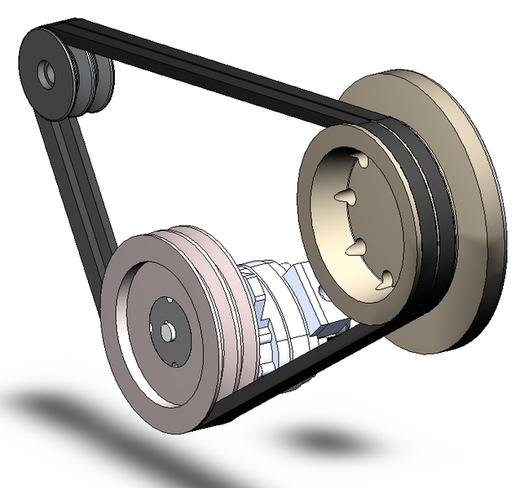

The global V-belt and pulley market is experiencing steady growth, driven by rising demand across industrial machinery, automotive, and agricultural sectors. According to Mordor Intelligence, the global V-belt market was valued at USD 2.67 billion in 2023 and is projected to reach USD 3.42 billion by 2029, growing at a CAGR of 4.1% during the forecast period. This expansion is fueled by the increasing need for efficient power transmission systems and the ongoing modernization of manufacturing infrastructure worldwide. Parallel growth in the pulley market—supported by advancements in material durability and performance optimization—further underscores the importance of reliable drive components in mechanical systems. With Asia-Pacific emerging as a key manufacturing and consumption hub, the competitive landscape is evolving rapidly. Based on market presence, innovation, production capacity, and global reach, we’ve identified the top 10 V-belt and pulley manufacturers shaping the industry today.

Top 10 V Belt And Pulley Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 BRECOflex: Timing Belt Manufacturer

Domain Est. 1996

Website: brecoflex.com

Key Highlights: BRECOflex CO., L.L.C. manufacturers timing belts, pulleys and drive components for linear drives, conveying & power transmission applications….

#2 V

Domain Est. 1997

Website: powerdrive.com

Key Highlights: PowerDrive manufactures Synchronous Drives, Sprockets, V-Belt Drives, Couplings & Bearings for high technology applications and power transmission industry….

#3 PIX Power Transmission Belts Manufacturer

Domain Est. 1998

Website: pixtrans.com

Key Highlights: PIX Transmissions Ltd is the world’s leading manufacturer of V belts, Timing belts, poly v belts and pulleys for nearly every application in the automotive ……

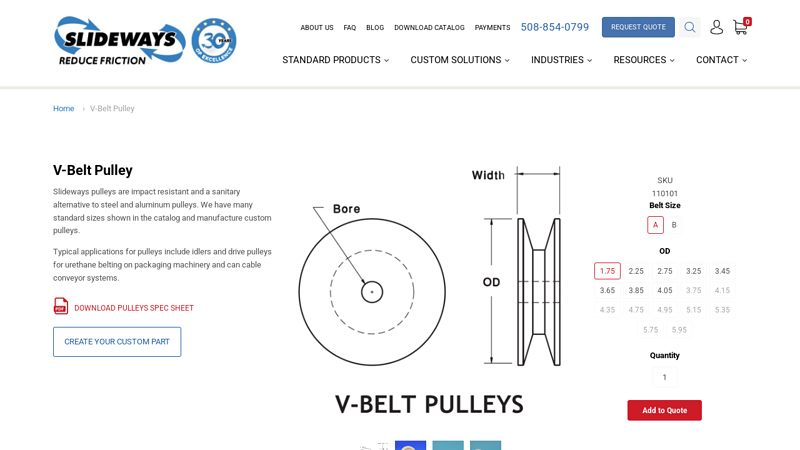

#4 V

Domain Est. 1998

Website: slideways.com

Key Highlights: Shop our v-belt pulleys, available in various sizes. Download specs sheets or find out how to get a custom quote on parts today!…

#5 V

Domain Est. 1999

Website: web.optibelt.com

Key Highlights: High-quality V-belts and timing belts from the german manufacturer Optibelt. We have been setting standards in drive systems with first-class system ……

#6 V

Domain Est. 1994

Website: gates.com

Key Highlights: We’ve designed our V-belts for wear, corrosion, and heat resistance with OE quality fit and construction for reliable, long-lasting performance….

