The global electrical conduit fittings market is experiencing robust growth, driven by rising infrastructure development, increased industrial automation, and stringent electrical safety regulations. According to Grand View Research, the global electrical conduit market size was valued at USD 12.9 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further fueled by expanding construction activities in both residential and commercial sectors, especially in emerging economies across Asia-Pacific and Latin America. As demand for safe and durable electrical installations rises, manufacturers of electrical conduit fittings are innovating to meet performance, corrosion resistance, and installation efficiency standards. Amid this evolving landscape, nine key types of manufacturers have emerged as industry leaders—each specializing in distinct conduit fitting solutions such as metallic, non-metallic, and explosion-proof variants—catering to diverse applications in industrial plants, data centers, healthcare, and smart buildings. These players are not only scaling production but also integrating advanced materials and smart technologies to stay competitive in a market that prioritizes reliability and compliance.

Top 9 Types Of Electrical Conduit Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Arlington

Domain Est. 1998

Website: aifittings.com

Key Highlights: A leading manufacturer of quality metallic and non-metallic electrical fittings and connectors, supports; as well as, low voltage, security, and audio/video ……

#2 Installation Products

Domain Est. 1990

Website: electrification.us.abb.com

Key Highlights: T&B Fittings – Cord & Cable Fittings · Rigid Conduit and Fittings. Rigid Conduit & Fittings · T&B Fittings Stainless & Rigid Fittings · Ocal PVC-Coated Conduit ……

#3 Conduit Fittings

Domain Est. 1994

Website: nema.org

Key Highlights: Conduit fittings connect conduit to other conduit or to an electrical box. They are available in various metals and with different levels of moisture protection ……

#4 Condulet

Domain Est. 1996

Website: eaton.com

Key Highlights: Conduit outlet bodies act as pull-outlets for conductors being installed and provide openings for making splices and taps in conductors….

#5 Cantex PVC Conduit

Domain Est. 1996

Website: cantexinc.com

Key Highlights: PVC Electrical Fittings: Schedule 40 & Schedule 80 PVC electrical fittings such as PVC Couplings, PVC Conduit Bodies, PVC Reducer Bushings, PVC Service Entrance ……

#6 Bridgeport

Domain Est. 2004

Website: nsiindustries.com

Key Highlights: Industry Verticals. Bridgeport can simplify every installation with our superior cable and conduit fittings, cord grips, wire mesh, molded cord and cordsets ……

#7 Electrical Conduit and Duct

Domain Est. 2007

Website: jmeagle.com

Key Highlights: JM Eagle offers a complete line of Electrical Conduit and Power Duct pipe that includes Schedule 40 and 80 Conduit (NEMA TC-2, ANSI/UL651), Encased and Direct ……

#8 Allied Tube & Conduit

Domain Est. 2010

Website: atkore.com

Key Highlights: We are a manufacturing leader of steel, PVC, and aluminum conduit as well as mechanical, safety, and traffic solutions….

