The global ball valve market is experiencing robust growth, driven by increasing demand across oil & gas, chemical processing, water treatment, and power generation industries. According to a report by Mordor Intelligence, the ball valve market was valued at USD 8.26 billion in 2023 and is projected to reach USD 11.43 billion by 2029, growing at a CAGR of 5.7% during the forecast period. Similarly, Grand View Research estimates rising infrastructure investments and stringent safety regulations as key contributors to market expansion, with industrial automation further accelerating adoption of high-performance valve solutions. As demand diversifies, manufacturers are specializing in various types of ball valves—ranging from floating and trunnion-mounted to top-entry and cryogenic designs—to meet specific performance, pressure, and environmental requirements. This growing specialization has led to a competitive landscape where innovation, material advancements, and application-specific engineering define market leadership. Below are the top 10 types of ball valve manufacturers shaping this dynamic industry.

Top 10 Types Of Ball Valves Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Powell Valves: Industrial Valve Manufacturer

Domain Est. 1998

Website: powellvalves.com

Key Highlights: Powell Valves has been a leading industrial manufacturer, providing high-quality gate, globe, check, bellow-seal & non-return valves. Contact a valve expert ……

#2 Industrial Valves Products

Domain Est. 1997

Website: flowserve.com

Key Highlights: Ball Valves · Butterfly Valves · Rotary Control Valves · Linear Control Valves · Severe Service Control Valves · Gate Valves · Globe Valves ……

#3 Valves

Domain Est. 2012

Website: klinger-international.com

Key Highlights: KLINGER offers a wide range of industrial valves, including ball valves, butterfly valves, piston valves, gate valves, globe valves, check valves, knife gate ……

#4 Valves and Actuation

Domain Est. 1987

Website: slb.com

Key Highlights: Types · Ball Valves. Reliable, bubble-tight sealing ideal for gas applications · 3D image of a butterfly valve. Butterfly Valves · 3D image of ……

#5 Jamesbury™ ball valves

Domain Est. 1991

Website: valmet.com

Key Highlights: Jamesbury ball valves are reliable and long-lasting valves. Their cycle life of can be as much as 100 times longer than with competitive products….

#6 Control Valves

Domain Est. 1995

Website: emerson.com

Key Highlights: High-Performance Butterfly Valves (16) · Angle Valves (11) · Segmented Ball Valves (8) · Three-Way Valves (3) · Eccentric Plug Valves (2)….

#7 KITZ

Domain Est. 1996

Website: kitz.com

Key Highlights: Through the manufacture and sale of valves that control the flow of water, air, oil and gas, the KITZ Group contributes to today’s affluent society….

#8 The Different Kinds of Ball Valves: Stainless Steel, Carbon …

Domain Est. 2001

Website: valtorc.com

Key Highlights: There are four major materials used in ball valves: stainless steel, carbon steel, cast iron, and brass ball valves. Each has its own advantages and uses….

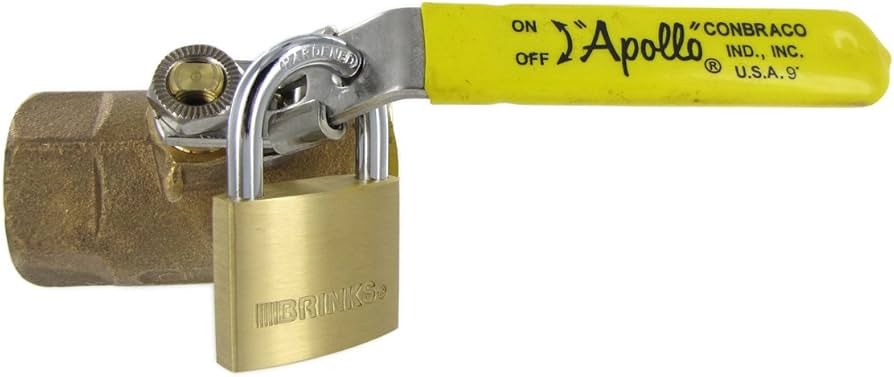

#9 Apollo Valves

Domain Est. 2021

Website: aalberts-ips.us

Key Highlights: Aalberts integrated piping systems is an amalgamation of different companies with many years of experience….