#7 Pulleys

Domain Est. 1996

Website: skf.com

Key Highlights: We offer a wide variety of pulleys, in all types of profile. These include wedge belt, V-belt and narrow wedge belt pulleys, plus classical and metric timing ……

#8 V

Domain Est. 1996

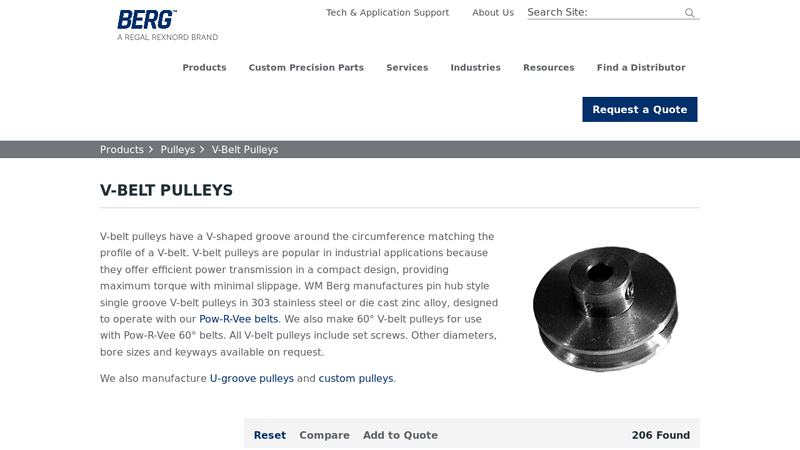

Website: wmberg.com

Key Highlights: WM Berg manufactures pin hub style single groove V-belt pulleys in 303 stainless steel or die cast zinc alloy, designed to operate with our Pow-R-Vee belts….

#9 B&B Manufacturing

Domain Est. 1999

Website: bbman.com

Key Highlights: Our expertly engineered belted drive solutions are trusted across industries like 3D Printing, Air-Cooled Heat Exchangers, CNC Machinery, and Oil & Gas, ……

#10 Power Transmission Solutions

Domain Est. 2018

Website: continental-industry.com

Key Highlights: As a company manufacturing the full range of power transmission belt, Continental offers a variety of Multi V-belts for wraparound drives with small pully ……

Expert Sourcing Insights for V Belt And Pulley

H2: 2026 Market Trends for V-Belts and Pulleys

The global V-belt and pulley market is poised for steady growth through 2026, driven by technological advancements, industrial automation, and rising demand across key end-use sectors. Below are the major trends shaping the market landscape:

-

Increased Demand from Automotive and Industrial Manufacturing

The automotive industry remains a primary consumer of V-belts and pulleys, particularly in internal combustion engine (ICE) vehicles. Despite the shift toward electric vehicles (EVs), ICE vehicles will continue to dominate global fleets through 2026, supporting ongoing demand. Additionally, growth in industrial manufacturing, especially in emerging economies, is fueling the need for efficient power transmission systems, boosting V-belt and pulley adoption. -

Adoption of High-Performance and Cogged V-Belts

There is a growing shift toward high-efficiency cogged V-belts and reinforced rubber compounds that offer improved heat resistance, longer lifespan, and better energy efficiency. These advanced belts reduce slippage and maintenance costs, making them ideal for heavy-duty and continuous-operation applications in sectors like mining, agriculture, and HVAC. -

Expansion in Renewable Energy and HVAC Applications

The renewable energy sector—particularly wind and solar power installations—relies on pulley and belt systems for auxiliary power transmission and cooling mechanisms. Similarly, increasing investments in energy-efficient HVAC systems are driving demand for precision-engineered pulleys and variable-speed belt drives that optimize energy consumption. -

Regional Growth in Asia-Pacific and Latin America

Asia-Pacific is expected to lead market growth due to rapid industrialization, infrastructure development, and expanding automotive production in countries like China, India, and Vietnam. Latin America is also witnessing increased demand, supported by growth in agriculture and mining industries that depend heavily on belt-driven machinery. -

Sustainability and Material Innovation

Manufacturers are focusing on sustainable materials and eco-friendly production processes. Development of bio-based rubber compounds and recyclable components is gaining traction to meet environmental regulations and corporate sustainability goals. This trend is expected to strengthen by 2026 as ESG (Environmental, Social, and Governance) criteria become more influential in procurement decisions. -

Integration with Predictive Maintenance and IoT

Smart pulley systems integrated with sensors and IoT platforms are emerging in industrial applications. These systems monitor belt tension, temperature, and wear in real time, enabling predictive maintenance and reducing unplanned downtime. While still in early adoption, this trend is expected to grow significantly by 2026, especially in smart factories and Industry 4.0 environments. -

Consolidation and Strategic Partnerships Among Key Players

Market leaders such as Gates Corporation, SKF, Mitsuboshi, and ContiTech are engaging in mergers, acquisitions, and R&D collaborations to enhance product portfolios and expand global reach. These strategic moves are helping companies innovate faster and respond to evolving customer needs.

