The global vacuum forming mold market is experiencing steady growth, driven by rising demand across industries such as packaging, automotive, medical devices, and consumer goods. According to a 2023 report by Mordor Intelligence, the vacuum forming market is projected to grow at a CAGR of approximately 4.8% from 2023 to 2028, fueled by advancements in thermoplastic materials and increasing adoption of lightweight, cost-effective manufacturing solutions. Similarly, Grand View Research valued the global thermoforming packaging market—at which vacuum forming is a key process—at USD 36.1 billion in 2022, with an expected CAGR of 4.6% through 2030. As industries prioritize scalable, precision-driven production, the need for high-quality vacuum forming molds has intensified. This demand has elevated the role of specialized mold manufacturers capable of delivering durable, accurate, and material-efficient solutions. In this evolving landscape, identifying top-tier manufacturers is critical for businesses seeking reliable partners in prototyping and volume production. The following list highlights the top 10 vacuum forming mold manufacturers renowned for innovation, technical expertise, and global reach.

Top 10 Vacuum Forming Mould Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Formech

Domain Est. 1998

Website: formech.com

Key Highlights: Formech is a designer & manufacturer of vacuum forming machines. Browse our range of compact desktop to fully automatic production vacuum machines….

#2 Vacuum Forming Services, Custom Plastic Vacuum Thermoforming

Domain Est. 1998

Website: productiveplastics.com

Key Highlights: Productive Plastics is a premier manufacturer specializing in custom plastic vacuum forming and heavy gauge thermoforming solutions….

#3 Vacuum Forming Company

Domain Est. 1999

Website: advancedplastiform.com

Key Highlights: A proven vacuum forming company elevating custom plastic part manufacturing with unparalleled durability, accuracy, and on-time delivery for trusted results….

#4 Vacuum Forming Companies

Domain Est. 2000 | Founded: 1976

Website: vacuumformedplastics.com

Key Highlights: Quality Plastics & Machine has been a leading manufacturer of vacuum forming since 1976. Whether you need a small batch of custom vacuum-formed parts or a ……

#5 Thermoforming Mold Introduction

Domain Est. 2004

Website: hongzu.com

Key Highlights: HongZu designs and produces efficient thermoforming molds and vacuum forming molds for a wide range of industrial applications. With over 35 years of experience ……

#6 Vacuum Forming Machines from FORM-V

Domain Est. 2021

Website: formv.biz

Key Highlights: Vacuum forming machines from FORM-V. ✓ Low prices with high quality. ✓ We produce desktop versions and industrial vacuum forming machines….

