The global conveyor systems market is experiencing robust growth, driven by rising demand for automation across manufacturing, logistics, and warehousing industries. According to Grand View Research, the global conveyor market was valued at USD 8.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by advancements in material handling technologies, increased e-commerce activity, and the need for operational efficiency in supply chains. Mordor Intelligence further supports this trend, projecting a CAGR of approximately 6.5% over the 2024–2029 forecast period, with heavy investments in smart factories and automated production lines accelerating adoption. As industries prioritize throughput, safety, and scalability, the diversity and specialization among conveyor manufacturers have expanded significantly. From belt and roller to overhead and modular systems, manufacturers are innovating to meet sector-specific demands. Below is a data-driven look at the top 10 types of conveyor manufacturers shaping the future of material handling.

Top 10 Types Of Conveyors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Conveyor Equipment Manufacturers Association

Domain Est. 1996

Website: cemanet.org

Key Highlights: Our Members are composed of the leading manufacturers of conveyors and conveying systems who design, produce and install all types of conveying machinery….

#2 Belt Conveyor Systems

Domain Est. 1998

Website: ultimationinc.com

Key Highlights: Ultimation is one of the top conveyor belt manufacturers. Our simple and versatile belt conveyor systems use two or more pulleys to drive looped belts….

#3 Span Tech Conveyors

Domain Est. 2017

Website: spantechconveyors.com

Key Highlights: Span Tech manufactures easy to integrate, modular custom conveyor solutions that can easily be modified or redesigned for all product changes. Pharmaceutical….

#4 Conveyor Manufacturers

Website: conveyorcompanies.com

Key Highlights: The different types of conveying systems include pneumatic, screw, belt, and roller. The construction of individual systems depends on the materials… Overhead ……

#5 Screw Conveyors, Feeders & Component Parts

Domain Est. 1997

Website: kwsmfg.com

Key Highlights: KWS is a screw conveyor manufacturing company that specializes in screw conveyors, screw feeders, slide gates, bucket elevators, component parts and other ……

#6 Conveyor systems

Domain Est. 1999

Website: elcom.fr

Key Highlights: The different types of conveyors · Flat belt conveyors · Timing belt conveyors · Roller conveyors · The different types of roller conveyors….

#7 US Conveyor

Domain Est. 2000

Website: usconveyor.net

Key Highlights: US Conveyor has a wide variety of belt conveyor types and styles for every application. Whether you need a rugged radial stacker after a shear or a low tonnage ……

#8 Conveyor

Domain Est. 2008

Website: conveyorconceptsinc.com

Key Highlights: We offer a wide selection of different conveyor systems – including roller conveyors chain conveyors, slat conveyors and so much more….

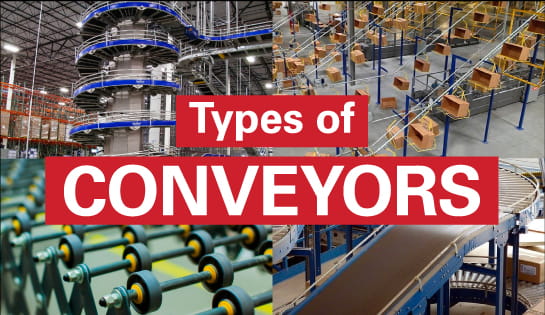

#9 Types of Conveyors

Domain Est. 2009

Website: mknorthamerica.com

Key Highlights: Chain Conveyor Systems · Cleated Belt Conveyors · Curved Conveyor Belts · Flat Belt Conveyor Systems · Incline Conveyor Systems · Modular Plastic Belt Conveyors….

#10 Modern Conveyor Systems for Unit Handling in Logistics …

Domain Est. 2012

Website: avancon.com

Key Highlights: modern conveyor systems, conveyors for unit handling, roller conveyors, belt conveyors, omnidirectional conveyor elements, conveyor rollers, conveyor flat ……

Expert Sourcing Insights for Types Of Conveyors

2026 Market Trends for Types of Conveyors

Rising Demand for Automated and Smart Conveyors

By 2026, the conveyor market is expected to experience significant growth driven by the increasing adoption of automation in manufacturing, logistics, and warehousing. Smart conveyors equipped with sensors, IoT connectivity, and real-time monitoring systems are becoming essential in Industry 4.0 environments. These intelligent systems offer predictive maintenance, improved operational efficiency, and seamless integration with warehouse management systems (WMS) and robotic picking solutions. Companies are investing heavily in conveyors with built-in data analytics capabilities to optimize throughput and reduce downtime.

