The global DC motor market is experiencing robust growth, driven by increasing demand across industrial automation, automotive, and consumer electronics sectors. According to a report by Mordor Intelligence, the DC motor market was valued at approximately USD 13.5 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. Similarly, Grand View Research estimates that the market will expand significantly, citing advancements in brushless DC (BLDC) motors and rising adoption in electric vehicles (EVs) as key growth catalysts. As industries prioritize energy efficiency and precision control, the landscape of DC motor manufacturing has diversified, giving rise to specialized producers catering to distinct application needs. This evolution has led to the emergence of nine prominent types of DC motor manufacturers, each differentiated by technology focus, scale of production, and end-use expertise. Understanding these segments is critical for procurement teams and engineers navigating an increasingly competitive and innovation-driven supply chain.

Top 9 Types Of Dc Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oriental Motor U.S.A. Corp.

Domain Est. 1997

Website: orientalmotor.com

Key Highlights: 200 W (1/4 HP) Stainless Steel Type Brushless DC Motor … We have introduced a 1/4 HP BLDC flat gear motor that’s made entirely with stainless steel and meets ……

#2 DC Motors Manufacturer

Domain Est. 2024

Website: nidec-conversion.com

Key Highlights: Based on a modular design, our DC machines offer a vast selection of mounting arrangements, cooling systems, types of protection and accessories to choose ……

#3 Industry DC Motors

Domain Est. 1996

Website: johnsonelectric.com

Key Highlights: The Johnson Electric DC motor series is the industry benchmark for micro motor driven actuation. This wide range of motor platforms can be custom engineered….

#4 Micro Motors

Domain Est. 1996

Website: portescap.com

Key Highlights: Explore our growing array of premium miniature electronic motors — brushless DC, brush DC, stepper motors and linear actuators — and related systems and ……

#5 DC Motors: Types, Benefits & Applications

Domain Est. 1997

Website: festo.com

Key Highlights: The main types of DC motors are Brushed DC Motors, Brushless DC Motors (BLDC), Stepper Motors, and Linear DC Motors. Below is a more detailed ……

#6 Types of DC Motors

Domain Est. 1998

Website: monolithicpower.com

Key Highlights: The two primary varieties are brushless and brushed DC motors. Various types suit a variety of applications due to their unique working principles, ……

#7 Top 13 electric motor manufactures in the world.

Domain Est. 2018

Website: china-bgmotor.com

Key Highlights: DC motors are divided into DC brushed motors, brushless DC motors, stepper motors, series motors, parallel excited motors, etc. BG motor mainly produces two ……

#8 DC Motors

Domain Est. 2021

Website: regalrexnord.com

Key Highlights: Learn about the types of electric motors, terminology, and how they work. We cover AC and DC motors, their enclosures, environments, and mounting features….

#9 Top 10 DC Motor Manufacturers in the World 2025

Domain Est. 2016

Website: twirlmotor.com

Key Highlights: Some of the major DC motor manufacturers include Twirl, ABB, MET Motors, and many more. A DC (direct current) motor is an electric motor that converts ……

Expert Sourcing Insights for Types Of Dc Motor

H2: 2026 Market Trends for Types of DC Motors

The global market for DC motors is undergoing significant transformation, driven by advancements in automation, energy efficiency regulations, and the rising demand for electric mobility. By 2026, key trends are expected to reshape the landscape across different types of DC motors—namely brushed DC motors, brushless DC (BLDC) motors, and specialty DC motors such as coreless and printed armature motors.

1. Dominance of Brushless DC (BLDC) Motors

BLDC motors are projected to lead the market by 2026, capturing the largest share due to their superior efficiency, longer lifespan, and lower maintenance requirements. Their adoption is accelerating in electric vehicles (EVs), HVAC systems, industrial automation, and consumer electronics. The integration of BLDC motors in EV powertrains—especially in two-wheelers and light-duty vehicles—is a key growth driver. Additionally, government regulations promoting energy-efficient appliances are boosting demand in HVAC and white goods sectors.

