The global UV printing market is experiencing robust expansion, driven by increasing demand for sustainable, high-speed, and versatile printing solutions across industries such as packaging, signage, and décor. According to Grand View Research, the global UV printing market size was valued at USD 18.4 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. This surge is fueled by the adoption of eco-friendly inks, stricter environmental regulations, and the superior performance of UV-curable technologies—including instant curing, enhanced durability, and compatibility with a wide range of substrates. As digital printing continues to evolve, UV technology stands out for its energy efficiency and reduced volatile organic compound (VOC) emissions. In this competitive landscape, a select group of manufacturers are leading innovation, scaling production capabilities, and shaping the future of industrial and commercial printing. Below are the top 10 UV printing manufacturers driving this transformation.

Top 10 Uv In Printing Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 DOCAN UV Inkjet Printer

Website: docanuv.com

Key Highlights: Specializing in industrial-grade UV printing solutions, providing high-quality, high-efficiency printing equipment and comprehensive technical support. Printer ……

#2 EUV lithography systems – Products

Website: asml.com

Key Highlights: ASML’s deep ultraviolet (DUV) lithography systems dive deep into the UV spectrum to print the tiny features that form the basis of the microchip. Technology….

#3 Packaging Solutions

Website: utprinting.com

Key Highlights: Ultra-Tech provides UV flexo printing technology and product packaging solutions in the CPG, medical, automotive, food & beverage industries….

#4 powerful UV curing solutions of highest quality

Website: ist-uv.com

Key Highlights: As one of the world’s leading suppliers we develop, manufacture and distribute drying & UV curing systems for the graphic arts and industrial applications….

#5 Sun Chemical

Website: sunchemical.com

Key Highlights: Sun Chemical develops a wide range of pigments and color materials for architectural, automotive and industrial coatings, cosmetics, plastics, printing inks, ……

#6 PRINT UV

Website: printuv.com

Key Highlights: The Print UV Conference is the premier all-in-one conference event for leaders in the global UV printing industry, and the ONLY conference dedicated to UV and ……

#7 swissQprint

Website: swissqprint.com

Key Highlights: We develop and build large-format UV-LED printers with passion. 100% made in Switzerland. Perform beyond the average. About us · Your local partner ……

#8 UV Printing Services

Website: trelleborg.com

Key Highlights: Trelleborg Engineered Coated Fabrics is pleased to offer on-site UV Printing services to make your next development stand out form the crowd….

#9 Pressroom Supplies

Website: fujifilm.com

Key Highlights: Pressroom Supplies – Blankets – UV & LED UV. An offset printing blanket defines lithography and our quality partners deliver definition….

#10 UVEXS INC

Website: uvexs.com

Key Highlights: UVEXS designs and manufactures a wide range of UV cured products. Including Inks, coatings and adhesives. Formulated to bond to various substrate types….

Expert Sourcing Insights for Uv In Printing

2026 Market Trends for UV in Printing

The ultraviolet (UV) curing technology sector within the printing industry is poised for significant evolution by 2026, driven by technological advancements, shifting market demands, and increasing environmental consciousness. Here are the key trends expected to shape the UV printing landscape in 2026:

Rising Demand for Sustainability and Low-VOC Solutions

Environmental regulations and consumer preference for eco-friendly products are accelerating the shift toward sustainable printing practices. UV printing, particularly UV-LED technology, offers a compelling advantage with near-zero volatile organic compound (VOC) emissions compared to traditional solvent-based inks. By 2026, stricter global emissions standards—especially in Europe and North America—are expected to push more print service providers to adopt UV-LED systems. This transition will be supported by growing corporate sustainability goals and green certifications, making low-VOC UV printing a compliance necessity as much as a competitive differentiator.

Expansion of UV-LED Technology Adoption

UV-LED curing is set to dominate the market by 2026 due to its energy efficiency, reduced heat output, longer lamp life, and lower maintenance costs. As LED technology continues to improve in power output and reliability, it will increasingly replace traditional mercury-vapor UV systems across a broader range of applications, including narrow-web, packaging, and industrial printing. The declining cost of UV-LED components will further democratize access, enabling small and mid-sized printers to integrate this technology. By 2026, UV-LED is expected to represent over 60% of new UV curing installations in commercial printing sectors.

Growth in Functional and Industrial Printing Applications

Beyond traditional graphic arts, UV printing is expanding into functional and industrial applications such as printed electronics, 3D printing, and smart packaging. UV-curable inks are ideal for depositing conductive traces, protective coatings, and textured finishes with high precision and durability. By 2026, demand will surge in sectors like automotive, medical devices, and consumer electronics, where UV printing enables rapid prototyping, on-demand manufacturing, and customization. This diversification will open high-margin opportunities for UV ink and equipment manufacturers.

