The global antifreeze coolant market is experiencing steady expansion, driven by rising vehicle production, increased demand for engine efficiency, and growing after-sales automotive maintenance activities. According to a report by Mordor Intelligence, the global antifreeze coolant market was valued at USD 2.85 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2029. This growth is further supported by Grand View Research, which highlights the increasing adoption of advanced cooling technologies in both passenger and commercial vehicles, as well as the expanding industrial machinery sector. With evolving engine designs and stricter environmental regulations pushing for longer-lasting, eco-friendly coolants, manufacturers are focusing on innovation in ethylene glycol and propylene glycol-based formulations. As demand surges across North America, Europe, and Asia-Pacific, a select group of industry leaders have emerged at the forefront of product development, quality assurance, and global distribution—setting the standard for performance and reliability in universal antifreeze coolant solutions.

Top 8 Universal Antifreeze Coolant Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Universal

Domain Est. 2016

Website: profleetantifreeze.com

Key Highlights: PROFLEET® Universal Antifreeze / Coolant is an HOAT technology, yellow in color, and can be used in nearly any vehicle. It meets ASTM D6210 for Heavy-Duty ……

#2 PEAK® All Vehicles Antifreeze + Coolant

Domain Est. 1995

Website: owi.com

Key Highlights: PEAK® All Vehicles Antifreeze + Coolant is formulated to protect all cooling system metals, including aluminum. It immediately protects against damaging rust ……

#3 Turbo Power Universal Antifreeze/Coolant

Domain Est. 1995

Website: recochem.com

Key Highlights: Universal (All Season) Antifreeze/Coolant is a superior quality ethylene glycol-based engine coolant with a low silicate corrosion inhibitor package….

