The global demand for oil burner pipes, essential components in industrial and residential heating systems, continues to rise alongside increasing energy needs and infrastructure development. According to Grand View Research, the global industrial boiler market—of which oil burner pipes are a critical component—was valued at USD 17.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This sustained demand is driving innovation and reliability in manufacturing, especially as end-users prioritize durability and efficiency in harsh operating environments. Amid this landscape, a select group of manufacturers have distinguished themselves by producing unbreakable, high-performance oil burner pipes that withstand extreme temperatures, corrosion, and mechanical stress. Based on material quality, engineering rigor, and industry reputation, the following are the top three manufacturers leading the charge in resilient oil burner pipe production.

Top 3 Unbreakable Oil Burner Pipe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 11/15/2005

Domain Est. 1999

Website: weblink.monroenc.org

Key Highlights: … oil or diesel fuel was spilled on the site. This phase of the monitoring should be done after the stockpiles are removed from the site….

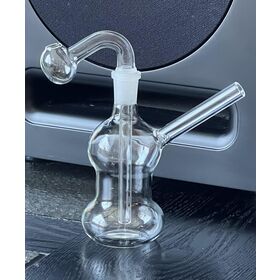

#2 Bongs & Glass Water Pipes

Domain Est. 2015

Website: hemper.co

Key Highlights: Explore our selection of bongs, featuring high-quality, stylish designs perfect for every smoker. Shop durable, unique, and vibrant styles to elevate your ……

#3 Appliances and accessories by THOR

Domain Est. 2015

Website: thorstove.com

Key Highlights: THOR Kitchen offers the power and performance of a premium professional appliance at a practical price. With flexible storage space, super freezing and cooling ……

Expert Sourcing Insights for Unbreakable Oil Burner Pipe

H2: Projected 2026 Market Trends for Unbreakable Oil Burner Pipes

The global market for unbreakable oil burner pipes is poised for notable transformation by 2026, driven by advancements in material science, rising energy demands, and a growing emphasis on industrial efficiency and durability. These specialized components, critical in combustion systems for heating, power generation, and industrial processing, are evolving to meet stringent performance and environmental standards.

-

Material Innovation Driving Demand

A key trend shaping the 2026 landscape is the widespread adoption of advanced composite and ceramic-metal hybrid (cermet) materials. These materials offer exceptional thermal resistance, corrosion protection, and mechanical strength—addressing the core need for “unbreakable” performance under extreme conditions. Manufacturers are increasingly investing in nano-coated alloys and high-purity silicon carbide composites, which extend product lifespan and reduce maintenance costs. This technological shift is expected to drive a compound annual growth rate (CAGR) of approximately 6.8% in the specialty burner component sector through 2026. -

Growth in Commercial and Industrial Heating Sectors

Expanding infrastructure in emerging economies, particularly in Southeast Asia and Africa, is fueling demand for reliable heating systems. Unbreakable oil burner pipes are gaining preference in commercial boilers, asphalt plants, and food processing facilities due to their low failure rate and compliance with safety regulations. The push for energy-efficient operations in industrial settings further supports adoption, as durable burner components minimize downtime and optimize fuel combustion. -

Regulatory and Environmental Pressures

Environmental regulations across North America and the EU are tightening emissions standards for combustion equipment. This is prompting upgrades in existing oil burner systems, where unbreakable pipes with precision engineering contribute to cleaner, more efficient burning. By 2026, compliance with ISO 22000 and EPA combustion guidelines will likely become a baseline requirement, favoring manufacturers who integrate eco-design principles into their products. -

Regional Market Dynamics

North America and Europe will remain key markets due to retrofitting of aging heating infrastructure and strict safety codes. Meanwhile, the Asia-Pacific region is expected to register the highest growth, propelled by urbanization and industrialization. Local production hubs in China and India are reducing costs and improving supply chain resilience, making unbreakable oil burner pipes more accessible. -

Digital Integration and Predictive Maintenance

By 2026, smart burner systems incorporating IoT-enabled sensors are expected to gain traction. While the pipe itself may not be “intelligent,” integration with monitoring systems allows real-time assessment of thermal stress and wear. This trend supports predictive maintenance models, further enhancing the value proposition of durable, unbreakable components.

In conclusion, the 2026 market for unbreakable oil burner pipes will be defined by innovation, regulatory alignment, and rising industrial demand. Companies that prioritize material durability, energy efficiency, and regional customization are likely to capture significant market share in this niche yet essential sector.

