The global UV-Vis spectroscopy market is experiencing robust growth, driven by rising demand for analytical instrumentation in pharmaceuticals, environmental monitoring, and academic research. According to Grand View Research, the market was valued at USD 592.1 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by technological advancements such as miniaturization, enhanced detector sensitivity, and integration with software analytics. Additionally, expanding applications in quality control and regulatory compliance across life sciences and chemical industries are increasing reliance on precise and reliable spectroscopic tools. As demand surges, a select group of manufacturers continues to lead innovation and market share—shaping the future of UV-Vis technology. Here, we spotlight the top nine manufacturers based on product range, global footprint, R&D investment, and customer adoption across key industry verticals.

Top 9 Uv Vis Spectroscopy Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Uv Spectroscopy Machine Manufacturer and Supplier …

Domain Est. 2023

Website: bjbfrl.com

Key Highlights: Beijing Beifen-Ruili Analytical Instrument (Group) Co., Ltd. is a renowned UV Spectroscopy Machine manufacturer, supplier, and factory based in China. Our state ……

#2 SpectroChemistry Systems (UV

Domain Est. 2002

Website: stellarnet.us

Key Highlights: StellarNet miniature research grade spectrometers allows for low cost measurements in the UV-VIS-NIR wavelength ranges….

#3 UV Vis Spectrometers

Domain Est. 2006

Website: thermofisher.com

Key Highlights: UV-Vis Spectrometers from Thermo Fisher Scientific provide reliable, quantitative spectroscopy chemical analysis for teaching, research, and industrial ……

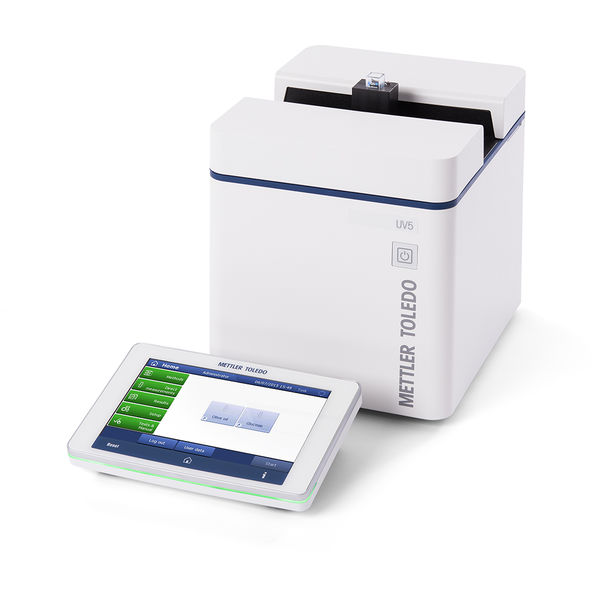

#4 UV/Vis Spectrophotometry by METTLER TOLEDO

Domain Est. 1993

Website: mt.com

Key Highlights: UV Vis spectrophotometers offer superior optical design and unparalleled performance across a wide range of applications including micro-volume measurements….

#5 UV

Domain Est. 1994

Website: shimadzu.com

Key Highlights: Shimadzu’s own UV-Vis-NIR spectrophotometers are renowned for their performance, featuring high-resolution optics, intuitive software and innovative ……

