The global wall anchor market is experiencing steady growth, driven by rising construction activities, urbanization, and demand for efficient fastening solutions in both residential and commercial sectors. According to a report by Mordor Intelligence, the global anchors and fasteners market is projected to grow at a CAGR of over 5.8% between 2023 and 2028, with wall anchors representing a significant segment due to their widespread use in drywall, masonry, and timber applications. Similarly, Grand View Research estimates that the construction fasteners market, which includes wall anchors, was valued at USD 34.5 billion in 2022 and is expected to expand at a CAGR of 6.2% from 2023 to 2030. This growth is fueled by advancements in anchor design, increasing DIY culture, and stringent building standards that prioritize structural safety. As demand surges, a diverse range of manufacturers—from large multinational corporations to specialized niche producers—have emerged, each offering distinct types of wall anchors tailored to specific load capacities, substrates, and installation environments. Below is a data-driven overview of the top 10 types of wall anchor manufacturers shaping this evolving market landscape.

Top 10 Types Of Wall Anchor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Electrical Construction Hardware Manufacturer & Supplier. Anchors

Domain Est. 1996

Website: minerallac.com

Key Highlights: Concrete/Masonry Anchors · Hollow Wall Anchors · Plastic Anchors · Wall Dog Universal Anchors….

#2 TOGGLER – High

Domain Est. 1995

Website: toggler.com

Key Highlights: SNAPTOGGLE®. Heavy-Duty Toggle Bolts. Hollow Materials. The Perfect TV Mount In Stainless Steel And Zinc Plated Carbon Steel ; TOGGLER®. Plastic Toggle Anchors….

#3 Simpson Strong

Domain Est. 1995

Website: strongtie.com

Key Highlights: Welcome to the Simpson Strong-Tie homepage showcasing our resources, products and services designed to help people build safer, stronger structures….

#4 Fasteners

Domain Est. 1995

Website: hilti.com

Key Highlights: Mechanical anchors · Chemical anchors · Anchor rods & elements · Cast-in anchors · Cast-in anchor channels · Screws · Nails · Threaded studs & standoffs….

#5 Cobra Anchors

Domain Est. 1999

Website: cobraanchors.com

Key Highlights: Discover Cobra Anchors’ strong, easy-to-install anchors and hanging hardware for drywall, masonry, concrete, and other projects….

#6 Drywall Anchors

Domain Est. 2002

Website: allfasteners.com

Key Highlights: 4-day delivery 30-day returnsFrom plastic expansion anchors to the metal toggle type, we have the perfect fasteners for hanging anything on the wall….

#7 EZ Ancor

Domain Est. 2006

Website: easyanchors.com

Key Highlights: EZ Ancors are a simple, secure, fast, and easy way to install whatever you need into drywall, with a holding of strength up to 100 pounds in shear applications….

#8 Understanding Anchors

Domain Est. 2006

Website: fastenermart.com

Key Highlights: Anchors fall into seven basic categories: Internally Threaded, Externally Threaded, Masonry Screw and Pin, Screw, Hollow Wall, Sleeve and Drive Anchors….

#9 Anchor Products

Domain Est. 2011

Website: anchorp.com

Key Highlights: Anchor Products provides innovative rooftop attachment solutions trusted by contractors and engineers nationwide. Our U-Anchor™ systems deliver secure, ……

#10 Wall Anchor Types & Selection Guide

Domain Est. 1994

Website: grainger.com

Key Highlights: Learn how to select the right wall anchor by considering base material, load requirements and environmental conditions….

Expert Sourcing Insights for Types Of Wall Anchor

H2: 2026 Market Trends for Types of Wall Anchors

The global market for wall anchors is poised for significant evolution by 2026, driven by advancements in construction technologies, growing demand for sustainable building materials, and a shift toward DIY (do-it-yourself) home improvement projects. As urbanization accelerates and renovation activities increase globally, the demand for reliable and versatile wall anchoring solutions is expected to rise across residential, commercial, and industrial sectors. Below is an analysis of key trends shaping the various types of wall anchors in the 2026 market landscape.