#10 Complete Guide to the Different Types of Valves

Domain Est. 1996

Website: geminivalve.com

Key Highlights: Though there are many different valve classifications, most valves fall within three categories: rotary, linear and self-actuated….

Expert Sourcing Insights for Types Of Ball Valves

H2: Market Trends for Types of Ball Valves in 2026

As the global industrial landscape evolves with increasing demands for energy efficiency, automation, and sustainability, the ball valve market is poised for significant transformation by 2026. Ball valves—valued for their reliability, durability, and versatility—are being further segmented and optimized based on design, material, and application. The following analysis highlights the key market trends expected in 2026 across the major types of ball valves: floating ball valves, trunnion-mounted ball valves, top-entry ball valves, and three-way ball valves.

-

Floating Ball Valves: Dominance in Low-to-Medium Pressure Applications

Floating ball valves are expected to maintain a strong market share in the low-to-medium pressure sectors, particularly in water treatment, HVAC, and general industrial applications. By 2026, advancements in polymer sealing materials (e.g., reinforced PTFE and PEEK) are enhancing their performance under higher temperatures and corrosive conditions. The trend toward compact, lightweight designs will support their adoption in modular and space-constrained installations. Additionally, cost-effectiveness and ease of maintenance continue to drive demand in emerging economies. -

Trunnion-Mounted Ball Valves: Growth in High-Pressure and Critical Service Sectors

Trunnion-mounted ball valves are projected to witness the fastest growth among ball valve types, especially in oil & gas, petrochemical, and LNG industries. Their ability to handle high pressures, large diameters, and abrasive media makes them ideal for upstream and midstream operations. By 2026, increasing offshore drilling activities and pipeline infrastructure expansions—particularly in the Middle East, North America, and Asia-Pacific—will fuel demand. Moreover, integration with smart monitoring systems (e.g., position sensors and remote actuation) will enhance operational safety and predictive maintenance capabilities. -

Top-Entry Ball Valves: Rising Preference for Maintenance Efficiency

Top-entry ball valves are gaining traction due to their in-line serviceability, which minimizes downtime and eliminates the need for full pipeline disassembly. This feature is particularly valuable in water and wastewater treatment plants, as well as in chemical processing facilities. By 2026, rising labor costs and stricter regulatory requirements for system reliability will boost the adoption of top-entry designs. Manufacturers are also focusing on corrosion-resistant alloys (e.g., duplex stainless steel and super duplex) to extend service life in aggressive environments. -

Three-Way and Multi-Port Ball Valves: Surge in Process Automation and Mixing Applications

The demand for three-way and multi-port ball valves is expected to grow significantly by 2026, driven by the expansion of automated process systems in pharmaceuticals, food & beverage, and chemical manufacturing. These valves enable flow diversion and mixing with high precision, supporting complex process control strategies. Integration with digital actuators and Industry 4.0 platforms (e.g., IoT-enabled valve monitoring) will allow real-time adjustments and data analytics, contributing to improved process efficiency and reduced waste.

Cross-Cutting Trends Influencing All Types:

– Material Innovation: Increased use of advanced alloys, composites, and anti-corrosion coatings to improve longevity and performance in harsh environments.

– Sustainability and Leak Prevention: Stricter environmental regulations (e.g., EPA methane rules, EU F-Gas regulations) are pushing manufacturers to develop low-emission and zero-leakage certified ball valves.

– Digitalization and Smart Valves: Growing integration of smart sensors, digital twins, and predictive maintenance software across all ball valve types to enhance reliability and reduce operational costs.

– Regional Shifts: Asia-Pacific, led by China, India, and Southeast Asia, will be the fastest-growing market due to rapid industrialization and infrastructure development, while North America and Europe focus on retrofitting aging systems with high-efficiency and smart valve solutions.

In conclusion, by 2026, the ball valve market will be characterized by product specialization, technological integration, and regional diversification. While floating and trunnion-mounted valves will dominate volume and value segments respectively, innovations in top-entry and multi-port designs will cater to niche but high-growth applications. Overall, the convergence of digitalization, regulatory compliance, and industrial automation will redefine the competitive landscape for ball valve manufacturers and end-users alike.

Common Pitfalls When Sourcing Types of Ball Valves (Quality and IP Considerations)

Sourcing ball valves requires careful evaluation of both quality and Ingress Protection (IP) ratings to ensure reliability and safety in various industrial applications. However, several common pitfalls can compromise performance and longevity if not addressed properly.