2. Gradual Decline of Brushed DC Motors

While brushed DC motors continue to serve cost-sensitive and low-complexity applications—such as toys, small appliances, and basic industrial tools—their market share is expected to decline. This is primarily due to their higher maintenance needs, shorter operational life, and lower efficiency compared to BLDC alternatives. However, they will retain relevance in niche markets where initial cost is a critical factor and performance demands are modest.

3. Growth in Specialty DC Motors

Emerging applications in medical devices, robotics, and aerospace are driving innovation in specialty DC motors such as coreless and pancake motors. These motors offer high acceleration, compact size, and precise control—ideal for surgical robots, drones, and portable medical equipment. By 2026, advancements in material science and miniaturization technologies are expected to expand their use in high-precision industries.

4. Regional Market Dynamics

Asia-Pacific, particularly China, India, and Japan, will remain the largest market for DC motors, fueled by manufacturing expansion, rising EV production, and urbanization. North America and Europe will witness steady growth, driven by automation in industrial processes and strict energy efficiency standards. The push for smart manufacturing and Industry 4.0 will further stimulate demand for intelligent, sensor-integrated BLDC motors.

5. Technological Integration and Smart Motor Systems

By 2026, the integration of IoT, AI, and advanced control algorithms into DC motor systems will become standard in industrial and automotive applications. Smart BLDC motors with embedded sensors and predictive maintenance capabilities will enable real-time monitoring and energy optimization, enhancing operational efficiency.

6. Sustainability and Regulatory Influence

Environmental regulations targeting carbon emissions and energy consumption will continue to favor high-efficiency motor technologies. Standards such as IE4 and IE5 efficiency classes are pushing manufacturers to phase out inefficient brushed motors in favor of BLDC and electronically commutated (EC) motors.

Conclusion

By 2026, the DC motor market will be characterized by a clear shift toward brushless and intelligent motor technologies. While brushed motors will persist in specific low-end applications, BLDC and specialty motors will dominate growth, driven by technological advancements, regulatory pressures, and evolving end-user demands across automotive, industrial, and consumer sectors.

Common Pitfalls When Sourcing Types of DC Motors (Quality and IP Rating)

Logistics & Compliance Guide for Types of DC Motors

When transporting and managing the compliance of various types of DC motors (Direct Current motors), it’s essential to consider logistics requirements, regulatory standards, and safety measures. Below is a comprehensive guide covering the main types of DC motors and their associated logistics and compliance considerations.

