The global cooling tower market is experiencing robust growth, driven by rising industrialization, increased demand for efficient thermal management systems, and expanding infrastructure in power generation, HVAC, and manufacturing sectors. According to a report by Mordor Intelligence, the cooling tower market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. Similarly, Grand View Research estimates that the market size reached USD 4.1 billion in 2023 and is expected to expand at a CAGR of 5.4% through 2030, fueled by advancements in energy-efficient designs and the adoption of sustainable materials. As demand intensifies across industries such as power plants, chemical processing, and commercial buildings, a diverse array of cooling tower manufacturers has emerged—each specializing in different technologies, materials, and configurations to meet specific application needs. From crossflow and counterflow designs to hybrid and closed-circuit systems, the market now includes manufacturers focusing on innovation, customization, and compliance with environmental standards. Understanding the top nine types of cooling tower manufacturers provides crucial insight into the competitive landscape shaping the future of thermal regulation.

Top 9 Types Of Cooling Tower Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cooling Tower Manufacturers

Domain Est. 2003

Website: cooling-towers.net

Key Highlights: Additional types include HVAC cooling towers, industrial cooling towers, evaporative cooling towers, water cooling towers, and chiller cooling towers. Open ……

#2 Cooling Towers

Domain Est. 1996

Website: deltacooling.com

Key Highlights: As the leading manufacturer of cooling towers in the United States, Delta’s cooling towers come with an industry-leading 20 Year Warranty. Call 1.800.BUY….

#3 AT Cooling Tower

Domain Est. 1996

Website: evapco.com

Key Highlights: The original Advanced Technology cooling tower provides an induced-draft, axial fan solution for a wide array of outdoor cooling capacities….

#4 The Different Types Of Cooling Towers

Domain Est. 1997

Website: chardonlabs.com

Key Highlights: While a cooling tower may fall into multiple categories, here are the five main types of cooling towers for HVAC and industrial processes….

#5 Paharpur Cooling Towers

Domain Est. 1998

Website: paharpur.com

Key Highlights: Paharpur Cooling towers is the world’s foremost manufacturer of reliable cooling solutions · PRODUCTS. Wet coolingDry coolingComponents · SERVICE & Support ……

#6 Cooling Towers companies

Domain Est. 2000

Website: btetorri.com

Key Highlights: As industrial cooling towers suppliers since years, we design industrial evaporative coolers in order to last forever: highly reliable, durable solutions, ……

#7 Cooling Tower Systems for Industrial Usage

Domain Est. 2015

Website: baikalmechanical.com

Key Highlights: Crossflow and counterflow cooling towers can be upgraded to integrate Baikal EC fans onto a tower Get Free Consultation (718) 768-3745….

#8 Baltimore Aircoil Company

Domain Est. 1998

Website: baltimoreaircoil.com

Key Highlights: BAC is proud to be the world’s cooling partner. Choose your location here….

#9

Domain Est. 1999

Website: coolingtowersystems.com

Key Highlights: Cooling Tower Systems has manufactured various models of cooling tower systems and related equipment for over 40 years, with five different models in production ……

Expert Sourcing Insights for Types Of Cooling Tower

2026 Market Trends for Types of Cooling Tower

The global cooling tower market is poised for significant evolution by 2026, driven by energy efficiency mandates, industrial growth, water scarcity concerns, and technological advancements. Key trends shaping the different types of cooling towers include:

Hybrid Cooling Towers Gaining Prominence

Hybrid cooling towers, combining wet and dry cooling technologies (wet/dry or dry/wet), are expected to see accelerated adoption by 2026. These systems offer a compelling balance between water conservation and thermal performance. In regions facing water stress or strict regulatory limits on water usage and plume visibility (e.g., Europe, parts of the US, Middle East), hybrid designs allow operators to switch to dry or dry-assisted modes during peak water demand or when plume abatement is required. This flexibility enhances operational resilience and sustainability, making hybrids a strategic choice for power plants, data centers, and industrial facilities aiming to meet ESG goals.

