The global trailer suspension systems market is experiencing steady growth, driven by rising demand for heavy-duty commercial vehicles and increasing emphasis on improving ride stability and load-carrying efficiency. According to Grand View Research, the global commercial vehicle suspension market size was valued at USD 12.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion is fueled by advancements in suspension technology, stricter regulatory standards for vehicle safety, and growing e-commerce logistics networks that rely heavily on trailer transport. As a result, manufacturers are innovating across various trailer suspension types—including leaf spring, air ride, rubber torsion, and mechanical spring systems—to meet diverse application needs in freight, refrigerated transport, and specialized hauling. With North America and Europe leading in adoption of advanced air and hybrid suspensions, and Asia Pacific witnessing rapid market penetration due to expanding fleet infrastructure, the competitive landscape features nine key types of suspension systems providers differentiated by technology, application, and regional footprint.

Top 9 Types Of Trailer Suspension Systems Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hendrickson

Domain Est. 1997

Website: hendrickson-intl.com

Key Highlights: Hendrickson is a leading global manufacturer and supplier of medium and heavy-duty mechanical, elastomeric, and air suspensions; integrated and non-integrated ……

#2 Hutchens Industries

Domain Est. 2000

Website: hutchensindustries.com

Key Highlights: Hutchens Industries, Inc. is a leader in the design and manufacturing of spring suspensions and sliding subframes for the trailer industry….

#3 Leading Manufacturer of Highly Engineered Components and …

Domain Est. 2018

Website: dexterindex.com

Key Highlights: Shop by Trailer Type. From boat and snowmobile trailers for recreation, to hard-working flat beds, utility, and agricultural trailers, Dexter is the industry’s ……

#4 Start page

Domain Est. 1995

Website: bendix.com

Key Highlights: Explore our products, technologies, and solutions in Advanced Driver Assistance, Air Supply and Air Management, Trailer, Vehicle Dynamics and Wheel-end. Quick ……

#5 Trailer Suspension Systems

Domain Est. 2000

Website: diamondc.com

Key Highlights: We offer 4 quality types of trailer suspension: Leaf Spring Suspension; Torsion Suspension; Heavy Duty Adjustable Suspension; Air Ride Suspension. Keep reading ……

#6 Heavy trucks: Suspension & steering systems

Domain Est. 2000

Website: simardsuspensions.com

Key Highlights: Simard Suspensions is the undisputed leader in developing ahead-of-the-curve, custom-fit suspension and steering systems for heavy trucks….

#7 Trailer Suspension

Domain Est. 2004

Website: wsdwheel.com

Key Highlights: Our product lineup includes everything from single-leaf to multi-leaf springs, along with complete suspension kits for seamless installation. Built using high- ……

#8 Trailer Axles and Suspension Systems

Domain Est. 2006

Website: safholland.com

Key Highlights: Trailer axle and suspension systems from SAF-HOLLAND are available for a multitude of transport tasks. A wide product range features high quality, and ……

#9 NeWay ADZ Suspensions

Domain Est. 2014

Website: newaysuspensions.com

Key Highlights: The ADZ is the industry’s lightest weight heavy-duty on and off-road drive axle air-ride suspension on the market. Simplified design and innovative ……

Expert Sourcing Insights for Types Of Trailer Suspension Systems

2026 Market Trends for Types of Trailer Suspension Systems

As the transportation and logistics industry evolves, trailer suspension systems are undergoing significant advancements to meet growing demands for efficiency, safety, durability, and compliance with environmental regulations. By 2026, several key trends are expected to shape the market for different types of trailer suspension systems, including leaf spring, air ride, rubber spring (torsion), and hybrid designs. These trends are driven by technological innovation, regulatory changes, and shifting customer preferences.

Growing Dominance of Air Ride Suspensions

Air ride suspension systems are projected to gain substantial market share by 2026, especially in premium and specialized trailers such as refrigerated units, flatbeds, and those used for transporting fragile goods. The primary drivers include:

- Enhanced Load Protection: Air suspensions offer superior shock absorption, reducing cargo damage and improving payload security.

