The global laser welding market is experiencing robust growth, driven by rising demand for precision manufacturing in automotive, aerospace, and electronics industries. According to Mordor Intelligence, the laser welding market was valued at USD 4.5 billion in 2023 and is projected to grow at a CAGR of over 7.5% from 2024 to 2029. This expansion is fueled by the increasing adoption of fiber laser technology and the shift toward automated production systems. As manufacturers seek cost-effective and high-performance solutions, the demand for used industrial laser welders has surged, offering scalable options without sacrificing quality. In this landscape, several manufacturers have emerged as leaders, providing reliable, refurbished systems that maintain high standards of efficiency and durability. The following list highlights the top nine manufacturers whose used laser welders are frequently sought after in the secondary market, based on market presence, technological innovation, and user-reported performance metrics.

Top 9 Used Laser Welders For Sale Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 New Fiber Laser Welders For Sale

Website: pioneermachinesales.com

Key Highlights: Discover a wide range of new Fiber Laser Welders from Pioneer Machine Sales Inc.. Choose from brands like IPG and more. Explore our extensive inventory and ……

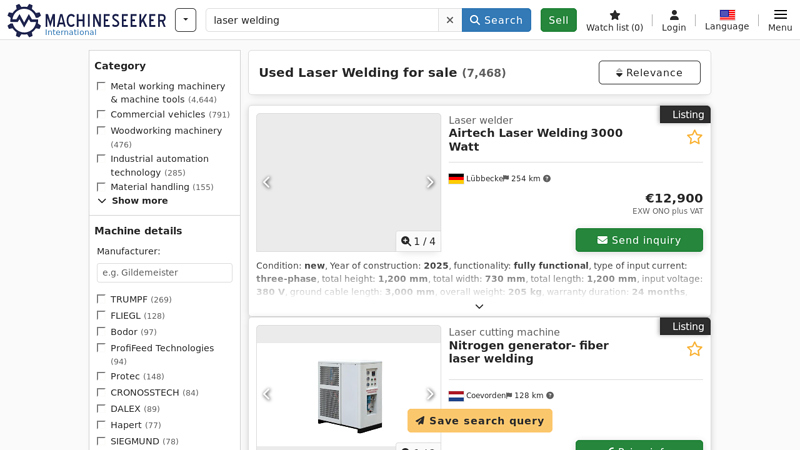

#2 Used Laser Welding for sale on Machineseeker.com

Website: machineseeker.com

Key Highlights: Used Laser Welding for sale on Machineseeker.com ✔️ great brands & offers available now ✔️ buy or sell Laser Welding on Machineseeker in the USA….

#3 B&D Sales and Service

Website: bdsales.com

Key Highlights: Welcome to B&D Sales and Service! We are the leading supplier of laser welders. We have laser welders for every need from jewelry repair to dental and ……

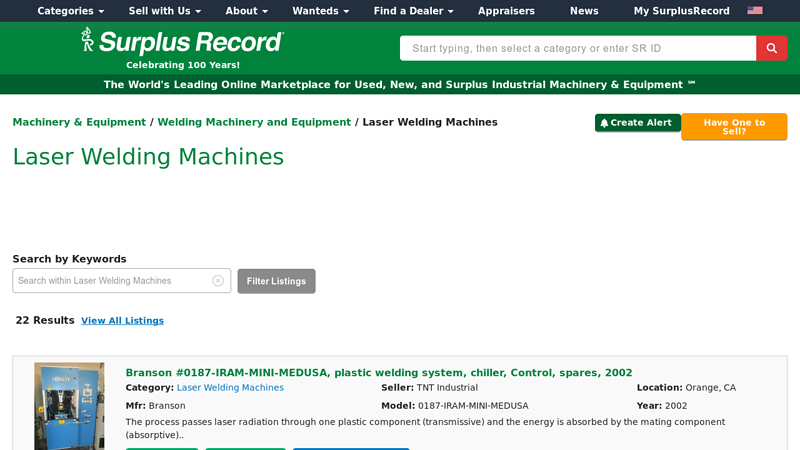

#4 Used Laser Welding Machines For Sale

Website: surplusrecord.com

Key Highlights: Find new and used Laser Welding Machines for sale from suppliers near you. Ipg, Trumpf, Branson and more….

