The global vacuum pump market is experiencing steady expansion, driven by increasing demand across industrial, semiconductor, pharmaceutical, and food processing sectors. According to a 2023 report by Mordor Intelligence, the vacuum pump market was valued at approximately USD 3.8 billion in 2022 and is projected to grow at a CAGR of 4.7% from 2023 to 2028. This growth is fueled by technological advancements in energy-efficient systems and the rising adoption of vacuum solutions in clean manufacturing processes. As capital expenditure pressures mount and operational flexibility becomes critical, the trend toward renting rather than purchasing vacuum pumps has gained momentum—especially among SMEs and project-based operations. With an increasing number of manufacturers now offering rental programs to meet short-term and scalable needs, selecting a reliable provider has become a strategic decision. Based on market presence, service range, and customer feedback, here are the top 10 vacuum pump manufacturers offering rental solutions to meet dynamic industry demands.

Top 10 Vacuum Pump For Rent Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Vacuum Pump Rentals

Domain Est. 1996

Website: kerrpump.com

Key Highlights: Kerr Pump and Supply offers industrial vacuum pump rentals used in a variety of industrial, medical, and chemical applications….

#2 Rentals for Air and Gas Handling

Domain Est. 1996

Website: geigerinc.com

Key Highlights: Gasho, now a part of Geiger Pump & Equipment, offers fast, dependable rental equipment for environmental or industrial air and gas handling needs….

#3 Vacuum Pump Rentals

Domain Est. 1997

Website: wintek-corp.com

Key Highlights: Wintek Corporation has ~25 industrial vacuum system and vacuum pump rentals of various configurations available for rent….

#4 Rentals and back

Domain Est. 2001

Website: leybold.com

Key Highlights: Our Field Service team and our fully equipped Service Technology Centers are at your disposal to have your vacuum pump serviced….

#5 Pump Rentals

Domain Est. 1996

Website: beckerpumps.com

Key Highlights: We offer both Oil-Flooded and Oil-less Vacuum Pumps for rent: VT Series; KVT Series; VTLF Series; U Series; O Series. We also offer blowers and compressors for ……

#6 Vacuum Pump for Rent

Domain Est. 1997

Website: unitedrentals.com

Key Highlights: Get rental information on Vacuum Pump from United Rentals. Rent equipment, tools or Pipe Plugs & Testing Equipment for your next project….

#7 Sunbelt Rentals

Domain Est. 1997

Website: sunbeltrentals.com

Key Highlights: Rent equipment from Sunbelt Rentals. With over 14000 types of equipment and 950+ locations, we can help with your project. Browse products & get a quote ……

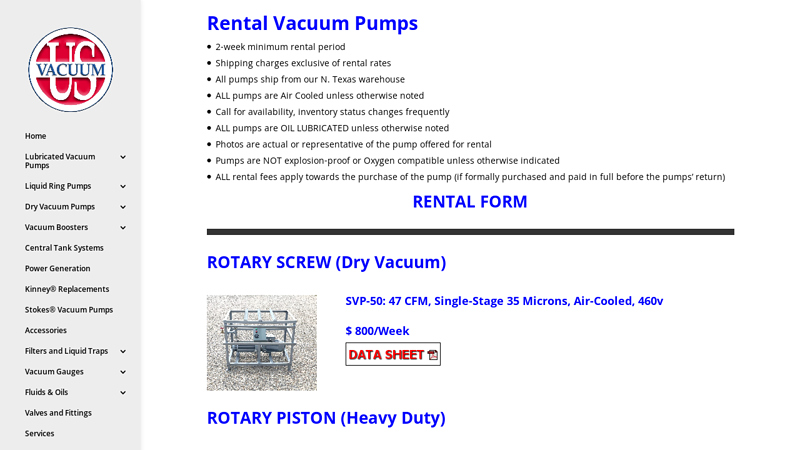

#8 Rental Vacuum Pumps

Domain Est. 2000

Website: usvacuumpumps.com

Key Highlights: Rental Vacuum Pumps. 2-week minimum rental period; Shipping charges exclusive of rental rates; All pumps ship from our N. Texas warehouse; ALL pumps are Air ……

#9 Busch Vacuum Pump Rental Service

Domain Est. 2011

Website: buschvacuum.com

Key Highlights: Rental service from Busch. Rental of vacuum pumps, blowers and compressors of all types and sizes….

#10 Herc Rentals

Domain Est. 2015

Website: hercrentals.com

Key Highlights: Find reliable equipment and tool rentals at Herc Rentals. Choose daily, weekly, or monthly rates across 610+ locations….