- Improved Driver Comfort and Safety: Smoother rides contribute to better handling and reduced driver fatigue, supporting compliance with occupational health and safety standards.

- Weight Efficiency: Modern air suspension systems are being designed with lightweight composite and aluminum components, aiding fuel efficiency and increasing payload capacity.

- Integration with Telematics: By 2026, many air ride systems will include sensors that monitor ride height, pressure, and wear, enabling predictive maintenance and real-time diagnostics through fleet management platforms.

Resurgence and Innovation in Rubber Torsion Suspensions

Rubber torsion (or “live axle”) suspensions are experiencing a revival, particularly in utility trailers, boat trailers, and smaller commercial applications. Key trends include:

- Low Maintenance and Durability: With fewer moving parts than leaf or air suspensions, rubber torsion systems require minimal maintenance and are highly resistant to corrosion.

- Compact Design: Their space-efficient design makes them ideal for trailers with height or space constraints.

- Advancements in Material Science: By 2026, manufacturers are expected to use advanced elastomers and composite enclosures to improve load capacity and longevity, expanding their use into medium-duty applications.

Steady Demand for Leaf Spring Suspensions in Cost-Sensitive Markets

Leaf spring suspensions remain dominant in emerging markets and for heavy-duty applications such as construction and long-haul freight due to their simplicity and cost-effectiveness. Trends include:

- Cost Efficiency: They continue to be the most economical option for manufacturers and fleet operators in price-sensitive regions.

- Reinforced Designs: Modern leaf springs are being upgraded with high-tensile steel and multi-leaf configurations to improve performance and fatigue resistance.

- Hybrid Configurations: Some manufacturers are combining leaf springs with shock absorbers or stabilizers to bridge the performance gap with air ride systems.

Rise of Hybrid and Smart Suspension Systems

A notable trend emerging by 2026 is the development of hybrid suspension systems that combine air and mechanical components, or integrate electronic controls for adaptive performance. These systems offer:

- Adaptive Damping: Electronically controlled suspensions can adjust stiffness based on load, road conditions, and driving mode, optimizing ride quality and stability.

- Energy Efficiency: Regenerative suspension technologies, while still in early stages, are being explored to recover kinetic energy from road vibrations.

- Autonomous Vehicle Readiness: As autonomous trailers gain traction, smart suspensions with real-time feedback loops will be essential for maintaining stability and ensuring safe operation.

Regulatory and Environmental Influences

Environmental regulations and emissions standards are pushing trailer manufacturers to reduce weight and improve fuel economy. This supports the adoption of lightweight suspension systems, particularly air and advanced rubber torsion designs. Additionally, noise pollution standards in urban areas favor quieter suspensions, giving air ride systems a competitive edge.

Regional Market Variations

- North America and Europe: These regions will lead in air and smart suspension adoption due to higher freight values, regulatory stringency, and advanced fleet infrastructure.

- Asia-Pacific: Leaf spring systems will remain prevalent, especially in India and Southeast Asia, though air suspension use is growing in premium logistics segments.

- Latin America and Africa: Cost-effective leaf spring suspensions will dominate, with gradual penetration of rubber torsion in light commercial sectors.

Conclusion

By 2026, the trailer suspension market will be characterized by a shift toward advanced, intelligent systems, with air ride suspensions leading in performance-driven segments. However, leaf spring and rubber torsion systems will maintain strong niches due to their reliability and cost advantages. The integration of digital technologies and a focus on sustainability will further differentiate product offerings and shape competitive dynamics across global markets.

Common Pitfalls When Sourcing Types of Trailer Suspension Systems (Quality, IP)

Sourcing trailer suspension systems involves critical decisions that impact performance, safety, and compliance. Overlooking key factors—particularly quality and intellectual property (IP) risks—can lead to costly setbacks. Below are common pitfalls to avoid:

Neglecting Material and Build Quality Standards

Many buyers focus on price and overlook the importance of material quality and manufacturing precision. Low-cost suspensions may use substandard steel, inferior rubber components, or poor welding practices, leading to premature failure, reduced load capacity, and safety hazards. Always verify that suppliers adhere to recognized industry standards (e.g., SAE, ISO) and conduct third-party testing.

