designed to deliver reliable, high-performance results in demanding waste ……

#4 Vacuum Trucks

Domain Est. 1997

Website: superproducts.com

Key Highlights: As a vacuum truck manufacturer, Super Products designs and engineers vacuum trucks with the most innovative features on the market today….

#5 Truck Vacuum Pumps

Domain Est. 1997

Website: hibon.com

Key Highlights: Discover Hibon’s high-performance truck vacuum pumps engineered for hydro-excavation, sewer cleaning, and industrial waste handling….

#6 Vactor Manufacturing Sewer Cleaners

Domain Est. 1996

Website: vactor.com

Key Highlights: Get ready to tackle tough jobs with Vactor’s reliable sewer cleaner equipment. Explore models like the Ramjet Truck Series for superior performance….

#7 Vac

Domain Est. 1996

Website: vac-con.com

Key Highlights: Vac•Con jetters are powerful and simple to operate. Available in both truck and trailer-mounted applications, our jetters are built with the operator in mind….

#8 National Vacuum Equipment

Domain Est. 1998

Website: natvac.com

Key Highlights: Our vacuum pumps and blowers embody our passion for creating rugged, reliable, and high-performing vacuum solutions. Every product, part, and service we offer ……

#9 Fruitland Manufacturing

Domain Est. 2012

Website: fruitlandmanufacturing.com

Key Highlights: Fruitland Manufacturing delivers high quality rotary vane vacuum pumps, rotary lobe blowers, and liquid ring pumps. Available in easy to install, Ready To ……