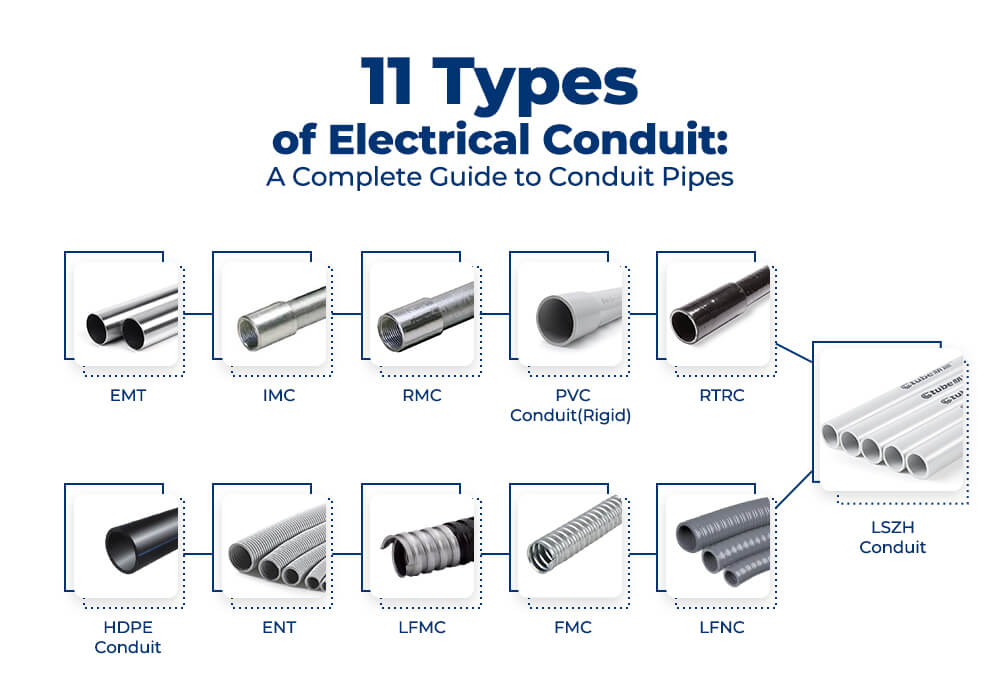

#9 11 Types of Electrical Conduit

Domain Est. 2020

Website: ctube-gr.com

Key Highlights: In this article, we’ll explore the different types of conduit pipes, their materials, sizes, and accessories like conduit bends, elbows, bodies, and boxes….

Expert Sourcing Insights for Types Of Electrical Conduit Fittings

H2: Market Trends for Types of Electrical Conduit Fittings in 2026

As the global construction, industrial, and energy sectors evolve, the demand for reliable and efficient electrical infrastructure continues to grow. Electrical conduit fittings—essential components used to connect, secure, and protect electrical conduits—play a critical role in ensuring the safety and integrity of electrical systems. By 2026, several key market trends are shaping the development and adoption of different types of electrical conduit fittings.

H2: Rising Demand for Corrosion-Resistant and Durable Materials

One of the most significant trends in 2026 is the increasing preference for conduit fittings made from corrosion-resistant materials such as stainless steel, PVC, and fiberglass-reinforced polymers. With rising construction in coastal, industrial, and high-humidity environments, specifiers and contractors are prioritizing fittings that withstand harsh conditions. Stainless steel fittings, in particular, are witnessing strong growth due to their durability and suitability for outdoor and hazardous locations.

H2: Growth in Non-Metallic Conduit Fittings

Non-metallic conduit fittings—especially those made from PVC and other thermoplastics—are gaining traction in commercial and residential applications. Their lightweight nature, ease of installation, and resistance to rust and chemicals make them ideal for use in corrosive environments like wastewater treatment plants and chemical facilities. The push for cost-effective and low-maintenance solutions is accelerating the adoption of non-metallic options in both new construction and retrofit projects.

H2: Expansion of Smart Building and Industrial Automation

The proliferation of smart buildings and Industry 4.0 technologies is driving demand for conduit fittings compatible with advanced electrical systems. In 2026, manufacturers are producing fittings designed to support data and power transmission in integrated systems. Features such as EMI/RFI shielding, precise grounding capabilities, and compatibility with structured cabling are becoming standard in high-performance metallic fittings, especially in sectors like manufacturing, healthcare, and data centers.

H2: Emphasis on Sustainability and Recyclability

Environmental regulations and corporate sustainability goals are influencing material choices in the conduit fittings market. There is a growing trend toward recyclable and eco-friendly products, with manufacturers developing fittings using recycled metals and plastics. Additionally, long-life products that reduce the need for replacement are favored, contributing to lower lifecycle environmental impact.

H2: Regional Infrastructure Development Driving Market Growth

Ongoing infrastructure investments—particularly in Asia-Pacific, the Middle East, and parts of Africa—are fueling demand for electrical conduit fittings. Countries like India, Saudi Arabia, and Nigeria are launching large-scale urban development and power grid expansion projects, increasing the need for both metallic and non-metallic fittings. In North America and Europe, modernization of aging electrical infrastructure is also creating opportunities for upgraded and code-compliant fittings.

