The global PVC pipe market is experiencing robust growth, driven by increasing demand across infrastructure, agriculture, and water management sectors. According to Mordor Intelligence, the global PVC pipe market was valued at USD 54.7 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029, reaching an estimated USD 76.3 billion by 2029. A key factor fueling this expansion is the rising need for durable, corrosion-resistant piping solutions—particularly UV-resistant PVC pipes, which offer enhanced longevity when exposed to outdoor conditions. With urbanization accelerating and governments investing heavily in water supply and irrigation projects, manufacturers are focusing on advanced formulations that improve UV stability and mechanical strength. As demand surges, especially in regions like Asia-Pacific and the Middle East, identifying reliable producers of UV-resistant PVC pipes has become critical for project efficiency and lifecycle performance. Here are the top 9 manufacturers leading innovation and quality in this space.

Top 9 Uv Resistant Pvc Pipe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Schedule 40 UV Light Resistant

Domain Est. 1998

Website: clearpvcpipe.com

Key Highlights: A clear UV resistant PVC piping that is suitable for exposure to sunlight. Unique UV blocking technology reduces harmful ultraviolet light wavelengths….

#2 IPEX Inc.

Domain Est. 2009

Website: ipexna.com

Key Highlights: IPEX Inc. manufactures advanced PVC & CPVC piping systems for several applications for the Canadian market. Learn more….

#3 PVC Pipe UV Resistant 3/4 in. x 20 ft. Schedule 40 Bell End

Domain Est. 1995

Website: siteone.com

Key Highlights: Pacific Plastics IPS Schedule series of PVC pipe is produced for use in above ground applications in which the maximum operating temperature is 140 Degree ……

#4 Plumbing systems

Domain Est. 1996

Website: rehau.com

Key Highlights: Up to 1-year UV resistance with RAUPEX UV shield pipe, best in class for PEX pipe; EVERLOC+ compression-sleeve fittings have four sealing edges for leak-free ……

#5 PVC Schedule 40 Pressure Pipe & Fittings

Domain Est. 1997

Website: charlottepipe.com

Key Highlights: PVC schedule 40 is highly durable, with high-tensile and high-impact strength. It is easy to install and has better sound-deadening qualities than PVC schedule ……

#6 GF Industry and Infrastructure Flow Solutions

Domain Est. 2001

Website: gfps.com

Key Highlights: See the difference a corrosion-free drainage system can make, providing low maintenance, weight savings and extended life, all within our paint-free UV ……

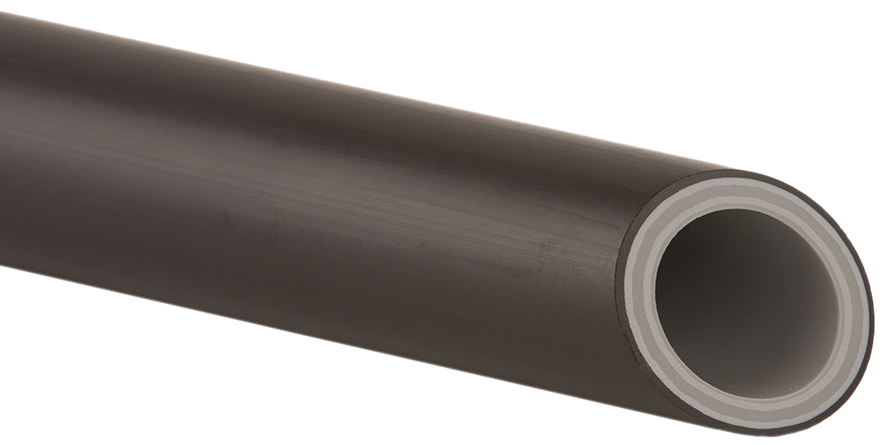

#7 UV resistant PP

Domain Est. 2002

Website: polymelt.com

Key Highlights: Our UV resistant plastic pipes and fittings are designed to withstand continuous exposure to sunlight, and will not rust, calcify, corrode, or crumble over time ……

#8 What are the effects of ultraviolet light on JM Eagle’s PVC Pipes?

Domain Est. 2007

Website: jmeagle.com

Key Highlights: It has been determined that ultraviolet degradation will not have significant adverse effects on the mechanical properties of underground formulated PVC pipe….

#9 uv resistant pvc pipe

Domain Est. 2018

Website: phtopindustry.com

Key Highlights: The UV-resistant PVC pipe can resist long-term exposure to ultraviolet rays without performance degradation and material aging through special anti-UV treatment ……

Expert Sourcing Insights for Uv Resistant Pvc Pipe

H2: 2026 Market Trends for UV-Resistant PVC Pipe

The global market for UV-resistant PVC pipe is poised for significant transformation by 2026, driven by technological advancements, growing demand in infrastructure and agriculture, and increasing awareness of material durability. The following analysis outlines key trends shaping the UV-resistant PVC pipe market in the near future.