#7 Vacuum Forming

Domain Est. 1986

Website: techfoundry.ucdavis.edu

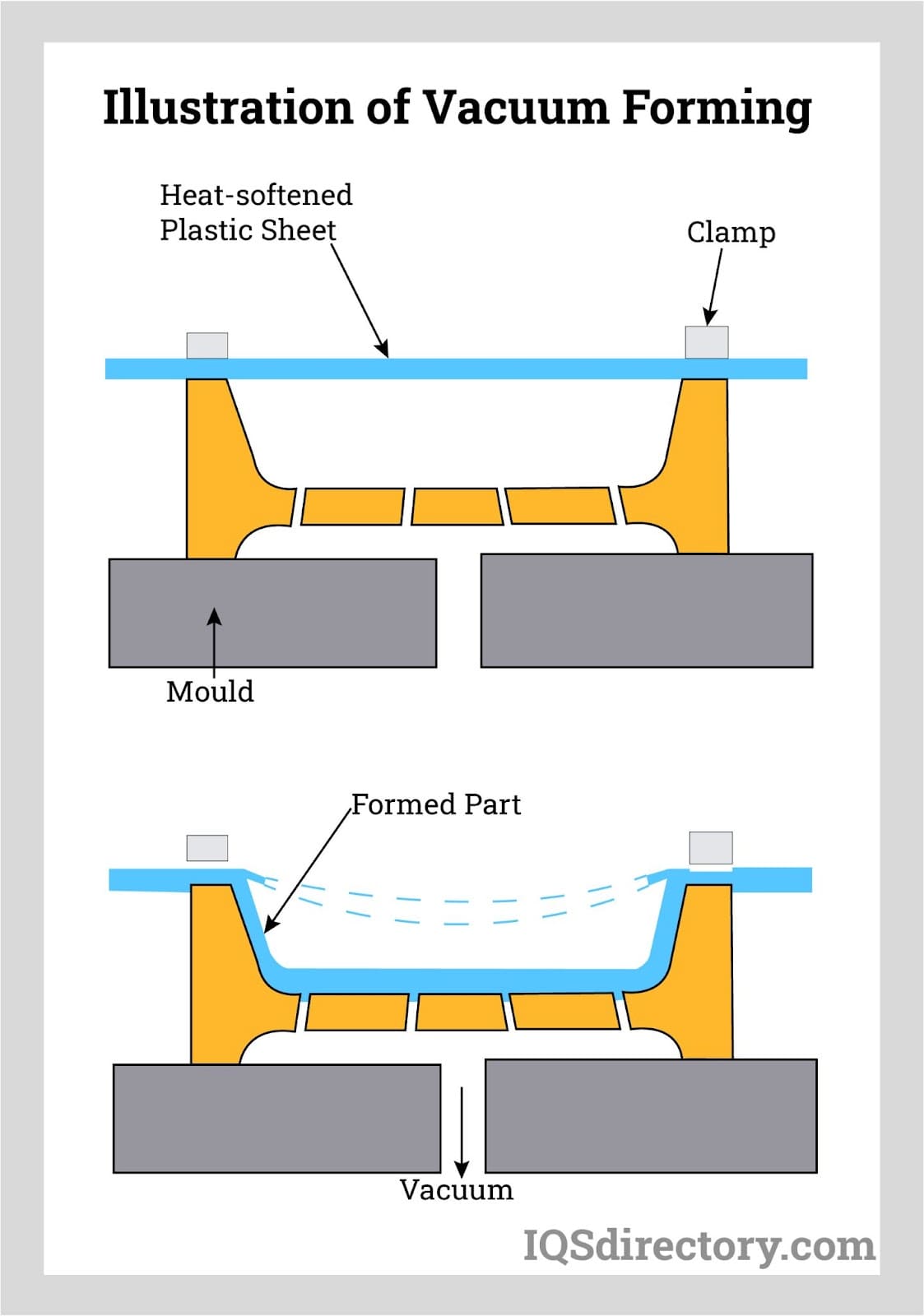

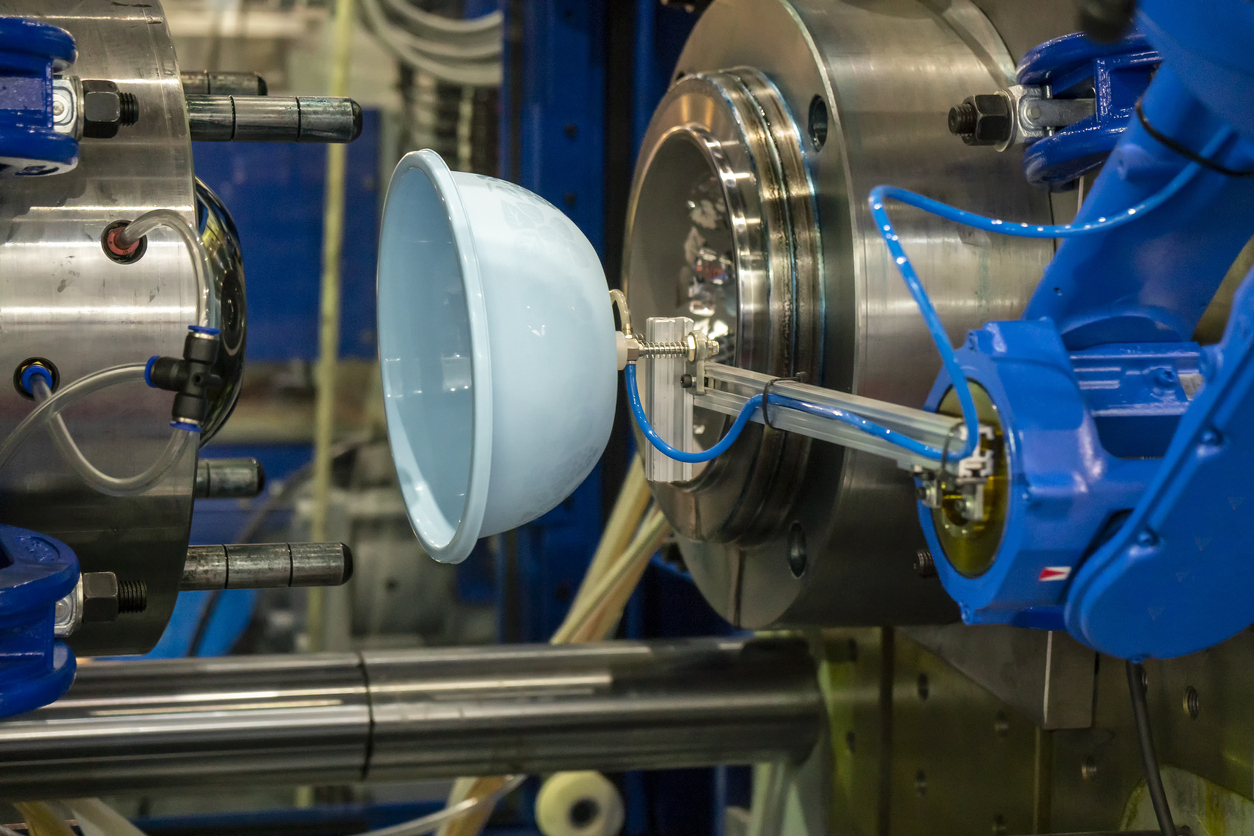

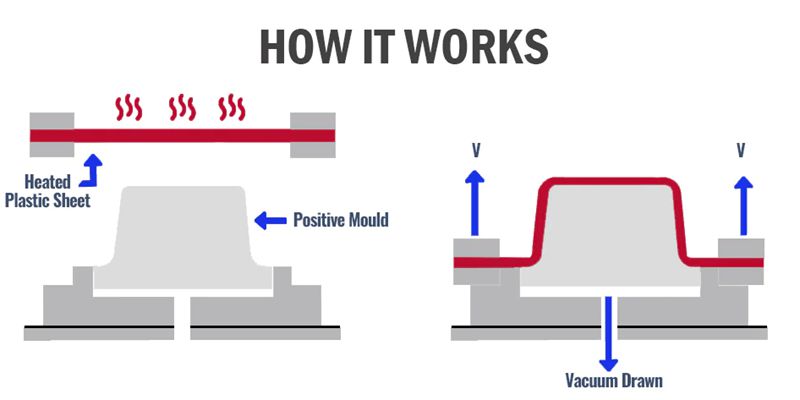

Key Highlights: Vacuum forming is a manufacturing process where a sheet of plastic is heated until pliable, then formed over a mold by applying a vacuum to ……

#8 Thermoforming & Vacuum Forming Services

Domain Est. 1999

Website: wshampshire.com

Key Highlights: WHAT IS VACUUM FORMING? Vacuum forming is a type of thermoforming that involves taking a plastic sheet and draping it over a mold to form a part of a shape….

#9 Global Thermoforming: Thermoforming Company

Domain Est. 2011

Website: globalthermoforming.com

Key Highlights: Global Thermoforming is an ISO-certified thermoforming company that offers vacuum forming, thick gauge, and thin gauge services….