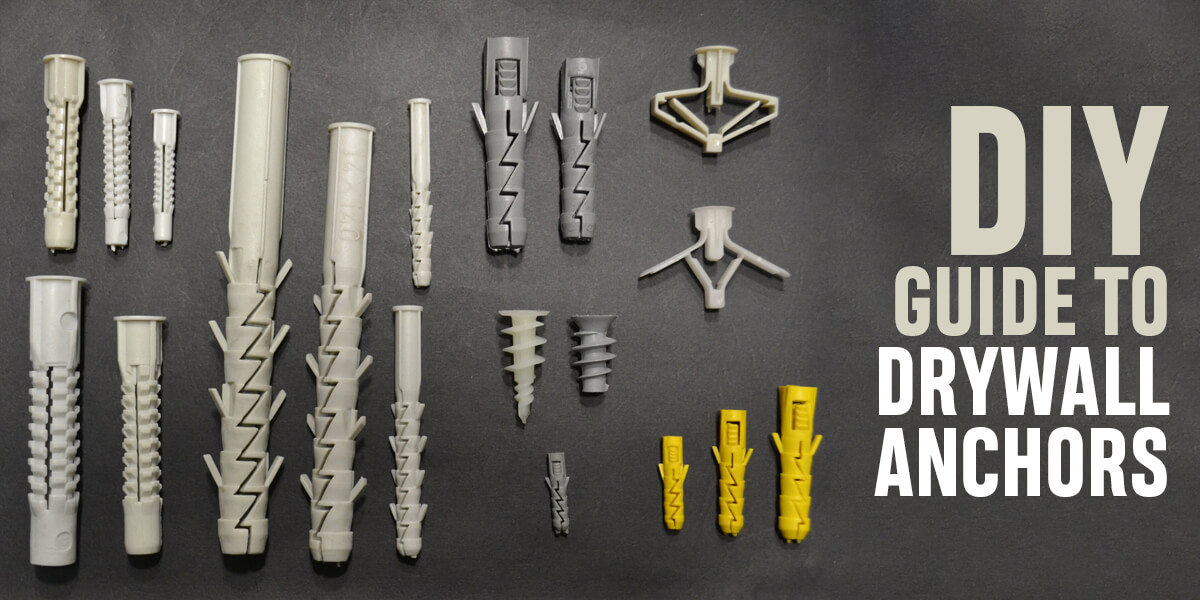

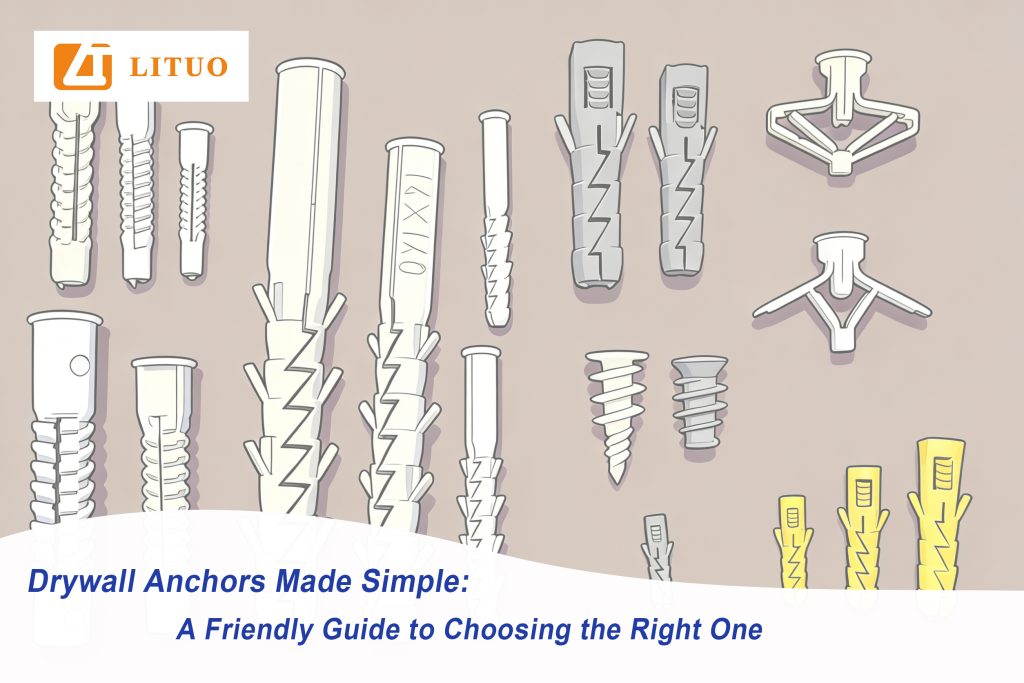

1. Expansion of Lightweight Anchor Solutions

By 2026, lightweight wall anchors—such as plastic expansion anchors, toggle bolts, and snap toggles—are anticipated to dominate the market, particularly in residential and DIY applications. The increasing popularity of drywall and hollow wall construction in modern buildings has boosted demand for anchors that offer ease of installation and sufficient load-bearing strength. Innovations in polymer materials are enhancing the durability and performance of plastic anchors, making them suitable for medium-duty applications.