1. Rising Demand in Construction and Infrastructure

By 2026, the construction and municipal infrastructure sectors are expected to remain primary drivers of UV-resistant PVC pipe adoption. Governments worldwide are investing heavily in water supply, sewage systems, and stormwater management, particularly in emerging economies. UV-stabilized PVC pipes offer extended service life when exposed to sunlight, making them ideal for outdoor applications. This durability reduces maintenance costs and supports long-term sustainability goals.

2. Expansion in Agricultural Irrigation

The agricultural sector is increasingly adopting UV-resistant PVC pipes for drip and sprinkler irrigation systems, especially in regions with high solar exposure such as Africa, the Middle East, and parts of South Asia. Climate change and water scarcity are pushing farmers to adopt efficient irrigation methods, where UV-resistant PVC piping ensures reliable performance over time without degradation from sun exposure.

3. Technological Innovations in Material Science

Ongoing R&D efforts are focused on enhancing the UV resistance of PVC through advanced stabilizers, such as nano-composite additives and hybrid polymer blends. By 2026, manufacturers are expected to launch next-generation UV-resistant PVC pipes with improved thermal stability, impact strength, and longer lifespans—some exceeding 50 years under direct sunlight. These innovations will differentiate products in a competitive market and open new application areas.

4. Regulatory and Environmental Pressures

Environmental regulations are increasingly influencing material choices in piping systems. The shift toward recyclable and low-carbon footprint materials benefits PVC, which is recyclable and energy-efficient to produce. However, concerns over plastic waste are prompting manufacturers to develop eco-friendly UV stabilizers and promote closed-loop recycling systems. By 2026, compliance with green building standards like LEED and BREEAM will be a competitive advantage for UV-resistant PVC pipe suppliers.

5. Regional Market Dynamics

Asia-Pacific is projected to lead global demand for UV-resistant PVC pipes by 2026, fueled by rapid urbanization in India, China, and Southeast Asia. North America and Europe will see steady growth due to infrastructure renewal projects and the adoption of smart water management systems. Meanwhile, the Middle East and Africa offer high-growth potential, particularly in solar-intensive environments where UV resistance is a critical performance factor.

6. Competitive Landscape and Strategic Alliances

The market is becoming increasingly consolidated, with key players such as JM Eagle, Uponor, and Advanced Drainage Systems investing in production capacity and distribution networks. Strategic partnerships with chemical suppliers for proprietary UV stabilizers and collaborations with engineering firms for custom solutions are expected to intensify by 2026. Smaller manufacturers may focus on niche markets, including custom diameters and specialty applications.

7. Price Volatility and Supply Chain Resilience

Fluctuations in raw material prices, particularly vinyl chloride monomer (VCM) and titanium dioxide (used in UV protection), may impact profitability. By 2026, leading companies are likely to adopt vertical integration and long-term supply contracts to mitigate risks. Additionally, regional manufacturing hubs will gain importance to reduce logistics costs and improve supply chain responsiveness.

Conclusion

By 2026, the UV-resistant PVC pipe market will be shaped by a confluence of infrastructural demand, material innovation, and environmental considerations. Companies that invest in R&D, sustainability, and regional market penetration will be best positioned to capitalize on emerging opportunities. As climate resilience becomes a priority, UV-resistant PVC pipes are set to play a critical role in building durable, cost-effective, and sustainable fluid transportation systems worldwide.

Common Pitfalls When Sourcing UV-Resistant PVC Pipe: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for UV Resistant PVC Pipe

Overview

UV resistant PVC (polyvinyl chloride) pipe is engineered to withstand prolonged exposure to ultraviolet (UV) radiation from sunlight, making it suitable for outdoor applications such as irrigation, plumbing, and drainage systems. This guide outlines key logistics considerations and compliance requirements for handling, storing, transporting, and using UV resistant PVC pipe in accordance with industry standards and regulatory frameworks.

Material Specifications and Standards

UV resistant PVC pipes are manufactured in compliance with various international and national standards to ensure performance and safety. Common standards include:

- ASTM D1785: Standard specification for polyvinyl chloride (PVC) plastic pipe, schedules 40, 80, and 120.

- ASTM F441/F441M: Standard specification for chlorinated poly(vinyl chloride) (CPVC) plastic pipe, schedule 40 and 80, with UV resistance requirements.