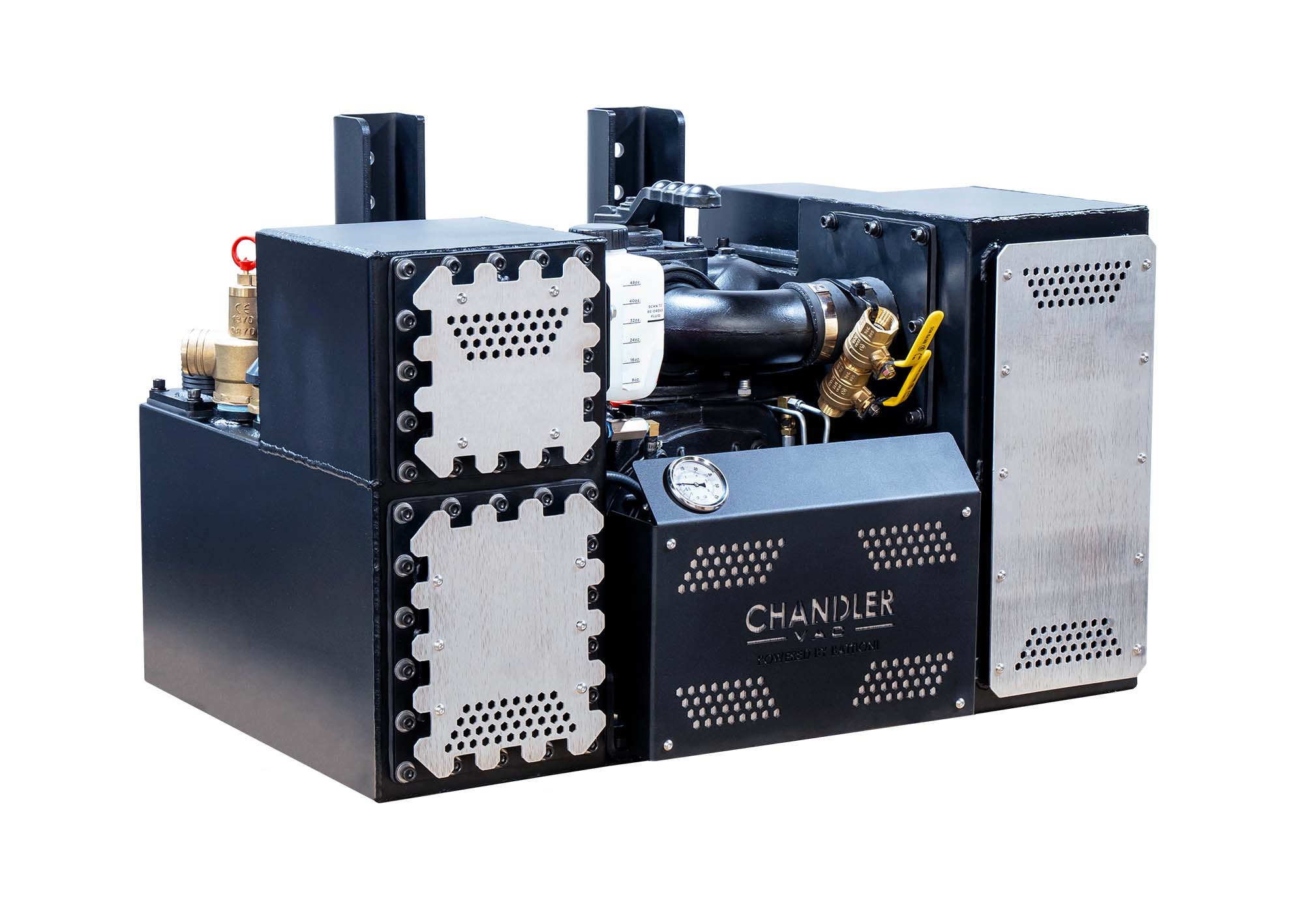

#10 Chandler VAC

Domain Est. 2018

Website: chandlervac.com

Key Highlights: Discover reliable vacuum pump and blower packages and tank components at Chandler VAC, ensuring quality solutions for all your liquid transportation needs….

Expert Sourcing Insights for Vacuum Truck Vacuum Pump

H2: 2026 Market Trends for Vacuum Truck Vacuum Pumps

The global market for vacuum truck vacuum pumps is poised for significant transformation by 2026, driven by technological innovation, regulatory changes, and increasing demand across key end-use sectors. As environmental regulations tighten and urbanization accelerates, the need for efficient waste management and industrial cleaning solutions is fueling demand for high-performance vacuum systems. Below are the key trends expected to shape the vacuum truck vacuum pump market in 2026:

-

Growth in Municipal and Industrial Waste Management

Rising urban populations and stricter environmental regulations are compelling municipalities and industries to upgrade their waste collection and treatment infrastructure. Vacuum trucks equipped with advanced vacuum pumps are increasingly used for sewage removal, septic tank cleaning, and industrial sludge transfer. This sustained demand is expected to drive market expansion, particularly in developing regions across Asia-Pacific, Latin America, and Africa. -

Adoption of Energy-Efficient and Low-Emission Technologies

Environmental sustainability is a key driver in the design and selection of vacuum pumps. By 2026, manufacturers are focusing on developing energy-efficient, low-noise, and low-emission vacuum pump systems, including electric and hybrid models. These align with global decarbonization goals and local emission standards such as Euro 7 and EPA Tier 4 Final, making them increasingly attractive to fleet operators. -

Shift Toward Electric and Alternative-Powered Vacuum Pumps

The transition to electric vehicles (EVs) is extending to specialized trucks, including vacuum trucks. Electric vacuum pumps powered by onboard batteries or hybrid systems are gaining traction due to their quiet operation, reduced maintenance, and zero tailpipe emissions. Innovations in battery technology and charging infrastructure are expected to accelerate this trend by 2026, particularly in urban sanitation applications. -

Integration of Smart Monitoring and IoT Technologies

The incorporation of IoT-enabled sensors and predictive maintenance systems in vacuum pumps is enhancing operational efficiency and reducing downtime. Real-time monitoring of pump performance, vacuum levels, and wear indicators allows for proactive servicing and optimized fleet management. By 2026, smart vacuum pumps are expected to become standard in premium vacuum truck models. -