1. Overlooking Material Quality and Compatibility

One of the most frequent mistakes is selecting ball valves made from substandard materials. Inferior metals or plastics may corrode, crack, or degrade when exposed to specific media, temperatures, or pressures. For example, using a brass ball valve in a highly corrosive chemical environment can lead to premature failure. Always verify material specifications (e.g., stainless steel 316, PVC, brass) and ensure compatibility with the fluid, temperature, and pressure conditions.

2. Ignoring Ingress Protection (IP) Ratings

IP ratings indicate the level of protection against dust and moisture. A common pitfall is sourcing ball valves with inadequate IP ratings for the intended environment. For instance, using an IP54-rated valve in a high-moisture or outdoor setting may result in internal component damage. Always match the IP rating (e.g., IP67 or IP68) to the operating environment—especially for automated ball valves with electric actuators.

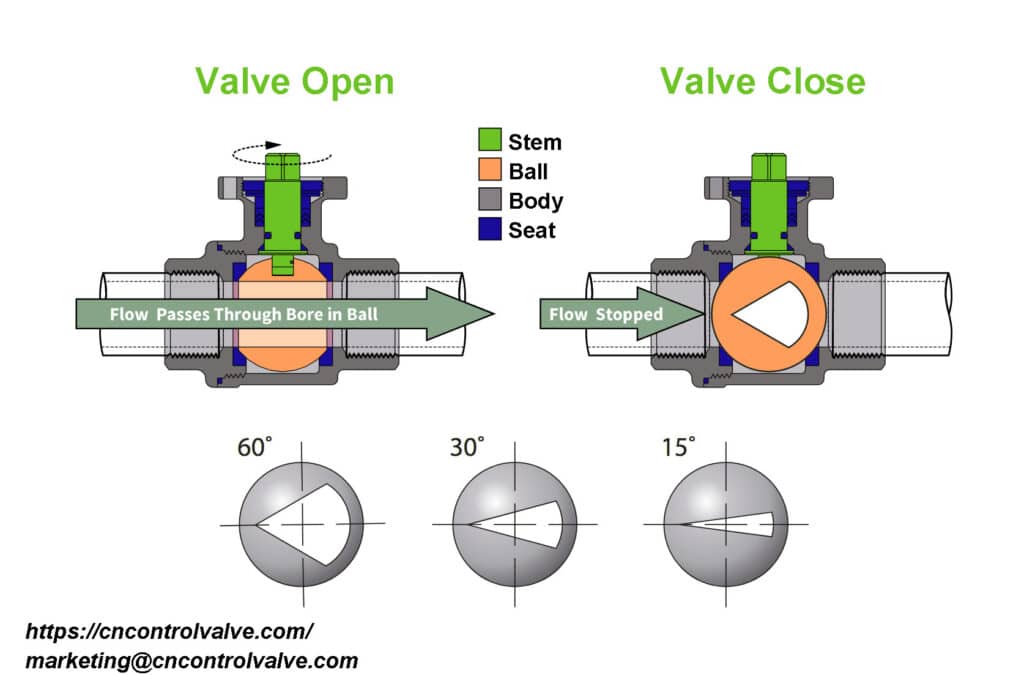

3. Assuming All Ball Valves Are Interchangeable

Different types of ball valves—such as full port, reduced port, multi-port, floating, and trunnion-mounted—serve distinct purposes. Sourcing the wrong type can lead to flow restrictions, inefficiencies, or system failure. For example, a reduced port valve may create unnecessary pressure drops in high-flow applications. Understand system requirements before selecting the valve type.

4. Failing to Verify Certifications and Standards

Procuring valves without proper certifications (e.g., ISO, API, ANSI, or CE) increases the risk of non-compliance and safety hazards. Low-cost suppliers may lack third-party testing or quality control. Always request documentation proving compliance with industry standards to ensure reliability and traceability.

5. Prioritizing Cost Over Long-Term Value

Choosing the cheapest option can lead to higher lifecycle costs due to frequent maintenance, downtime, or replacement. Low-quality seals, poor machining, or weak stem designs often result in leaks or failure. Invest in valves from reputable manufacturers—even at a higher initial cost—to ensure durability and performance.

