The global plaster market is experiencing steady expansion, driven by rising construction activities and demand for energy-efficient building materials. According to Grand View Research, the global gypsum market—key to plaster production—was valued at USD 44.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increased residential and commercial development, particularly in emerging economies, as well as the growing preference for lightweight, fire-resistant, and sound-absorbing wall solutions. With innovation in manufacturing processes and product formulations, plaster producers are adapting to meet sustainability standards and performance demands across diverse applications. As the industry evolves, nine distinct types of plaster manufacturers have emerged as key players, each specializing in formulations ranging from traditional lime and cement-based plasters to advanced synthetic and eco-friendly variants tailored for modern construction needs.

Top 9 Types Of Plaster Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 USG

Domain Est. 1996

Website: usg.com

Key Highlights: USG Corporation remains a leading manufacturer of ceiling, wall, backerboard, underlyament, gypsum, roofing, sheathing, and industrial products….

#2 National Gypsum® Products & Brands

Domain Est. 1998

Website: nationalgypsum.com

Key Highlights: High-performance drywall, plaster and industrial products for commercial and residential use. Manufactured by Gold Bond Building Products, LLC. Visit Website….

#3 Homeowners

Domain Est. 1999

Website: modernmasters.com

Key Highlights: Modern Masters was the first USA manufacturer of acrylic Venetian Plaster, which has been used by professional applicators and do-it-yourselfers on thousands ……

#4 GYPSUM BRANDS

Domain Est. 1995

Website: saint-gobain.com

Key Highlights: OUR OFFER. We design, manufacture and supply plaster, dry lining and ceilings innovative products and systems that improve wellbeing in living spaces….

#5 Product Catalog

Domain Est. 1995

Website: buildgp.com

Key Highlights: From gypsum panels, OSB, plywood, radiant barriers, WRB/AB to versatile Southern Yellow Pine, explore GP Building Products tailored for every project….

#6 American Gypsum Company

Domain Est. 1998

Website: americangypsum.com

Key Highlights: American Gypsum has been manufacturing, selling, and distributing gypsum wallboard products throughout the United States for over 50 years….

#7 Novacolor USA

Domain Est. 2005

#8 BASWA acoustic Sound Absorbing Plaster Finishes

Domain Est. 2008

Website: baswana.com

Key Highlights: BASWA acoustic offers the original seamless acoustical plaster systems used to absorb excessive sound with the highest NRC ratings in the industry….

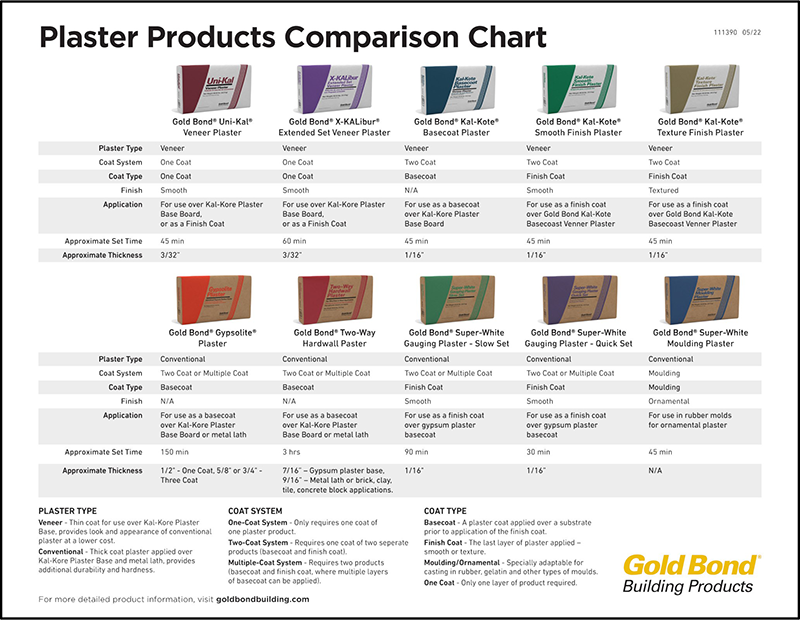

#9 Gold Bond® Gypsolite® Plaster

Domain Est. 2020

Website: goldbondbuilding.com

Key Highlights: Gypsolite® Plaster is a lightweight, basecoat plaster and manufactured to be trowel applied as a basecoat over gypsum or metal lath. Learn more here….