2. Growth in Heavy-Duty and Structural Anchors

The commercial and industrial construction sectors are driving demand for heavy-duty anchors like wedge anchors, sleeve anchors, and drop-in anchors. With the rise in high-rise buildings, infrastructure projects, and seismic retrofitting, structural integrity is paramount. The 2026 market will see increased adoption of corrosion-resistant and high-tensile steel anchors, especially in regions prone to extreme weather or seismic activity. Smart anchoring systems with load-monitoring capabilities may begin emerging in niche applications.

3. Sustainability and Eco-Friendly Materials

Environmental concerns are influencing anchor manufacturing, with a trend toward recyclable and low-impact materials. By 2026, manufacturers are expected to launch bio-based or recycled-content plastic anchors and promote eco-conscious packaging. Additionally, longer-lasting anchors that reduce the need for replacements align with green building certifications like LEED and BREEAM, further boosting market appeal.

4. Rise of Smart and Hybrid Anchoring Systems

While still in early stages, smart anchors integrated with sensors for stress, vibration, or moisture detection are expected to gain traction in critical infrastructure and high-security installations. Though not mainstream by 2026, research and pilot projects in this area will lay the groundwork for future adoption. Hybrid anchors that combine the benefits of multiple technologies (e.g., toggle-expansion designs) will become more common, offering versatility across different wall substrates.

5. Regional Market Dynamics

North America and Europe will remain key markets due to high rates of home renovation and strict building codes. In contrast, the Asia-Pacific region—especially China, India, and Southeast Asia—will experience the fastest growth, fueled by rapid urbanization and government-led infrastructure development. Localized manufacturing and distribution networks will expand to meet rising demand in these regions.

6. E-Commerce and Consumer Accessibility

The DIY trend, accelerated by online tutorials and home improvement platforms, will continue to influence purchasing behavior. By 2026, e-commerce channels will account for a significant share of wall anchor sales, with consumers favoring kits that include multiple anchor types for various applications. Enhanced product labeling and augmented reality (AR) tools may help users select the right anchor type for their specific wall material.

Conclusion

By 2026, the wall anchor market will be characterized by innovation, sustainability, and diversification. While traditional anchor types will remain in strong demand, advancements in materials and design will cater to evolving construction needs and consumer preferences. Stakeholders in the market—manufacturers, retailers, and contractors—must adapt to these trends to maintain competitiveness in an increasingly dynamic and globalized industry.

Common Pitfalls When Sourcing Types of Wall Anchors (Quality, IP)

Sourcing the right wall anchors is critical for ensuring structural integrity, safety, and long-term performance in construction and installation projects. However, several common pitfalls can compromise quality and lead to improper Ingress Protection (IP) ratings, especially in demanding environments. Being aware of these issues helps avoid costly failures and rework.

Overlooking Material Quality and Durability

One of the most frequent mistakes is selecting wall anchors based solely on cost without evaluating the material quality. Low-grade metals (such as uncoated zinc or thin steel) are prone to corrosion, especially in humid or outdoor environments. This compromises holding strength over time and can lead to anchor failure. Always verify material specifications—stainless steel (e.g., A2 or A4) or hot-dip galvanized options are recommended for durability and resistance to rust.

Ignoring Load Capacity and Application Requirements

Suppliers may offer anchors that appear similar but vary significantly in load-bearing capacity. Using an anchor rated below the required load leads to pull-out or cracking in the base material (e.g., drywall, concrete, or masonry). It’s essential to match the anchor type (e.g., toggle, sleeve, or plastic expansion) to both the substrate and the expected mechanical load, including dynamic forces or vibration.