6. Neglecting Actuator and Automation Compatibility

For automated systems, a common oversight is sourcing ball valves that aren’t compatible with available actuators or control systems. Mismatches in torque requirements, mounting standards, or electrical specifications can render automation ineffective. Ensure valve-actuator integration is verified during procurement.

7. Inadequate Supplier Vetting

Sourcing from unverified suppliers, especially through online marketplaces, increases the risk of counterfeit or misrepresented products. Conduct due diligence: check references, review quality management systems, and, if possible, conduct factory audits.

By avoiding these pitfalls, buyers can ensure they source high-quality ball valves with appropriate IP protection, suited for their specific application and operational environment.

Types of Ball Valves: Logistics & Compliance Guide

Understanding the various types of ball valves is essential for efficient logistics planning and ensuring regulatory compliance across industries such as oil & gas, chemical processing, water treatment, and pharmaceuticals. This guide outlines the common types of ball valves and highlights key logistics and compliance considerations for each.

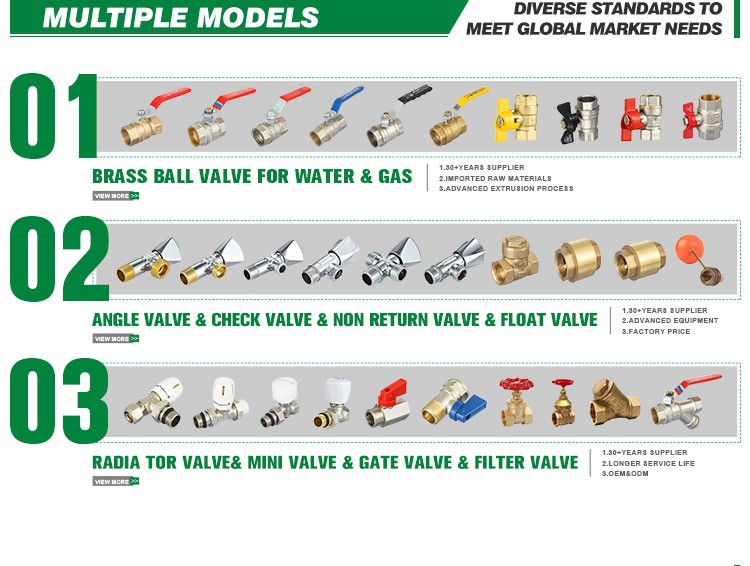

Full Port Ball Valves

Full port (or full bore) ball valves feature a ball with a bore diameter equal to the pipeline’s internal diameter, minimizing pressure drop and allowing unrestricted flow. They are ideal for applications requiring pigging or where low friction loss is critical.

Logistics Considerations:

– Larger dimensions and heavier weight due to oversized body design may increase shipping costs and require specialized handling.

– Packaging must protect the enlarged valve body and sealing surfaces during transit.

– Storage requires more space; stacking may not be feasible without proper support.

Compliance Considerations:

– Must comply with ASME B16.34 for pressure and temperature ratings.

– Materials must meet relevant standards (e.g., ASTM A216 for carbon steel) depending on fluid service.

– Suitable for API 6D applications in pipeline systems requiring through-bore access.

– In hazardous environments, certification to ATEX or IECEx may be required if actuators are used.

Reduced Port Ball Valves

Reduced port (or reduced bore) ball valves have a ball bore smaller than the pipe size, resulting in a slight pressure drop. These are cost-effective and commonly used in non-critical flow applications.

Logistics Considerations:

– Compact size and lighter weight reduce shipping and handling costs.

– Standardized packaging options are widely available.

– Ideal for high-volume shipments due to smaller footprint.

Compliance Considerations:

– Must meet pressure-temperature ratings per ASME B16.34 or EN 1983-3.

– Material traceability (e.g., MTRs) required for industrial applications.

– Suitable for general industrial use but not for pigging or high-flow efficiency systems.

V-Port Ball Valves

V-port ball valves feature a “V”-shaped ball or seat, providing precise flow control and good throttling capabilities. They are used in modulating applications such as chemical dosing and process control.

Logistics Considerations:

– Often shipped with protective caps on the V-notch to prevent damage.

– Sensitive sealing surfaces require careful packaging and handling.

– May require climate-controlled transport if elastomeric seals are sensitive to temperature extremes.