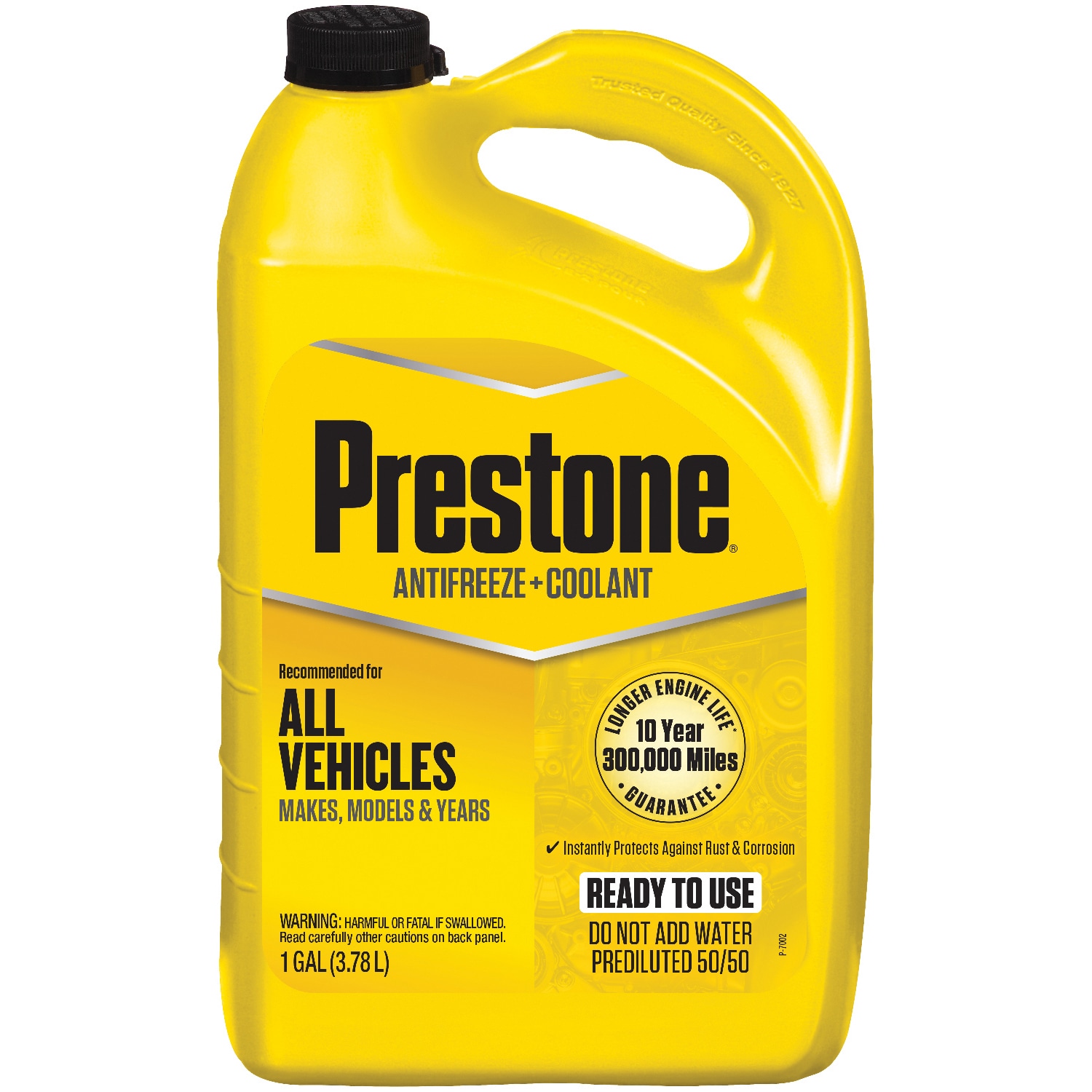

#4 Prestone® Antifreeze+Coolant

Domain Est. 1996

Website: prestone.com

Key Highlights: Prestone® is the number one branded consumer choice for antifreeze/coolant, brake fluid and power steering fluid in North America….

#5 Havoline® Universal Antifreeze/Coolant

Domain Est. 1999

Website: chevronlubricants.com

Key Highlights: Chevron Havoline® Universal Antifreeze/Coolant is a single phase, ethylene glycol antifreeze/coolants designed for all makes and models of passenger cars and ……

#6 Universal Antifreeze & Coolant for Sale

Domain Est. 2004

Website: petroleumservicecompany.com

Key Highlights: $99 delivery · 30-day returnsPetroleum Service Company’s Universal Car and Truck Formula Coolants meet or exceed all ASTM and SAE performance standards, while the patented formula…

#7 Premium Antifreeze & Coolant

Domain Est. 2020

Website: ultra1plus.com

Key Highlights: Free delivery 30-day returnsAntifreeze & Coolant. Whether you need Universal IAT, Extended Life OAT, or Heavy-Duty NOAT formulas, our collection offers maximum protection against f…

#8 Zerex™ American Vehicle Antifreeze / Coolant

Domain Est. 2022

Website: valvolineglobal.com

Key Highlights: Rating 4.9 (24) · $11.99 delivery · 30-day returnsZerex American Vehicle Antifreeze/Coolant is proven to maximize engine life in American vehicles such as Ford, Chrysler and G…

Expert Sourcing Insights for Universal Antifreeze Coolant

H2: 2026 Market Trends for Universal Antifreeze Coolant

The universal antifreeze coolant market in 2026 is poised for transformation, driven by evolving vehicle technologies, stringent environmental regulations, and shifting consumer demands. Key trends shaping the landscape include:

1. Electrification Impact & Hybrid Complexity:

* Challenge to “Universal” Claims: The rise of Battery Electric Vehicles (BEVs) reduces overall engine coolant demand, as BEVs don’t require traditional engine cooling systems. However, they do need coolant for battery thermal management and power electronics, creating a different coolant segment.

* Hybrid Dominance & Coolant Demands: Hybrids (HEVs, PHEVs) remain a significant growth area. These vehicles have complex thermal management systems requiring coolant to handle both the internal combustion engine and the battery/electronics. This complexity demands coolants with enhanced stability, wider temperature ranges, and compatibility with diverse materials (e.g., copper in power electronics). True “universality” is increasingly challenged by these specific hybrid requirements.