Expert Sourcing Insights for Vacuum Pump For Rent

H2: 2026 Market Trends for Vacuum Pump Rental Services

The vacuum pump rental market is poised for notable transformation and growth by 2026, driven by evolving industrial demands, technological advancements, and a rising preference for cost-effective, flexible equipment solutions. As businesses across sectors prioritize operational efficiency and capital preservation, renting vacuum pumps has emerged as a strategic alternative to outright purchases. The following key trends are expected to shape the vacuum pump for rent market in 2026:

1. Increasing Demand in Industrial and Manufacturing Sectors

Industries such as pharmaceuticals, food and beverage, semiconductor manufacturing, and HVAC are experiencing heightened need for vacuum technology in processes like packaging, degassing, and contamination control. With fluctuating production volumes and project-based operations, companies are increasingly opting to rent vacuum pumps rather than invest in permanent installations. This trend is expected to accelerate through 2026, particularly in emerging markets undergoing industrial expansion.

2. Growth in Oil & Gas and Petrochemical Applications

Vacuum pumps play a critical role in refining, gas processing, and pipeline maintenance. As global energy demand persists and upstream activities expand, especially in regions like the Middle East, North America, and Asia-Pacific, temporary vacuum solutions for maintenance turnarounds and emergency repairs are driving rental demand. The shift toward modular and mobile vacuum units further supports short-term leasing in remote or offshore operations.

3. Rise of Sustainable and Energy-Efficient Technologies

By 2026, environmental regulations and corporate sustainability goals will push rental providers to offer energy-efficient, low-emission vacuum pumps—particularly dry screw, claw, and oil-free models. These technologies reduce environmental impact and maintenance costs, making them attractive for rental use. Customers are more likely to rent advanced, eco-friendly models that would otherwise be cost-prohibitive to purchase.

4. Expansion of Rental Fleets and Service Offerings

Leading equipment rental companies are expanding their vacuum pump fleets and integrating value-added services such as remote monitoring, predictive maintenance, and on-site technical support. This shift toward a service-oriented model enhances customer experience and ensures optimal pump performance during rental periods, fostering long-term client relationships.

5. Digitalization and IoT Integration

The integration of Internet of Things (IoT) sensors in rented vacuum pumps is expected to become standard by 2026. Real-time data on pump performance, usage, and maintenance needs allows rental providers and clients to improve operational efficiency, prevent downtime, and optimize rental durations. Digital platforms for booking, tracking, and managing rentals will further streamline the customer journey.

6. Regional Market Diversification

While North America and Europe currently dominate the vacuum pump rental market due to mature industrial infrastructure, the Asia-Pacific region is projected to witness the fastest growth by 2026. Rapid industrialization in countries like India, Vietnam, and Indonesia, along with government-led infrastructure projects, will boost demand for temporary vacuum solutions.

7. Impact of Economic Volatility and CAPEX Constraints

Ongoing economic uncertainties and tighter capital budgets are prompting businesses to adopt an “as-a-service” mindset. Renting vacuum pumps allows companies to access high-performance equipment without significant upfront investment, aligning with broader trends toward operational flexibility and scalability.

In conclusion, the vacuum pump for rent market in 2026 will be defined by technological innovation, sustainability priorities, and a growing preference for flexible, service-enhanced rental models. Companies that invest in modern, connected equipment and responsive customer support will be best positioned to capitalize on these evolving market dynamics.

Common Pitfalls When Sourcing a Vacuum Pump for Rent (Quality & IP)

Renting a vacuum pump offers flexibility and cost savings, but it also comes with risks—particularly concerning equipment quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure a reliable, secure rental experience.

Poor Equipment Quality and Performance

One of the most frequent issues in vacuum pump rentals is receiving equipment that does not meet required performance standards. Rental providers may offer older, poorly maintained, or refurbished units that lack documentation or calibration records. This can lead to inconsistent vacuum levels, higher failure rates, and unplanned downtime. Always verify the pump’s maintenance history, age, and certification (e.g., ISO standards), and ask for recent performance test data before committing.

Lack of Verification and Testing

Many rental agreements do not include pre-delivery performance testing. Without independent verification, renters risk receiving pumps with internal wear, seal leaks, or degraded components. To mitigate this, insist on a performance check—such as ultimate vacuum measurement and leak rate testing—before final acceptance. Request documentation confirming the test results to avoid operational surprises.

Inadequate Documentation and Specifications

Rental providers sometimes supply vacuum pumps without complete technical specifications, operation manuals, or service logs. This lack of transparency complicates troubleshooting and integration into sensitive processes. Ensure the rental agreement includes access to full technical documentation, including pump curves, materials of construction, and compatibility with process gases.

Intellectual Property Exposure

When renting vacuum pumps—especially for R&D, pilot plants, or proprietary processes—there is a risk of IP exposure. If the rental provider or third-party technicians require access to your facility or process data to service the equipment, sensitive information could be inadvertently disclosed. To protect IP, use non-disclosure agreements (NDAs), limit access to critical areas, and clarify data handling protocols in the rental contract.

Unauthorized Data Collection or Monitoring

Some modern vacuum pumps come with built-in IoT sensors or remote monitoring systems. If not properly configured, these systems could transmit operational data—including process parameters—back to the manufacturer or rental company. This poses a significant IP and cybersecurity risk. Before installation, disable or restrict remote connectivity features and confirm data privacy policies with the provider.