Integration with Digital and Hybrid Workflows

Digital printing, especially inkjet, continues to grow, and UV-curable inks are a natural fit for industrial and wide-format digital presses. By 2026, seamless integration of UV inkjet into hybrid and fully digital production lines will become standard, enabling on-demand, short-run, and mass customization capabilities. Advances in software for color management, workflow automation, and real-time curing control will enhance productivity and consistency. The convergence of UV curing with digital printing platforms will drive innovation in smart factories and Industry 4.0 environments.

Innovation in Ink Formulations and Substrate Compatibility

To meet the demands of diverse applications, ink manufacturers are developing next-generation UV formulations with improved adhesion, flexibility, and environmental performance. By 2026, expect wider adoption of bio-based monomers and oligomers, water-assisted UV systems (hybrid UV-waterborne), and inks compatible with challenging substrates like recycled plastics, bioplastics, and flexible films. These innovations will expand the application scope of UV printing in sustainable packaging and reduce dependency on petroleum-based raw materials.

Regional Market Diversification and Competitive Landscape

While North America and Europe remain strong markets for UV printing due to regulatory and environmental drivers, Asia-Pacific—particularly China, India, and Southeast Asia—is projected to experience the fastest growth by 2026. Increasing industrialization, rising packaging demand, and government support for green manufacturing will fuel adoption in this region. The competitive landscape will intensify, with local manufacturers offering cost-effective UV solutions and global players focusing on innovation and premium applications.

In conclusion, the 2026 UV printing market will be characterized by a strong emphasis on sustainability, technological convergence, and diversification into high-value industrial applications. Companies that invest in UV-LED infrastructure, eco-friendly inks, and digital integration will be best positioned to capitalize on these emerging opportunities.

Common Pitfalls in Sourcing UV Printing Services (Quality, IP)

When outsourcing UV printing, businesses often face significant challenges related to print quality and intellectual property (IP) protection. Being aware of these pitfalls is essential to ensure consistent results and safeguard your brand assets.

Inconsistent Print Quality

One of the most frequent issues in UV printing is variability in output quality. Factors such as improper ink curing, substrate incompatibility, and poorly maintained equipment can lead to smudging, cracking, or uneven finishes. Additionally, not all UV printers offer the same resolution or color accuracy, which can result in colors appearing dull or misaligned, especially in complex designs. Without clear quality benchmarks and thorough vendor vetting, the final product may fall short of expectations.

Poor Material and Ink Compatibility

UV inks bond differently depending on the substrate—plastics, glass, metal, or coated materials may react unpredictably. Sourcing from providers unfamiliar with specific material requirements can result in poor adhesion, fading, or delamination over time. This mismatch not only affects durability but also undermines the professional appearance of printed items.

Lack of Intellectual Property Protection

When sharing design files for UV printing, especially with overseas or third-party vendors, there is a heightened risk of IP theft or unauthorized reproduction. Many suppliers operate without robust confidentiality agreements or digital security measures, making it easy for designs to be copied or resold. This is particularly concerning for proprietary packaging, limited-edition products, or patented designs.

Inadequate Proofing and Approval Processes

Skipping or rushing the proofing stage can lead to costly errors. Without physical or digital proofs that accurately represent the final UV print—including texture, gloss level, and color—clients may receive products that differ significantly from the intended design. A reliable sourcing partner should offer structured approval workflows to minimize such risks.

Hidden Costs and Minimum Order Constraints

Some UV printing vendors advertise low prices but include hidden fees for setup, color matching, or custom tooling. Additionally, minimum order quantities (MOQs) may not align with your production needs, forcing overproduction or inflated costs. Transparency in pricing and flexibility in order size are crucial when evaluating potential suppliers.

By addressing these pitfalls proactively—through due diligence, clear contracts, and strong IP safeguards—you can ensure high-quality UV printing outcomes while protecting your creative and commercial interests.

