The global automotive suspension components market is experiencing robust growth, driven by rising vehicle production, increasing demand for improved ride comfort, and the expansion of electric and commercial vehicle segments. According to Grand View Research, the global automotive suspension market was valued at USD 38.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030. A critical yet often overlooked component in this ecosystem is the upper strut mount, essential for reducing vibration, supporting the suspension system, and enhancing steering precision. With original equipment manufacturers (OEMs) and aftermarket suppliers increasingly focused on performance and durability, innovation among upper strut mount manufacturers has intensified. As the market expands, particularly in Asia-Pacific and North America, a select group of manufacturers are leading the charge in quality, engineering, and global reach—shaping the future of vehicle dynamics.

Top 7 Upper Strut Mount Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Suspension Strut Mounts

Domain Est. 1999

Website: anchor-online.com

Key Highlights: Anchor Industries Suspension Strut Mounts meet or exceed OEM standards, using premium elastomer rubber materials to ensure perfect fit and function….

#2 OEM Replacement Strut Mounts & Boots

Domain Est. 1995

Website: monroe.com

Key Highlights: A Strut-Mate mounting kit is a direct fit for the OE strut mount while a Strut-Mate boot kit is a direct fit OE replacement for a damaged jounce bumper or boot….

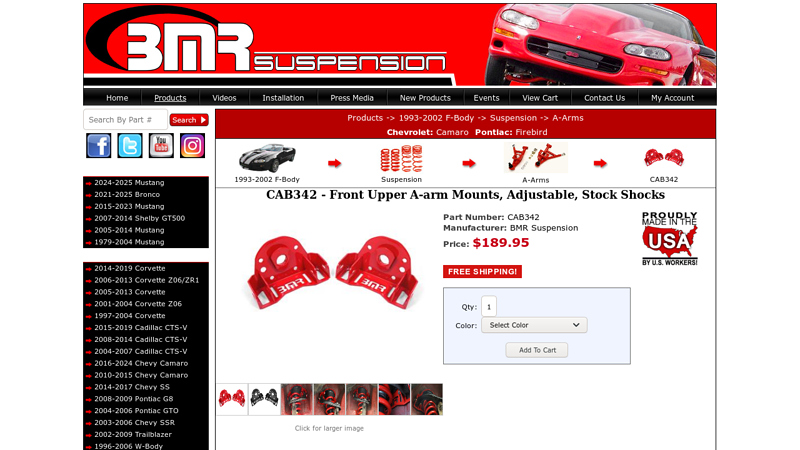

#3 CAB342

Domain Est. 2002

Website: bmrsuspension.com

Key Highlights: In stockFactory upper strut mounts are made from weak stamped steel. BMR’s Front Upper A-Arm Mount (CAB342) provides the strength needed for high performance and is ……

#4 Strut Mounts and Boots

Domain Est. 1996

Website: kyb.com

Key Highlights: KYB Strut Mounts optimize suspension and steering performance. Reduce suspension, road noises, and vibrations. Learn more and see our videos here….

#5 BILSTEIN Corporate

Domain Est. 1996

Website: bilstein.com

Key Highlights: At BILSTEIN, we manufacture high-quality shock absorbers and suspension systems. As an employer, we are as innovative as our technologies and as passionate ……

#6

Domain Est. 1996

Website: gabriel.com

Key Highlights: Visit our easy-to-use dealer locator to find a Gabriel dealer today! From ReadyMount Complete Strut Assemblies all the way to FleetLine & GasSLX Heavy Duty ……

#7 Homepage • STRUT

Domain Est. 2013

Website: strutlife.com

Key Highlights: STRUT represents boldness and expert craftsmanship, transforming refined vehicles into masterpieces of uniqueness and elegance….

Expert Sourcing Insights for Upper Strut Mount

H2: Projected Market Trends for Upper Strut Mounts in 2026

The global market for upper strut mounts is poised for significant transformation by 2026, driven by advancements in vehicle technology, rising demand for enhanced ride comfort, and the expansion of electric and autonomous vehicles. As a critical component of automotive suspension systems, the upper strut mount plays a vital role in noise, vibration, and harshness (NVH) reduction, contributing directly to improved driving dynamics and passenger comfort.