Assuming All Anchors Are Suitable for Wet or Harsh Environments

Ingress Protection (IP) ratings are often overlooked when sourcing wall anchors for use in bathrooms, outdoor installations, or industrial settings. While wall anchors themselves aren’t typically assigned formal IP ratings, their compatibility with sealed enclosures or wet locations depends on corrosion resistance and sealing mechanisms. Using non-IP-compatible anchors in damp environments can result in internal rust, weakening, and electrical hazards in installations involving electrical boxes or equipment.

Relying on Inconsistent or Unverified Supplier Specifications

Some suppliers provide incomplete or exaggerated technical data, such as overstated pull-out strength or misleading compatibility claims. This is particularly common with generic or off-brand anchors. Always request third-party test certifications or performance data, and source from reputable manufacturers with traceable quality control processes.

Failing to Consider Installation Variables

Even high-quality anchors can underperform if installation conditions aren’t considered. Common issues include drilling incorrect hole sizes, using worn drill bits, or improper setting techniques (e.g., over-tightening plastic anchors). These factors affect anchor expansion and grip, reducing effective holding power and potentially compromising the IP integrity of sealed enclosures.

Not Accounting for Regulatory or Industry Standards

In certain applications—especially in commercial, healthcare, or public infrastructure—anchors must comply with regional building codes or fire safety standards. Sourcing anchors without verifying compliance (e.g., ASTM, ETA, or CE markings) can result in failed inspections or liability issues. Always confirm that the anchor type meets project-specific regulatory requirements.

Choosing the Wrong Anchor Type for the Substrate

Using a masonry anchor in drywall or a plastic anchor in concrete leads to immediate or premature failure. Each wall anchor is engineered for specific substrates. Mismatched pairings not only reduce holding strength but also risk damaging the base material, which can affect the overall integrity and environmental sealing of the installation.

By avoiding these common pitfalls and prioritizing quality, correct application, and environmental suitability (including IP considerations), sourcing professionals can ensure reliable, long-lasting performance of wall anchor installations.

Logistics & Compliance Guide for Types of Wall Anchors

Understanding the logistics and compliance considerations for wall anchors is essential for manufacturers, distributors, retailers, and installers. This guide outlines key aspects related to transportation, storage, labeling, safety standards, and regulatory compliance across various types of wall anchors.