2. Stricter Environmental Regulations & Sustainability:

* Phosphate, Silicate, and Nitrite Restrictions: Regulations (like EU REACH, EPA guidelines) continue to push for reduced or eliminated use of traditional inhibitors like phosphates (eutrophication risk), silicates (sediment issues), and nitrites (nitrosamine formation). This drives the shift towards more sustainable, long-life Organic Acid Technology (OAT) and Hybrid OAT (HOAT) formulations.

* Biodegradability & Recyclability Focus: Expect increased demand for coolants formulated with higher percentages of bio-based glycols (e.g., from renewable feedstocks) and improved end-of-life recyclability processes. Life Cycle Assessment (LCA) will become a more critical factor for OEMs and large fleets.

* Reduced Toxicity: Formulations minimizing ethylene glycol (toxic) in favor of safer propylene glycol (less toxic, though often less efficient) or advanced glycol alternatives will gain traction, especially in consumer and sensitive environmental applications.

3. Performance & Longevity Demands:

* Extended Drain Intervals (EDIs): OEMs continue to specify longer service intervals (5-7 years, 150k+ miles). Universal coolants must meet or exceed these demanding longevity requirements, necessitating highly stable OAT/HOAT formulations with superior corrosion inhibition and oxidation resistance.

* Material Compatibility: Modern engines use more aluminum, magnesium, and advanced plastics. Universal coolants must provide broad-spectrum protection for these diverse materials without causing degradation or galvanic corrosion.

* Thermal Management Efficiency: As engines become more efficient and operate at higher temperatures (for efficiency and emissions), coolants need superior heat transfer properties and higher boiling points.

4. Market Consolidation & Brand Differentiation:

* “Universal” Becomes Nuanced: The term “universal” will face scrutiny. Leading brands will differentiate by emphasizing specific certifications (e.g., meeting multiple OEM specs like GM Dex-Cool, Ford WSS-M97B44-D, European standards), proven longevity data, and environmental credentials rather than just broad compatibility.

* OEM Partnerships & Private Label Growth: Major chemical companies will strengthen partnerships with OEMs for factory-fill and service-fill supply. Simultaneously, private label offerings from large retailers and distributors will compete on price, potentially driving down margins for standard universal products.

* Focus on Aftermarket & DIY: The aftermarket remains crucial. Brands will invest in clear consumer education about compatibility, mixing risks, and the true meaning of “universal” to maintain trust and prevent misuse.

5. Supply Chain & Raw Material Volatility:

* Glycol Price Fluctuations: Prices for ethylene glycol (EG) and propylene glycol (PG) are tied to crude oil and natural gas markets. Geopolitical instability and energy transitions will likely cause continued volatility, impacting coolant pricing.

* Strategic Sourcing: Manufacturers will focus on securing stable supply chains for key inhibitors (organic acids, specific silicates) and exploring alternative raw materials to mitigate risk and ensure formulation consistency.

Conclusion for 2026:

The universal antifreeze coolant market in 2026 will be characterized by increased specialization within the “universal” category. While broad compatibility remains a selling point, success will depend on:

* Advanced Formulations: Dominance of long-life OAT/HOAT technologies meeting stringent environmental and performance standards.

* Sustainability Leadership: Strong focus on reduced environmental impact, bio-based content, and recyclability.

* Hybrid Vehicle Focus: Development of coolants specifically validated for the complex thermal systems in hybrids.

* Transparency & Trust: Clear communication of specifications, certifications, and limitations to navigate the evolving landscape of vehicle technology and regulations.

The market will move beyond simple “one-size-fits-all” claims towards “universally compatible, highly specialized, and sustainably advanced” solutions.

Common Pitfalls When Sourcing Universal Antifreeze Coolant (Quality & Intellectual Property)

Sourcing Universal Antifreeze Coolant can be cost-effective, but it comes with significant risks related to product quality and intellectual property (IP) concerns. Being aware of these common pitfalls is essential for maintaining vehicle performance, warranty compliance, and legal integrity.

Quality-Related Pitfalls

1. Inconsistent or Substandard Formulation

Many generic or “universal” coolants lack rigorous quality control, leading to variations in chemical composition. Poorly formulated coolants may not provide adequate corrosion inhibition, leading to premature degradation of radiator, water pump, and heater core components. This can result in costly repairs and reduced engine lifespan.

