The global hydraulics market is experiencing robust growth, driven by increasing demand across industrial, construction, agricultural, and manufacturing sectors. According to Mordor Intelligence, the hydraulic equipment market was valued at USD 33.5 billion in 2023 and is projected to reach USD 43.2 billion by 2029, growing at a CAGR of 4.3% during the forecast period. This expansion is fueled by ongoing industrial automation, the need for high-power density systems, and advancements in energy-efficient hydraulic technologies. Amid this growth, universal hydraulics manufacturers—those offering broad, cross-industry solutions—are playing a pivotal role in shaping system performance, reliability, and innovation. As market demand evolves, a select group of global leaders continues to dominate through technological expertise, extensive product portfolios, and strategic global reach. Here’s a look at the top 7 universal hydraulics manufacturers driving the industry forward.

Top 7 Universal Hydraulics Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Universal Hydraulics & Pneumatics

Domain Est. 2009

Website: universalhydro.com

Key Highlights: UNIVERSAL HYDRAULICS & PNEUMATICS – is one of the renowned manufacturer, supplier and distributor of Hydraulic Tube Fittings from Chennai, Tamil Nadu….

#2 Universal Hydraulics USA

Domain Est. 2023

Website: universalhydraulicsusa.com

Key Highlights: Premium hydraulic, industrial & automotive hoses, couplings and accessories in Miami, FL. Custom hose assembly, replacement, and repair services for heavy ……

#3 Universal Hydraulics International

Domain Est. 1999

Website: uhiltd.com

Key Highlights: At Universal Hydraulics International, we take pride in our extensive inventory. With over 100+ valve and filter products currently stocked in our warehouse….

#4 Hydraulic systems, cooling systems, and heat exchangers

Domain Est. 2014

Website: universalhydraulik-usa.com

Key Highlights: Universal Hydraulik designs Innovative and customer-oriented systems designing hydraulic systems, cooling systems, and heat exchangers which are used all ……

#5 Universal Hydraulics

Domain Est. 2014

Website: universal-hydraulics.com

Key Highlights: We service, repair, test and sell hydraulic equipment to all types of industries such as Construction, Oilfield, Railroad, Off-road vehicles (like Rock Crawlers) ……

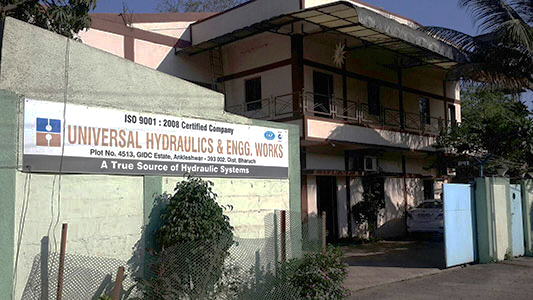

#6 Universal Hydraulics & Engg. Works

Domain Est. 2016

Website: universalhydraulicsengg.com

Key Highlights: We manufacture hydraulic machines such as hydraulic press, Hydraulic elevator, and special purpose hydraulic machines Hydraulic extruding machine. We are ……

#7 Universal Hydraulics

Website: universalhydraulics.co.nz

Key Highlights: Universal Hydraulics is one of the largest hydraulic wholesalers providing parts and products to both national and international customers….

Expert Sourcing Insights for Universal Hydraulics

2026 Market Trends for Universal Hydraulics

The global hydraulics market is poised for significant transformation by 2026, driven by technological innovation, sustainability mandates, and shifting industrial demand. For Universal Hydraulics, a leading player in hydraulic systems and components, understanding these key trends is critical for strategic positioning and sustained growth.

1. Accelerated Electrification and Hybridization of Hydraulic Systems

A dominant trend shaping the 2026 landscape is the integration of electric and hybrid technologies into traditional hydraulic systems. Electrified hydraulics—such as electro-hydrostatic actuators (EHAs) and pump-motor units powered by variable frequency drives—offer enhanced energy efficiency, reduced emissions, and greater control precision. Universal Hydraulics will need to expand its portfolio with smart, electrified solutions tailored for off-highway machinery (e.g., construction and agriculture), industrial automation, and mobile applications where fuel economy and environmental compliance are paramount.