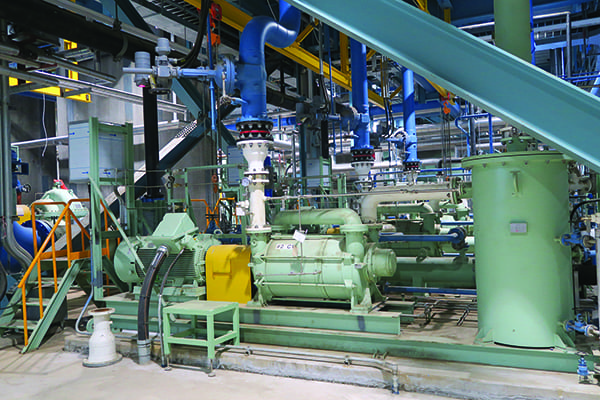

Increased Demand in Oil & Gas and Construction Sectors

The oil & gas industry relies on vacuum trucks for well cleaning, hydro-excavation, and spill recovery. As exploration and pipeline maintenance activities resume post-pandemic and expand in shale-rich regions, demand for rugged and reliable vacuum pumps will grow. Similarly, construction and civil engineering projects are driving demand for hydrovac trucks that use high-capacity vacuum systems for non-destructive digging. -

Regional Market Expansion and Localization

While North America and Europe remain mature markets with steady growth, Asia-Pacific is expected to witness the highest CAGR due to rapid infrastructure development and expanding municipal services in countries like India, China, and Indonesia. Local manufacturing and partnerships with regional players are becoming essential for global suppliers aiming to capture market share. -

Material and Design Innovation

Vacuum pump manufacturers are investing in advanced materials such as composite polymers and corrosion-resistant alloys to improve durability and reduce weight. These enhancements contribute to longer service life and lower total cost of ownership, making them attractive in harsh operating environments.

In conclusion, the 2026 vacuum truck vacuum pump market will be defined by sustainability, digitalization, and performance optimization. Companies that prioritize innovation, regulatory compliance, and customer-specific solutions will be best positioned to capitalize on emerging opportunities across municipal, industrial, and energy sectors.

Common Pitfalls When Sourcing a Vacuum Truck Vacuum Pump (Quality & IP)

Sourcing a vacuum pump for a vacuum truck involves critical decisions that directly impact performance, longevity, and compliance. Falling into common pitfalls related to quality and intellectual property (IP) can lead to costly failures, downtime, and legal risks. Here are key issues to avoid:

Poor Quality Components and Construction

One of the most frequent and damaging pitfalls is selecting a vacuum pump based solely on price without verifying the quality of materials and workmanship. Low-quality pumps often use substandard castings, inferior seals, and weak drive components, leading to:

- Premature Wear and Failure: Poorly machined rotors or low-grade bearings reduce pump life and increase maintenance costs.

- Reduced Suction Efficiency: Inadequate sealing and internal clearances diminish vacuum performance, impacting truck productivity.

- Increased Downtime and Repair Costs: Frequent breakdowns disrupt operations and inflate total cost of ownership.

Tip: Always request documentation on materials (e.g., rotor material, seal types), conduct factory audits if possible, and prioritize suppliers with proven track records in heavy-duty applications.

Counterfeit or Clone Pumps Infringing IP Rights

The vacuum pump market, especially in certain regions, is plagued by counterfeit or cloned versions of well-known branded pumps (e.g., mimics of Becker, Pompasini, or Körting designs). These copies often:

- Violate Intellectual Property: Reproduce patented designs, logos, and technical specifications without authorization.

- Mislead Buyers with Fake Certifications: Display forged CE, ISO, or ATEX markings to appear compliant.

- Lack Technical Support and Spare Parts: Genuine manufacturers disavow cloned products, leaving end-users without service or replacement components.

Tip: Verify the supplier’s authorization to distribute branded products. Request official documentation, cross-check part numbers with OEM databases, and be wary of deals that seem too good to be true.

Inadequate IP Protection in Custom or OEM Designs

When sourcing custom-engineered vacuum pumps or working with OEMs, failing to secure proper IP agreements is a serious oversight. Risks include:

- Loss of Design Ownership: Suppliers may retain rights to custom modifications, limiting your ability to switch vendors or scale production.

- Reverse Engineering by Third Parties: Unprotected designs can be copied by other buyers or even the supplier itself.

- Lack of Exclusivity: Without clear contracts, the same design may be sold to competitors.

Tip: Use comprehensive contracts that explicitly define IP ownership, non-disclosure, and usage rights. Ensure all design files and technical data are transferred under agreed terms.

Ignoring Compliance with International Standards

Even if a pump appears high-quality, lacking proper certification for safety and environmental standards constitutes an IP and operational risk. Non-compliant pumps may:

- Fail Regulatory Inspections: Especially in regions requiring ATEX (explosive atmospheres) or CE marking.