2. Inadequate Corrosion and Cavitation Protection

Universal coolants often fail to meet OEM-specific performance standards (e.g., ASTM D3306, D4985, or manufacturer specs like GM 6277M, Ford WSS-M97B44-D). Without proper inhibitors (e.g., silicates, phosphates, or organic acid technology), metals in the cooling system can corrode, and cylinder liners may suffer from cavitation erosion—especially in diesel engines.

3. Incompatibility with Modern Engine Materials

Newer engines use aluminum, magnesium, and various elastomers. Low-quality universal coolants may not be formulated to protect these materials, causing seal degradation, leaks, or internal deposits that reduce heat transfer efficiency.

4. Shortened Service Life

While some universal coolants claim extended-life performance, inferior additive packages deplete quickly. This results in premature coolant breakdown, sludge formation, and the need for more frequent changes—undermining cost-saving assumptions.

5. Lack of Verification and Testing

Reputable brands conduct extensive field and lab testing. Generic suppliers often skip these steps. Without third-party certification or OEM approvals, buyers have no assurance of performance or reliability.

Intellectual Property (IP) Pitfalls

1. Misrepresentation of OEM Approvals

Some suppliers falsely claim their universal coolant meets specific OEM standards (e.g., Toyota Type LL, Honda Type 2) without proper testing or licensing. This misrepresentation can void vehicle warranties and expose buyers to liability, especially in commercial or fleet operations.

2. Trademark and Brand Infringement

Unethical manufacturers may use packaging or labeling that mimics well-known brands (e.g., color schemes, logos, or names like “Gold” or “Platinum” equivalents), misleading consumers. This constitutes trademark infringement and can lead to legal action.

3. Use of Proprietary Technology Without Licensing

Certain antifreeze formulations involve patented additive technologies (e.g., hybrid organic acid technology – HOAT). Sourcing coolants that replicate these without proper licensing infringes on intellectual property rights and may expose distributors or large-scale buyers to legal risk.

4. Poor Traceability and Documentation

Generic brands often lack batch traceability, safety data sheets (SDS), or technical documentation. This makes it difficult to verify compliance, investigate failures, or prove due diligence in regulatory or warranty disputes.

5. Supply Chain Transparency Issues

Many universal coolants originate from suppliers with unclear manufacturing origins. This opacity increases the risk of counterfeit products, non-compliant materials, or unethical practices—further compounding IP and quality concerns.

Best Practices to Avoid Pitfalls

- Verify OEM Approvals: Check for documented, test-backed compliance with required specifications.

- Demand Certifications: Require test reports, SDS, and ISO certification from suppliers.

- Avoid “Too Good to Be True” Pricing: Extremely low prices often indicate substandard quality or IP violations.

- Work with Reputable Distributors: Partner with trusted suppliers who provide full product traceability.

- Conduct Independent Testing: Periodically test coolant batches for pH, freeze point, and inhibitor levels.

By recognizing these quality and IP-related pitfalls, organizations can make informed sourcing decisions that protect equipment, ensure compliance, and mitigate legal and operational risks.

H2: Logistics & Compliance Guide for Universal Antifreeze Coolant

This guide outlines the critical logistics and compliance requirements for the safe, legal, and efficient handling, storage, transportation, and disposal of Universal Antifreeze Coolant from Universal. Adherence is mandatory for all personnel involved.

H2: 1. Product Identification & Classification

* Product Name: Universal Antifreeze Coolant

* Common Components: Primarily Ethylene Glycol or Propylene Glycol, water, and proprietary additive packages (corrosion inhibitors, anti-foam agents, pH buffers). Always verify the specific formulation using the SDS.

* Hazard Classification (Typical – Verify SDS):

* GHS Classification: Acute Toxicity (Oral, Category 3 or 4 – Harmful if swallowed), Specific Target Organ Toxicity – Single Exposure (Category 1 or 2 – May cause damage to organs), Hazardous to the Aquatic Environment (Acute, Category 1; Chronic, Category 1).