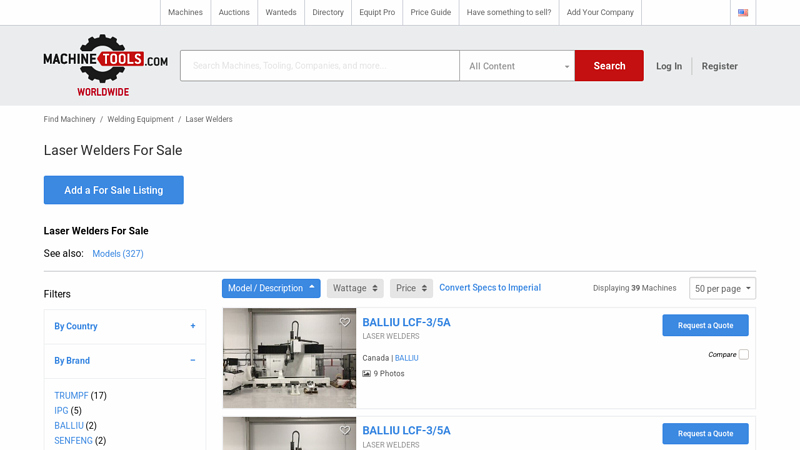

#5 Laser Welders for sale listings

Website: machinetools.com

Key Highlights: Welding Equipment – Laser Welders for sale listings – We have 38 listings for Laser Welders listed below. Find items by using the following search options….

#6 Laser Welders

Website: awisco.com

Key Highlights: STINGER 1500 LASER WELDER USED. LONE STAR CUTTING SOLUTIONS · STINGER 1500 LASER WELDER USED. Item Code: LONRAYEDGE1500CO. 11 Locations: 1 EA In-Stock. Category ……

#7 Fanuci & Falcon

Website: fanuci-falcon.com

Key Highlights: We offer, among others, laser welders, cleaning lasers, laser cutters for pipes, profiles, and sheet metal, nitrogen generators, and 3D laser printers for ……

#8 Full Spectrum Laser

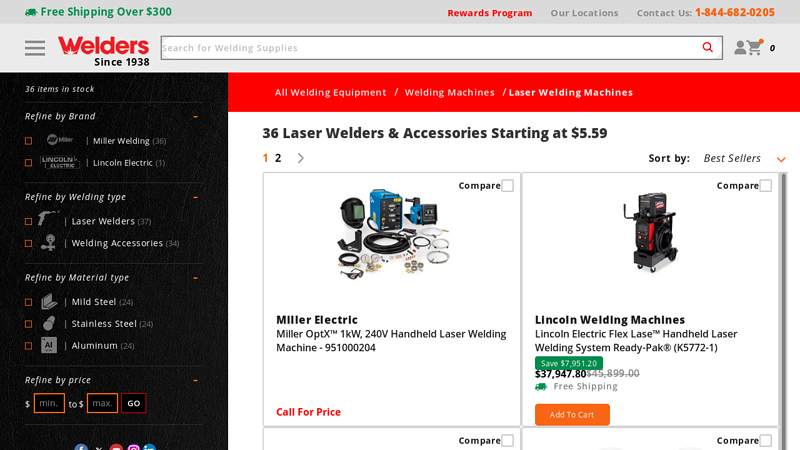

#9 36 Laser Welders & Accessories for sale from $5.59

Website: weldersupply.com

Key Highlights: Free delivery over $300 · 14-day returnsBuy portable laser welders for on-the-go repairs & projects. High precision, fast welding speeds. Shop now & get fast, free shipping over $…

Expert Sourcing Insights for Used Laser Welders For Sale

H2: 2026 Market Trends for Used Laser Welders For Sale

The market for used laser welders is poised for notable transformation by 2026, driven by evolving industrial demands, technological advancements, and sustainability initiatives. As companies across manufacturing, automotive, aerospace, and electronics sectors seek cost-effective and efficient production solutions, the demand for pre-owned laser welding systems is expected to grow steadily. Below are key trends shaping the 2026 landscape for used laser welders for sale:

-

Increased Demand for Cost-Effective Automation

With rising pressure to reduce operational costs and maintain competitiveness, small and medium-sized enterprises (SMEs) are increasingly turning to used laser welders as a budget-friendly entry into automated welding. These systems offer high precision and repeatability at a fraction of the cost of new models, making them attractive for businesses upgrading from manual or traditional welding processes. -

Advancements in Fiber Laser Technology

The widespread adoption of fiber laser technology in new systems has led to a growing influx of high-performance, second-hand fiber laser welders into the used market. By 2026, these models—once considered premium—are becoming more accessible as early adopters upgrade to newer versions. Used fiber laser welders now offer superior beam quality, energy efficiency, and lower maintenance costs compared to older CO2 or Nd:YAG systems. -