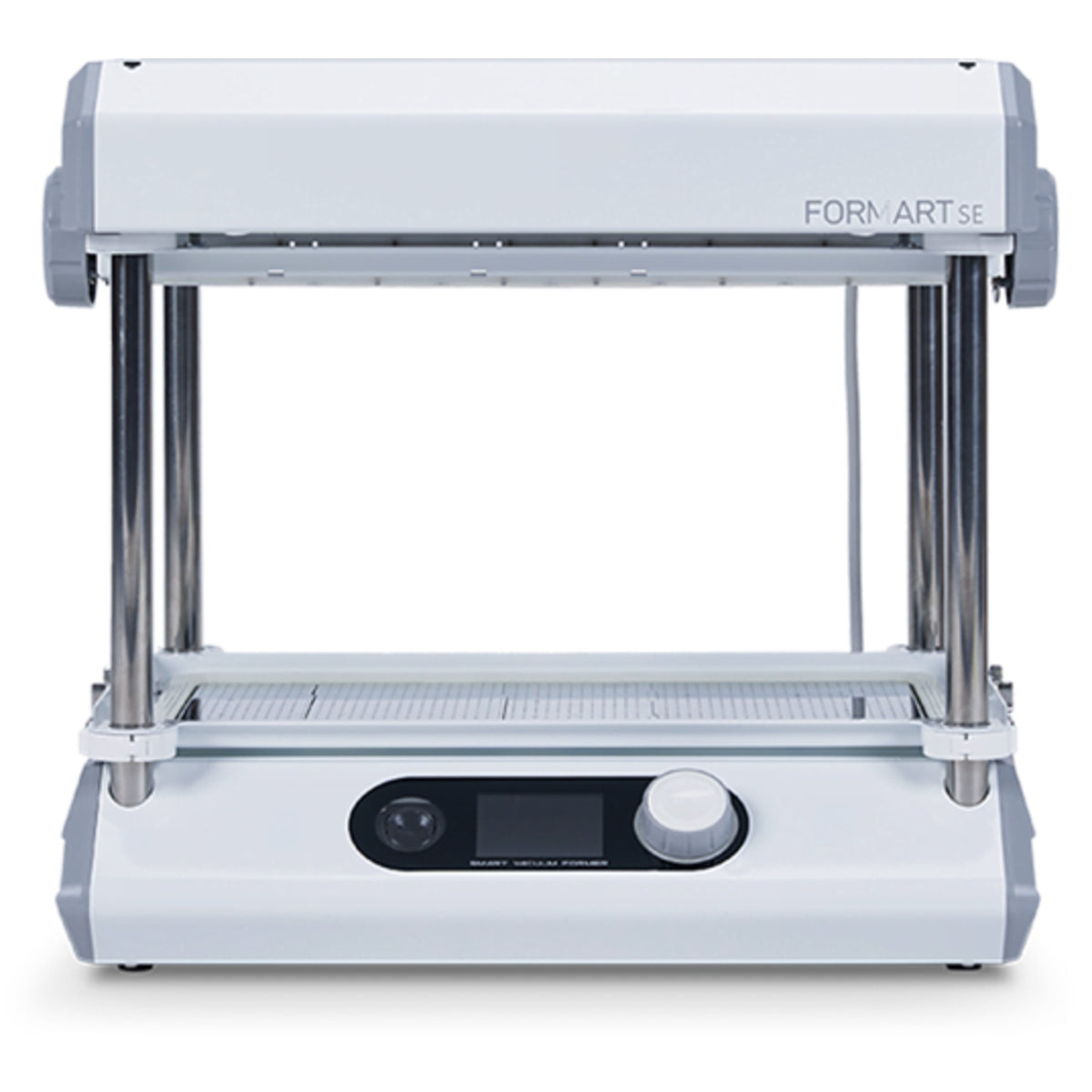

#10 Vacuum Former For You

Domain Est. 2018

Website: myyardtech.com

Key Highlights: FORMART – The Smart Vacuum Former with 4 sizes forming area, 3 suction modes and many special functions. DIY with FORMART now!…

Expert Sourcing Insights for Vacuum Forming Mould

H2: 2026 Market Trends for Vacuum Forming Mould

The vacuum forming mould market is projected to experience significant evolution by 2026, driven by advancements in materials, automation, and increasing demand across end-use industries such as packaging, automotive, healthcare, and consumer goods. Key trends shaping the market include:

-

Growing Demand for Lightweight and Sustainable Packaging

The packaging industry remains a primary driver for vacuum forming moulds. With rising consumer and regulatory emphasis on sustainability, manufacturers are shifting toward recyclable and biodegradable thermoplastics like PLA (polylactic acid) and recycled PET. Vacuum forming is well-suited for producing thin-gauge packaging using these materials, boosting demand for precision-engineered moulds capable of high-speed, low-waste production. -

Adoption of Advanced Materials and Coatings

By 2026, there is an increasing integration of aluminum and composite moulds with specialized surface coatings to improve release properties, reduce wear, and extend service life. Innovations such as anodized aluminum and ceramic-coated moulds are gaining traction for their thermal conductivity and durability, especially in high-volume manufacturing environments. -

Digitalization and Smart Manufacturing Integration

The integration of Industry 4.0 technologies—such as CAD/CAM design, 3D printing for rapid prototyping, and IoT-enabled monitoring systems—is streamlining vacuum forming mould production. Digital twin simulations allow for precise mold design optimization, reducing time-to-market and minimizing defects. Additive manufacturing is also enabling complex geometries that were previously difficult or costly to machine. -