- ISO 1452: Plastics piping systems for water supply and for drainage and sewerage under pressure — Unplasticized poly(vinyl chloride) (PVC-U).

- NSF/ANSI 14 and NSF/ANSI 61: Certifications for material safety and suitability for potable water applications.

Ensure that all UV resistant PVC pipes are clearly labeled with compliance markings, including material type, pressure rating, size, manufacturer information, and relevant standard certifications.

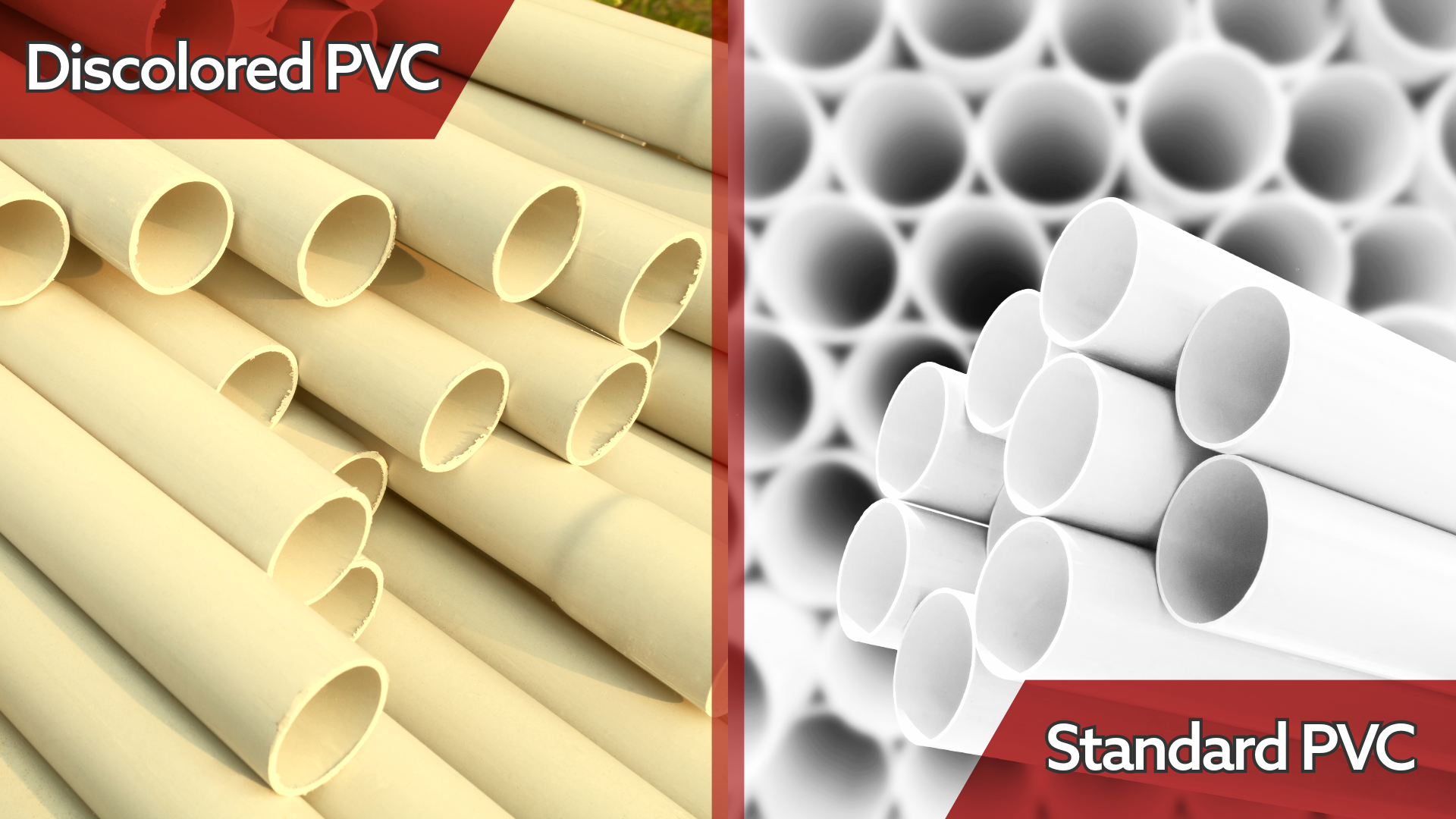

UV Resistance Properties

UV resistant PVC pipes contain additives such as titanium dioxide or carbon black to inhibit degradation from prolonged sun exposure. These additives prevent embrittlement, discoloration, and loss of mechanical strength. Verify that the UV stabilization meets the manufacturer’s specifications and is suitable for the intended climate and exposure duration.