- Void Insurance Coverage: Use of non-certified equipment can invalidate liability policies.

- Expose Buyers to Legal Liability: For using equipment that doesn’t meet local or international safety norms.

Tip: Require valid, traceable certification documents. Confirm testing was performed by accredited third parties, not self-declared by the manufacturer.

By proactively addressing these quality and IP-related pitfalls, buyers can ensure reliable performance, legal compliance, and long-term value from their vacuum truck vacuum pump investment.

H2: Logistics & Compliance Guide for Vacuum Truck Vacuum Pumps

This guide outlines critical logistics and compliance considerations for the transportation, handling, import/export, and operation of vacuum pumps used in vacuum trucks. Adherence ensures safety, avoids delays, and maintains regulatory compliance.

H2: 1. Pre-Shipment & Packaging Requirements

- Secure Mounting: Pumps must be firmly mounted on skids or within crates using rated straps/bolts to prevent movement during transit. Isolate from vibration where possible.

- Protective Covers: Install protective caps on all ports (inlet, outlet, oil fill, drain) to prevent contamination, moisture ingress, and damage. Seal electrical connections.

- Oil Handling:

- Drain Oil: For air transport (IATA) and often international ground/sea freight, pump oil must be completely drained. Oil is classified as a hazardous material (Class 9 – Miscellaneous Dangerous Goods) due to environmental hazards and flammability.

- Clean & Dry: After draining, flush and dry the pump chamber if possible to prevent internal corrosion. Document the drain.

- Separate Oil Shipment: Ship drained oil separately in UN-certified containers, properly labeled as hazardous waste/lubricant (e.g., UN 3082, ENVIRONMENTALLY HAZARDOUS SUBSTANCE, LIQUID, N.O.S. (Used Lubricating Oil), Class 9, Packing Group III). This requires full Dangerous Goods documentation.

- Documentation: Include detailed packing list, commercial invoice, and technical specifications with the shipment. Clearly mark “Fragile” and “This Side Up” on packaging.

H2: 2. Transportation & Handling (In-Transit)

- Hazardous Materials (HazMat) Regulations:

- Drained Pumps: Generally non-hazardous for transport. Standard freight rules apply.

- Pumps with Oil: Subject to strict HazMat regulations (e.g., US DOT 49 CFR, ADR in Europe, IATA/ICAO for air). Requires:

- Proper hazard class labeling (Class 9) on packaging.

- Shipper’s Declaration for Dangerous Goods (for air/international).

- Use of certified HazMat transporters.

- Specific segregation requirements (e.g., away from food, oxidizers).

- Never ship a pump containing oil via air freight without full HazMat compliance.

- Mode-Specific Considerations:

- Air Freight: Highest restrictions. Drained pumps preferred. Strict weight limits and security screening. HazMat shipment adds significant cost and complexity.

- Ocean Freight (FCL/LCL): More tolerant of weight/dimensions. Drained pumps standard. HazMat requires specific container segregation and documentation (IMDG Code).

- Ground Freight (Truck/Rail): Most common. Drained pumps standard. HazMat requires placarding, documentation (Bill of Lading with HazMat notation), and certified drivers/vehicles (DOT HazMat endorsement).

- Handling: Use appropriate lifting equipment (forklifts, cranes). Avoid dropping or impacting the pump. Protect from weather during loading/unloading.

H2: 3. Import/Export & Customs Compliance

- Harmonized System (HS) Codes: Essential for accurate classification. Typical codes (verify locally):

- 8414.80.xx: Pumps for liquids, whether or not fitted with a measuring device (Primary code for vacuum pumps).

- 8413.70.xx: Other rotary positive displacement pumps (Alternative depending on specific pump type).

- 8424.89.xx: Other machinery for projecting, dispersing or spraying liquids… (If pump is part of a complete truck system).

- Critical: Confirm the exact 8-10 digit code with customs brokers in both origin and destination countries. Misclassification causes delays and penalties.

- Required Documentation:

- Commercial Invoice (Detailed description, value, HS code, Incoterms).

- Packing List.

- Bill of Lading (BOL) or Air Waybill (AWB).