* UN Number: UN 3082 (ENVIRONMENTALLY HAZARDOUS SUBSTANCE, LIQUID, N.O.S. – if meeting criteria) or UN 1993 (FLAMMABLE LIQUID, N.O.S. – if flash point ≤ 60°C/140°F, though most coolants are >60°C). Crucially confirm the UN number and proper shipping name on the Safety Data Sheet (SDS) Section 14.

* Regulatory Basis: Classification is primarily based on the ethylene/propylene glycol content and aquatic toxicity. Ethylene Glycol is significantly more toxic than Propylene Glycol.

H2: 2. Safety Data Sheet (SDS) Management

* Mandatory: The current, supplier-specific SDS must be obtained and readily accessible for every batch prior to handling, storage, or transport.

* Primary Source: The SDS is the authoritative document for hazard classification, first aid, firefighting, accidental release, handling, storage, exposure controls, and regulatory information (Sections 2, 4, 5, 6, 7, 8, 14, 15).

* Review: Personnel must review the relevant SDS sections (especially Hazards, Handling, Storage, Exposure Controls, Transport) before any activity involving the coolant.

H2: 3. Handling Procedures

* Personal Protective Equipment (PPE – Refer to SDS Section 8):

* Always: Chemical-resistant gloves (e.g., nitrile, neoprene – verify compatibility with SDS), safety goggles or face shield, chemical-resistant apron or clothing.

* Recommended: Closed-toe shoes, respiratory protection (if ventilation is inadequate or during large spills – consult SDS).

* Engineering Controls: Use in well-ventilated areas. Local exhaust ventilation is recommended where significant vapor or mist generation is possible (e.g., large transfer operations).

* Hygiene: Wash hands thoroughly after handling, even when wearing gloves. Do not eat, drink, or smoke in areas where coolant is handled.

* Minimize Exposure: Avoid contact with skin, eyes, and clothing. Prevent ingestion. Avoid breathing vapors or mists.

H2: 4. Storage Requirements

* Containers: Store only in original, tightly closed, UN-approved containers or compatible, properly labeled secondary containers. Ensure compatibility (typically HDPE, specific plastics, stainless steel).

* Location: Store in a cool, dry, well-ventilated area away from direct sunlight, heat sources, and ignition sources. Segregate from:

* Strong oxidizing agents (e.g., nitrates, peroxides, chlorates).

* Strong acids and bases.

* Food, feed, and pharmaceuticals.

* Spill Containment: Store within a secondary containment system (e.g., spill pallet, bunded area) capable of holding at least 110% of the largest container or 25% of the total stored volume, whichever is greater.

* Labeling: Ensure all containers (primary and secondary) are clearly labeled with the product name, hazards (GHS pictograms if applicable), and “Keep Out of Reach of Children.”

* Inventory: Implement stock rotation (FIFO – First In, First Out). Regularly inspect containers for damage, leaks, or degradation.

H2: 5. Transportation (On-Site & Off-Site)

* Classification & Documentation: ABSOLUTELY CRITICAL: Use the exact UN Number, Proper Shipping Name, Hazard Class, and Packing Group specified in the SDS (Section 14) for all transport documentation (Shipping Papers, Dangerous Goods Note).

* Packaging: Use only UN-specification packaging (drums, IBCs, jerricans) certified for the specific hazard class and packing group. Ensure packaging is in good condition, correctly closed, and secured against leakage and movement.

* Marking & Labeling: All packages must display:

* Proper Shipping Name

* UN Number

* Hazard Class Label(s) (e.g., Environmentally Hazardous Substance, Flammable Liquid if applicable)

* GHS Pictograms (if applicable)

* “Marine Pollutant” mark if applicable (common for glycol-based coolants).

* Vehicle Requirements: Vehicles transporting hazardous goods must comply with relevant regulations (e.g., ADR in Europe, 49 CFR in the US). Placarding may be required based on quantity and hazard.

* Driver Training: Drivers must be trained and certified in the transport of dangerous goods (e.g., ADR certification, HAZMAT endorsement).

* On-Site Transport: Use appropriate, spill-proof containers (e.g., safety cans, jerry cans on hand trucks). Secure loads during movement. Avoid routes where spills could enter drains or waterways.