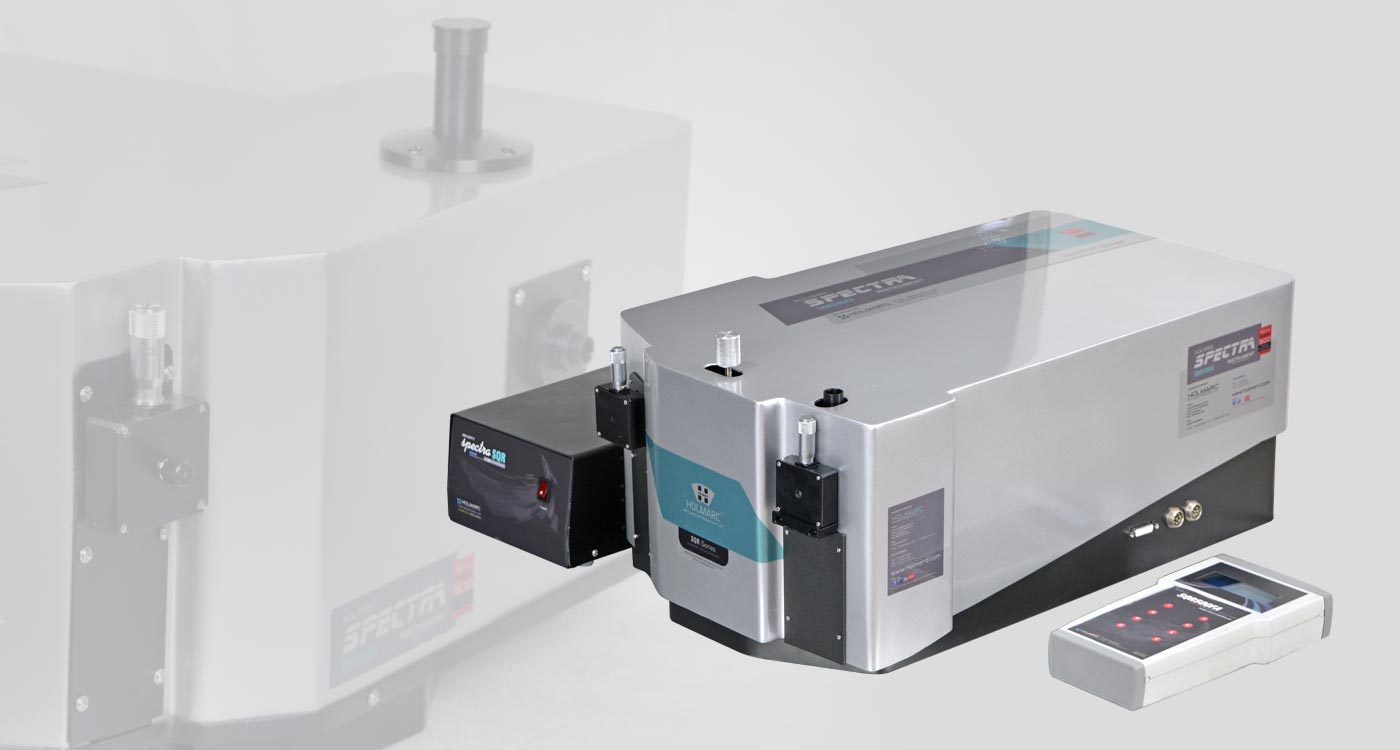

#6 Monochromators, spectrometers, optical systems for spectroscopy …

Domain Est. 1996

Website: mcphersoninc.com

Key Highlights: Monochromators & Spectrometers · High Resolution UV-Vis to Infrared · VUV & Extreme Ultraviolet · Soft X-ray and Extreme UV · Light Sources · Detectors….

#7 Ultraviolet

Domain Est. 1998

Website: perkinelmer.com

Key Highlights: From compact, mobile UV/Vis spectrometers to advanced benchtop UV/Vis/NIR systems, our solutions are tailored to your laboratory’s specific requirements….

#8 Avantes

Domain Est. 1999

Website: avantes.com

Key Highlights: Avantes is a leading company in development and manufacturing of high-class spectrometers, lightsources and unique software….

#9 Implen

Website: implen.de

Key Highlights: The Implen NanoPhototometer is the most compact high performance UV/Vis spectrophotometer for nanovolume and cuvette applications….

Expert Sourcing Insights for Uv Vis Spectroscopy Machine

2026 Market Trends for UV-Vis Spectroscopy Machines

Rising Demand in Pharmaceutical and Biotechnology Sectors

The pharmaceutical and biotechnology industries are expected to be primary drivers of the UV-Vis spectroscopy machine market in 2026. Increasing R&D investments, growing drug discovery activities, and stringent regulatory requirements for quality control are fueling demand for accurate and reliable analytical instruments. UV-Vis spectrophotometers are essential for quantifying nucleic acids, proteins, and small molecules during various stages of drug development and production. The expansion of personalized medicine and biosimilars is further intensifying the need for high-throughput and precise spectroscopic analysis, positioning UV-Vis systems as indispensable tools in modern laboratories.

Advancements in Instrumentation and Automation

By 2026, UV-Vis spectroscopy machines are anticipated to feature significant technological enhancements, including improved sensitivity, faster scanning speeds, and greater automation. Integration with robotics and laboratory information management systems (LIMS) enables seamless data acquisition, analysis, and traceability—critical for compliance with Good Manufacturing Practice (GMP) and Good Laboratory Practice (GLP). Miniaturization and the development of portable or handheld UV-Vis devices are also gaining traction, allowing for on-site analysis in environmental monitoring, food safety, and field research. These innovations are broadening the application scope and making the technology accessible to non-traditional users.

Growth in Emerging Markets

Emerging economies in Asia-Pacific, Latin America, and Africa are expected to contribute substantially to market growth in 2026. Increasing government funding for scientific research, expansion of academic and industrial laboratories, and rising awareness of quality control in manufacturing are key factors driving adoption in these regions. Countries such as China, India, and Brazil are investing heavily in healthcare infrastructure and environmental monitoring, creating robust demand for analytical instrumentation. Local manufacturing and strategic partnerships with global players are also reducing costs and improving market penetration.