Packaging and Handling

Packaging Requirements

- Pipes should be bundled securely using UV-resistant strapping or banding.

- End caps or protective covers are recommended to prevent damage to pipe ends.

- Bundles should be labeled with product specifications, batch number, compliance marks, and handling instructions.

Handling Guidelines

- Use proper lifting equipment (e.g., forklifts with wide forks or slings) to avoid deformation.

- Avoid dragging pipes across rough surfaces to prevent scratches and gouges.

- Handle with care to prevent impact damage, which can compromise structural integrity.

Storage Conditions

Indoor Storage (Preferred)

- Store in a cool, dry, and well-ventilated area away from direct sunlight, even if the pipe is UV resistant.

- Keep away from heat sources and flammable materials.

- Stack horizontally on flat, level surfaces using cradles or skids to prevent warping.

- Limit stack height to prevent bottom pipes from being crushed (typically no more than 1.5 meters or as recommended by the manufacturer).

Outdoor Storage (If Necessary)

- Cover with opaque, UV-stable tarpaulins to reduce UV exposure.

- Elevate bundles off the ground using wooden skids to prevent moisture absorption and ground contact.

- Avoid long-term outdoor storage; limit exposure to less than 6 months unless otherwise specified by the manufacturer.

Transportation

Loading and Securing

- Load pipes evenly to distribute weight and prevent overhang.

- Secure bundles using straps or chains to avoid shifting during transit.

- Use edge protectors on straps to prevent damage to pipe surfaces.

- Avoid sharp bends or kinks during loading.

Environmental Protection

- Shield pipes from extreme weather conditions (e.g., excessive heat, rain, snow).

- Ensure vehicles are covered or tarped when transporting outdoors.

International Shipping Considerations

- Comply with International Maritime Dangerous Goods (IMDG) Code — PVC is non-hazardous but must be properly packaged.

- Provide accurate Harmonized System (HS) Code (e.g., 3917.32 for rigid PVC pipes) for customs clearance.

- Include Material Safety Data Sheets (MSDS/SDS) and certificates of compliance (e.g., ISO, NSF, ASTM) in shipping documentation.

Regulatory and Compliance Requirements

Environmental Regulations

- PVC production and disposal may be subject to regulations under REACH (EU) and TSCA (USA). Ensure manufacturer compliance with chemical substance reporting.

- Avoid open burning of PVC waste due to dioxin emissions.

Building and Plumbing Codes

- Confirm local code acceptance (e.g., IPC – International Plumbing Code, UPC – Uniform Plumbing Code).

- Use only UV resistant PVC in outdoor or exposed applications per code requirements.

Import/Export Compliance

- Verify country-specific import regulations (e.g., CE marking for EU, WRAS approval for UK, UPC listing for North America).

- Some regions require third-party certification for potable water applications.

Quality Assurance and Documentation

- Maintain traceability of batches through documentation.

- Conduct visual inspections upon receipt to check for damage, deformation, or weathering.

- Retain compliance certificates, test reports, and warranty information.

Disposal and Recycling

- PVC is recyclable (Resin Identification Code 3).

- Follow local waste management regulations for disposal.

- Partner with certified recyclers to ensure environmentally responsible end-of-life management.

Conclusion

Proper logistics and compliance practices are essential for maintaining the quality and safety of UV resistant PVC pipe throughout its lifecycle. Adherence to handling, storage, transportation, and regulatory standards ensures optimal performance in field applications and helps avoid liability, product failure, or environmental harm. Always consult manufacturer guidelines and local regulations when in doubt.

Conclusion for Sourcing UV-Resistant PVC Pipe:

When sourcing UV-resistant PVC pipe, it is essential to prioritize materials specifically formulated to withstand prolonged exposure to sunlight. Standard PVC pipes degrade quickly when exposed to UV radiation, leading to brittleness, discoloration, and reduced structural integrity. Therefore, selecting PVC pipes with built-in UV stabilizers or protective coatings ensures long-term durability, especially for outdoor applications such as irrigation systems, outdoor plumbing, and construction projects.

Key considerations when sourcing include verifying manufacturer specifications for UV resistance, checking compliance with relevant standards (such as ASTM D1785 or NSF certifications), and ensuring proper labeling indicating outdoor suitability. Additionally, sourcing from reputable suppliers who provide technical data sheets and warranties enhances confidence in product performance.

In conclusion, investing in certified UV-resistant PVC pipe may involve a higher initial cost, but it significantly reduces maintenance, replacement, and failure risks over time. This makes it a cost-effective and reliable choice for any outdoor or sun-exposed installation.