Increased Demand for Closed-Circuit Cooling Towers

Closed-circuit cooling towers (also known as fluid coolers) are projected to experience strong growth, particularly in specialized industrial applications and HVAC systems for critical facilities. By keeping the process fluid in a closed loop, these towers prevent contamination, minimize water loss, and reduce maintenance needs. By 2026, their use is expected to expand in pharmaceuticals, food and beverage, data centers, and renewable energy (e.g., solar thermal, battery storage cooling), where fluid purity and reliability are paramount. Advancements in coil materials and heat transfer efficiency will further boost their appeal.

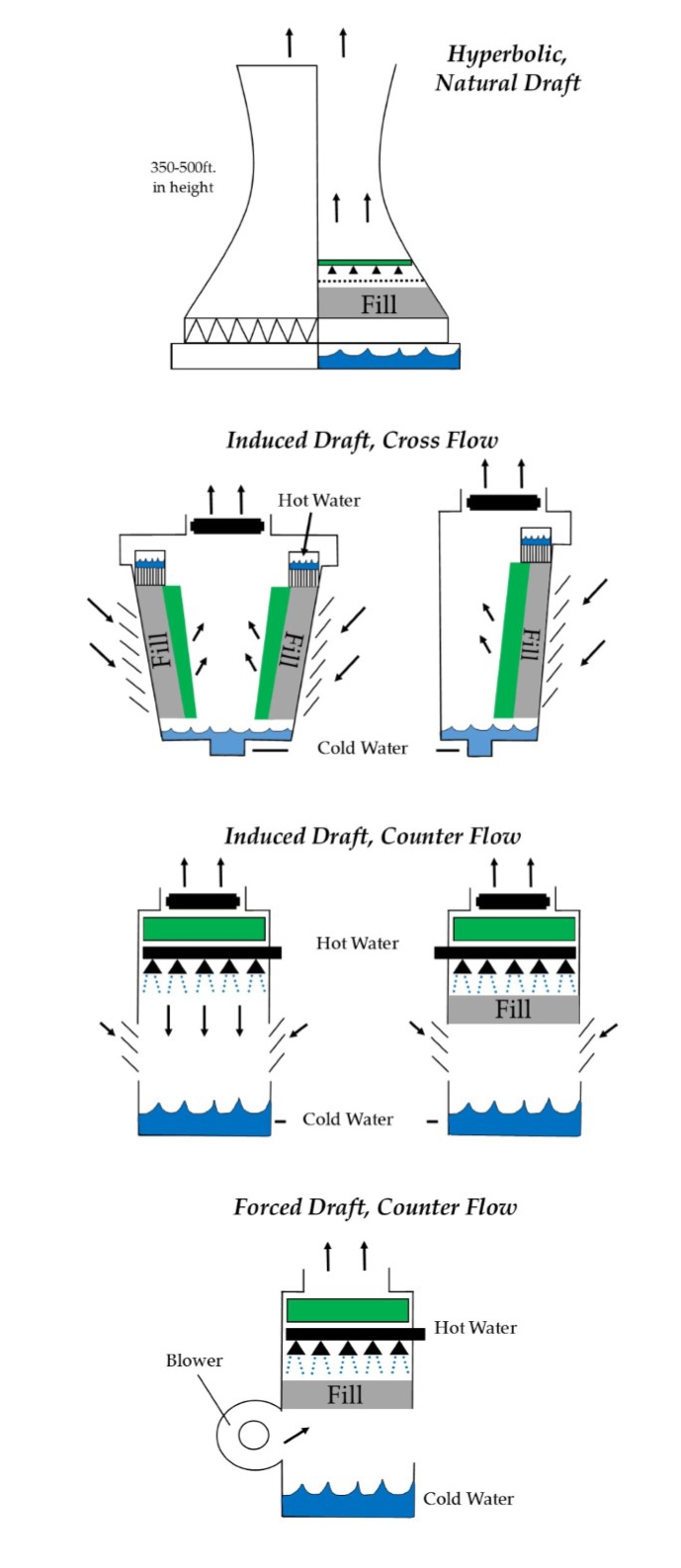

Natural Draft Towers Focus on Efficiency and Sustainability

While large-scale natural draft cooling towers remain dominant in the power generation sector, especially for nuclear and large thermal plants, the 2026 outlook emphasizes efficiency retrofits and sustainability upgrades. New constructions will be limited but focused on regions with high electricity demand and available land. Key trends include the integration of advanced fill materials to improve heat transfer, implementation of water treatment innovations to reduce blowdown and chemical usage, and enhanced monitoring systems for predictive maintenance. Plume abatement technologies may also be increasingly incorporated to address environmental and community concerns.