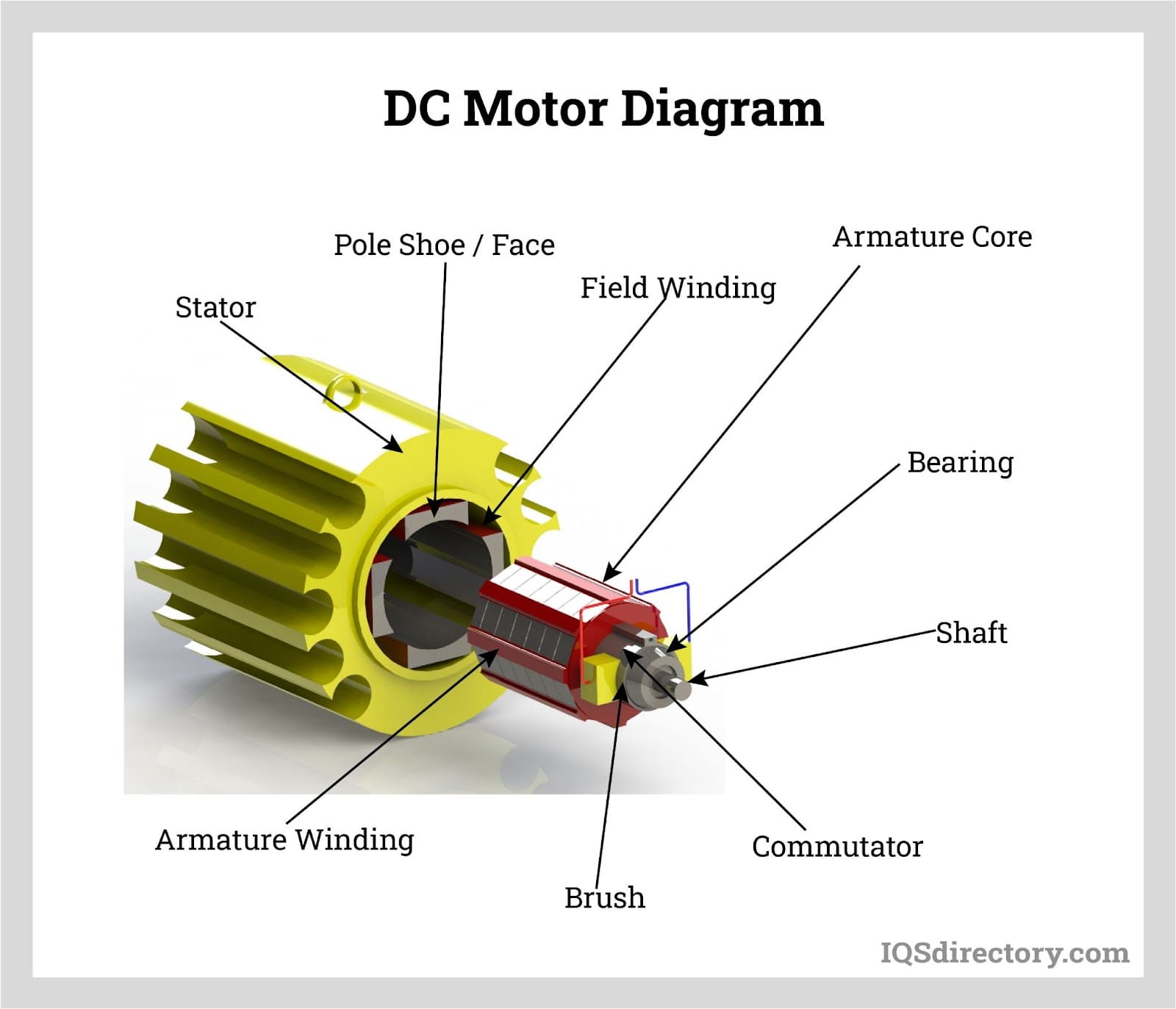

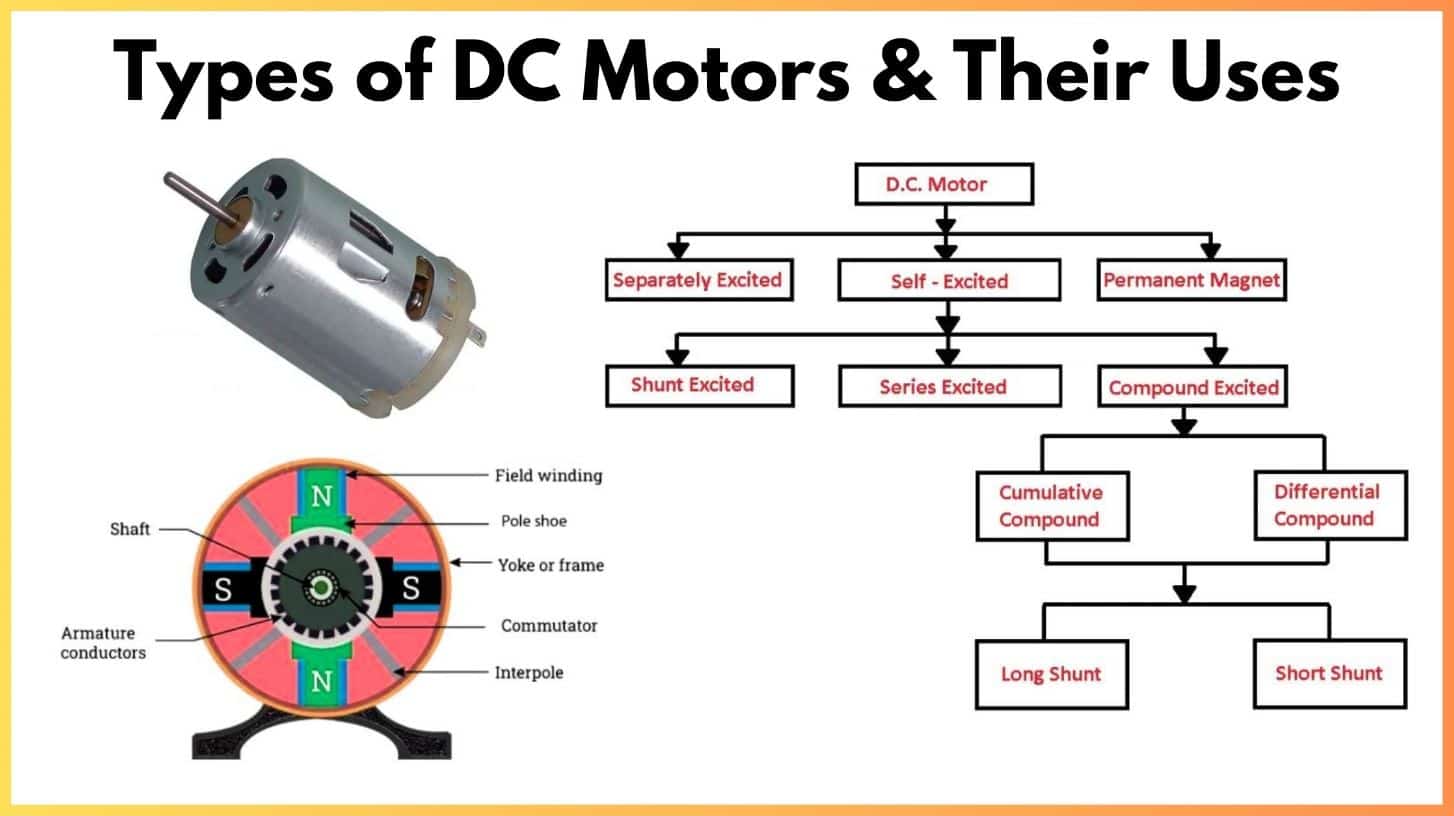

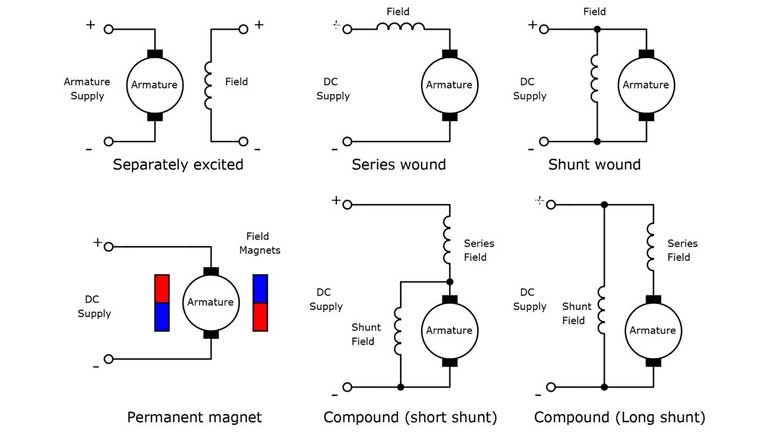

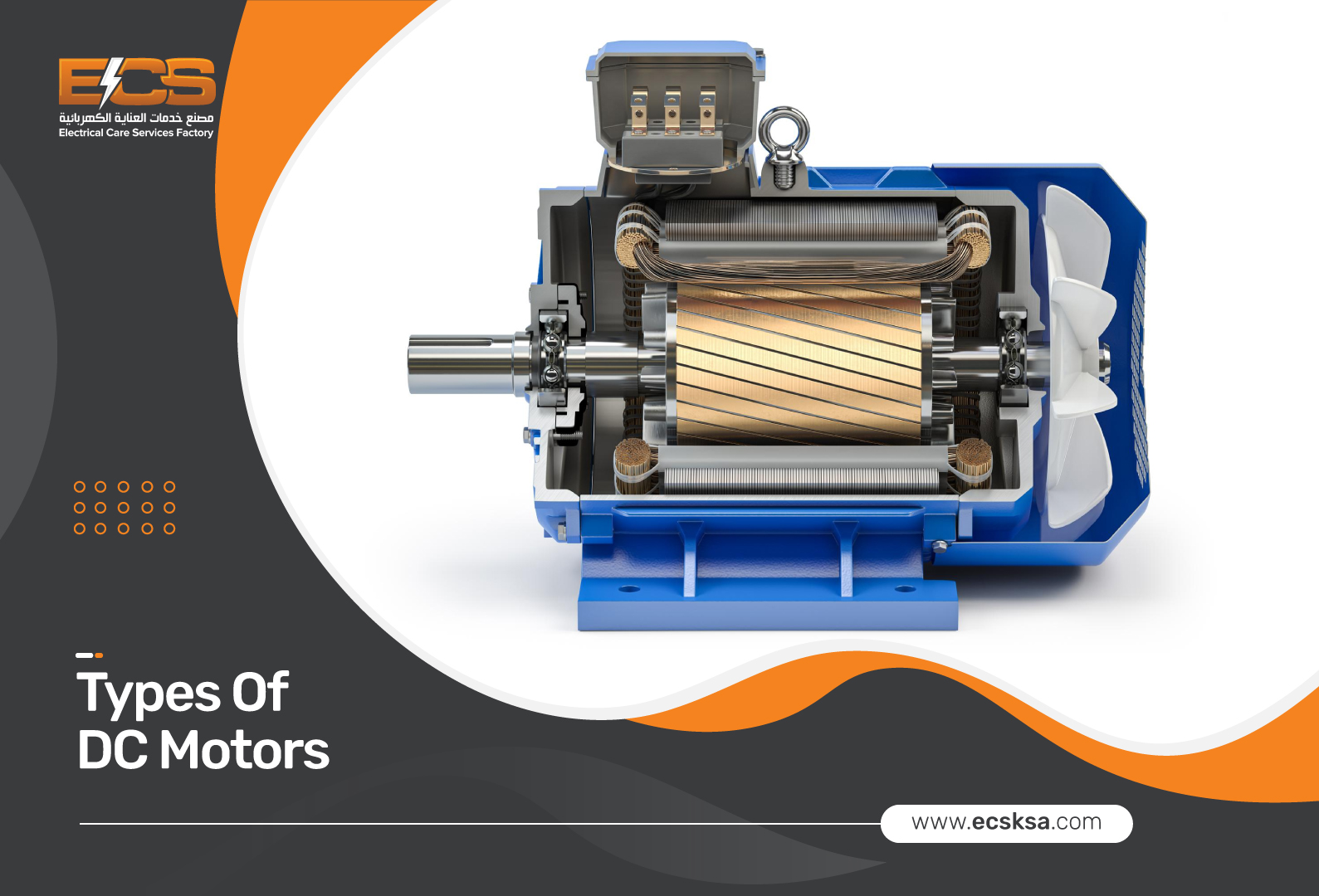

1. Overview of DC Motor Types

Understanding the different types of DC motors is crucial for proper handling, storage, and compliance:

- Permanent Magnet DC Motors (PMDC)

- Series Wound DC Motors

- Shunt Wound DC Motors

- Compound Wound DC Motors (Cumulative & Differential)

- Brushless DC Motors (BLDC)

- Coreless DC Motors

Each type has unique construction, performance characteristics, and handling requirements that influence logistics and compliance practices.

2. Packaging and Handling Requirements

Proper packaging is vital to prevent damage during transit and storage:

- Anti-static Packaging: Especially critical for brushless DC (BLDC) motors with sensitive electronic components.

- Moisture Protection: Use desiccants and moisture-resistant wrapping to prevent corrosion on windings and metal parts.

- Shock Absorption: Employ cushioning materials (foam, bubble wrap) to protect against vibration and impact.

- Secure Mounting: Motors should be immobilized in crates or containers to avoid internal damage from movement.

3. Transportation and Shipping Compliance

Ensure compliance with international and regional transportation regulations:

- IATA/IMDG Regulations: If shipping by air or sea, verify that motors (especially those with magnetic properties) meet IATA Dangerous Goods Regulations or IMDG Code requirements.