In summary, the V-belt and pulley market in 2026 will be shaped by technological innovation, regional industrial growth, and a shift toward energy-efficient and intelligent power transmission solutions. While facing long-term challenges from electrification and direct-drive systems, the market remains resilient due to its critical role in diverse mechanical systems worldwide.

Common Pitfalls When Sourcing V-Belts and Pulleys (Quality and Intellectual Property)

Sourcing V-belts and pulleys involves more than just finding the lowest price—overlooking key quality and intellectual property (IP) factors can lead to costly failures, downtime, and legal risks. Below are common pitfalls to avoid:

Inadequate Quality Standards and Material Verification

One of the most frequent issues is sourcing belts and pulleys that fail to meet required performance standards. Low-cost suppliers may use substandard rubber compounds, improper reinforcing cords, or poor manufacturing techniques, resulting in premature wear, slippage, or even catastrophic failure. Always verify compliance with international standards such as ISO 4184 (V-belt dimensions) or RMA/IPA guidelines, and request material certifications.

Counterfeit or Branded Imitations

Purchasing “branded” belts (e.g., Gates, Dayco, or ContiTech) at suspiciously low prices often leads to counterfeit products. These imitations may mimic logos and packaging but lack the engineering and durability of genuine parts. Using counterfeit components can void equipment warranties and introduce safety hazards. Always source from authorized distributors and verify authenticity through batch numbers or supplier credentials.

Mismatched Pulley Groove Geometry

Even if a V-belt meets dimensional specs, incompatibility with pulley groove angles (e.g., 34° vs. 38°) can drastically reduce efficiency and lifespan. Sourcing pulleys without verifying groove profile, pitch diameter, and surface finish can lead to belt slippage, excessive heat, and vibration. Ensure pulley specifications match OEM requirements or industry standards.

Lack of IP Due Diligence in Custom Designs

When sourcing custom pulleys or proprietary belt profiles, failing to address intellectual property rights can result in infringement claims. Some suppliers may replicate patented designs without authorization. Before production, confirm that your supplier has the right to manufacture the requested design and consider including IP indemnification clauses in contracts.

Poor Tolerance and Dimensional Accuracy

Low-quality pulleys often exhibit inconsistent bore diameters, runout, or unbalanced masses. These flaws can cause misalignment, increased wear, and bearing failure. Always request geometric dimensioning and tolerancing (GD&T) data and conduct incoming inspections, especially for high-speed or high-torque applications.

Overlooking Environmental and Operational Compatibility

V-belts used in extreme temperatures, oily environments, or outdoor settings require specific compounds (e.g., neoprene, EPDM). Sourcing generic belts without considering environmental resistance can lead to rapid degradation. Verify that materials are suited for your operating conditions to avoid unplanned maintenance.

Absence of Traceability and Documentation

Reliable suppliers provide lot traceability, test reports, and compliance documentation. Lack of such records makes it difficult to investigate failures or prove product authenticity, especially in regulated industries. Ensure your supplier maintains a quality management system (e.g., ISO 9001) and can provide full documentation upon request.

Final Recommendation

To mitigate these risks, establish a vetting process for suppliers that includes factory audits, sample testing, and legal review of IP rights. Prioritize long-term reliability and compliance over initial cost savings—poor-quality belts and pulleys can lead to far greater expenses in downtime, repairs, and liability.

Logistics & Compliance Guide for V-Belt and Pulley Systems

Product Classification and HS Codes

V-belts and pulleys are typically classified under Harmonized System (HS) codes based on material composition, design, and intended use. Common classifications include:

– 4010.31 – V-belts of vulcanized rubber

– 4010.32 – V-belts of other rubber types

– 8483.90 – Pulleys and sheaves for mechanical power transmission

Accurate HS code selection is critical for determining import duties, taxes, and regulatory requirements in target markets. Always verify with local customs authorities or a customs broker prior to shipment.