Overlooking Application-Specific Requirements

Trailer suspensions vary widely—leaf spring, air ride, torsion axle, and walking beam systems each serve different purposes. Sourcing the wrong type for the intended application (e.g., using leaf springs for high-vibration freight) results in poor ride quality, cargo damage, and excessive wear. Ensure compatibility with load type, terrain, and usage frequency.

Ignoring Durability and Maintenance Needs

Some suspension systems require frequent maintenance or have shorter service lives. Failing to assess long-term durability and service intervals increases total cost of ownership. Request maintenance schedules, lifecycle data, and real-world performance reports from suppliers.

Falling for Counterfeit or Non-Certified Components

The trailer parts market includes counterfeit or unbranded suspensions that mimic reputable brands. These may lack proper engineering, certifications, or traceability. Always source from authorized distributors and verify certifications like DOT, AAR, or OEM approvals.

Underestimating Intellectual Property (IP) Risks

Using suspension designs that infringe on patented technologies—such as specific air spring configurations or proprietary mounting systems—can result in legal action, product recalls, or import bans. Conduct due diligence to ensure components do not violate existing patents, especially when sourcing from overseas manufacturers.

Relying Solely on Supplier Claims Without Verification

Suppliers may exaggerate load ratings, lifespan, or performance benefits. Without independent verification through test reports, customer references, or sample evaluations, buyers risk receiving underperforming products. Request performance data and, if possible, conduct field testing.

Failing to Secure Proper Documentation and Traceability

Lack of documentation—such as material certifications, design schematics, or compliance reports—can hinder quality audits, warranty claims, or regulatory compliance. Ensure suppliers provide complete traceability and technical documentation for every batch.

Not Considering Aftermarket Support and Spare Parts Availability

Even high-quality suspensions will eventually need parts or service. Sourcing from suppliers with poor aftermarket support leads to extended downtime. Evaluate the availability of replacement components and technical assistance before finalizing procurement.

Avoiding these pitfalls ensures reliable performance, legal compliance, and long-term value when sourcing trailer suspension systems. Prioritize quality verification, IP due diligence, and supplier transparency to make informed procurement decisions.

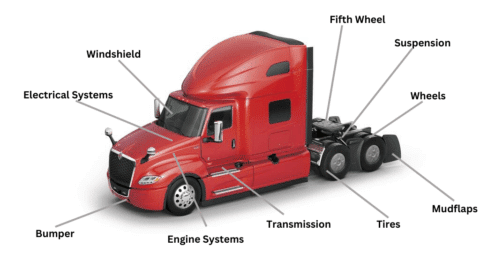

Types of Trailer Suspension Systems: Logistics & Compliance Guide

Understanding the various trailer suspension systems is essential for safe, efficient, and compliant freight transportation. The choice of suspension impacts load stability, ride quality, maintenance requirements, and regulatory adherence. This guide outlines common types of trailer suspensions, their logistical considerations, and compliance implications.