Expert Sourcing Insights for Types Of Plaster

2026 Market Trends for Types of Plaster

As we approach 2026, the global market for different types of plaster is undergoing significant transformation, driven by advancements in construction technologies, sustainability demands, and evolving architectural preferences. This analysis explores key trends shaping the future of major plaster types, including gypsum plaster, lime plaster, cement plaster, and specialty plasters.

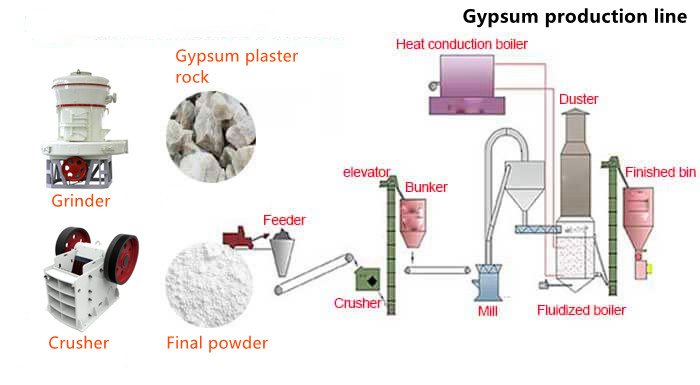

Gypsum Plaster: Dominance in Interior Applications

Gypsum plaster continues to dominate the interior finishing segment, particularly in residential and commercial buildings. By 2026, its market share is expected to grow due to its lightweight nature, fire resistance, and smooth finish. Innovations in prefabricated gypsum boards and moisture-resistant formulations are expanding its applications in high-humidity environments. Additionally, rising construction activities in Asia-Pacific and the Middle East are fueling demand, supported by government initiatives promoting faster, more efficient building methods.

Lime Plaster: Resurgence in Sustainable and Heritage Projects

Lime plaster is experiencing a resurgence, especially in eco-conscious and heritage restoration projects. With growing emphasis on breathable, non-toxic building materials, lime-based plasters are favored for their ability to regulate moisture and resist mold. By 2026, increased awareness of green building certifications (such as LEED and BREEAM) is expected to boost demand. Artisanal and decorative finishes using lime plaster are also gaining popularity in high-end residential and boutique commercial developments.

Cement Plaster: Steady Demand in Exterior and Infrastructure Use

Cement plaster remains a staple in exterior wall applications and infrastructure projects due to its durability and weather resistance. Although facing competition from newer alternatives, it maintains steady demand in developing economies where cost-effectiveness and structural strength are paramount. By 2026, trends indicate a shift toward modified cement plasters incorporating polymers and fiber reinforcements to improve crack resistance and flexibility, especially in seismic-prone regions.

Specialty Plasters: Innovation Driving Niche Growth

Specialty plasters—including acrylic, polymer-modified, and insulating plasters—are emerging as high-growth segments. These products offer enhanced properties such as thermal insulation, impact resistance, and aesthetic versatility. The push for energy-efficient buildings is accelerating adoption of insulating plasters in passive house designs. Meanwhile, decorative and textured plasters are being integrated into modern architectural aesthetics, supported by digital rendering tools that allow for customized finishes. By 2026, smart plasters with embedded sensors for structural health monitoring may begin entering pilot stages in smart city projects.

Regional and Sustainability Trends

Regionally, the Asia-Pacific market is projected to lead plaster consumption, driven by urbanization in India, China, and Southeast Asia. In contrast, Europe emphasizes sustainability, favoring low-carbon and natural plasters. Regulatory pressures to reduce embodied carbon in construction materials are pushing manufacturers to develop eco-friendly plaster solutions, including recycled gypsum and bio-based binders.

Conclusion

The 2026 outlook for the plaster market reflects a diversification of demand across types, with innovation and sustainability as central themes. While traditional plasters maintain strong footholds, technological advancements and environmental priorities are reshaping consumer preferences and product development strategies across the industry.