Rise of Refurbished Equipment Market

The 2026 market will see an expansion in certified refurbishment services, where used laser welders are professionally restored, updated with modern controls, and offered with warranties. This trend builds buyer confidence and blurs the performance gap between new and used machines, further fueling market growth. -

Sustainability and Circular Economy Influence

Environmental regulations and corporate sustainability goals are encouraging industries to adopt circular economy practices. Reusing and repurposing industrial equipment like laser welders aligns with these goals, reducing electronic waste and carbon footprint. As a result, procurement departments are more open to purchasing used equipment with verified performance records. -

Globalization of the Used Equipment Trade

Online marketplaces and industrial equipment platforms are making it easier to buy and sell used laser welders internationally. By 2026, emerging markets in Asia, Eastern Europe, and Latin America are expected to become major hubs for used laser welding systems, driven by industrialization and infrastructure development. -

Integration with Smart Manufacturing

Used laser welders are increasingly being retrofitted with IoT-enabled sensors and connectivity features to support Industry 4.0 initiatives. This allows older models to integrate into smart factories, offering real-time monitoring, predictive maintenance, and data analytics—enhancing their value in modern production environments. -

Supply-Demand Imbalance and Pricing Trends

As demand for laser welding grows—especially in electric vehicle (EV) battery manufacturing—the supply of used systems may tighten, particularly for high-power or specialized models. This could lead to moderate price increases in the used market by 2026, though they will likely remain significantly lower than new equipment.

In conclusion, the 2026 market for used laser welders for sale will be defined by technological accessibility, economic pragmatism, and environmental responsibility. Buyers will benefit from a more transparent, globalized, and service-oriented marketplace, making pre-owned laser welders a strategic choice for modern manufacturing needs.

Common Pitfalls When Sourcing Used Laser Welders (Quality & IP Concerns)

Purchasing a used laser welder can offer significant cost savings, but it comes with notable risks, especially regarding equipment quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial to making a safe and reliable investment.

Hidden Mechanical and Optical Degradation

Used laser welders often suffer from wear that isn’t immediately visible. Critical components such as laser optics (lenses, mirrors), focusing heads, and motion systems may be scratched, misaligned, or contaminated, leading to inconsistent weld quality and reduced beam efficiency. Cooling systems, power supplies, and control electronics may also degrade over time, increasing the risk of unexpected downtime or costly repairs post-purchase.

Lack of Maintenance and Service History

Many second-hand units come without comprehensive documentation or service records. Without proof of regular maintenance, calibration, or prior repairs, buyers cannot verify the machine’s reliability or remaining lifespan. This opacity makes it difficult to assess true operational readiness and exposes the buyer to potential hidden failures.

Outdated or Obsolete Technology

The laser welding industry evolves rapidly. Older models may use outdated control software, lack modern safety features, or be incompatible with current production requirements. Sourcing a machine with obsolete technology can lead to integration challenges, reduced productivity, and difficulty finding replacement parts or technical support.

Voided or Expired Warranties and Support

Used laser welders typically come with no manufacturer warranty. Even if the machine is functional at purchase, the absence of service support can be a major liability. OEMs may refuse to service equipment not under active agreement, leaving buyers dependent on third-party technicians who may lack specialized knowledge or access to proprietary components.

Intellectual Property (IP) Risks from Embedded Software

Many industrial laser systems contain proprietary software, firmware, or configuration files that may still be protected by IP rights. Purchasing a used machine with unlicensed or improperly transferred software can expose the buyer to legal risks, especially if the previous owner did not de-license or transfer rights properly. Unauthorized use of such software may violate licensing agreements or intellectual property laws.

Data Security and Residual Data Exposure

Laser welders often store production data, welding parameters, and operational logs. If the previous owner fails to securely wipe the system, sensitive information could remain accessible. This poses a data security risk, especially if the machine previously operated in a high-tech or competitive manufacturing environment.

Non-Compliance with Safety and Regulatory Standards

Used equipment may not meet current safety regulations (e.g., laser safety Class 1 enclosure requirements, CE, or OSHA standards). Upgrading or retrofitting to meet compliance can be expensive and time-consuming. Operating a non-compliant machine may result in workplace hazards, regulatory fines, or insurance complications.