Rise in Customization and Low-Volume Production

The demand for customized packaging and niche industrial components is encouraging the use of vacuum forming for short-run and bespoke production. This trend is fueling demand for cost-effective, quickly fabricated moulds, particularly those made from machined aluminum or 3D-printed materials, which offer faster turnaround than traditional steel tooling. -

Expansion in Automotive and Medical Applications

In the automotive sector, vacuum formed parts are increasingly used for interior trims, dashboards, and protective covers due to their lightweight and cost-efficient nature. Similarly, in healthcare, sterile, single-use trays and enclosures for medical devices are driving demand for high-precision, clean-room-compatible moulds. These applications require tight tolerances and compliance with regulatory standards, pushing innovation in mould accuracy and surface finish. -

Regional Market Shifts and Capacity Growth

Asia-Pacific, particularly China, India, and Southeast Asia, is expected to dominate growth in the vacuum forming mould market by 2026, due to expanding manufacturing bases and rising consumer demand. North America and Europe are focusing on high-value, technologically advanced moulds, especially for medical and aerospace applications, supported by strong R&D investments. -

Sustainability and Circular Economy Initiatives

Mould manufacturers are responding to environmental concerns by developing reusable, long-life moulds and supporting closed-loop recycling systems. There is also a move toward energy-efficient heating systems in vacuum forming machines, which influences mould design for optimal heat distribution and reduced cycle times.

In summary, by 2026, the vacuum forming mould market will be shaped by technological innovation, sustainability imperatives, and diversification across high-growth industries. Companies that invest in digital workflows, eco-friendly materials, and application-specific mould solutions are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls in Sourcing Vacuum Forming Moulds: Quality and Intellectual Property Risks

Sourcing vacuum forming moulds, especially from overseas or unfamiliar suppliers, can present significant challenges. Overlooking key quality and intellectual property (IP) concerns often leads to production delays, increased costs, and legal complications. Here are the most common pitfalls to avoid:

Poor Material and Construction Quality

One of the most frequent issues is receiving moulds made from substandard materials or with poor craftsmanship. Moulds constructed from low-grade aluminum, inadequately finished wood, or porous composites can result in inconsistent part thickness, surface defects (like pitting or grain transfer), and shortened tool life. Inadequate wall thickness or poor venting design further reduces performance and durability, leading to frequent replacements and inconsistent production output.

Inadequate Tolerances and Dimensional Accuracy

Vacuum forming relies on precise mould geometry to produce accurate parts. Moulds that lack tight dimensional tolerances—due to imprecise machining or poor design translation—result in parts that don’t fit properly or require costly post-processing. This is especially critical for assemblies or parts with tight mating requirements. Suppliers unfamiliar with your specifications may overlook tolerances, causing downstream manufacturing issues.

Lack of Design for Manufacturability (DFM) Input

Many suppliers simply replicate provided designs without offering feedback on formability. A major pitfall is sourcing from vendors who don’t perform or recommend Design for Manufacturability reviews. Without proper draft angles, radius transitions, or material thinning analysis, the mould may produce parts with excessive webbing, tearing, or incomplete forming—resulting in scrapped batches and wasted material.

Insufficient Surface Finish and Detail Reproduction

The surface quality of the mould directly affects the aesthetic and functional properties of the final part. Poor polishing, inconsistent textures, or failure to replicate fine details can degrade product quality. Suppliers may cut corners on finishing to reduce costs, leading to parts that require secondary polishing or fail customer inspection, especially in consumer-facing applications.

Intellectual Property (IP) Misappropriation

When sharing detailed CAD models or physical prototypes, there’s a risk the supplier or their subcontractors will duplicate or reverse-engineer your design. This is particularly concerning when sourcing from regions with weaker IP enforcement. Without a robust legal framework—such as a well-drafted Non-Disclosure Agreement (NDA) and clear contractual IP ownership clauses—your design could be sold to competitors or used without authorization.

No Clear Ownership and Usage Rights

Even with an NDA, ambiguity around IP ownership can lead to disputes. Some suppliers claim co-ownership of tooling or restrict your ability to modify or reproduce the mould elsewhere. Failing to explicitly define that the buyer owns the mould design and retains full rights to replicate or transfer tooling can limit future production flexibility and increase dependency on a single vendor.

Inadequate Documentation and Traceability

Pitfalls also arise when suppliers fail to provide complete documentation—such as CAD files, material certifications, or manufacturing records. Without this, reproducing the mould elsewhere or verifying compliance becomes difficult. Lack of traceability also complicates quality audits and liability in case of defects or safety issues.