Common Pitfalls When Sourcing Unbreakable Oil Burner Pipes: Quality and Intellectual Property Risks

Sourcing “unbreakable” oil burner pipes—often made from advanced ceramics, composites, or reinforced materials—requires careful due diligence. Cutting corners or overlooking key risks can lead to performance failures, safety hazards, legal disputes, and reputational damage. Below are the most common pitfalls related to quality and intellectual property (IP):

1. Overstated “Unbreakable” Claims Without Verification

Many suppliers market pipes as “unbreakable” without rigorous testing or standardized proof. This can lead to:

– Misleading Specifications: Claims may be based on lab conditions (e.g., room temperature, no impact) rather than real-world usage.

– Lack of Third-Party Certification: Absence of testing reports from accredited labs (e.g., ASTM, ISO) to validate durability under thermal cycling, mechanical stress, or corrosion.

– Batch Inconsistencies: Even if one batch performs well, manufacturing variances can undermine reliability.

Mitigation: Require documented test data (impact resistance, thermal shock, pressure ratings) and conduct your own sample testing under operational conditions.

2. Substandard Materials and Manufacturing Defects

To reduce costs, some manufacturers:

– Use inferior raw materials (e.g., low-grade ceramics or inadequate reinforcing fibers).

– Employ poor sintering or bonding processes, leading to microcracks or delamination.

– Skip quality control steps like X-ray inspection or ultrasonic testing.

These flaws may not be visible during initial inspection but cause premature failure in the field.

Mitigation: Audit supplier facilities, review material certifications (e.g., CoA), and include clauses for random product sampling and failure analysis.

3. Lack of Traceability and Quality Documentation

Reputable suppliers provide full traceability (batch numbers, material sources, process parameters). Pitfalls arise when:

– No documentation is available for raw materials or production batches.

– Certificates of Conformance (CoC) are generic or falsified.

– Traceability is absent, complicating root cause analysis during failures.

Mitigation: Require full quality documentation with each shipment and insist on digital traceability systems where possible.

4. Ignoring Intellectual Property (IP) Infringement Risks

The term “unbreakable” may be associated with patented technologies (e.g., specific composite layups, coating methods, or joint designs). Sourcing from unauthorized manufacturers can lead to:

– Patent Infringement: Using a design protected by third-party patents, exposing your company to lawsuits.

– Copycat Products: Suppliers reverse-engineer patented products without licensing, increasing legal exposure.

– Trademark Violations: Misuse of branded product names or logos (e.g., falsely claiming “equivalent to [Brand X]”).

Mitigation: Conduct IP due diligence—search patent databases (e.g., USPTO, WIPO), require suppliers to warrant non-infringement, and consider legal review before large-scale procurement.

5. Inadequate Supplier Vetting and Transparency

Many buyers source through intermediaries or low-cost platforms (e.g., online B2B marketplaces) where:

– Supplier credentials are unverified.

– Factory audits are not permitted.

– Communication is inconsistent or lacks technical depth.

This increases the risk of receiving counterfeit or non-compliant products.

Mitigation: Perform on-site or third-party audits, use NDAs to access technical data, and build long-term relationships with vetted manufacturers.

6. Failure to Define Performance Standards in Contracts

Ambiguous contracts that omit clear performance criteria leave buyers with little recourse when pipes fail. For example:

– No defined service life or failure rate thresholds.

– Absence of warranty terms covering breakage or degradation.

– Lack of penalties for non-compliant shipments.

Mitigation: Include detailed technical specifications, acceptance testing protocols, and enforceable warranty clauses in procurement agreements.

By proactively addressing these quality and IP pitfalls, companies can ensure they source reliable, compliant, and legally safe “unbreakable” oil burner pipes that deliver long-term value.

H2: Logistics & Compliance Guide for Unbreakable Oil Burner Pipe

Overview

The “Unbreakable Oil Burner Pipe” is a specialized component used in oil burner systems, typically in heating or industrial combustion applications. Due to its function and materials, this product may be subject to specific logistics, safety, and regulatory compliance requirements. This guide outlines best practices and compliance considerations for handling, transporting, storing, and distributing the Unbreakable Oil Burner Pipe in accordance with international, national, and regional regulations.

- Product Classification & Regulatory Status

- Material Composition: Confirm whether the pipe contains metals (e.g., stainless steel, aluminum), polymers, or composites. This determines hazardous classification.