Common Pitfalls When Sourcing Types of Plaster (Quality and Intellectual Property)

Sourcing various types of plaster—whether for construction, art, or industrial applications—can present several challenges, particularly concerning quality assurance and intellectual property (IP) considerations. Being aware of these pitfalls helps in making informed procurement decisions.

1. Inconsistent Material Quality

One of the most frequent issues is variability in plaster quality. Different grades (e.g., plaster of Paris, lime plaster, gypsum plaster) have distinct physical properties, setting times, and durability. Sourcing from unreliable suppliers may result in:

– Impurities or incorrect composition

– Inconsistent particle size affecting workability

– Poor adherence or cracking after application

Tip: Always request material data sheets (MDS) and conduct third-party testing when large volumes are involved.

2. Mislabeling or Incorrect Classification

Suppliers may incorrectly label plaster types, such as marketing low-grade gypsum as “mold-grade” or “artistic” plaster. This can lead to project failures, especially in precision applications like sculpture casting or architectural restoration.

Tip: Verify technical specifications with standardized nomenclature (e.g., ASTM, EN standards) to confirm the plaster type.

3. Lack of Traceability and Certification

Without proper certification (e.g., ISO, CE, or country-specific construction standards), it’s difficult to ensure the plaster meets safety and performance requirements. This is especially critical in load-bearing or fire-resistant applications.

Tip: Require documentation proving compliance with relevant industry standards.

4. Intellectual Property Infringement

When sourcing specialty or proprietary plaster formulations (e.g., fire-resistant blends, eco-friendly composites), there’s a risk of inadvertently using products that infringe on patented technologies. Some suppliers may replicate branded formulations without authorization.

Tip: Conduct due diligence on formulation patents, especially when importing or using innovative plaster types. Consult legal counsel if licensing is unclear.

5. Counterfeit or Gray Market Products

In global sourcing, counterfeit versions of well-known plaster brands may be offered at lower prices. These often lack quality control and may violate IP rights.

Tip: Purchase only through authorized distributors and verify authenticity with the manufacturer.

6. Inadequate Technical Support

Low-cost suppliers may not provide sufficient technical guidance on mixing ratios, curing conditions, or compatibility with other materials. This increases the risk of application failure.

Tip: Choose suppliers that offer detailed technical support and application guidelines.

7. Ignoring Regional Variations and Environmental Impact

Plaster performance can vary based on climate and regional raw material sources. Additionally, some plasters may contain additives protected under environmental regulations or IP laws (e.g., bio-based binders).

Tip: Consider local availability and environmental compliance to avoid delays and legal issues.

By addressing these pitfalls proactively—focusing on quality verification, regulatory compliance, and IP integrity—buyers can ensure reliable, lawful, and effective sourcing of plaster materials.

Logistics & Compliance Guide for Types of Plaster

Understanding the logistics and compliance requirements for various types of plaster is essential for safe handling, transportation, storage, and regulatory adherence. This guide outlines the key considerations for common plaster types, including gypsum plaster, lime plaster, cement-based plaster, and specialty plasters.

Gypsum Plaster

Gypsum plaster, derived from calcium sulfate dihydrate, is widely used in interior wall and ceiling applications. Its handling and transport require specific precautions due to its sensitivity to moisture.

Transportation Requirements

- Must be transported in dry, covered vehicles to prevent exposure to rain or humidity.

- Palletized loads should be secured to prevent shifting during transit.

- Avoid stacking heavy materials on top of plaster bags or boards to prevent crushing.

Storage Guidelines

- Store in a dry, well-ventilated area off the ground using pallets.

- Relative humidity should remain below 60% to prevent premature hydration.

- Keep away from sources of moisture, such as water pipes or exterior walls.

Regulatory Compliance

- Classified as a non-hazardous material under most transport regulations (e.g., ADR, DOT).

- Requires proper labeling indicating product name, batch number, and manufacturer details.

- Safety Data Sheet (SDS) must be available and comply with GHS standards.

Lime Plaster

Lime plaster, composed primarily of slaked lime (calcium hydroxide), is valued for its breathability and mold resistance, commonly used in heritage restoration.

Transportation Requirements

- Transport in sealed containers or moisture-resistant packaging.