Misuse of Equipment in Prior Applications

Vacuum pumps used in previous rentals may have been exposed to hazardous, corrosive, or contaminating substances. Residual contamination can compromise your current process, especially in high-purity applications like semiconductor manufacturing or pharmaceuticals. Require a cleaning and decontamination certificate, and consider onsite validation testing before use.

Unclear Liability for IP or Process Contamination

In the event that a rented pump introduces contamination or fails in a way that disrupts your process, liability terms must be clearly defined. Standard rental agreements often limit the provider’s responsibility, leaving the renter to bear costs for downtime or product loss. Negotiate terms that address contamination risks and include service-level agreements (SLAs) for response time and replacement availability.

By proactively addressing these quality and IP-related pitfalls, businesses can confidently rent vacuum pumps while safeguarding both operational integrity and proprietary information.

Logistics & Compliance Guide for Vacuum Pump Rental

This guide outlines the essential logistics and compliance considerations when renting a vacuum pump, ensuring safe, efficient, and legally compliant operations.

Equipment Delivery and Pickup

Coordinate precise delivery and pickup schedules with the rental provider. Confirm site accessibility for delivery vehicles, including road conditions, weight limits, and required permits. Ensure a clear and level setup area is prepared in advance. Verify that the receiving team is available to inspect the equipment upon arrival and sign all delivery documentation, noting any pre-existing damage.

Transport and Handling Requirements

Use appropriate lifting and transport equipment (e.g., forklifts, pallet jacks, crane) to move the vacuum pump safely. Follow the manufacturer’s guidelines for securing the pump during transit to prevent damage. Ensure personnel are trained in safe handling procedures and wear proper PPE (gloves, safety shoes, etc.). Avoid tilting or laying the pump on its side unless explicitly permitted by the manufacturer.

Site Preparation and Installation

Prepare a stable, vibration-free foundation with adequate ventilation and clearance around the pump. Confirm electrical compatibility (voltage, phase, frequency) and ensure proper grounding. Provide necessary connections for cooling water (if applicable) and exhaust venting. Follow the manufacturer’s installation manual strictly and verify alignment and leveling before operation.

Operational Compliance and Safety

Adhere to all local, national, and industry-specific safety regulations (e.g., OSHA, EU Machinery Directive). Conduct a risk assessment prior to operation. Implement lockout/tagout (LOTO) procedures during maintenance. Monitor for abnormal noise, vibration, or overheating. Use appropriate personal protective equipment (PPE), including hearing protection where noise levels exceed safety thresholds.

Maintenance and Inspection Protocols

Follow the rental provider’s and manufacturer’s recommended maintenance schedule. Perform routine checks on oil levels (for oil-lubricated pumps), filters, belts, and seals. Document all inspections and maintenance activities. Report any mechanical issues immediately to the rental company. Never bypass safety interlocks or alarms.

Environmental and Emissions Compliance

Ensure proper containment and disposal of used pump oil and other hazardous fluids in accordance with environmental regulations (e.g., EPA, local waste disposal laws). For pumps venting process gases, verify that exhaust emissions meet air quality standards. Use vapor recovery or filtration systems if required. Prevent leaks and spills with regular inspections and secondary containment where applicable.

Documentation and Recordkeeping

Maintain accurate records of delivery/pickup logs, maintenance, inspections, operator training, and any incidents. Keep copies of the rental agreement, equipment manuals, and safety data sheets (SDS) for consumables on-site. These records support compliance audits and ensure accountability throughout the rental period.

Return Conditions and Final Inspection

Before return, clean the vacuum pump thoroughly and perform a final operational check. Address any damage or wear in consultation with the rental provider—unauthorized repairs may void agreements. Schedule a joint inspection with the rental company to document the equipment’s condition. Ensure all accessories, hoses, and documentation are returned as specified in the rental contract.

Conclusion: Sourcing a Vacuum Pump for Rent

After evaluating various rental options, suppliers, and technical requirements, renting a vacuum pump presents a cost-effective and flexible solution for short-term projects, maintenance work, or testing applications. It eliminates the need for a large upfront capital investment, allows access to high-quality or specialized equipment, and reduces long-term maintenance and storage responsibilities. Additionally, rental agreements often include technical support, maintenance services, and the ability to upgrade or switch models as project needs evolve.

When sourcing a vacuum pump for rent, it is essential to consider factors such as required specifications (e.g., pumping speed, vacuum level, compatibility with process gases), rental duration, service and support availability, and total cost of rental versus ownership. Selecting a reputable supplier with a strong service record and flexible terms ensures reliability and minimizes operational downtime.

In conclusion, renting a vacuum pump is a strategic and practical choice for temporary or project-based needs. With proper planning and vendor selection, organizations can achieve operational efficiency, cost savings, and technical performance without the long-term commitment of purchasing equipment.