Logistics & Compliance Guide for UV Printing

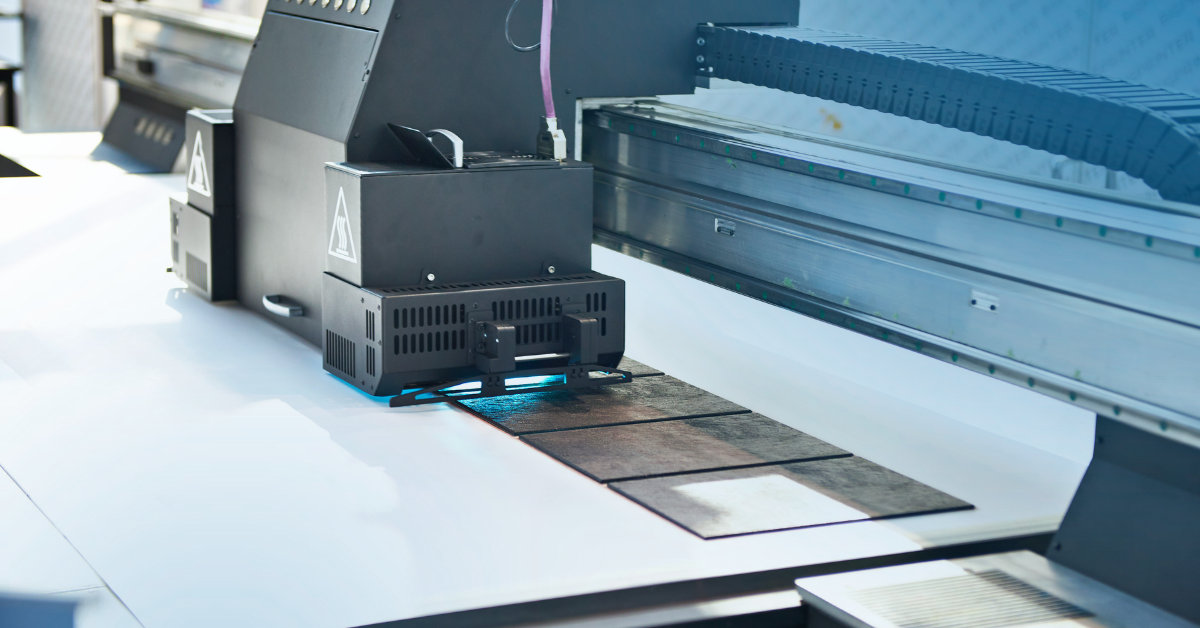

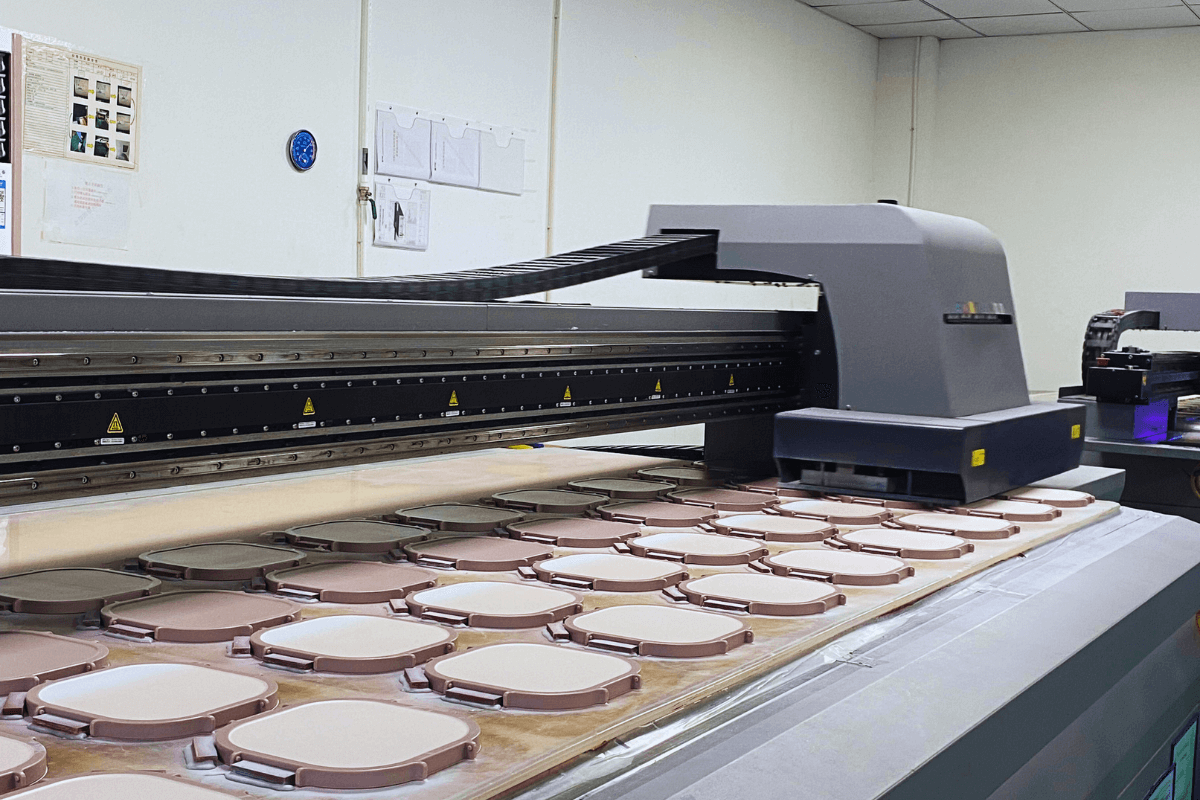

Overview of UV Printing Technology

UV (ultraviolet) printing is a digital printing method that uses ultraviolet lights to cure or dry ink as it is applied to a substrate. This technology allows for fast production, high durability, and the ability to print on a wide variety of materials, including plastics, glass, metal, and wood. Due to its efficiency and versatility, UV printing is widely used in packaging, signage, industrial labeling, and promotional products.

Regulatory Compliance Requirements

UV printing operations must adhere to several regulatory standards, depending on the region and application. Key compliance areas include:

Environmental Regulations

UV inks contain photoinitiators and oligomers that can pose environmental risks if not managed properly. Compliance with local environmental protection agencies (e.g., EPA in the U.S. or REACH in the EU) is essential. Facilities must ensure proper disposal of waste materials and manage emissions from curing processes.

Health and Safety Standards

The UV curing process emits ozone and volatile organic compounds (VOCs), requiring adequate ventilation and air filtration systems. Operators must be protected from UV radiation exposure through shielding and personal protective equipment (PPE). Compliance with OSHA (U.S.) or equivalent occupational safety authorities is mandatory.

Chemical Handling and Storage

UV inks and cleaning solvents are classified as hazardous materials. Facilities must follow guidelines under GHS (Globally Harmonized System) for labeling, safety data sheets (SDS), and safe storage practices. Flammable materials should be stored in approved containers and areas.

Transportation and Shipping Considerations

When shipping UV printed goods or raw materials (inks, substrates), logistics must comply with transportation safety regulations:

Hazardous Materials Classification

Some UV inks may be classified as hazardous for transport under regulations such as IATA (air), IMDG (sea), or 49 CFR (U.S. ground). Proper classification, packaging, labeling, and documentation (e.g., shipping manifests, SDS) are required.

Packaging and Protection