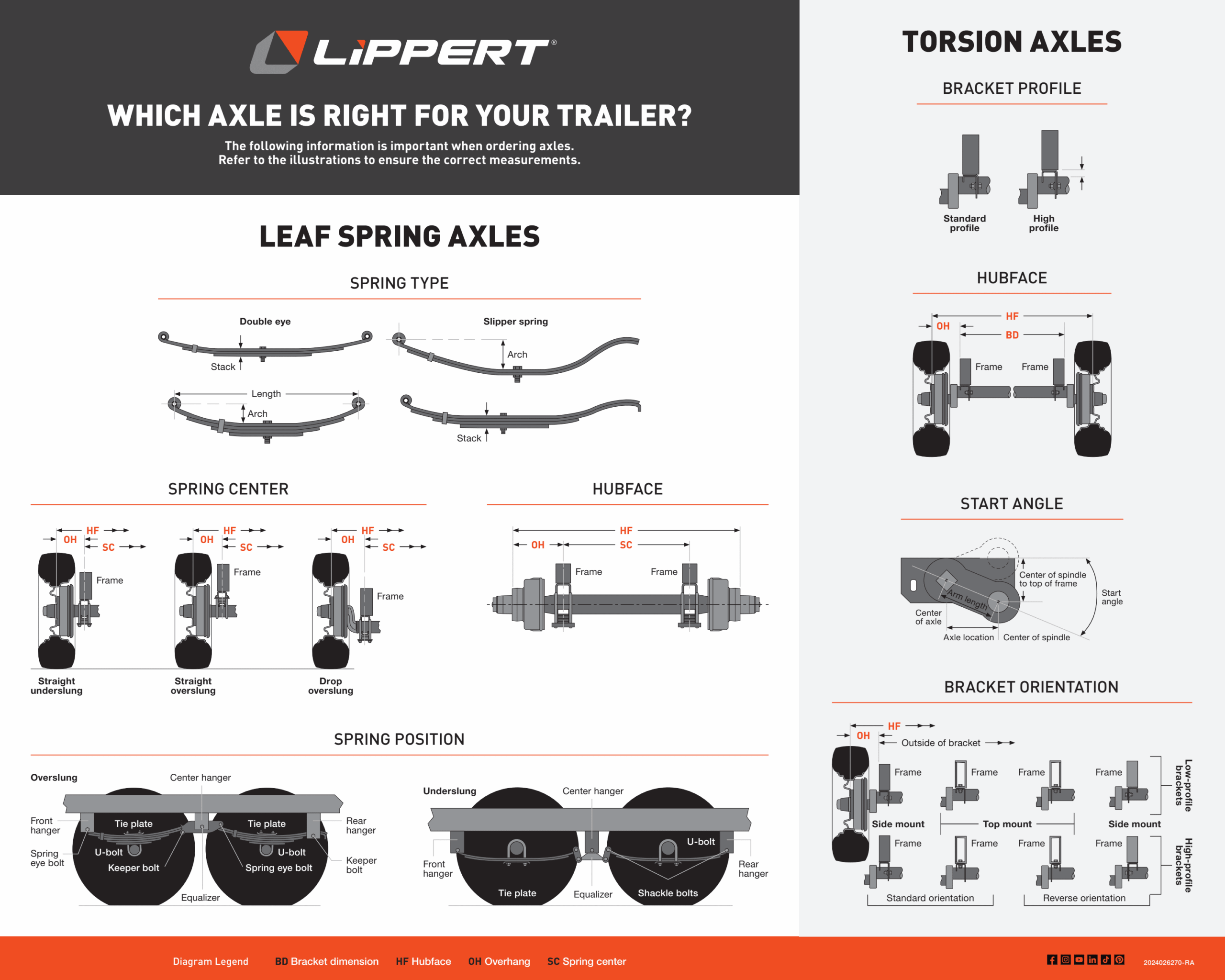

Leaf Spring Suspension

Leaf spring suspension is one of the most traditional and widely used systems in the trailer industry. It consists of multiple curved steel plates (leaves) stacked together and attached to the trailer frame and axle.

Logistics Considerations:

– Durability: Ideal for heavy-duty applications and rough terrain due to its robust construction.

– Load Capacity: Well-suited for high-load operations such as flatbed and dump trailers.

– Maintenance: Requires regular greasing and inspection for cracked or broken leaves.

– Weight: Heavier than some modern alternatives, which can impact payload capacity.

Compliance Implications:

– Must comply with FMVSS (Federal Motor Vehicle Safety Standards) requirements for structural integrity.

– Inspect for sagging or deformation during DOT inspections; excessive wear can lead to out-of-service violations.

– Proper U-bolts and fasteners must be used and torqued to manufacturer specifications.

Air Ride Suspension

Air ride suspension uses air springs (rubber bellows filled with compressed air) instead of metal springs. It is popular in dry van, refrigerated, and intermodal trailers where cargo protection is critical.

Logistics Considerations:

– Ride Quality: Provides a smoother ride, minimizing cargo damage—ideal for sensitive freight.

– Adjustability: Air pressure can be adjusted based on load weight, improving tire wear and fuel efficiency.

– Maintenance: Requires regular checks of air lines, valves, and bellows for leaks; compressors and dryers need servicing.

– Cost: Higher initial cost but often justified by reduced cargo claims and tire wear.

