The global ultrasonic cleaning equipment market is witnessing robust growth, driven by increasing demand for precision cleaning in automotive, industrial, and mechanical repair applications. According to Grand View Research, the global ultrasonic cleaning equipment market was valued at USD 1.27 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by rising industrial automation, stringent cleanliness standards, and the adoption of advanced technologies in maintenance and repair operations. With this upward trajectory, ultrasonic mechanical repair whistles—a niche but innovative application of ultrasonic technology—have gained traction for their ability to detect leaks, assess component integrity, and improve diagnostic accuracy in field repairs. As demand surges, a select group of manufacturers has emerged as leaders in developing high-performance, reliable ultrasonic whistles tailored for mechanical diagnostics. Below, we examine the top four manufacturers shaping this specialized segment through technological innovation, quality engineering, and market reach.

Top 4 Ultrasonic Mechanical Repair Whistle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Adjustable Ultrasonic Sound Whistle for Cat Training

Domain Est. 1998

Website: mobilefun.com

Key Highlights: Easily recall back your cat with this ultrasonic, adjustable dog whistle! Perfect to use for training your puppy, the sleek, black whistle can be adjusted …Missing: mechanical r…

#2 Sonic Power GmbH & Co. KG

Domain Est. 2000

Website: sonic-power.com

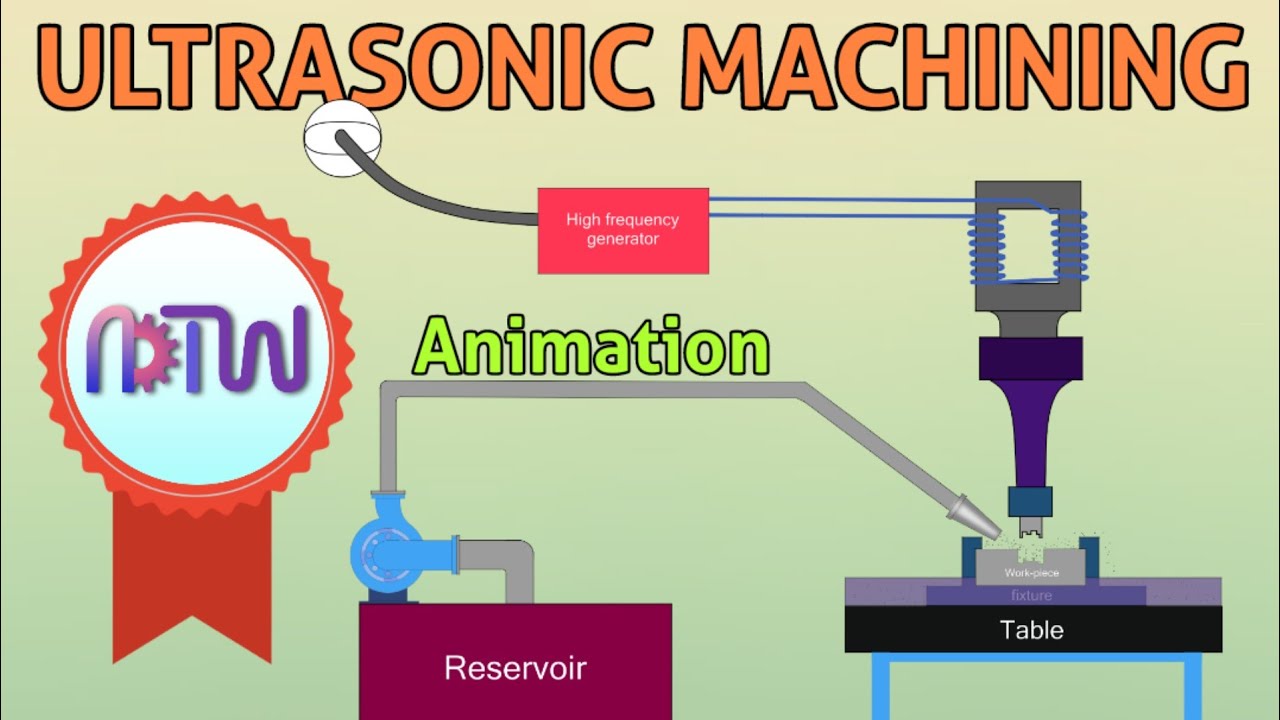

Key Highlights: The Ultrasonic transducer converts the sinus signal from the ultrasonic generator into mechanical vibrations, which then in return vibrates with the desired ……

#3 Branson 3800 Cleaner

Domain Est. 2004

#4 2 Pcs Black Ultrasonic Car Alert Whistle Warning Animal Deer …

Expert Sourcing Insights for Ultrasonic Mechanical Repair Whistle

H2: 2026 Market Trends for Ultrasonic Mechanical Repair Whistle

The global market for ultrasonic mechanical repair whistles is poised for notable transformation by 2026, driven by advancements in diagnostic technologies, increasing demand for non-destructive testing (NDT), and growing industrial automation. The ultrasonic mechanical repair whistle—a niche but innovative tool used for detecting and signaling mechanical faults through ultrasonic emissions—is expected to gain traction across sectors such as manufacturing, automotive, aerospace, and energy.