Sustainability and Green Chemistry Initiatives

Environmental concerns and the push toward sustainable practices are influencing the design and use of UV-Vis spectrophotometers. In 2026, manufacturers are focusing on energy-efficient instruments, reduced solvent consumption through micro-volume sample analysis, and recyclable components. These eco-friendly features align with green chemistry principles and appeal to environmentally conscious organizations. Additionally, UV-Vis spectroscopy supports sustainability by enabling real-time monitoring of pollutants in air and water, contributing to environmental protection efforts.

Competitive Landscape and Market Consolidation

The UV-Vis spectroscopy market in 2026 is expected to remain competitive, with key players such as Shimadzu, Agilent Technologies, PerkinElmer, Thermo Fisher Scientific, and JASCO dominating the landscape. These companies are focusing on product differentiation through software integration, user-friendly interfaces, and advanced data analytics powered by artificial intelligence. Strategic mergers, acquisitions, and collaborations are likely to increase as firms aim to expand their product portfolios and geographical reach. Customization and after-sales services, including remote diagnostics and cloud-based support, are becoming critical differentiators in a maturing market.

Conclusion

The 2026 market for UV-Vis spectroscopy machines reflects a convergence of technological innovation, regulatory demands, and global expansion. Driven by pharmaceutical advancements, automation, and sustainability trends, the market is poised for steady growth. As analytical requirements become more complex, UV-Vis spectrophotometers will continue to evolve, maintaining their status as fundamental instruments in scientific and industrial laboratories worldwide.

Common Pitfalls When Sourcing UV-Vis Spectroscopy Machines: Quality and Intellectual Property Concerns

Sourcing a UV-Vis spectroscopy machine involves careful evaluation beyond just price and specifications. Overlooking quality assurance and intellectual property (IP) aspects can lead to significant operational, legal, and financial setbacks. Below are key pitfalls to avoid in these critical areas.

Quality-Related Pitfalls

Inadequate Verification of Instrument Performance Specifications

Suppliers may advertise theoretical or best-case performance metrics that do not reflect real-world conditions. Buyers often fail to validate critical parameters such as photometric accuracy, wavelength accuracy, resolution, and baseline stability under routine lab conditions. Relying solely on datasheet claims without requesting third-party validation reports or on-site demonstrations can result in acquiring instruments that underperform.

Lack of Compliance with Industry Standards

A common oversight is sourcing equipment that does not comply with international standards such as ISO/IEC 17025, USP <857>, or pharmacopeial requirements. This can compromise data integrity and regulatory compliance, particularly in pharmaceutical, food, and environmental testing labs. Always confirm that the instrument meets applicable standards and comes with documented calibration traceable to NIST or equivalent bodies.

Poor Build Quality and Material Selection

Low-cost instruments may use substandard optical components, unstable light sources, or non-durable cuvette holders, leading to frequent maintenance, inconsistent results, and shortened lifespan. Inspect the construction quality, materials used (e.g., fused silica lenses, deuterium/tungsten-halogen lamps), and overall design robustness before purchase.

Insufficient After-Sales Support and Service Network

Even high-quality instruments require maintenance and technical support. Sourcing from vendors without reliable local service, readily available spare parts, or trained technicians can result in prolonged downtime. Evaluate the supplier’s service history, response time, and availability of support in your region.

Intellectual Property (IP) Pitfalls

Procurement of Instruments with Infringing or Unlicensed Software

Some low-cost or rebranded UV-Vis systems may use software that violates IP rights—either through unauthorized copying of proprietary algorithms or unlicensed use of third-party libraries. Using such software exposes the buyer to legal risks, including liability for copyright infringement and potential shutdown of operations during audits.

Lack of Transparency in Software Ownership and Licensing

Vendors may not clearly disclose whether the control and analysis software is developed in-house or licensed from another party. This ambiguity can lead to unexpected licensing fees, limitations on software updates, or restrictions on data export and integration with laboratory information management systems (LIMS).

Risk of Counterfeit or Clone Instruments

In certain markets, counterfeit or cloned spectrophotometers replicate the design and branding of reputable brands without authorization. These machines not only compromise data reliability but also expose the buyer to IP infringement claims. Ensure the supplier is an authorized distributor and verify the instrument’s authenticity through serial numbers and manufacturer certifications.

Absence of IP Indemnification Clauses in Contracts

Many procurement agreements fail to include indemnification clauses protecting the buyer from third-party IP claims related to the equipment or software. Always include contractual provisions requiring the supplier to assume liability for any IP disputes arising from the supplied instrument.