Hidden Costs from Rework and Delays

Underestimating the total cost of poor-quality moulds is a common financial pitfall. Initial savings from low-cost suppliers are quickly eroded by expenses related to rework, shipping corrections, production downtime, and expedited tooling fixes. Delays caused by mould defects can disrupt supply chains and damage customer relationships.

To avoid these pitfalls, conduct thorough supplier vetting, insist on prototypes or samples, secure IP legally, and maintain open communication throughout the sourcing process.

Logistics & Compliance Guide for Vacuum Forming Moulds

Overview

Vacuum forming moulds are critical tools used in the thermoforming process to shape heated plastic sheets into desired products. Proper logistics handling and regulatory compliance are essential to ensure safe transport, avoid damage, and meet international trade and safety standards.

Packaging and Handling

Vacuum forming moulds, typically made from materials such as aluminum, wood, or composite resins, require secure packaging to prevent deformation or surface damage. Use wooden crates or heavy-duty pallets with corner protectors and foam padding. Clearly label packages with orientation indicators (e.g., “This Side Up”) and handling instructions (e.g., “Fragile,” “Do Not Stack”). Avoid exposure to moisture and extreme temperatures during storage and transit.

Transportation Requirements

Ship moulds via freight services suitable for heavy industrial goods. For international shipments, ensure compliance with IATA (air) or IMDG (sea) regulations if hazardous materials (e.g., certain coatings or adhesives) are present. Provide accurate weight, dimensions, and material composition details to carriers. Utilize trackable freight services and obtain shipping insurance to mitigate loss or damage risks.

Import/Export Compliance

Verify that the export or import of vacuum forming moulds complies with destination country regulations. Most moulds are classified under HS Code 8480.71 (moulds for working rubber or plastic). Confirm tariff classifications, applicable duties, and any required permits. For shipments to the EU, UK, or USA, ensure adherence to customs documentation standards (e.g., commercial invoice, packing list, bill of lading). Monitor trade agreements or sanctions that may affect shipment eligibility.

Regulatory and Safety Standards

Ensure moulds meet relevant industry standards such as ISO 9001 (quality management) or ISO 14001 (environmental management) if applicable. Surface finishes and materials must comply with REACH (EU) or RoHS directives if they involve restricted substances. For food-grade or medical applications, validate that moulds meet FDA (U.S.) or EC 1935/2004 (EU) requirements for material safety.

Environmental and Disposal Compliance

At end-of-life, manage mould disposal in accordance with local environmental regulations. Aluminum moulds can often be recycled; wooden or composite moulds may require special waste handling. Maintain records of disposal to demonstrate compliance with waste management laws (e.g., EPA regulations in the U.S. or WEEE in the EU).

Documentation and Traceability

Maintain comprehensive records including material certifications, design specifications, shipping documents, and compliance declarations. Implement a traceability system to track moulds through their lifecycle, supporting quality audits and regulatory inspections.

Conclusion

Effective logistics and compliance management for vacuum forming moulds reduce operational risks, ensure timely delivery, and support adherence to global regulatory requirements. Proactive planning and documentation are key to successful international trade and long-term use of these industrial tools.

Conclusion for Sourcing Vacuum Forming Moulds

Sourcing vacuum forming moulds requires a strategic approach that balances cost, quality, material compatibility, lead time, and production volume requirements. After evaluating various suppliers and manufacturing methods, it is clear that selecting the right partner involves more than just upfront pricing—factors such as precision, durability, and technical expertise play a crucial role in long-term success.

For low-volume or prototype production, materials like aluminum, wood, or resin-based moulds offer cost-effective and quick solutions. However, for high-volume, consistent production runs, machined aluminum or composite moulds provide superior heat conductivity, longevity, and dimensional accuracy.

Engaging with experienced manufacturers who offer design support, rapid prototyping, and post-production services can significantly enhance efficiency and reduce time-to-market. Additionally, considering geographical proximity, communication capabilities, and scalability ensures smoother collaboration and future growth potential.

In conclusion, a well-informed sourcing decision—based on thorough evaluation of technical capabilities, material selection, and supplier reliability—will ensure optimal performance of vacuum forming moulds, reduce operational costs, and support consistent product quality in the manufacturing process.