- Magnetic Field Restrictions: DC motors may be classified as “magnetized materials” under IATA. Measure magnetic field strength (using a flux meter); if over 0.159 A/m at 2.1 m from the package, special labeling and documentation are required.

- Labeling: Use appropriate hazard labels (e.g., “Magnetized Material”), handling instructions (“This Side Up”), and environmental protection labels.

4. Import/Export Regulations and Documentation

Compliance with customs and trade regulations is essential for international shipments:

- Harmonized System (HS) Codes: Common codes for DC motors include:

- 8501.31 – DC motors and generators, output ≤ 750 W

- 8501.32 – DC motors and generators, output > 750 W

Confirm exact classification based on motor specifications. - Certificates of Conformity (CoC): Required in many countries (e.g., CE in EU, UKCA in UK, CCC in China).

- Export Controls: Some high-performance or specialized motors may be subject to export control regulations (e.g., EAR in the U.S.).

5. Environmental and Safety Compliance

Adhere to environmental and workplace safety standards:

- RoHS Compliance: Ensure motors are free from restricted substances (lead, mercury, cadmium, etc.), especially in EU and other regulated markets.

- REACH Regulation: Confirm no use of Substances of Very High Concern (SVHC) in motor components.

- WEEE Directive: Provide take-back and recycling information for motors sold in the EU.

- OSHA & WHMIS: Proper handling instructions and employee training required for industrial DC motors in workplaces.

6. Storage Conditions

Maintain motors in optimal conditions prior to deployment:

- Temperature: Store between 10°C and 40°C; avoid extreme cold or heat.

- Humidity: Keep relative humidity below 70% to prevent condensation and corrosion.

- Ventilation: Store in dry, well-ventilated areas away from corrosive chemicals.

- Orientation: Follow manufacturer guidelines—some motors must be stored upright to prevent bearing damage.

7. Quality and Testing Standards

Ensure motors meet recognized quality and performance standards:

- IEC 60034 Series: International standards for rotating electrical machines.

- NEMA MG-1: Common standard in North America for motor performance and safety.

- UL/CSA Certification: Required for motors used in consumer and industrial equipment in North America.

8. Maintenance and Traceability

- Batch Tracking: Maintain logs of motor batch numbers, manufacturing dates, and shipping details for traceability.

- Calibration Records: For precision motors (e.g., in robotics or medical devices), maintain calibration and performance testing logs.

- Spare Parts Logistics: Plan for availability of brushes, bearings, and controllers—particularly for brushed DC motors.

9. End-of-Life and Recycling

- Disposal Guidelines: Follow local e-waste regulations; do not dispose of motors in regular landfill.

- Recycling Programs: Partner with certified e-waste recyclers to recover copper, steel, and rare earth magnets (especially in PMDC and BLDC motors).

Conclusion

Effective logistics and compliance management for DC motors requires understanding their types, proper packaging, adherence to transportation rules, and conformity with environmental and safety standards. By following this guide, businesses can ensure safe, legal, and efficient handling of DC motors across the supply chain.

Conclusion on Sourcing Types of DC Motors

In conclusion, sourcing the appropriate type of DC motor depends heavily on the specific requirements of the intended application, including factors such as speed control precision, torque demands, maintenance considerations, and budget constraints. Permanent Magnet DC (PMDC) motors offer simplicity and reliability for low to medium power applications, while Series, Shunt, and Compound DC motors provide varied performance characteristics suitable for industrial machinery and high-torque applications. Brushless DC (BLDC) motors are increasingly preferred for their efficiency, long life, and low maintenance, especially in modern applications like electric vehicles, robotics, and precision equipment. When sourcing, it is essential to evaluate suppliers based on quality certifications, customization capabilities, reliability, and after-sales support. Advancements in motor technology and global supply chains offer diverse sourcing options, but a thorough understanding of technical specifications and application needs remains crucial to making an optimal selection. Ultimately, aligning motor type with performance goals and sourcing strategy ensures improved system efficiency, longevity, and cost-effectiveness.