Compliance Considerations:

– Must comply with control valve standards such as ISA-75 when used for throttling.

– Materials must resist erosion and corrosion from controlled media (e.g., HF acid, slurries).

– In regulated industries (e.g., pharma), compliance with FDA or 3-A Sanitary Standards may apply.

– Emission standards (e.g., ISO 15848, TA-Luft) must be met for fugitive emissions in chemical plants.

Trunnion Mounted Ball Valves

Trunnion mounted ball valves use additional mechanical anchoring (trunnions) to support the ball, making them suitable for high-pressure, large-diameter, and high-cycle applications.

Logistics Considerations:

– Heavy and bulky; require lifting equipment and secure crating.

– Often shipped on wooden skids with lifting lugs clearly marked.

– International shipments must comply with ISPM-15 for wood packaging materials.

Compliance Considerations:

– Designed to meet API 6D and API 6A standards for pipeline and wellhead service.

– Fire-safe design per API 607/API 6FA is often mandatory in oil & gas.

– Material certifications (e.g., NACE MR0175/ISO 15156) required for sour service environments.

– May require third-party inspection (e.g., API 5A, CE marking) prior to shipment.

Floating Ball Valves

In floating ball valves, the ball is not mechanically fixed and “floats” slightly downstream under pressure, pressing the ball against the seat to ensure sealing. Common in low-to-medium pressure applications.

Logistics Considerations:

– Lightweight and compact, ideal for containerized shipping.

– Standard carton or crate packaging usually sufficient.

– Low risk of internal damage if properly capped.

Compliance Considerations:

– Must meet ASME B16.34 pressure ratings and end connection standards (e.g., ASME B16.5 flanges).

– Suitable for general industrial use; compliance with PED (Pressure Equipment Directive) required in the EU.

– For oxygen service, must be cleaned and certified per CGA G-4.1 or ASTM G93.

Multi-Port Ball Valves

Multi-port ball valves (e.g., 3-way, 4-way) allow flow diversion or mixing through multiple inlet/outlet ports. Used in process systems requiring flow routing.

Logistics Considerations:

– Complex port configurations require orientation-specific packaging to avoid damage.

– Installation manuals and flow diagrams should be included with shipment.

– Fragile internal mechanisms necessitate shock-absorbing packaging.

Compliance Considerations:

– Design must comply with applicable piping codes (e.g., ASME B31.3).

– Sealing materials must be compatible with all routed media; documentation required.

– In hygienic applications (e.g., food, biotech), must meet 3-A, EHEDG, or FDA standards.

– CE marking and UKCA certification needed for European and UK markets.

Top Entry Ball Valves

Top entry ball valves allow internal maintenance and repair without removing the valve from the pipeline, making them ideal for offshore and buried installations.

Logistics Considerations:

– Often shipped disassembled with internal components protected.

– Requires sturdy, reusable crates for offshore projects.

– Inventory tracking is critical due to high value and long lead times.

Compliance Considerations:

– Must meet API 6D with additional requirements for subsea or offshore use (e.g., API 17D).

– Material and weld procedures must comply with NORSOK or DNV standards in offshore environments.

– Non-destructive testing (NDT) records and third-party verification (e.g., DNV-GL, Lloyds Register) often required.

Conclusion

Selecting the correct type of ball valve involves more than functional fit—it directly impacts logistics efficiency and regulatory compliance. Proper packaging, handling, documentation, and certification ensure safe delivery and adherence to international, industry-specific, and environmental standards. Always verify material traceability, pressure ratings, and application-specific certifications before procurement and deployment.

In conclusion, selecting the appropriate type of ball valve for a specific application requires careful consideration of various sourcing factors, including valve design (such as floating, trunnion-mounted, or top-entry), materials of construction, pressure and temperature ratings, actuation method, and industry standards. Each type of ball valve offers distinct advantages—floating ball valves are cost-effective and suitable for lower-pressure applications, while trunnion-mounted valves provide enhanced performance in high-pressure and large-diameter systems. Additionally, sourcing decisions should take into account supplier reliability, compliance with international standards (e.g., API, ASME, ISO), lead times, and total cost of ownership. By aligning the technical requirements of the system with the right valve type and a trusted supply chain, organizations can ensure optimal performance, longevity, and operational safety in their fluid control systems.