H2: 6. Spill Response & Emergency Procedures

* Contain: Immediately contain the spill using absorbents (clay, sand, commercial spill kits – avoid combustible materials like sawdust if flammable), dikes, or drain covers. Prevent entry into drains, sewers, or waterways.

* Notify: Alert supervisors and emergency personnel as per site procedures. Report significant spills to relevant authorities as required by local regulations.

* Recovery: Collect spilled material and contaminated absorbents/sorbents into labeled, compatible, sealable containers for proper disposal.

* Clean-Up: Wash affected area thoroughly with water. Collect wash water as contaminated waste.

* Personal Protection: Responders must wear full PPE as specified in Section 8 of the SDS.

* First Aid: Know and follow first aid procedures (SDS Section 4) for skin contact, eye contact, inhalation, and ingestion. Seek immediate medical attention for ingestion or significant exposure.

H2: 7. Waste Disposal

* Classification: Used or waste Universal Antifreeze Coolant is typically classified as Hazardous Waste due to toxicity (glycol content) and potential heavy metal contamination (from engine components). Never pour down drains, onto the ground, or into sewers.

* Regulations: Disposal is strictly regulated (e.g., RCRA in the US, WFD in EU). Compliance with local, state/provincial, and national regulations is mandatory.

* Management: Store waste coolant in clearly labeled, compatible, leak-proof containers (e.g., dedicated drums) within secondary containment.

* Disposal: Arrange disposal only through licensed and permitted hazardous waste treatment, storage, and disposal facilities (TSDFs). Obtain and retain all waste manifests and disposal certificates.

H2: 8. Regulatory Compliance & Record Keeping

* Key Regulations: Adhere to all applicable regulations, including:

* OSHA Hazard Communication Standard (HCS) / GHS

* EPA regulations (e.g., RCRA, CERCLA, Clean Water Act)

* DOT / Transport Canada / ADR regulations for transport

* State/Provincial environmental and workplace safety regulations

* Local fire codes and environmental ordinances.

* Essential Records:

* Current Safety Data Sheets (SDS)

* Transport documentation (Shipping Papers, Dangerous Goods Notes)

* Waste manifests and disposal certificates

* Training records for personnel (handling, spill response, transport)

* Spill response logs

* Inspection logs (storage, containers, containment)

H2: 9. Training

* All personnel involved in handling, storing, transporting, or disposing of Universal Antifreeze Coolant must receive comprehensive training covering:

* Product hazards (health, fire, environmental)

* SDS interpretation

* Required PPE and its use/maintenance

* Safe handling, storage, and transport procedures

* Spill response and emergency procedures

* Waste disposal requirements

* Applicable regulations

* Training must be initial and repeated periodically (e.g., annually) or when procedures change.

Disclaimer: This guide provides general information based on typical coolant properties. The specific Safety Data Sheet (SDS) provided by Universal for the exact product batch is the legally binding document for hazard communication, handling, storage, transport, and emergency response. Always consult the current SDS first. Regulations vary significantly by jurisdiction; consult local authorities for specific requirements.

Conclusion for Sourcing Universal Antifreeze Coolant

In conclusion, sourcing a universal antifreeze coolant requires careful consideration of compatibility, performance standards, quality assurance, and supplier reliability. A high-quality universal antifreeze must meet or exceed industry specifications (such as ASTM D3306, D4985, or OEM standards) to ensure protection across a wide range of vehicle makes and models. Long-life formulations with OAT (Organic Acid Technology) or HOAT (Hybrid Organic Acid Technology) provide extended service intervals and enhanced protection against corrosion, overheating, and cavitation.

When selecting a supplier, factors such as certification, consistency of supply, pricing, and technical support are crucial. Opting for reputable manufacturers or authorized distributors helps minimize the risk of counterfeit or substandard products. Additionally, sustainability and environmental considerations, such as recyclability and low-toxicity formulas, are increasingly important in modern sourcing decisions.

Ultimately, sourcing the right universal antifreeze coolant ensures optimal engine performance, longevity, and reduced maintenance costs across diverse applications. A strategic, informed procurement approach supports both operational efficiency and vehicle reliability in automotive, industrial, and fleet operations.