By proactively addressing these quality and IP-related pitfalls, organizations can ensure they acquire reliable, compliant, and legally sound UV-Vis spectroscopy systems that support accurate analysis and long-term operational success.

Logistics & Compliance Guide for UV-Vis Spectroscopy Machine

Shipping and Receiving Procedures

Ensure the UV-Vis spectrophotometer is shipped in its original packaging or a similarly robust, manufacturer-approved container with adequate internal cushioning. Verify that all shock indicators are intact upon delivery. Designate a trained receiving personnel to inspect the shipment for external damage, confirm the model number and serial number match the purchase order, and log the delivery in the equipment inventory system within 24 hours. Retain all packaging materials for at least 30 days in case of return or warranty service.

Installation Site Preparation

Select an installation location that is clean, dry, and free from excessive dust, vibrations, and direct sunlight. The area must have stable power supply (per manufacturer specifications, typically 100–240 V AC, 50/60 Hz) with a dedicated grounded outlet. Ensure ambient temperature is maintained between 15°C and 30°C, and relative humidity is within 20–80% (non-condensing). Provide sufficient clearance around the instrument (minimum 10 cm on all sides) for ventilation and maintenance access. A stable, level bench capable of supporting the instrument’s weight (typically 10–20 kg) is required.

Import and Customs Compliance

For international shipments, ensure all import documentation is prepared in advance, including commercial invoice, packing list, bill of lading/airway bill, and certificate of origin. Classify the instrument under the correct Harmonized System (HS) code (commonly 9027.20 or 9027.50, depending on region and functionality). Confirm compliance with import regulations in the destination country, including any required permits, pre-arrival notifications, or laboratory equipment declarations. Retain all customs documentation for a minimum of five years.

Regulatory and Safety Standards

Verify that the UV-Vis spectrophotometer meets applicable international and local safety standards, such as IEC 61010-1 (safety requirements for electrical equipment) and electromagnetic compatibility (EMC) standards (e.g., IEC 61326-1). Ensure the device carries relevant certifications (e.g., CE, UL, or UKCA marks) based on the region of operation. Perform a risk assessment upon installation to identify potential hazards (e.g., electrical, optical radiation) and implement control measures, including user training and safety signage.

Operational Compliance and Documentation

Maintain a comprehensive compliance file including the user manual, calibration certificate, installation qualification (IQ), operational qualification (OQ), and any validation reports (e.g., for GxP environments). Establish a routine maintenance schedule per manufacturer recommendations and document all service activities. For regulated laboratories (e.g., GLP, GMP), ensure the instrument is registered in the lab’s equipment management system and undergoes periodic audits and requalification.

Waste and Disposal Management

Dispose of consumables such as quartz or plastic cuvettes, solvent waste, and packaging materials according to local environmental and hazardous waste regulations. Cuvettes contaminated with hazardous chemicals must be decontaminated or disposed of as chemical waste. At end-of-life, contact the manufacturer or an authorized e-waste recycler for proper decommissioning and recycling of the instrument to comply with WEEE (Waste Electrical and Electronic Equipment) directives or equivalent local regulations.

Training and User Authorization

Only trained and authorized personnel may operate the UV-Vis spectrophotometer. Conduct initial and periodic refresher training covering instrument operation, safety procedures, sample handling, and emergency shutdown. Maintain training records with signatures and dates. Implement user access controls if the instrument includes software with audit trail functionality (e.g., in regulated environments).

Calibration and Performance Verification

Perform initial calibration upon installation and schedule regular performance verification using traceable standards (e.g., holmium oxide or didymium filters for wavelength accuracy, neutral density filters for photometric accuracy). Frequency should align with manufacturer guidelines and quality system requirements (e.g., annually or semi-annually). Document all calibration results and corrective actions in the instrument logbook or electronic quality management system.

Conclusion for Sourcing a UV-Vis Spectroscopy Machine

After a thorough evaluation of technical specifications, application requirements, budget constraints, and supplier reliability, sourcing a UV-Vis spectroscopy machine is a strategic investment that will significantly enhance our analytical capabilities. The selected instrument offers reliable performance, high accuracy, and essential features such as a wide wavelength range, high resolution, user-friendly software, and compliance with regulatory standards, making it well-suited for our routine quality control, research, and development activities.

Additionally, considerations such as after-sales support, warranty coverage, calibration services, and ease of maintenance have been factored into the decision to ensure long-term operational efficiency. The chosen supplier demonstrates strong technical expertise and responsiveness, further reinforcing confidence in the procurement decision.

In conclusion, acquiring this UV-Vis spectrophotometer aligns with our organization’s goals of improving analytical precision, ensuring product quality, and supporting innovation. It represents a cost-effective and future-ready solution that will serve as a vital tool in our laboratory for years to come.