- Certificate of Origin (May be required for tariff preferences like USMCA, etc.).

- Dangerous Goods Declaration (If shipping with oil).

- Import/Export Licenses (Check destination country regulations – rare for standard pumps, but possible).

- Duties & Taxes: Calculate based on HS code, declared value, and destination country regulations. Factor into total cost.

- Incoterms: Clearly define responsibilities (e.g., FOB, EXW, DDP). DDP (Delivered Duty Paid) simplifies import for the buyer but increases seller risk/cost.

H2: 4. On-Site Handling & Installation

- Unpacking: Inspect packaging for damage immediately upon receipt. Check pump for visible damage before removing protective covers.

- Storage (If Delayed): Store indoors, dry, and level. Keep port covers on. Protect from dust and moisture. Rotate shaft periodically if stored long-term.

- Installation:

- Follow manufacturer’s instructions precisely.

- Ensure proper alignment and secure mounting to the truck chassis.

- Use correct fittings and hoses rated for vacuum and potential media.

- Oil Filling: Use only the manufacturer-specified vacuum pump oil. Fill to the correct level (usually sight glass). Dispose of used oil containers properly.

- Electrical Connections: Connect according to specifications (voltage, phase, grounding). Ensure secure connections.

H2: 5. Operational Compliance & Safety

- Environmental Regulations (Critical for Vacuum Trucks):

- Waste Disposal: Vacuum pumps handle contaminated fluids (sewage, sludge, chemicals). The entire system (pump, tank, hoses) is subject to strict environmental regulations (e.g., US EPA, EU WFD) regarding:

- Collection, transport, and disposal of hazardous waste.

- Spill prevention and containment (SPCC Plans in US).

- Permits for hauling and dumping at approved facilities.

- Manifests and record-keeping for waste tracking.

- Pump Oil Disposal: Used pump oil is hazardous waste. Must be collected, stored in labeled containers, and disposed of by licensed hazardous waste handlers according to local regulations (e.g., US EPA 40 CFR Part 266/279). Never drain on the ground.

- Waste Disposal: Vacuum pumps handle contaminated fluids (sewage, sludge, chemicals). The entire system (pump, tank, hoses) is subject to strict environmental regulations (e.g., US EPA, EU WFD) regarding:

- Workplace Safety (OSHA/Equivalent):

- Provide appropriate PPE for operators (gloves, eye/face protection, respiratory protection if handling hazardous vapors).

- Ensure proper ventilation when operating near the pump (potential for noise, heat, fumes).

- Lockout/Tagout (LOTO) procedures for maintenance.

- Train operators on safe operation, emergency procedures, and spill response.

- Noise Regulations: Vacuum pumps can be loud. Ensure operation complies with local noise ordinances, especially in urban areas or near residential zones.

- Manufacturer’s Specifications: Always adhere to the pump’s operating limits (temperature, pressure, duty cycle, fluid compatibility) to ensure safety and longevity.

Key Takeaway: The primary compliance focus for vacuum pump logistics is oil management (draining for safe transport) and accurate HS coding. However, the overall compliance burden for the vacuum truck system is dominated by environmental regulations governing the hazardous waste it handles. Always consult with freight forwarders, customs brokers, and environmental specialists familiar with your specific route and waste types.

Conclusion: Sourcing Vacuum Truck Vacuum Pumps

In conclusion, sourcing the right vacuum pump for vacuum trucks is a critical decision that directly impacts operational efficiency, reliability, and long-term maintenance costs. After evaluating various suppliers, pump types (such as rotary vane, liquid ring, and claw pumps), performance specifications, durability, and after-sales support, it is evident that selecting a pump tailored to the specific application—whether for sewage, sludge, or industrial waste—is essential.

Key considerations such as suction capacity, durability under harsh conditions, fuel efficiency, and ease of maintenance must be balanced against initial investment and lifecycle costs. Partnering with reputable manufacturers or suppliers offering proven performance, robust warranties, and local technical support ensures minimized downtime and sustained productivity.

Ultimately, a strategic sourcing approach that prioritizes quality, compatibility, and long-term value—rather than just upfront cost—will lead to improved operational outcomes and a better return on investment for vacuum truck fleets.