Mechanical Draft Towers Evolving with Smart Technology

Mechanical draft towers (both induced and forced draft) continue to serve a broad range of industrial and commercial applications. By 2026, the trend is toward smarter, more efficient units. Variable Frequency Drives (VFDs) on fans and pumps will become standard, significantly reducing energy consumption. Integration with Building Management Systems (BMS) and Industrial IoT platforms will enable real-time monitoring, remote diagnostics, and predictive maintenance, improving uptime and operational efficiency. Additionally, there is a growing shift toward non-wood, corrosion-resistant materials like fiberglass-reinforced plastic (FRP) for longer lifespans and lower maintenance.

Focus on Water and Energy Efficiency Across All Types

Water and energy efficiency will be the overarching drivers across all cooling tower types by 2026. Stricter environmental regulations, rising utility costs, and corporate sustainability targets will push demand for high-efficiency designs, advanced water treatment (e.g., ozone, electrochemical), and zero liquid discharge (ZLD) compatibility. Cooling towers with higher cycles of concentration, low-drift eliminators, and optimized airflow design will be preferred. This trend will benefit all types but particularly boost innovation in closed-circuit and hybrid systems.

In conclusion, the 2026 cooling tower market will be characterized by a shift toward smarter, more sustainable, and adaptable solutions. Hybrid and closed-circuit towers are expected to grow fastest, while traditional natural and mechanical draft towers will incorporate advanced technologies to meet evolving efficiency and environmental standards.

Common Pitfalls When Sourcing Types of Cooling Towers (Quality, IP Rating)

Sourcing the right cooling tower involves more than just selecting a type (e.g., crossflow, counterflow, open, closed circuit). Critical considerations around quality and Ingress Protection (IP) ratings are often overlooked, leading to performance issues, safety hazards, and increased lifecycle costs. Here are common pitfalls to avoid:

Overlooking Build Quality and Materials

One of the most frequent mistakes is focusing solely on upfront cost while neglecting the long-term implications of subpar construction. Low-quality cooling towers may use thin-gauge metals, inferior fill media, or poorly fabricated components that degrade quickly under continuous exposure to water, UV radiation, and chemicals. This results in reduced efficiency, frequent maintenance, and premature failure. Always verify material specifications—such as corrosion-resistant galvanized steel, stainless steel, or fiber-reinforced polymer (FRP)—and insist on quality certifications or third-party testing.

Ignoring IP Rating Requirements for the Environment

The Ingress Protection (IP) rating defines a cooling tower’s resistance to dust and moisture intrusion, particularly critical for electrical components like fans and motors. A common pitfall is selecting equipment with inadequate IP ratings for the installation environment. For example, using an IP54-rated motor in a high-humidity or outdoor coastal setting may lead to electrical failures. Always match the IP rating to site conditions—IP55 or higher is typically recommended for outdoor or harsh environments to ensure reliability and safety.

Assuming All Cooling Tower Types Perform Equally in All Conditions

Different cooling tower types have varying efficiency, maintenance needs, and suitability based on climate and application. A frequent error is choosing a crossflow tower for a space-constrained urban rooftop without considering footprint and maintenance access, or selecting an open recirculating tower in areas with high particulate pollution, which increases fouling risk. Closed-circuit towers may be over-specified for simple HVAC applications, inflating costs unnecessarily. Conduct a thorough site and application analysis before finalizing the type.