Growth in E-Commerce Fuels Roller and Belt Conveyor Demand

The exponential rise of e-commerce continues to be a major driver for conveyor systems, particularly roller and belt conveyors. By 2026, fulfillment centers and distribution hubs will require high-speed, modular conveyor configurations to manage increasing parcel volumes. Roller conveyors are favored for their ability to handle heavy and irregularly shaped items, while belt conveyors are preferred for delicate or small packages. The trend toward same-day and next-day delivery is pushing companies to upgrade their material handling infrastructure with scalable conveyor solutions.

Expansion of Accumulation and Sortation Conveyors in Logistics

Accumulation conveyors—especially zero-pressure and multi-parallel types—are gaining traction due to their ability to manage product flow without damage during bottlenecks. In tandem with advanced sortation systems, these conveyors are critical for parcel handling, postal services, and automated distribution centers. By 2026, the integration of cross-belt and tilt-tray sorters with high-speed accumulation conveyors will be standard in large logistics operations, enabling precise, high-volume sorting with minimal labor.

Sustainability and Energy-Efficient Conveyor Designs

Environmental concerns and rising energy costs are pushing manufacturers toward energy-saving conveyor technologies. By 2026, energy-efficient motors, regenerative drives, and low-friction components will be standard features in new conveyor systems. Additionally, modular and reconfigurable conveyor designs will reduce waste and extend system lifecycles, aligning with circular economy principles. Companies are also favoring conveyors made from recyclable materials and those that support LEED-certified facility goals.

Increased Adoption of Overhead and Pallet Conveyors in Automotive and Manufacturing

In industries such as automotive, aerospace, and heavy manufacturing, overhead conveyors and powered roller pallet conveyors are seeing renewed interest. These systems optimize floor space and streamline assembly line operations. By 2026, overhead conveyors with programmable control systems will be widely used for paint shops and final assembly, while pallet conveyors will integrate with automated guided vehicles (AGVs) to support just-in-time (JIT) production models.

Regional Market Dynamics and Technological Adoption

Asia-Pacific is expected to lead conveyor market growth by 2026, fueled by rapid industrialization, expansion of e-commerce in China and India, and government initiatives like “Make in India” and “Smart Manufacturing.” North America and Europe will focus on retrofitting existing facilities with smart conveyors and upgrading legacy systems for better interoperability. Meanwhile, Latin America and the Middle East will see steady growth in conveyor installations within food & beverage, pharmaceutical, and logistics sectors.

Conclusion

By 2026, the conveyor market will be defined by intelligence, efficiency, and adaptability. The convergence of automation, data analytics, and sustainable design will reshape conveyor types across industries. Businesses that invest in next-generation conveyor systems—particularly those offering scalability, energy efficiency, and seamless integration—will gain a competitive edge in an increasingly automated global supply chain.

Common Pitfalls When Sourcing Types of Conveyors (Quality and IP Considerations)

When sourcing conveyor systems for industrial or manufacturing applications, organizations often focus on cost and delivery timelines while overlooking critical quality and intellectual property (IP) concerns. Failing to address these aspects can lead to operational inefficiencies, legal exposure, and long-term financial losses. Below are common pitfalls to avoid:

1. Overlooking Build Quality and Material Specifications

One of the most frequent issues is selecting conveyors based solely on upfront cost without verifying the quality of materials and construction. Low-cost conveyors may use inferior metals, substandard bearings, or weak frame designs that lead to frequent breakdowns, increased maintenance, and safety hazards. Always request detailed specifications and third-party certifications (e.g., ISO, CE) to ensure durability and performance under expected operating conditions.

2. Inadequate Verification of Component Sourcing

Many conveyor manufacturers outsource key components such as motors, rollers, and control systems. Without transparency into the supply chain, buyers risk receiving systems with counterfeit or non-compliant parts. Ensure suppliers disclose component origins and adhere to recognized quality standards. Request documentation such as material test reports or compliance certificates.