2. Rising Demand for Smart Hydraulics and IoT Integration

The Industrial Internet of Things (IIoT) is revolutionizing hydraulic systems through real-time monitoring, predictive maintenance, and data-driven performance optimization. By 2026, smart hydraulics equipped with embedded sensors, wireless connectivity, and cloud-based analytics will become standard in sectors like manufacturing, aerospace, and renewable energy. Universal Hydraulics must invest in digital capabilities, offering integrated software platforms that enable remote diagnostics, condition monitoring, and performance benchmarking to add value beyond hardware.

3. Stringent Environmental Regulations Driving Efficiency and Fluid Innovations

Global emissions standards and environmental regulations, particularly in Europe and North America, are pushing industries to adopt energy-efficient hydraulic designs and eco-friendly fluids. Universal Hydraulics will face increasing demand for low-leakage components, energy recovery systems, and compatibility with biodegradable or synthetic hydraulic fluids. Compliance with directives such as the EU’s Green Deal and EPA Tier 4 Final standards will be essential for market access and customer retention.

4. Expansion in Emerging Markets and Infrastructure Development

Robust infrastructure investment in Asia-Pacific, Latin America, and parts of Africa will drive demand for heavy machinery and industrial equipment, directly benefiting hydraulic component suppliers. Countries like India, Indonesia, and Brazil are prioritizing urbanization and transportation projects, creating growth opportunities for Universal Hydraulics in construction, mining, and material handling sectors. Strategic partnerships and localized manufacturing or distribution will be key to capturing this demand.

5. Supply Chain Resilience and Localization Strategies

Following disruptions from geopolitical tensions and global pandemics, industrial OEMs are prioritizing supply chain resilience. By 2026, Universal Hydraulics will need to demonstrate agility through nearshoring, regional inventory hubs, and digital supply chain tools. Customers will favor suppliers with transparent, responsive, and sustainable sourcing practices, making supply chain robustness a competitive differentiator.

6. Growing Role in Renewable Energy and Green Technologies

Hydraulic systems are increasingly vital in renewable energy applications, including wind turbine pitch and yaw control, wave energy converters, and large-scale solar tracking systems. As the world transitions to clean energy, Universal Hydraulics can leverage its expertise to develop specialized, high-reliability components for these high-growth sectors, positioning itself as an enabler of sustainable infrastructure.

In conclusion, the 2026 market for Universal Hydraulics will be defined by digitalization, sustainability, and global expansion. To thrive, the company must innovate across product design, embrace smart technologies, comply with environmental standards, and strengthen supply chain and market access strategies in high-growth regions.

Common Pitfalls When Sourcing Universal Hydraulics: Quality and Intellectual Property Risks

Sourcing universal hydraulics—components designed to be compatible with a wide range of equipment from various manufacturers—can offer cost savings and supply chain flexibility. However, it also introduces significant risks related to quality consistency and intellectual property (IP) infringement. Being aware of these pitfalls is essential for avoiding costly downtime, safety hazards, and legal exposure.

Quality Inconsistencies and Performance Shortfalls

One of the most prevalent risks in sourcing universal hydraulics is inconsistent product quality. Because these components are often manufactured by third-party suppliers aiming to match original equipment manufacturer (OEM) specifications, there can be wide variations in materials, tolerances, and workmanship.

- Substandard Materials: Universal parts may use lower-grade seals, hoses, or metals that degrade faster under pressure or extreme temperatures, leading to premature failure.

- Inadequate Testing: Unlike OEM components, universal hydraulics may not undergo rigorous performance and durability testing, increasing the risk of leaks, bursts, or system contamination.

- Fit and Function Issues: Even minor dimensional differences can result in improper fit, causing misalignment, increased wear, or complete system incompatibility.

- Lack of Traceability: Poor documentation and batch tracking make it difficult to identify the source of failures or conduct effective recalls.

These quality issues not only compromise system reliability but can also pose safety risks in high-pressure hydraulic applications.

Intellectual Property and Legal Exposure

Another major concern when sourcing universal hydraulics is the potential infringement of intellectual property rights. Many OEM hydraulic components are protected by patents, trademarks, or design rights, and universal equivalents may cross legal boundaries.

- Patent Infringement: Replicating patented designs—such as valve configurations or cylinder mechanisms—without licensing can lead to lawsuits, injunctions, and financial penalties.

- Trademark Violations: Using logos, part numbers, or branding that mimics OEMs, even unintentionally, may constitute trademark infringement.

- Gray Market Components: Some suppliers repackage or reverse-engineer OEM parts, selling them as “universal” alternatives, which can violate IP laws and void equipment warranties.

- Limited Legal Recourse: In cases of IP disputes, buyers may find themselves liable alongside the supplier, especially if due diligence was not performed.