H2: Advancements in Installation Efficiency and Labor Cost Reduction

In response to labor shortages and rising installation costs, manufacturers are innovating with quick-connect, self-grounding, and pre-assembled conduit fittings. These designs minimize on-site labor and improve installation speed without compromising safety or code compliance. Threadless fittings and snap-in connectors are seeing increased adoption, especially in commercial construction where time-to-completion is critical.

H2: Regulatory Compliance and Safety Standards

By 2026, adherence to international safety standards such as NEC (National Electrical Code), IEC, and UL certifications is more critical than ever. There is growing market pressure for conduit fittings that meet stringent fire-resistance, grounding, and explosion-proof requirements—especially in oil & gas, mining, and chemical industries. This trend is pushing manufacturers to invest in R&D to ensure compliance and gain certification advantages.

In conclusion, the 2026 market for electrical conduit fittings is being reshaped by technological innovation, environmental concerns, and global infrastructure needs. As industries demand smarter, safer, and more sustainable solutions, the diversity and performance of conduit fittings continue to expand, positioning the market for sustained growth across multiple segments.

Common Pitfalls When Sourcing Types of Electrical Conduit Fittings (Quality, IP Rating)

Sourcing electrical conduit fittings requires careful attention to both material quality and Ingress Protection (IP) ratings to ensure long-term safety, compliance, and performance. Here are the most common pitfalls buyers encounter:

Poor Material Quality and Durability

One of the most frequent issues is selecting conduit fittings made from substandard materials such as low-grade zinc alloys or thin-walled steel. These materials are prone to corrosion, cracking, or deformation, especially in harsh environments like outdoor installations or industrial settings. Always verify that fittings are made from suitable materials—such as galvanized steel, stainless steel, or UV-resistant PVC—depending on the application.

Misunderstanding or Ignoring IP Ratings

The Ingress Protection (IP) rating indicates the level of protection against dust and moisture. A common mistake is assuming that all conduit fittings are suitable for wet or dusty areas. For instance, using an IP54-rated fitting in a high-moisture environment requiring IP66 or higher can lead to electrical faults or safety hazards. Always match the IP rating of the fitting to the environmental conditions specified in the project.

Non-Compliance with Regional Standards

Electrical components must meet regional safety standards (e.g., UL in the U.S., CE in Europe, or IEC globally). Sourcing fittings without proper certification can result in failed inspections, rework, or legal liabilities. Ensure all conduit fittings are certified to the applicable standards for your region and application.

Incorrect Sizing and Thread Compatibility

Mismatched thread types (NPT, BSPT, metric) or incorrect diameters can lead to improper sealing and installation failures. This not only compromises the IP rating but also increases the risk of conduit system leakage or mechanical failure. Double-check dimensional specifications and thread standards before procurement.

Overlooking Environmental Conditions

Buyers often fail to account for environmental stressors such as UV exposure, temperature extremes, or chemical exposure. For example, plastic conduit fittings may degrade under prolonged sunlight if not UV-stabilized. Always assess the installation environment and select fittings designed to withstand those specific conditions.

Choosing the Lowest-Cost Option Without Verification

While cost is a consideration, opting for the cheapest available fittings often leads to higher lifecycle costs due to premature failure, maintenance, or replacement. Conduct supplier audits, request product samples, and verify material test reports to ensure value over the long term.

Insufficient Supplier Due Diligence

Sourcing from unreliable suppliers or manufacturers without proper quality control processes increases the risk of receiving counterfeit or non-compliant products. Work with reputable suppliers who provide traceability, technical documentation, and after-sales support.

Types of Electrical Conduit Fittings: Logistics & Compliance Guide

Electrical conduit fittings play a critical role in protecting and routing electrical wiring in residential, commercial, and industrial applications. Proper selection, logistics handling, and compliance with industry standards are essential to ensure safety, performance, and regulatory adherence. This guide outlines the major types of electrical conduit fittings and provides key logistics and compliance considerations.