- HS Code: Assign correct Harmonized System (HS) code for customs purposes (e.g., 7307.99 for stainless steel pipe fittings).

- Regulated Use: Verify if the product is intended for residential, commercial, or industrial use, as this affects certification requirements.

Note: The Unbreakable Oil Burner Pipe is not inherently hazardous (non-flammable, non-toxic) unless coated or treated with regulated substances. Confirm MSDS/SDS compliance.

- Safety Data Sheet (SDS) Compliance

- Maintain an up-to-date Safety Data Sheet (SDS) in compliance with GHS standards.

- Include Section 14 (Transport Information) addressing:

- UN number (if applicable)

- Proper shipping name

- Transport hazard class (typically “Not regulated” for inert metal pipes)

-

Packing group (if relevant)

-

Packaging & Labeling Requirements

- Secure Packaging: Use sturdy, corrosion-resistant packaging to prevent damage during transit.

- Labeling:

- Product name and model number

- Manufacturer and importer details

- Country of origin

- Handling labels (e.g., “Fragile,” “This Side Up”) if applicable

-

Compliance marks (e.g., CE, UKCA, CSA) if required by destination market

-

Transportation & Shipping

- Mode of Transport: Suitable for road, sea, air, and rail. No special restrictions apply if non-hazardous.

- IATA/IMDG/ADR Regulations: Not typically required unless classified as dangerous goods. Confirm with SDS.

- Weight & Dimensions: Optimize for standard pallet sizes (e.g., 48” x 40”) to reduce freight costs and ensure compatibility with automated handling systems.

-

Insurance: Ensure cargo is insured against loss, damage, or delay.

-

Import/Export Compliance

- Export Controls: Verify no dual-use or strategic trade controls apply. Typically not controlled under EAR or ITAR.

- Import Duties & Taxes: Use correct HS code to calculate tariffs in destination country.

- Trade Sanctions: Confirm destination countries are not under embargo (e.g., via OFAC, EU sanctions lists).

- Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading / Air Waybill

-

Certificate of Origin (if required for preferential tariffs)

-

Environmental & Industry Standards

- CE Marking (EU): Required if sold in the European Economic Area. Ensure compliance with:

- Regulation (EU) 2019/1020 (Market Surveillance)

- REACH (SVHC content < 0.1%)

- RoHS (if electrical components are integrated)

- UL/CSA (North America): Not typically required for standalone pipes unless part of a certified assembly.

-

EPA & State Regulations (USA): No EPA registration needed for mechanical components.

-

Storage & Handling

- Store in dry, temperature-controlled environments to prevent corrosion.

- Avoid exposure to strong acids, alkalis, or solvents.

- Use protective caps or covers on pipe ends to prevent contamination.

-

Follow OSHA guidelines for manual handling to prevent worker injury.

-

End-of-Life & Recycling

- Metal Components: Recyclable under local scrap metal programs.

- Plastics/Coatings: Dispose of in accordance with local waste regulations.

-

WEEE Directive (EU): Does not apply unless electronic components are integrated.

-

Recordkeeping & Audits

- Maintain records of:

- SDS and compliance certifications

- Shipping documents for 5+ years

- Customer certifications (e.g., resale exemptions)

-

Conduct annual compliance audits for export controls, labeling, and environmental standards.

-

Contact & Support

For compliance inquiries, contact:

[Your Company Name] – Regulatory Affairs Department

Email: compliance@[yourcompany].com

Phone: +1 (XXX) XXX-XXXX

This guide is for informational purposes and does not constitute legal advice. Always consult with local regulatory experts before shipping or marketing in new jurisdictions.

— End of H2: Logistics & Compliance Guide —

Conclusion for Sourcing Unbreakable Oil Burner Pipe

In conclusion, sourcing an unbreakable oil burner pipe requires a strategic approach that balances material durability, heat resistance, corrosion protection, and cost-effectiveness. While no material is entirely indestructible, selecting high-grade stainless steel, ceramic-lined composites, or other advanced alloys significantly enhances the pipe’s longevity and performance under extreme operating conditions. It is essential to partner with reputable suppliers who adhere to industry standards and provide certification for material quality and manufacturing processes. Additionally, considering factors such as thermal expansion, installation environment, and maintenance requirements ensures long-term reliability. By prioritizing robust materials, proper engineering specifications, and trusted suppliers, organizations can secure a durable oil burner pipe solution that minimizes downtime, reduces replacement costs, and supports efficient, uninterrupted operations.