Types of Wall Anchors Overview

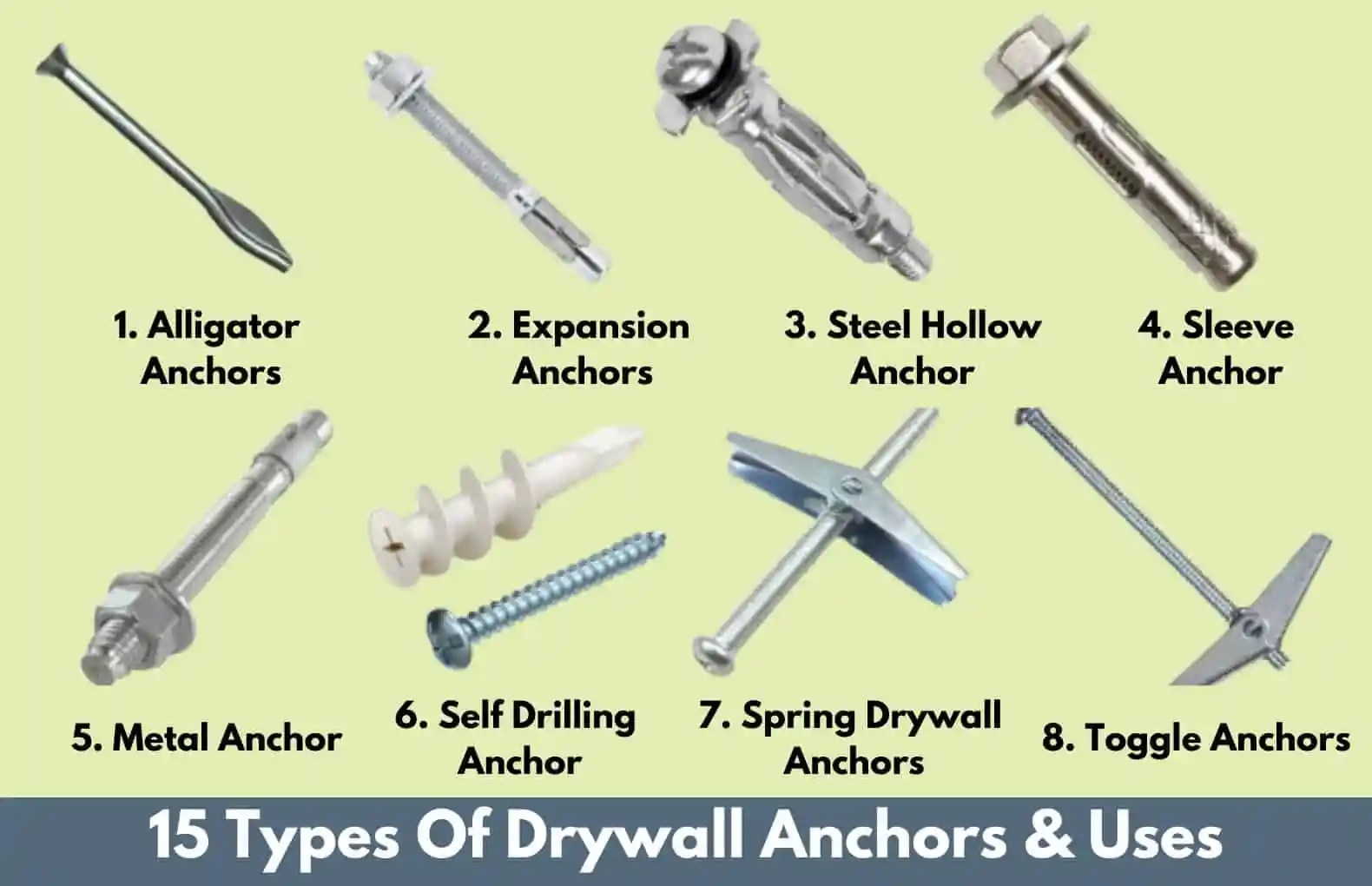

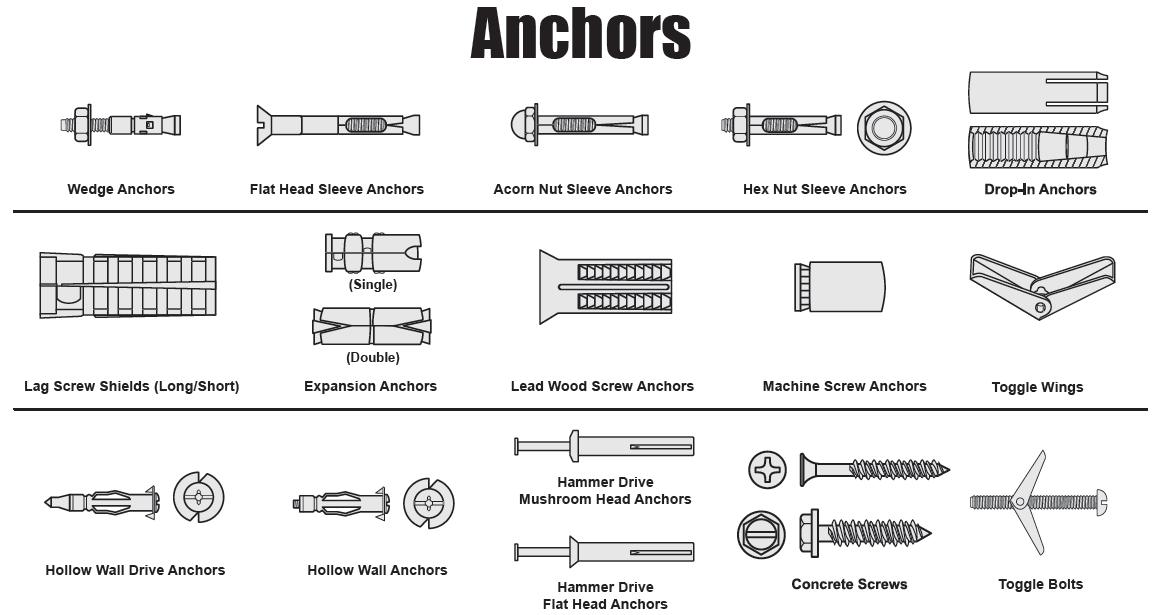

Wall anchors are fastening devices used to secure objects to walls, especially in hollow or brittle materials like drywall, plaster, or masonry. Common types include:

- Plastic Expansion Anchors

- Toggle Bolts (Butterfly Anchors)

- Molly Bolts

- Threaded Inserts (Sleeve Anchors)