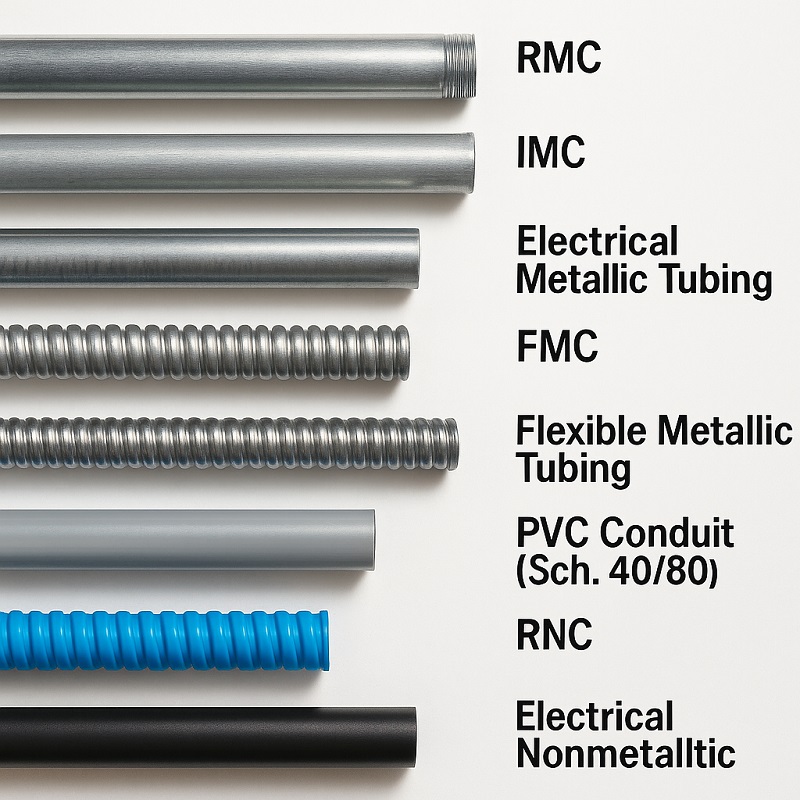

Rigid Metal Conduit (RMC) Fittings

Rigid Metal Conduit (RMC) fittings are heavy-duty threaded connectors used with galvanized or stainless steel conduits. They provide excellent mechanical protection and are commonly used in industrial and outdoor installations.

Logistics Considerations

- Packaging: Typically shipped in crates or bulk bundles; require secure strapping to prevent movement.

- Storage: Store in dry, covered areas to avoid rust and corrosion.

- Handling: Use mechanical aids (e.g., forklifts) for large quantities due to weight.

- Transport: Ensure compliance with load distribution standards for heavy freight.

Compliance Requirements

- Must meet UL 514B and ANSI C80.1 standards.

- Compliant with NEC (National Electrical Code) Article 344.

- Suitable for hazardous locations if labeled accordingly (e.g., Class I, Division 1).

Intermediate Metal Conduit (IMC) Fittings

IMC fittings are similar to RMC but slightly thinner and lighter, offering a cost-effective alternative while maintaining durability.

Logistics Considerations

- Packaging: Often boxed or bundled; lighter than RMC, allowing higher stacking.

- Shipping: Ideal for standard freight; weight savings reduce shipping costs.

- Inventory Management: Label clearly to differentiate from RMC to prevent substitution errors.

Compliance Requirements

- Certified under UL 1242 and ANSI C80.6.

- Must comply with NEC Article 342.

- Require proper grounding and bonding per NEC 250.

Electrical Metallic Tubing (EMT) Fittings

EMT fittings are thin-walled, lightweight connectors used with EMT conduit. Commonly used in commercial buildings due to ease of installation.

Logistics Considerations

- Packaging: Sold in cartons or shrink-wrapped bundles; lightweight and space-efficient.

- Storage: Store indoors to prevent denting; avoid exposure to moisture.

- Handling: Can be manually handled in small quantities; use pallet jacks for bulk.

Compliance Requirements

- Must meet UL 514B and ANSI C80.3.

- Compliant with NEC Article 358.

- Grounding continuity must be maintained; use listed grounding fittings.

Electrical Nonmetallic Tubing (ENT) Fittings

ENT fittings are used with flexible, corrugated plastic conduit, ideal for indoor residential and light commercial use.

Logistics Considerations

- Packaging: Flexible and compact; often boxed or banded.