Compliance Implications:

– Air systems must be leak-free; visible air leaks can result in roadside violations.

– Height control valves and ride height must meet FMVSS and state regulations.

– DOT inspections include checks for proper air spring inflation and structural integrity.

Torsion Suspension

Torsion suspension uses rubber cords or tubes encased in a tube to provide spring action through twisting. Common in utility, boat, and small enclosed trailers.

Logistics Considerations:

– Low Maintenance: No need for greasing; fewer moving parts than leaf springs.

– Smooth Ride: Offers better vibration damping over small bumps and uneven surfaces.

– Compact Design: Saves space, beneficial for trailers with limited undercarriage room.

– Limited Load Range: Best for lighter loads; not ideal for heavy freight applications.

Compliance Implications:

– Rubber elements must be inspected for cracking, swelling, or wear during safety checks.

– Mounting brackets and axle housings must be secure and corrosion-free.

– Not typically used in commercial Class 7–8 trucks; verify state regulations for commercial use.

Rubber Ride (Rubber-in-Shear) Suspension

This system uses molded rubber springs that compress and shear to absorb road shocks. Brands like Hendrickson’s PRIMAAX and Meritor’s Q-Spring are examples.

Logistics Considerations:

– Maintenance-Free: No lubrication required; resistant to corrosion and environmental damage.

– Weight Savings: Lighter than traditional suspensions, increasing payload capacity.

– Performance: Excellent for on-road applications with consistent pavement.

– Replacement: Entire modules may need replacement if damaged, increasing long-term cost.

Compliance Implications:

– Must meet FMVSS and manufacturer load ratings.

– Regular inspection for rubber degradation, especially in extreme temperatures or UV exposure.

– Ensure axle alignment is maintained to prevent tire wear and handling issues.

Walking Beam Suspension

Commonly used in heavy-haul and multi-axle trailers, the walking beam system links axles with a pivoting beam to distribute weight evenly across uneven terrain.

Logistics Considerations:

– Weight Distribution: Excels in off-road or uneven surface conditions, such as construction or logging sites.

– Complexity: More moving parts require skilled maintenance.

– Ground Clearance: Higher clearance beneficial for rough terrain but increases center of gravity.

Compliance Implications:

– Must be rated for the intended gross vehicle weight (GVW) and axle load limits.

– Pivot points and bushings require regular inspection for wear.

– DOT inspectors check for excessive movement or structural damage during roadside exams.

Selecting the Right Suspension for Compliance and Efficiency

Choosing the appropriate trailer suspension involves balancing load type, operating environment, maintenance resources, and regulatory requirements. Always ensure:

– The suspension system is rated for the trailer’s intended GVWR.

– Manufacturer installation guidelines are strictly followed.

– Regular preventive maintenance is performed per OEM recommendations.

– All components meet or exceed federal and state safety standards.

Consult with OEMs and compliance specialists to match suspension types with your freight profile and regulatory obligations. Proper selection and upkeep enhance safety, reduce downtime, and support DOT compliance.

In conclusion, sourcing the appropriate type of trailer suspension system requires a thorough understanding of the specific application, load requirements, operating conditions, and performance expectations. The main types—leaf spring, air ride, torsion (rubber) axle, and hydraulic suspensions—each offer distinct advantages and limitations in terms of durability, ride quality, maintenance needs, and cost.

Leaf spring suspensions are robust and cost-effective, making them ideal for heavy-duty and commercial applications. Air ride systems provide superior ride comfort and load leveling, suitable for transporting sensitive or high-value cargo. Torsion axle suspensions offer a smoother ride and reduced maintenance, commonly used in recreational and utility trailers. Hydraulic suspensions, though less common, provide advanced adjustability and stability for specialized uses.

When sourcing, it is essential to consider factors such as payload capacity, terrain, frequency of use, and budget. Partnering with reliable suppliers and manufacturers who offer quality certifications, technical support, and warranty services further ensures long-term reliability and performance. Ultimately, selecting the right trailer suspension system enhances safety, prolongs trailer life, improves fuel efficiency, and ensures cargo integrity—making it a critical decision in trailer procurement and operation.