3. Neglecting Environmental and Operational Compatibility

Different conveyor types—belt, roller, chain, overhead, etc.—are designed for specific environments (e.g., food-grade, high-temperature, corrosive). Sourcing the wrong type or failing to confirm environmental resistance (e.g., stainless steel for washdown areas) leads to premature failure. Conduct a thorough site assessment and match conveyor specifications to actual operating conditions.

4. Ignoring Intellectual Property Rights

Some conveyor designs, control systems, or proprietary technologies are protected by patents, trademarks, or copyrights. Sourcing from vendors that use or replicate patented designs without authorization can expose your business to legal liability. Verify that the supplier owns or has licensed rights to any proprietary technology included in the conveyor system.

5. Failing to Review Design and Engineering Documentation

Incomplete or unclear engineering drawings, schematics, or software interfaces can cause integration challenges and maintenance issues. Ensure all technical documentation is provided, accurate, and free of IP conflicts. If the system includes custom software, confirm licensing terms and whether source code access is permitted for troubleshooting or modifications.

6. Skipping Factory Acceptance Testing (FAT)

Bypassing on-site or virtual factory testing increases the risk of receiving a non-conforming or malfunctioning system. A formal FAT allows buyers to inspect build quality, verify performance, and ensure compliance with agreed specifications before shipment. Make FAT a contractual requirement.

7. Underestimating After-Sales Support and Spare Parts Availability

Even high-quality conveyors require maintenance. Sourcing from vendors without reliable technical support or spare parts networks can result in extended downtime. Confirm service agreements, warranty terms, and parts lead times before finalizing procurement.

8. Assuming Standardization Without Validation

While modular or standardized conveyors offer cost benefits, assuming compatibility with existing systems without validation can lead to integration failures. Confirm interface dimensions, control protocols (e.g., PLC compatibility), and load-handling capabilities match your operational needs.

By proactively addressing these pitfalls—focusing on both quality assurance and IP integrity—organizations can ensure reliable, compliant, and legally sound conveyor system sourcing.

Logistics & Compliance Guide for Types of Conveyors

Understanding the various types of conveyors is essential for optimizing material handling operations while ensuring compliance with safety, environmental, and industry regulations. This guide outlines common conveyor types along with key logistics considerations and compliance requirements.

Belt Conveyors

Belt conveyors use a continuous loop of material (often rubber, fabric, or PVC) to transport items across flat or inclined planes. They are widely used in manufacturing, packaging, and distribution centers.

Logistics Considerations:

– Ideal for transporting bulk materials or individual packages over long distances.

– Can be curved or straight; suitable for integrating into automated systems.

– Low maintenance when properly aligned and tensioned.

– Speed and load capacity must match operational throughput requirements.

Compliance Requirements:

– Must comply with OSHA (Occupational Safety and Health Administration) standards for guarding moving parts (e.g., 29 CFR 1910.212).

– Electrical components should meet NEC (National Electrical Code) standards.

– Fire-resistant belts are required in certain environments (e.g., mining, food processing) per NFPA (National Fire Protection Association) codes.

– Regular inspection and maintenance records must be maintained.

Roller Conveyors

Roller conveyors consist of parallel rollers mounted in a frame, allowing gravity or powered movement of goods. They are commonly used in sorting, accumulation, and loading zones.

Logistics Considerations:

– Gravity rollers are cost-effective for lightweight loads and manual handling.

– Powered rollers (live rollers) support automated material flow and accumulation.

– Spacing between rollers must accommodate the size and weight of transported items.

– Suitable for cartons, totes, and pallets.

Compliance Requirements:

– Exposed pinch points and rotating shafts must be guarded per OSHA regulations.

– Powered conveyors require emergency stop systems within easy reach (ANSI B15.1 Safety Standard for Mechanical Power Transmission Apparatus).

– Noise levels should comply with OSHA permissible exposure limits (29 CFR 1910.95).

– Electrical drives must meet local and national electrical codes.

Chain Conveyors

Chain conveyors use chains to move heavy or bulky loads through industrial processes. They are commonly found in automotive, metal fabrication, and heavy manufacturing.

Logistics Considerations:

– High load capacity and durability for heavy or irregularly shaped items.