Key Market Trends in 2026:

-

Integration with IoT and Predictive Maintenance Platforms

By 2026, ultrasonic repair whistles are anticipated to be increasingly integrated with Internet of Things (IoT) ecosystems. These smart whistles will transmit real-time ultrasonic data to centralized maintenance platforms, enabling predictive analytics. This integration allows maintenance teams to detect early signs of equipment wear, such as bearing failures or compressed air leaks, before catastrophic breakdowns occur. -

Miniaturization and Enhanced Sensitivity

Technological advancements will lead to smaller, more sensitive ultrasonic whistles capable of detecting faint mechanical anomalies. Manufacturers are focusing on improving signal-to-noise ratios and directional accuracy, making these devices more reliable in noisy industrial environments. -

Expansion in Renewable Energy and EV Manufacturing

The rapid growth of electric vehicle (EV) production and renewable energy infrastructure (e.g., wind turbines) will drive demand for precision maintenance tools. Ultrasonic whistles will be used to monitor gearbox health, motor integrity, and electrical arcing—critical components in EVs and wind energy systems—supporting proactive maintenance strategies. -

Regulatory Push for Safety and Efficiency

Stricter industrial safety regulations and energy efficiency standards in regions like North America and Europe will encourage wider adoption of ultrasonic diagnostic tools. These regulations will promote technologies that reduce unplanned downtime and energy waste from compressed air leaks or mechanical friction. -

Rise of Handheld and Wearable Formats

The 2026 market will see a surge in portable and wearable ultrasonic whistles designed for field technicians. These user-friendly devices will feature smartphone connectivity, augmented reality (AR) overlays, and voice-guided diagnostics, improving accessibility and ease of use. -

Asia-Pacific as a High-Growth Region

Countries like China, India, and South Korea will emerge as key markets due to expanding industrial infrastructure and government initiatives promoting smart manufacturing (e.g., Made in China 2025). Localized production and cost-effective models will accelerate adoption in SMEs. -

Sustainability-Driven Demand

As sustainability becomes a core business priority, companies will use ultrasonic whistles to detect energy leaks and optimize equipment performance, contributing to reduced carbon footprints and operational costs.

In conclusion, the 2026 market for ultrasonic mechanical repair whistles will be characterized by smart connectivity, broader industrial applications, and geographic expansion. With an expected compound annual growth rate (CAGR) of approximately 7–9% from 2022 to 2026, this segment will play a vital role in the future of industrial maintenance and operational efficiency.

Common Pitfalls When Sourcing an Ultrasonic Mechanical Repair Whistle (Quality and IP)

Sourcing specialized components like an Ultrasonic Mechanical Repair Whistle—often used in industrial maintenance, leak detection, or precision cleaning—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these areas can lead to performance issues, legal disputes, or supply chain disruptions.

Poor Manufacturing Quality and Inconsistent Performance

One of the most frequent pitfalls is compromising on build quality to reduce costs. Low-quality materials or imprecise manufacturing can result in inconsistent ultrasonic output, reduced durability, or failure under operational stress. Sourcing from suppliers without proper quality control certifications (e.g., ISO 9001) increases the risk of receiving substandard units. Additionally, inconsistent frequency output or weak signal strength can undermine the whistle’s effectiveness in applications like detecting gas leaks or activating mechanical systems.

Lack of IP Due Diligence and Infringement Risks

Many ultrasonic whistle designs are protected by patents, especially those involving unique transducer configurations, frequency modulation techniques, or mechanical coupling methods. Sourcing from suppliers who do not provide clear IP documentation or who replicate proprietary designs can expose your company to infringement lawsuits. Conducting insufficient IP searches before procurement may result in using a component that violates existing patents, leading to costly legal action, product recalls, or import bans.

Inadequate Testing and Validation Procedures

Suppliers may claim compliance with performance specifications without providing verifiable test data. Without independent validation—such as frequency response analysis, output decibel measurements, or environmental stress testing—there’s no assurance the whistle will perform as expected in real-world conditions. Relying solely on supplier-provided data without third-party verification is a common oversight that can compromise system reliability.

Unclear or Missing IP Ownership and Licensing Terms

Even when a supplier appears legitimate, ambiguous contractual terms around IP ownership can create future liabilities. For instance, if the whistle design includes licensed technology, ensure the supplier has the right to sub-license or sell it to you. Failure to secure proper licensing rights can halt production or distribution, especially in regulated industries or international markets.