Failing to Verify Compliance with Industry Standards

Procuring cooling towers that don’t meet recognized standards (e.g., CTI, ISO, ASHRAE) can result in poor performance and safety risks. Some suppliers may offer non-certified units at lower prices, but these often lack proper balancing, noise control, or structural integrity. Always request compliance documentation and ensure the design adheres to relevant quality and safety benchmarks.

Neglecting Long-Term Maintenance and Service Support

Even high-quality, correctly specified cooling towers require regular maintenance. A key sourcing pitfall is not evaluating the supplier’s after-sales support, spare parts availability, and service network. Choosing a vendor with limited local presence can lead to extended downtime during repairs. Include service agreements and parts lead times in your evaluation criteria.

By addressing these quality and IP-related pitfalls early in the sourcing process, organizations can ensure reliable operation, extend equipment lifespan, and reduce total cost of ownership.

Logistics & Compliance Guide for Types of Cooling Towers

Introduction to Cooling Tower Types and Their Logistics Implications

Cooling towers are essential components in industrial, commercial, and HVAC systems, providing efficient heat rejection through evaporation. The logistics and compliance requirements vary significantly based on the type of cooling tower used. Understanding these differences ensures efficient transportation, installation, operation, and regulatory adherence. This guide outlines the primary types of cooling towers—open circuit (direct) and closed circuit (indirect)—and examines their logistical and compliance considerations.

Open Circuit Cooling Towers (Wet/Direct)

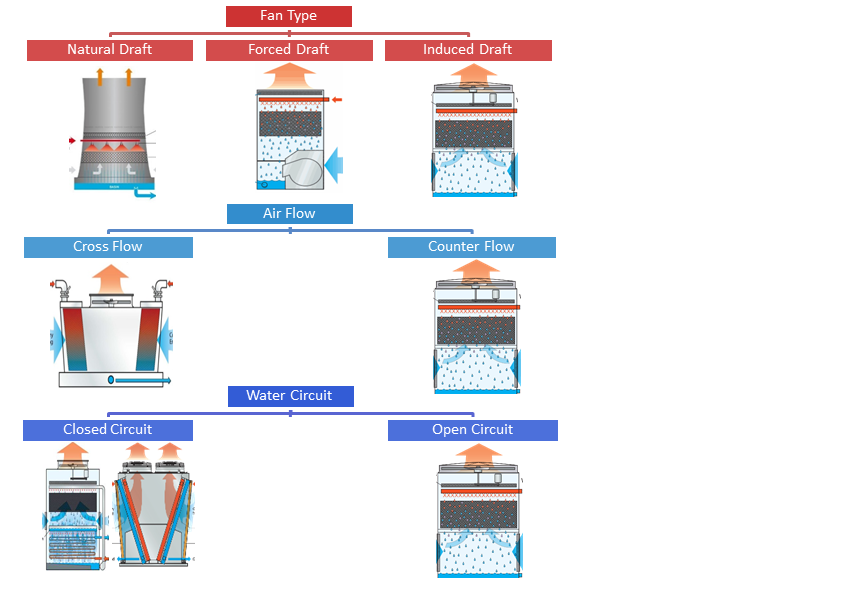

Open circuit cooling towers, also known as wet or direct cooling towers, expose the process water directly to the atmosphere. Air flows through the falling water, causing partial evaporation and cooling. These towers come in various configurations, including crossflow and counterflow designs.

Logistics Considerations

- Size and Weight: Open circuit towers are typically large and modular, requiring careful planning for transportation. Field-erected units may need on-site assembly, necessitating crane access and secure staging areas.

- Transportation: Pre-assembled units are often shipped via flatbed trucks or containerized for international shipping. Permits may be required for oversized loads.

- Installation: Requires a solid, level foundation due to high water load and operational vibration. On-site labor and equipment (e.g., cranes, forklifts) are essential for assembly.

- Water Supply and Drainage: Proximity to a reliable water source and proper drainage infrastructure must be planned in advance to support makeup water and blowdown.

Compliance Requirements

- Water Quality and Treatment: Must comply with local water conservation and discharge regulations. Chemical treatment programs are required to control scaling, corrosion, and biological growth (e.g., Legionella).