- Self-Drilling Anchors (e.g., Snap-Toggles)

- Adhesive Anchors (e.g., epoxy or chemical anchors)

- Lead Screw Anchors

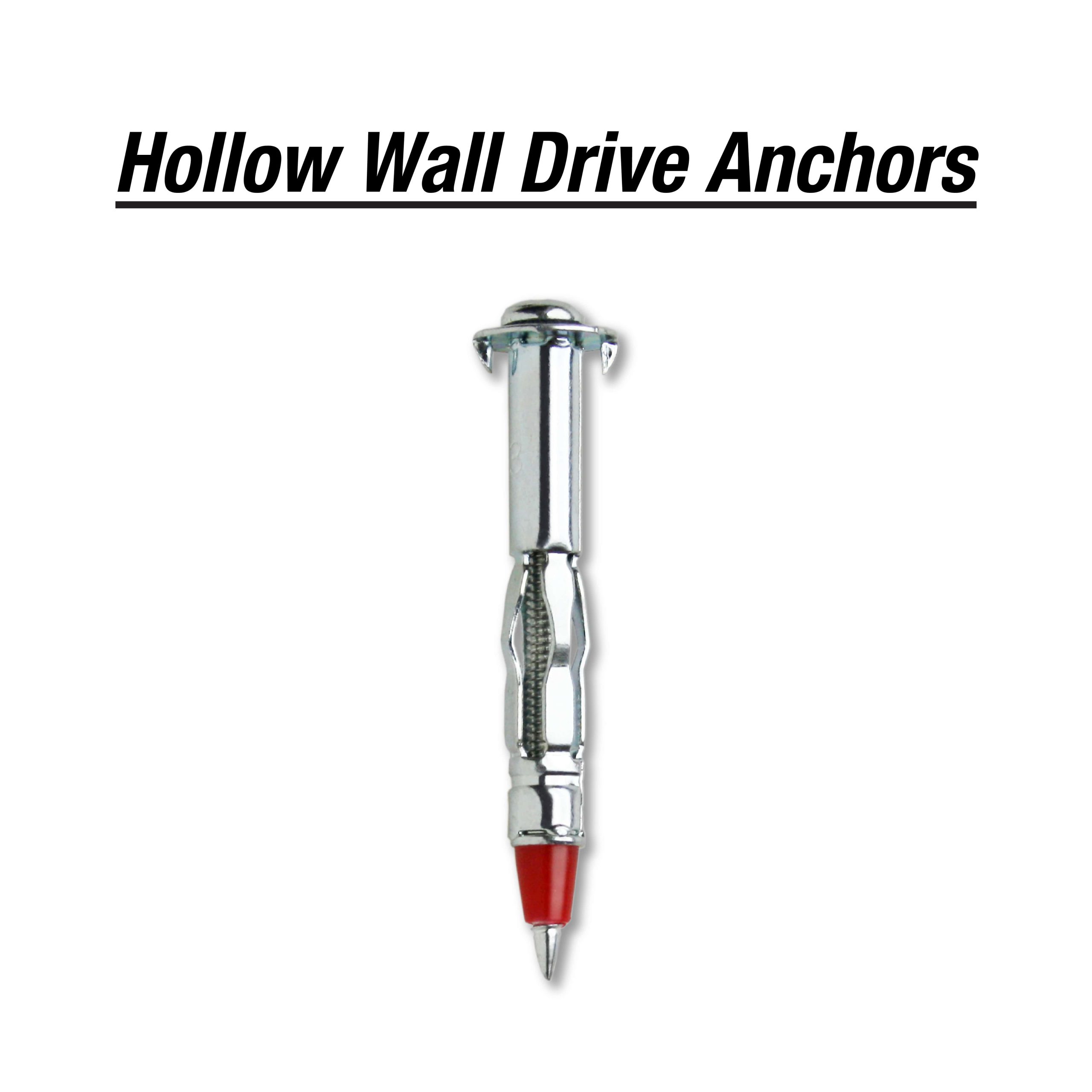

- Hollow Wall Anchors (e.g., spring toggles)

Each type has distinct material compositions, load capacities, and installation methods, which influence logistics and compliance requirements.

Packaging and Labeling Requirements

Proper packaging and labeling ensure product integrity and regulatory compliance during distribution.