– Can operate in high-temperature or harsh environments.

– Typically slower than belt or roller systems.

– Requires lubrication and regular chain tension checks.

Compliance Requirements:

– Chain guards are mandatory to prevent entanglement (OSHA 29 CFR 1910.219).

– Lubricants must be appropriate for the environment (e.g., food-grade in food processing to meet FDA or USDA standards).

– Anchoring and structural integrity must comply with load-bearing codes.

– Lockout/Tagout (LOTO) procedures required during maintenance (OSHA 29 CFR 1910.147).

Screw Conveyors

Screw conveyors (augers) use a rotating helical screw blade to move bulk materials through a trough or tube. They are used in agriculture, waste treatment, and chemical processing.

Logistics Considerations:

– Ideal for granular, powdered, or semi-solid materials.

– Can transport materials vertically or horizontally in confined spaces.

– Sealed designs prevent dust and spillage.

– Limited to non-sticky, free-flowing materials.

Compliance Requirements:

– Dust control measures required to meet OSHA PELs and environmental regulations (e.g., EPA standards).

– Explosion-proof motors and seals may be needed in combustible dust environments (NFPA 654).

– Confined space entry protocols apply for cleaning and maintenance.

– Material contact surfaces must comply with industry-specific hygiene standards (e.g., 3A Sanitary Standards in food and pharma).

Overhead Conveyors

Overhead conveyors suspend loads from an overhead track using trolleys or carriers. They are common in painting, assembly, and warehousing operations.

Logistics Considerations:

– Frees up floor space and supports continuous product movement.

– Ideal for heavy loads or processes requiring vertical movement.

– Can integrate with lift-and-carry systems for complex routing.

– Requires sufficient ceiling height and structural support.

Compliance Requirements:

– Load-bearing structures must meet engineering codes and safety factors (ASME B30.17 for overhead hoists).

– Emergency stops and overload protection required.

– Regular inspection for wear, corrosion, and track alignment.

– Fall protection required for workers performing overhead maintenance (OSHA 29 CFR 1910.28).

Pneumatic Conveyors

Pneumatic conveyors use air pressure or vacuum to move dry materials through enclosed pipelines. Used in food, pharmaceutical, and chemical industries.

Logistics Considerations:

– High-speed transport with minimal contamination.

– Closed system reduces dust and spillage.

– Suitable for fragile materials when controlled properly.

– Requires significant energy for air compression.

Compliance Requirements:

– Explosion and fire risk mitigation for combustible materials (NFPA 69, ATEX in EU).

– Air filtration systems must comply with EPA and local air quality regulations.

– System pressure vessels must meet ASME Boiler and Pressure Vessel Code.

– Noise levels from compressors must be controlled per OSHA and local ordinances.

General Compliance Best Practices

Regardless of conveyor type, the following best practices support regulatory compliance and operational safety:

- Conduct regular risk assessments and equipment inspections.

- Train personnel on safe operating procedures and emergency protocols.

- Maintain detailed records of maintenance, repairs, and safety checks.

- Ensure all equipment is CE-marked (in Europe) or meets UL, CSA, or other applicable standards (in North America).

- Integrate conveyors with facility-wide safety systems (e.g., fire alarms, emergency shutdowns).

By aligning conveyor selection and operation with both logistical efficiency and compliance standards, organizations can enhance productivity, protect workers, and avoid regulatory penalties.

In conclusion, sourcing the right type of conveyor system is a critical decision that depends on various factors including the nature of the materials to be handled, production throughput, available space, operational environment, and long-term maintenance requirements. Different conveyor types—such as belt, roller, chain, overhead, and screw conveyors—each offer unique advantages suited to specific applications across industries like manufacturing, logistics, food processing, and mining.

When sourcing conveyors, it is essential to conduct a thorough needs assessment, consider scalability and integration with existing systems, and evaluate total cost of ownership—not just initial purchase price, but also installation, energy consumption, upkeep, and durability. Working with reputable suppliers who offer customization, technical support, and after-sales service can significantly enhance system efficiency and reduce downtime.

Ultimately, selecting the most appropriate conveyor type through informed sourcing ensures improved operational efficiency, safety, and productivity, providing a solid return on investment and supporting long-term operational success.