- Environmental Regulations: Discharge of blowdown water may require permits under the Clean Water Act (U.S.) or equivalent national legislation. Compliance with National Pollutant Discharge Elimination System (NPDES) permits is often necessary.

- Health and Safety: Risk of Legionella must be managed per OSHA and CDC guidelines. Regular monitoring and maintenance are mandatory. Local building and fire codes may restrict tower placement due to drift and plume concerns.

Closed Circuit Cooling Towers (Indirect/Dry)

Closed circuit cooling towers, also called fluid coolers or closed-loop towers, keep the process fluid in a sealed coil, which is cooled by water sprayed over the coil and air drawn across it. This design prevents direct contact between the process fluid and the environment.

Logistics Considerations

- Compact Design: Typically smaller and factory-assembled, making transportation easier than large field-erected open towers. Suitable for container shipping and standard trucking.

- Installation Flexibility: Can be installed on rooftops or in tight spaces. Requires less structural support than open towers but still needs proper vibration isolation and access for maintenance.

- Fluid Handling: Requires planning for the closed-loop fluid (e.g., glycol, oil), including filling, expansion tanks, and pumps. Fluid compatibility with piping and coils must be verified.

Compliance Requirements

- Reduced Biological Risk: Since process fluid is isolated, the risk of Legionella is lower, easing some health regulations. However, the spray water circuit still requires treatment and monitoring.

- Environmental Regulations: Blowdown from the spray water circuit may still require discharge permits, though volume is lower than open systems. Antifreeze additives (e.g., glycol) may be regulated under hazardous material handling laws.

- Refrigerant and Fluid Regulations: If used in refrigeration systems, compliance with EPA Section 608 (U.S.) for refrigerant handling may apply. International equivalents (e.g., F-Gas Regulation in EU) must also be observed.

Hybrid Cooling Towers (Dry/Wet Combination)

Hybrid cooling towers combine dry (non-evaporative) and wet (evaporative) sections, allowing operation in both modes depending on ambient conditions and water availability.

Logistics Considerations

- Complexity and Weight: Larger footprint and more components (e.g., dual heat exchangers, controls) increase shipping and handling complexity.

- Installation Requirements: Requires significant space and robust structural support. Integration with building management systems (BMS) demands skilled technicians.

- Utility Connections: Needs electrical, water, and control connections. Dual piping systems (for dry and wet sections) must be properly routed and insulated.

Compliance Requirements

- Energy Efficiency Standards: Often designed to meet LEED, ENERGY STAR, or local energy codes. Documentation for energy performance may be required for certification.

- Water Conservation: Operates in dry mode during cooler periods, reducing water use. This may qualify for water efficiency incentives or meet local water restriction mandates.

- Dual-System Maintenance: Both wet and dry sections require maintenance schedules compliant with manufacturer specifications and industry standards (e.g., ASHRAE Guideline 12).

General Compliance and Best Practices

Regardless of cooling tower type, the following compliance and logistical best practices apply:

- Permitting: Secure building, electrical, and environmental permits prior to installation.

- Standards Compliance: Adhere to ASHRAE, OSHA, EPA, and local codes. Follow CTI (Cooling Technology Institute) guidelines for performance and safety.

- Documentation: Maintain records of water treatment, inspections, maintenance, and compliance audits.

- Training: Ensure personnel are trained in safe operation, chemical handling, and emergency response procedures.

Conclusion

Selecting the appropriate cooling tower type involves more than technical performance—it significantly impacts logistics planning and regulatory compliance. Open circuit towers offer high efficiency but demand rigorous water and environmental management. Closed and hybrid systems provide operational flexibility and reduced biological risks but may involve more complex installations. A holistic approach, integrating logistics, safety, and regulatory considerations from the design phase, ensures reliable and compliant cooling tower operations.