Counterfeit or Unauthorized Modifications

Some used laser systems on the market may have been modified with counterfeit parts or unauthorized upgrades. These alterations can compromise performance, safety, and reliability. Additionally, such modifications may void any residual IP licenses or violate OEM terms, increasing liability for the new owner.

Inadequate Verification and Testing Before Purchase

Buyers often make the mistake of not conducting thorough on-site inspections or performance tests. Without witnessing the machine in operation or verifying beam quality, welding accuracy, and repeatability, it’s difficult to confirm it meets required specifications. Relying solely on seller claims increases the risk of acquiring underperforming or faulty equipment.

Supply Chain and Spare Parts Availability

Older or discontinued models may no longer have available spare parts or consumables. This can lead to extended downtime when repairs are needed. Buyers should verify parts availability and consider the long-term sustainability of maintaining the specific model before finalizing the purchase.

Logistics & Compliance Guide for Used Laser Welders For Sale

Understanding International Trade Regulations

When selling used laser welders across borders, compliance with international trade regulations is essential. These machines may be subject to export controls due to their advanced technology and potential dual-use applications (civilian and military). Sellers must determine whether the equipment falls under export control lists such as the Export Administration Regulations (EAR) in the United States or the EU Dual-Use Regulation. Classification under Harmonized System (HS) codes is required to determine tariffs and regulatory requirements in destination countries.

Export Documentation and Licensing

Proper documentation is critical for legal exportation. Required documents typically include a commercial invoice, bill of lading, packing list, and certificate of origin. In cases where the laser welder is classified as a controlled item, an export license may be required. This involves submitting an application to the relevant national authority—such as the U.S. Department of Commerce’s Bureau of Industry and Security (BIS). Failure to obtain necessary licenses can result in fines, shipment seizures, or legal penalties.

Laser Safety and Equipment Certification

Used laser welders must comply with safety standards such as the IEC 60825 (International Electrotechnical Commission) or FDA 21 CFR Part 1040.10 (in the U.S.). Before sale, ensure that the machine has valid laser safety certifications and includes required warning labels, interlocks, and protective enclosures. Buyers may require proof of compliance, especially in regions with strict occupational safety regulations such as the EU or Canada.

Packaging and Transportation Requirements

Used laser welders are heavy and sensitive to shock, moisture, and temperature fluctuations. They must be securely packaged using industrial-grade materials, including wooden crates with shock-absorbing padding. Proper lifting points and handling labels should be clearly marked. Transport via sea, air, or land must comply with International Maritime Dangerous Goods (IMDG) Code or IATA regulations if batteries or hazardous components are present.

Import Compliance in Destination Countries

Importing countries may impose additional compliance requirements, such as conformity assessment, local certification (e.g., CE marking in Europe, CCC in China), or electromagnetic compatibility (EMC) testing. Import duties, value-added tax (VAT), and customs clearance procedures vary by country. Engaging a licensed customs broker in the destination country helps ensure smooth entry and reduces the risk of delays.

Environmental and Waste Regulations

Used industrial equipment may contain components regulated under environmental laws, such as PCBs, lead, or refrigerants. Compliance with the Basel Convention is required when shipping equipment that could be considered electronic waste. Ensure that any hazardous materials are properly documented and handled to avoid violations during customs inspections or upon equipment decommissioning.

Warranty, Liability, and After-Sales Support

Selling used laser welders often involves offering limited warranties or as-is conditions. Clearly define terms of sale, including liability disclaimers and return policies. Providing technical documentation, maintenance history, and remote support can enhance buyer confidence and help meet compliance expectations in regulated markets.

Recordkeeping and Audit Readiness

Maintain detailed records of all transactions, including export licenses, safety certifications, shipping documents, and communications with buyers. These records must be retained for a minimum of five years in many jurisdictions and may be subject to audit by government agencies. Robust recordkeeping supports compliance and facilitates resolution of disputes or regulatory inquiries.

In conclusion, sourcing used laser welders for sale can be a cost-effective solution for businesses looking to adopt advanced welding technology without the high upfront investment of new equipment. However, it is essential to conduct thorough research, assess the reputation of the seller, and evaluate the machine’s condition, maintenance history, and technical specifications to ensure reliability and performance. Verifying compatibility with your production needs, requesting demonstrations, and checking for available warranties or post-purchase support are critical steps in the decision-making process. When approached carefully, purchasing a used laser welder can offer substantial savings while still delivering precision, efficiency, and durability in industrial applications.