One of the key market drivers by 2026 will be the growing production of electric vehicles (EVs). Unlike internal combustion engine (ICE) vehicles, EVs emphasize quiet operation and smooth ride quality, increasing the demand for high-performance upper strut mounts with superior NVH insulation. Manufacturers are responding by developing advanced elastomeric and hybrid materials that offer better durability and noise dampening under diverse operating conditions.

Additionally, the push toward lightweight vehicle design to improve fuel efficiency and extend EV range is influencing material innovation in strut mounts. By 2026, there will be a notable shift toward composite and aluminum-based upper strut mounts, reducing unsprung mass without compromising structural integrity.

Regional trends also indicate strong growth in Asia-Pacific, particularly in China, India, and Southeast Asia, due to expanding automotive production and increasing consumer demand for premium ride experiences. Meanwhile, North America and Europe are expected to lead in adopting smart suspension technologies, integrating sensors and adaptive damping systems where upper strut mounts may incorporate intelligent materials or monitoring capabilities.

Supply chain optimization and sustainability concerns will further shape the market. By 2026, leading suppliers are anticipated to adopt circular economy principles—using recyclable materials and improving manufacturing efficiency—to meet stringent environmental regulations and OEM sustainability targets.

In summary, the upper strut mount market in 2026 will be characterized by technological innovation, material advancements, and a strategic alignment with electrification and smart mobility trends, positioning it as a crucial element in next-generation vehicle suspension systems.

Common Pitfalls Sourcing Upper Strut Mounts (Quality, IP)

When sourcing upper strut mounts—critical components in a vehicle’s suspension system—overlooking key quality and intellectual property (IP) concerns can lead to significant performance, safety, and legal issues. Below are common pitfalls to avoid:

1. Prioritizing Cost Over Quality

Many buyers focus solely on price, leading to the selection of low-cost, substandard mounts. These often use inferior rubber compounds or weak metal housings, resulting in premature failure, increased noise, vibration, harshness (NVH), and reduced vehicle handling. Always verify material specifications and durability testing data before procurement.

2. Lack of OEM or OE-Spec Compliance

Non-compliant strut mounts may not meet original equipment manufacturer (OEM) dimensional, load, or damping specifications. This can cause improper fitment, accelerated wear on other suspension components, and compromised ride comfort. Ensure parts are certified to OE standards (e.g., ISO/TS 16949) and request validation documentation.

3. Ignoring Intellectual Property (IP) Risks

Sourcing counterfeit or reverse-engineered parts infringes on OEM patents and trademarks. This exposes buyers to legal liability, customs seizures, and reputational damage. Always work with authorized distributors or licensed manufacturers and verify IP clearance for the product and packaging.

4. Inadequate Testing and Certification

Many aftermarket suppliers lack proper testing protocols for dynamic load, temperature resistance, and fatigue life. Without documented test results (e.g., from accredited labs), there’s no assurance the mount will perform under real-world conditions. Demand full certification reports prior to bulk orders.

5. Poor Supply Chain Transparency

Opaqueness in the manufacturing origin or sub-tier suppliers increases the risk of receiving inconsistent or non-compliant products. Conduct supplier audits, require traceability documentation, and avoid intermediaries with no direct factory oversight.

6. Overlooking Environmental and Durability Factors

Upper strut mounts operate under extreme conditions. Sourcing mounts not rated for local climate (e.g., UV resistance, cold cracking, or ozone degradation) leads to premature deterioration. Confirm suitability for operating temperature ranges and environmental exposure.

7. Inconsistent Quality Control Processes

Suppliers without robust in-line QC may deliver mixed batches with varying torque specs, rubber hardness, or bonding integrity. Implement incoming inspection protocols and require statistical process control (SPC) data from suppliers.

Avoiding these pitfalls ensures reliable performance, regulatory compliance, and long-term cost savings—making due diligence in quality and IP essential when sourcing upper strut mounts.

Logistics & Compliance Guide for Upper Strut Mount

This guide provides essential information for the safe, efficient, and compliant handling, transportation, and documentation of Upper Strut Mount components throughout the supply chain.

Product Overview

The Upper Strut Mount is a critical suspension component typically used in automotive applications to connect the shock absorber or strut assembly to the vehicle chassis. It provides structural support, dampens vibrations, and helps maintain proper alignment. This guide applies to all variants of the Upper Strut Mount unless otherwise specified.