Packaging and Handling Requirements

Proper packaging ensures product integrity during transit:

– V-belts: Should be coiled or folded (if permitted by manufacturer) and packed in moisture-resistant, labeled polybags or cartons. Avoid sharp bending to prevent internal damage.

– Pulleys: Pack in sturdy corrugated boxes with cushioning (foam, cardboard dividers) to prevent surface scratches or deformation.

– Clearly label packages with SKU, quantity, weight, and handling instructions (e.g., “Do Not Stack,” “Fragile”).

– Use pallets for bulk shipments, secured with stretch wrap or strapping.

Transportation and Storage Conditions

- Temperature: Store and transport in a dry, temperature-controlled environment (ideally 10–30°C). Avoid exposure to extreme heat or cold, which can degrade rubber components.

- Humidity: Relative humidity should not exceed 70% to prevent corrosion of metal pulleys and rubber deterioration.

- UV Exposure: Protect V-belts from direct sunlight and UV radiation, which can cause cracking and premature aging.

- Shelf Life: Rubber V-belts typically have a shelf life of 6–10 years when stored properly. Rotate stock using FIFO (First In, First Out) practices.

Regulatory and Safety Compliance

- REACH (EU): Ensure V-belt materials comply with REACH regulations regarding restricted substances (e.g., phthalates, heavy metals). Suppliers must provide SVHC (Substances of Very High Concern) declarations if applicable.

- RoHS (EU/UK/China): Applicable to pulleys with electrical components or coatings; verify lead, cadmium, and other hazardous substance limits.

- OSHA (USA): Installed pulley systems must comply with machinery guarding standards (29 CFR 1910.212) to protect operators from moving parts.

- CE Marking: Required for pulleys and drive systems placed on the EU market; involves conformity assessment and technical documentation.

Import/Export Documentation

Key documents required for international shipping:

– Commercial Invoice (with declared value, HS codes, country of origin)

– Packing List (itemized contents, weights, dimensions)

– Bill of Lading or Air Waybill

– Certificate of Origin (may be required for preferential tariffs)

– Material Safety Data Sheet (MSDS) – especially for rubber components

– Compliance Certificates (e.g., CE, RoHS, REACH) where applicable

Customs Clearance and Duties

- Verify duty rates and import taxes in the destination country using the correct HS code.

- Some countries impose anti-dumping duties on imported mechanical power transmission components—confirm current trade regulations.

- Use Incoterms (e.g., EXW, FOB, DDP) clearly in contracts to define responsibility for logistics, insurance, and customs clearance.

Environmental and End-of-Life Compliance

- WEEE (EU): Not typically applicable to standalone V-belts and pulleys unless part of an electrical assembly.

- Tire and Rubber Disposal: Used V-belts should be disposed of or recycled per local environmental regulations. Some regions classify waste rubber under special handling rules.

- Encourage return programs or recycling initiatives for industrial customers to support sustainability goals.

Quality and Certification Standards

Ensure products meet relevant international standards:

– ISO 4184: Testing of V-belts (tensile strength, elongation)

– ISO 1081: Dimensions and tolerances for classical V-belts

– ISO 9981: Specifications for pulleys (groove profiles, pitch diameters)

– DIN 2211, RMA IP-20: Common industry standards in Europe and North America

Provide test reports and conformity certificates upon request.

Supplier and Supply Chain Due Diligence

- Audit suppliers for compliance with labor, environmental, and quality standards (e.g., ISO 9001, ISO 14001).

- Ensure traceability of raw materials (e.g., rubber sourcing, steel for pulleys).

- Maintain documentation for conflict minerals, if applicable (e.g., tin, tungsten in pulley components).

By adhering to this logistics and compliance guide, businesses can ensure smooth international trade, regulatory adherence, and product reliability for V-belt and pulley systems.

In conclusion, sourcing V-belts and pulleys requires careful consideration of several key factors to ensure optimal performance, longevity, and compatibility within a power transmission system. It is essential to accurately assess specifications such as belt type, dimensions, material quality, pulley groove size, and alignment requirements to match the operational demands of the machinery. Choosing reliable suppliers that offer certified, high-quality components—along with proper technical support—can significantly reduce downtime and maintenance costs. Additionally, considering total cost of ownership rather than just initial price helps in making a more informed and cost-effective decision. By prioritizing compatibility, durability, and supplier reputation, businesses can ensure efficient and reliable operation of their mechanical systems.