Failing to verify the legal legitimacy of universal components exposes organizations to reputational damage, supply chain disruption, and costly litigation.

Mitigation Strategies

To minimize these risks, procurement teams should:

– Conduct thorough supplier audits and request certifications (e.g., ISO 9001).

– Require material test reports and performance validation data.

– Consult legal counsel to assess IP compliance, especially for critical or patented systems.

– Prioritize suppliers with transparent manufacturing processes and clear design differentiation from OEM parts.

By addressing both quality and IP concerns proactively, businesses can leverage the benefits of universal hydraulics while safeguarding performance, safety, and legal integrity.

Logistics & Compliance Guide for Universal Hydraulics

Overview

This guide outlines the standardized logistics and compliance procedures for Universal Hydraulics. Adherence to these protocols ensures efficient operations, regulatory compliance, and customer satisfaction across all supply chain activities.

Shipping & Transportation

All outbound shipments must be scheduled through the central logistics portal. Standard lead times are 2–5 business days for domestic deliveries and 5–10 business days for international shipments. Universal Hydraulics utilizes approved carriers that meet ISO 28000 standards. Proper packaging, including moisture-resistant wrapping and secure crating for heavy components, is mandatory. All shipments require a detailed packing list and bill of lading.

Import/Export Compliance

Universal Hydraulics complies with all U.S. Export Administration Regulations (EAR) and International Traffic in Arms Regulations (ITAR), where applicable. Export classification (ECCN) must be verified for every product prior to international shipment. Required documentation includes commercial invoices, export declarations (e.g., AES filings), and certificates of origin. Prohibited destinations and restricted parties are screened using automated compliance software prior to every shipment.

Regulatory Certifications

Hydraulic components must meet relevant industry standards, including ISO 4413 (fluid power systems), ISO 10763 (hydraulic fluid contamination), and CE marking for EU markets. All products undergo periodic compliance audits. Certificates of Conformity (CoC) and Material Test Reports (MTR) are maintained in the quality documentation system and available upon request.

Inventory Management

Raw materials and finished goods are tracked using a real-time warehouse management system (WMS) integrated with ERP. Safety stock levels are set per SKU based on lead time and demand forecasting. Cycle counts are performed weekly, with annual physical inventories reconciled to financial records. Hazardous materials (e.g., hydraulic oils) are stored in designated, ventilated areas with secondary containment.

Customs Clearance

For international shipments, Universal Hydraulics partners with licensed customs brokers. Accurate Harmonized System (HS) codes must be applied to all products. Duties and tariffs are calculated using the latest tariff schedules. Documentation must be complete and submitted at least 24 hours prior to arrival for customs pre-clearance. Any customs holds are escalated immediately to the Compliance Officer.

Environmental & Safety Compliance

Universal Hydraulics follows OSHA and EPA guidelines for material handling and storage. Spill response kits are stationed in warehouse zones, and staff undergo annual HAZMAT training. Waste hydraulic fluid is disposed of through certified recyclers with proper manifests. The company adheres to REACH regulations for chemical substances used in manufacturing.

Record Retention

All logistics and compliance records—including shipping documents, customs filings, compliance certifications, and audit reports—are retained for a minimum of seven years in secure digital archives. Access is restricted to authorized personnel only, in compliance with data protection policies.

Responsibilities

The Logistics Manager oversees shipment execution and carrier performance. The Compliance Officer ensures adherence to trade regulations and coordinates audits. All employees involved in logistics must complete annual compliance training. Non-compliance incidents must be reported through the internal incident reporting system within 24 hours.

Continuous Improvement

Quarterly reviews of logistics KPIs (on-time delivery, freight costs, error rates) and compliance metrics (audit findings, customs delays) are conducted. Process improvements are implemented through the company’s quality management system (QMS) under ISO 9001 standards.

Conclusion on Sourcing Universal Hydraulics:

In conclusion, sourcing universal hydraulics offers a strategic advantage in terms of cost-efficiency, flexibility, and ease of maintenance across diverse equipment and applications. The interchangeability and widespread availability of universal hydraulic components streamline procurement processes, reduce downtime, and minimize inventory requirements. However, it is essential to ensure compatibility, quality, and adherence to industry standards when selecting suppliers to maintain system performance and safety. By partnering with reliable manufacturers and conducting thorough due diligence, organizations can effectively leverage universal hydraulics to enhance operational efficiency and adaptability in dynamic industrial environments.