- Temperature Sensitivity: Store below 50°C (122°F); avoid direct sunlight.

- Stacking: Can be stacked but avoid excessive weight to prevent deformation.

Compliance Requirements

- Listed under UL 651 and NEC Article 362.

- Flame retardant and moisture-resistant per NFPA 70.

- Not suitable for outdoor or direct burial without additional protection.

Liquidtight Flexible Metal Conduit (LFMC) Fittings

LFMC fittings connect flexible, liquid-resistant metal conduit used in wet or corrosive environments.

Logistics Considerations

- Packaging: Coiled with protective end caps; shipped on reels or in boxes.

- Cold Weather: Avoid bending below freezing; store above 0°C (32°F).

- Inventory: Track by size and seal type (e.g., NEMA 4X, explosion-proof).

Compliance Requirements

- Certified under UL 360 and NEC Article 350.

- Must provide watertight seal; gaskets and seals must meet IP66/IP68.

- Approved for use in hazardous locations when listed (e.g., UL HazLoc).

Flexible Metallic Conduit (FMC) Fittings

FMC fittings connect helically wound metal conduit used for short runs and vibration-prone areas.

Logistics Considerations

- Packaging: Shipped in coils; protect ends from deformation.

- Handling: Avoid kinking; use gloves to prevent cuts.

- Storage: Hang or lay flat; avoid compression.

Compliance Requirements

- Must comply with UL 3 and NEC Article 348.

- Limited to 6 feet in length unless used for equipment flexibility.

- Requires bonding and grounding in accordance with NEC 250.

PVC Conduit Fittings

PVC fittings are used with rigid polyvinyl chloride conduit in corrosive or underground applications.

Logistics Considerations

- UV Sensitivity: Store indoors or under cover; prolonged UV exposure causes brittleness.

- Temperature Range: Avoid extreme cold; becomes brittle below -10°C (14°F).

- Handling: Lightweight but can crack if dropped; handle with care.

Compliance Requirements

- Listed under UL 651 and ASTM D2466/D2467.

- Compliant with NEC Article 352 (PVC) and Article 355 (High-Density Polyethylene).

- Solvent cement joints must meet ASTM F1498 thread standards.

Compliance & Certification Best Practices

General Compliance Guidelines

- Ensure all fittings are UL-listed or ETL-listed.

- Verify product markings include: manufacturer, material type, size, and compliance standard.

- Confirm suitability for intended environment (indoor, outdoor, hazardous, corrosive).

International Considerations

- For export: Check IEC standards (e.g., IEC 61386 for conduit systems).

- CE marking required for EU shipments; UKCA for UK.

- Local electrical codes may impose additional requirements (e.g., CCC in China, RCM in Australia).

Documentation & Traceability

- Maintain Certificates of Compliance (CoC) and test reports.

- Track lot numbers and manufacturing dates for quality control.

- Provide SDS (Safety Data Sheets) for PVC and solvent-based products.

Summary

Selecting the correct electrical conduit fitting involves understanding application requirements, material compatibility, and compliance standards. Effective logistics planning ensures fittings arrive undamaged and ready for installation. Always prioritize certified products and maintain proper documentation to meet regulatory demands and ensure long-term system safety.

In conclusion, selecting the appropriate type of electrical conduit fitting is essential for ensuring the safety, durability, and compliance of electrical installations. The choice depends on various factors such as the type of conduit used (e.g., EMT, rigid metal, PVC), the installation environment (indoor, outdoor, wet, corrosive, hazardous), and the specific application requirements (e.g., grounding needs, cable protection, flexibility). Common fitting types—including couplings, connectors, elbows, adapters, and expansion fittings—serve distinct purposes and must be matched to the conduit system and local electrical codes, such as the NEC.

Proper sourcing should prioritize certified, code-compliant products from reputable manufacturers to ensure quality and reliability. Additionally, considering environmental conditions and long-term maintenance needs will enhance system performance and reduce the risk of failures. Ultimately, a well-informed selection and sourcing strategy for electrical conduit fittings contribute significantly to the integrity, efficiency, and safety of electrical systems across residential, commercial, and industrial applications.