UV printed products, especially on rigid substrates, must be packaged to prevent scratching, cracking, or exposure to moisture. Use of anti-static materials may be necessary depending on the application.

Temperature and Environmental Control

Avoid exposing UV printed materials or inks to extreme temperatures during transit, as this can affect ink adhesion and material integrity. Climate-controlled transport may be necessary for sensitive substrates.

Documentation and Traceability

Maintain accurate records to support compliance and quality control:

- Batch tracking of inks and substrates

- Safety Data Sheets (SDS) for all chemicals on-site

- Compliance certifications (e.g., ISO 14001, OHSAS 18001)

- Customer-specific requirements for regulated industries (e.g., food packaging, medical devices)

Sustainable Practices and Waste Management

Sustainability is increasingly important in UV printing:

- Use of low-migration or bio-based UV inks where possible

- Recycling of substrates and containers

- Implementation of closed-loop systems for ink and solvent recovery

- Energy-efficient UV-LED curing systems to reduce power consumption and heat output

Conclusion

Successfully managing logistics and compliance in UV printing requires a proactive approach to regulatory requirements, chemical safety, and sustainable operations. By adhering to industry standards and maintaining thorough documentation, businesses can ensure safe, efficient, and legally compliant UV printing processes.

In conclusion, sourcing UV (ultraviolet) printing technology or services involves careful consideration of equipment, ink, substrates, and vendor reliability. UV printing offers significant advantages such as fast curing times, durability, eco-friendliness due to low VOC emissions, and the ability to print on a wide range of materials. When sourcing UV printing solutions, businesses should evaluate suppliers based on technical support, cost-effectiveness, compatibility with existing workflows, and the quality of UV inks and curing systems. Additionally, selecting certified and reputable manufacturers ensures long-term performance and compliance with environmental and safety standards. Ultimately, a well-informed sourcing strategy for UV printing can enhance productivity, reduce operational costs, and support sustainable printing practices, making it a valuable investment for modern print operations.