Packaging Requirements

All Upper Strut Mounts must be packaged to prevent damage during handling and transit. Acceptable packaging includes:

– Corrugated cardboard boxes with internal partitions or foam inserts to prevent movement

– Shrink-wrapped pallet loads with edge protectors for bulk shipments

– Individual protective wrapping (e.g., polyethylene sleeves) for coated or precision-finished parts

Packages must be clearly labeled with part number, quantity, batch/lot number, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

Storage Conditions

Store Upper Strut Mounts in a dry, temperature-controlled environment with the following specifications:

– Temperature: 10°C to 30°C (50°F to 86°F)

– Relative Humidity: Below 60%

– Avoid direct sunlight and exposure to corrosive chemicals

– Keep off the floor using pallets or shelving to prevent moisture absorption and pest infestation

Transportation Guidelines

- Use enclosed, weatherproof vehicles for all road shipments

- Secure cargo to prevent shifting during transit (strapping, dunnage, load bars)

- Avoid extreme temperature exposure; do not leave containers in direct sun for extended periods

- Max stack height: 1.8 meters (6 feet) when palletized; do not exceed weight limits of packaging

- For international shipments, ensure compliance with IMDG (sea), IATA (air), or ADR (road) regulations as applicable

Export Documentation

Required documentation for international shipments includes:

– Commercial Invoice (with full product description, HTS code, value, origin)

– Packing List (itemized by SKU, weight, dimensions)

– Certificate of Origin (preferably Form A for preferential tariffs)

– Bill of Lading or Air Waybill

– Export Declaration (as required by exporting country)

Regulatory Compliance

Ensure all Upper Strut Mounts meet relevant regulatory standards:

– REACH (EU): Confirm no Substances of Very High Concern (SVHC) above threshold

– RoHS (EU): Compliance with restrictions on hazardous substances

– DOT (USA): Compliance with FMVSS No. 113 if applicable to vehicle safety

– Proposition 65 (California): Provide warnings if containing listed chemicals

– Customs-Trade Partnership Against Terrorism (C-TPAT): Follow security guidelines for shipments to the U.S.

Harmonized System (HS) Code

Recommended HS Code: 8708.80.50 – “Parts and accessories of bodies (including cabs), for tractors, motor vehicles…: Other: Other”

Note: Confirm classification with local customs authority; may vary by material and vehicle type.

Import Considerations

- Verify tariff rates and import duties in destination country using the correct HS code

- Some countries require homologation or type approval for automotive safety parts

- Ensure labeling includes local language requirements (e.g., Spanish in Mexico, French in Canada)

- Be prepared for customs inspections; maintain traceability records for at least 5 years

Quality & Traceability

Each batch of Upper Strut Mounts must have:

– Unique batch/lot number traceable to manufacturing date and location

– Quality inspection report (including dimensional checks and material certification)

– Supplier compliance statement confirming adherence to environmental and safety standards

Environmental & Safety Handling

- No special hazardous labeling required under GHS for standard metal/rubber components

- Recycle packaging materials according to local regulations

- Dispose of defective units per regional waste management rules; metal components should be recycled

- Use appropriate PPE (gloves, safety glasses) when handling sharp or heavy batches

Contact Information

For compliance or logistics inquiries, contact:

Logistics Manager

Email: [email protected]

Phone: +1 (555) 123-4567

Last Updated: April 2024

Version: 1.2

Conclusion for Sourcing Upper Strut Mount:

After a thorough evaluation of technical specifications, quality standards, cost considerations, and supplier capabilities, sourcing the upper strut mount requires a balanced approach that prioritizes reliability, durability, and supply chain efficiency. It is recommended to select a supplier that demonstrates consistent quality control, compliance with OEM standards (such as ISO/TS 16949 or IATF 16949), and proven performance in vibration damping and load-bearing applications. Additionally, considering total cost of ownership—including logistics, lead times, and potential warranty claims—will ensure long-term operational efficiency. Final selection should be supported by sample testing, on-site audits (if applicable), and a strong after-sales service agreement to mitigate risks and support seamless integration into the assembly process.