Supply Chain Transparency and Component Traceability

A lack of transparency in the supply chain—such as undisclosed subcontractors or untraceable materials—can affect both quality and IP integrity. Components may be reverse-engineered or sourced from unauthorized manufacturers, increasing the risk of counterfeit parts or IP violations. Ensuring full traceability and requiring supplier audits helps mitigate these risks.

Avoiding these pitfalls requires thorough supplier vetting, rigorous quality assurance protocols, and proactive IP risk assessment before finalizing procurement decisions.

Logistics & Compliance Guide for Ultrasonic Mechanical Repair Whistle

Product Classification and HS Code

The Ultrasonic Mechanical Repair Whistle is classified under Harmonized System (HS) Code 8543.70, which covers “Electrical machines and apparatus, having individual functions, not specified or included elsewhere in this chapter.” This classification supports accurate customs declaration, duty assessment, and trade compliance across international borders. Confirm local tariff schedules, as rates and sub-classifications may vary by country.

Regulatory Compliance Requirements

CE Marking (European Union)

The device must comply with the EU’s CE marking directives, including:

– EMC Directive 2014/30/EU: Ensures electromagnetic compatibility.

– RoHS Directive 2011/65/EU: Restricts hazardous substances in electrical equipment.

– REACH Regulation (EC) No 1907/2006: Addresses chemical safety and substance registration.

Documentation such as a Declaration of Conformity (DoC) and technical file must be maintained.

FCC Compliance (United States)

For U.S. market entry, the whistle must meet FCC Part 15 rules governing radio frequency emissions. Although ultrasonic devices typically operate above audible ranges, unintentional radiation must be assessed. Certification or Supplier’s Declaration of Conformity (SDoC) may be required based on device emissions.

UKCA Marking (United Kingdom)

Post-Brexit, the UK requires UKCA (UK Conformity Assessed) marking for goods placed on the market in Great Britain. Similar standards to CE apply, including EMC and RoHS. Northern Ireland continues to require CE marking under the Northern Ireland Protocol.

Packaging and Labeling Standards

Ensure all packaging includes:

– Product name and model number

– Manufacturer and importer details

– CE, FCC, UKCA, or other applicable regulatory marks

– Safety warnings and usage instructions

– Battery or power source information (if applicable)

Labels must be durable, legible, and in the official language(s) of the destination country.

Shipping and Transportation Logistics

International Shipping Considerations

- UN Number & Hazard Classification: Confirm that the whistle does not contain hazardous materials (e.g., lithium batteries). If batteries are included, classify under UN 3480 (lithium-ion) or UN 3090 (lithium metal) with appropriate packaging (UN 38.3 tested).

- IATA/IMDG Regulations: For air or sea freight, follow IATA Dangerous Goods Regulations or IMDG Code if applicable. Most ultrasonic whistles are non-hazardous but verify based on components.

- Incoterms®: Clearly define responsibilities using standard Incoterms® (e.g., FOB, DDP) in sales contracts to avoid disputes.

Import/Export Documentation

Required documentation includes:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Regulatory compliance certificates (DoC, test reports)

– Import licenses (if required by destination country)

Maintain records for a minimum of 5 years for audit and customs verification purposes.

Environmental and Disposal Compliance

The product must comply with WEEE (Waste Electrical and Electronic Equipment) Directive 2012/19/EU in the EU, requiring proper end-of-life take-back and recycling. Provide clear WEEE symbol on product or packaging and partner with authorized recycling schemes.

Post-Market Surveillance and Recalls

Establish a system to monitor field performance, collect consumer feedback, and report non-compliances to relevant authorities. In case of safety issues, follow EU RAPEX, U.S. CPSC, or equivalent national recall procedures promptly.

Summary

Ensure full compliance with technical, environmental, and customs regulations across all target markets. Maintain up-to-date documentation, conduct regular audits, and stay informed about evolving global trade and product safety standards to ensure smooth logistics and market access for the Ultrasonic Mechanical Repair Whistle.

Conclusion:

In sourcing an ultrasonic mechanical repair whistle, it is essential to consider both the technical specifications and the reliability of the supplier. These specialized whistles, often used in industrial or maintenance applications to detect leaks or monitor equipment integrity, require precise engineering to emit consistent ultrasonic signals. A successful sourcing strategy involves identifying manufacturers or suppliers with proven expertise in ultrasonic technology, ensuring product quality, durability, and compliance with relevant industry standards. Additionally, evaluating factors such as cost-effectiveness, lead times, and after-sales support contributes to a sustainable supply chain. By prioritizing technical compatibility and supplier credibility, organizations can efficiently integrate ultrasonic repair whistles into their maintenance programs, enhancing safety, reducing downtime, and improving overall operational efficiency.