- Avoid extreme temperatures during transit, as thermal fluctuations can affect setting properties.

- Ensure packaging is resistant to punctures and leaks.

Storage Guidelines

- Store in a cool, dry place with stable temperatures.

- Keep sealed until ready for use to prevent carbonation (reaction with CO₂ in air).

- Prolonged storage may reduce workability; first-in, first-out (FIFO) inventory practice is recommended.

Regulatory Compliance

- Not classified as hazardous, but may be alkaline and require pH safety labeling.

- SDS must detail potential skin and respiratory irritation risks.

- Comply with local building material standards (e.g., EN 459-1 for hydrated lime in Europe).

Cement-Based Plaster

Cement-based plasters are durable and moisture-resistant, often used in exterior and damp-prone areas. They typically consist of Portland cement, sand, and additives.

Transportation Requirements

- Transport in dry conditions; moisture can initiate premature setting.

- Use tarps or enclosed trailers for bulk or bagged loads.

- Prevent contamination from other construction materials.

Storage Guidelines

- Store bags on elevated, dry platforms in a covered area.

- Limit storage duration; cementitious materials lose strength over time (typically 3–6 months shelf life).

- Rotate stock regularly to avoid using expired product.

Regulatory Compliance

- Regulated as a non-hazardous construction material, but may generate dust.

- Must comply with OSHA or equivalent workplace safety standards for dust control.

- Packaging must include batch traceability and conformity marks (e.g., CE marking in EU).

Specialty Plasters

Specialty plasters include polymer-modified, fire-resistant, acoustic, and decorative plasters. These may contain additives that affect handling and compliance.

Transportation Requirements

- Follow manufacturer-specific instructions due to chemical sensitivities.

- Temperature-controlled transport may be required for pre-mixed or liquid formulations.

- Segregate from incompatible materials (e.g., acids, oxidizers).

Storage Guidelines

- Store according to technical data sheets (TDS), particularly for temperature and shelf life.

- Keep containers tightly sealed to prevent evaporation or skinning.

- Monitor expiration dates closely.

Regulatory Compliance

- May contain hazardous ingredients (e.g., solvents, biocides); classify according to GHS.

- Transport under relevant regulations (e.g., ADR for dangerous goods if applicable).

- Provide site-specific SDS and ensure WHMIS/GHS-compliant labeling.

General Compliance & Best Practices

To maintain compliance and ensure product integrity across all plaster types:

Documentation

- Maintain up-to-date SDS, conformity certificates, and batch records.

- Ensure all labels meet local regulatory requirements.

Worker Safety

- Provide PPE such as gloves, masks, and eye protection.

- Train staff on safe handling, spill response, and storage protocols.

Environmental Considerations

- Prevent plaster runoff into waterways; dispose of waste according to local regulations.

- Recycle packaging where possible (e.g., polypropylene bags, cardboard).

Quality Assurance

- Verify product upon delivery for damage or moisture exposure.

- Conduct periodic audits of storage conditions and inventory management.

By adhering to these logistics and compliance guidelines, businesses can ensure the safe, efficient, and legally compliant handling of all types of plaster throughout the supply chain.

In conclusion, selecting the appropriate type of plaster for a construction or renovation project depends on several key factors including the application environment, desired finish, durability requirements, cost, and compatibility with underlying materials. Common plaster types—such as gypsum plaster, lime plaster, cement plaster, and modern polymer-modified plasters—each offer distinct advantages and ideal use cases. Gypsum plaster provides a smooth, quick-setting finish suitable for interior walls, while lime plaster offers breathability and flexibility, making it ideal for historic or moisture-prone buildings. Cement plaster is highly durable and weather-resistant, best suited for exterior applications and wet areas. Meanwhile, specialized plasters like clay or synthetic plasters cater to eco-friendly or decorative needs.

Careful consideration of the project’s structural, aesthetic, and environmental demands is essential when sourcing plaster. Additionally, evaluating the availability of materials, labor expertise, and long-term maintenance implications will ensure optimal performance and longevity. Ultimately, the right plaster choice enhances both the functionality and visual appeal of a structure, underscoring the importance of informed sourcing and application strategies.