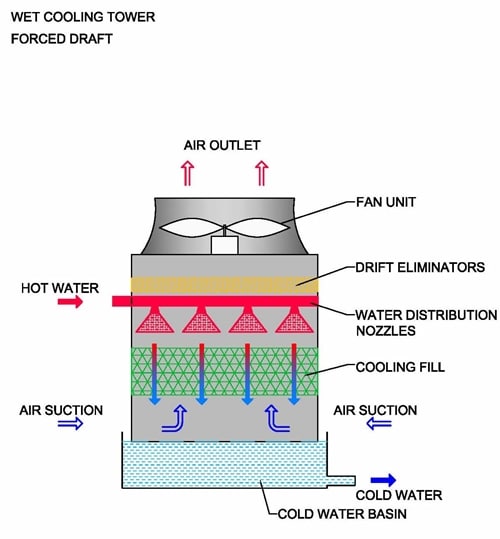

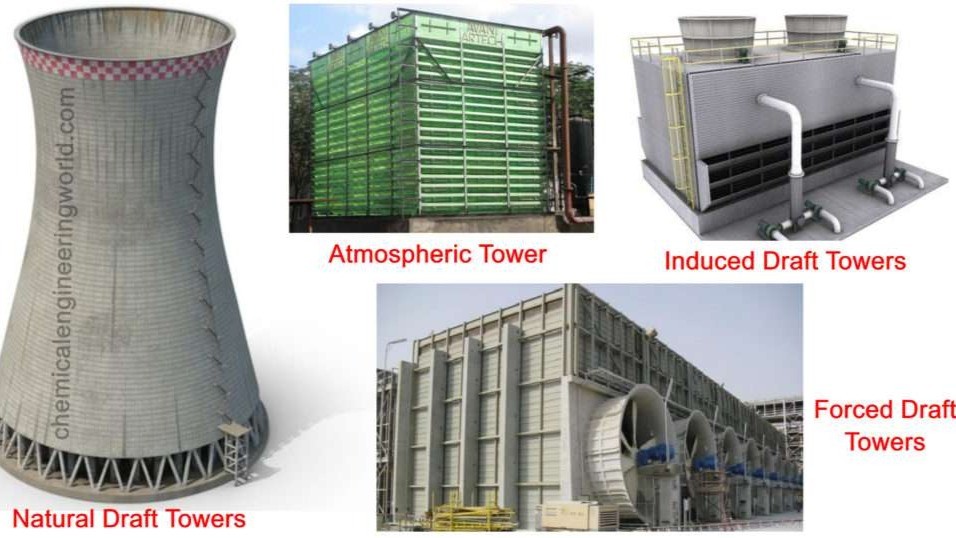

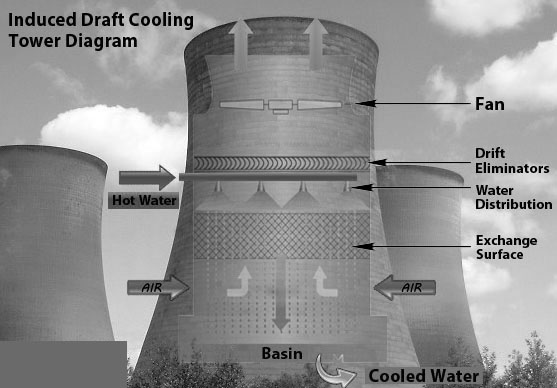

In conclusion, selecting the appropriate type of cooling tower for a specific application involves a careful evaluation of various factors including cooling requirements, available space, water quality, environmental conditions, energy efficiency, maintenance needs, and operational costs. The two main types—natural draft and mechanical draft cooling towers—each offer distinct advantages and limitations. Mechanical draft towers, further categorized into forced draft, induced draft, and counterflow or crossflow designs, provide greater control and are suitable for a wide range of industrial applications. Natural draft towers, while more energy-efficient and effective for large-scale operations like power plants, require significant space and higher initial investment.

Ultimately, the decision should align with the system’s thermal performance needs, sustainability goals, and long-term operational efficiency. By understanding the characteristics and applications of each cooling tower type, engineers and facility managers can make informed sourcing decisions that optimize performance, reduce lifecycle costs, and support reliable industrial operations.