- Packaging: Wall anchors should be packed in moisture-resistant, tamper-evident packaging to prevent corrosion (especially for metal anchors). Bulk packaging must prevent part mixing and physical damage.

- Labeling Must Include:

- Product name and type (e.g., “Plastic Wall Anchor, 1/4\””)

- Material composition (e.g., polypropylene, zinc-plated steel)

- Load ratings (shear and tensile) in both metric and imperial units

- Recommended drill bit size

- Installation instructions (or reference to online guide)

- Manufacturer/importer name and contact information

- Country of origin

- UPC or SKU for inventory tracking

Transportation and Storage Guidelines

Safe and efficient transportation and storage help preserve product quality and ensure worker safety.

- Transportation:

- Secure anchor packages to prevent shifting during transit.

- Avoid exposure to extreme temperatures or humidity, which can degrade plastic components.

-

Segregate metal anchors from corrosive materials during shipping.

-

Storage:

- Store in a dry, temperature-controlled environment.

- Use shelving to avoid floor contact and moisture absorption.

- Organize by anchor type and size to reduce picking errors and support inventory management.

Regulatory and Safety Compliance

Wall anchors must comply with regional safety and construction standards.

- United States:

- Governed by ASTM standards such as ASTM F1815 (Standard Specification for Expansion Anchors for Use in Concrete and Masonry).

- OSHA regulations may apply during installation (e.g., fall protection when mounting heavy fixtures).

-

Consumer Product Safety Commission (CPSC) guidelines may apply if used in consumer kits.

-

European Union:

- Must comply with CE marking requirements under the Construction Products Regulation (CPR) (Regulation (EU) No 305/2011).

- Harmonized standards such as EN 17749 (Anchors for use in masonry) apply.

-

REACH and RoHS compliance required for material substances (e.g., lead, cadmium).

-

Canada:

- Must meet CSA standards or be evaluated under the Canadian Building Code.

-

Health Canada may regulate chemical anchors containing hazardous substances.

-

Australia/New Zealand:

- Compliance with AS/NZS 1562.2 for non-structural fixings in masonry.

- Product Safety Australia oversees consumer product requirements.

Environmental and Sustainability Considerations

Environmental compliance is increasingly important in logistics and sourcing.

- Material Sourcing: Use recyclable or sustainably sourced plastics and metals where possible.

- Waste Management: Recycle packaging materials and manage industrial waste per local regulations.

- Carbon Footprint: Optimize shipping routes and consolidate orders to reduce emissions.

Import and Export Compliance

For international trade, specific documentation and approvals are required.

- Customs Declarations: Accurate HS codes (e.g., 7318.15 for threaded fasteners) must be used.

- Documentation: Include commercial invoices, packing lists, certificates of origin, and compliance certificates (e.g., CE, RoHS).

- Duty and Tariff Classification: Wall anchors may be subject to import duties depending on material and country of manufacture.

Quality Assurance and Traceability

Maintaining product quality throughout the supply chain is critical.

- Batch Tracking: Assign lot numbers to enable traceability in case of recalls.

- Testing and Certification: Conduct load testing and provide certification reports upon request.

- Supplier Audits: Regularly audit manufacturers to ensure consistent quality and compliance.

Installation and End-User Compliance

While not part of logistics per se, end-use compliance affects product design and labeling.

- Provide clear installation instructions aligned with safety standards.

- Warn against overloading or improper use (e.g., using drywall anchors in concrete).

- Include warnings for high-risk applications (e.g., anchoring heavy shelves above beds).

Conclusion

Effectively managing the logistics and compliance of wall anchors requires coordination across packaging, transportation, regulatory standards, and environmental practices. Adhering to these guidelines ensures product safety, legal compliance, and customer satisfaction across global markets.

In conclusion, selecting the appropriate type of wall anchor depends on several key factors including the wall material (such as drywall, plaster, concrete, or wood), the load weight, the size and type of fastener used, and the specific application requirements. Common types of wall anchors—such as plastic expansion anchors, self-drilling anchors, toggle bolts, molly bolts, and sleeve anchors—each offer distinct advantages in different scenarios. Lightweight applications may only require simple plastic anchors, while heavier fixtures demand more robust solutions like toggle or molly bolts. Proper installation technique is also crucial to ensure secure and long-lasting performance. By understanding the strengths and limitations of each anchor type and matching them to the wall substrate and load requirements, users can achieve reliable and safe mounting solutions for a wide range of projects.