The global marking equipment market is experiencing robust growth, driven by increasing demand for product traceability, brand protection, and regulatory compliance across industries such as automotive, pharmaceuticals, electronics, and food & beverage. According to Grand View Research, the global industrial marking and coding equipment market was valued at USD 5.3 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is fueled by advancements in laser and inkjet technologies, rising automation in manufacturing, and the need for high-precision, permanent marking solutions. As industries prioritize supply chain transparency and anti-counterfeiting measures, manufacturers specializing in diverse marking technologies—including laser, dot pin, inkjet, and electrochemical methods—are scaling innovation to meet evolving requirements. The following overview highlights the top 8 types of marking manufacturers shaping this dynamic landscape.

Top 8 Type Of Marking Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 CE marking – obtaining the certificate, EU requirements

Website: europa.eu

Key Highlights: Many products require CE marking before they can be sold in the EU. With this marking, the manufacturer indicates that a product meets the requirements set ……

#2 UL certification

Website: markshub.ul.com

Key Highlights: UL Marks are the most prominent demonstration of your certification status and can be used in a variety of ways, such as on labels affixed, die-stamped, molded ……

#3 Product Certification Marks

Website: csagroup.org

Key Highlights: The CSA mark demonstrates that a product has been rigorously tested to applicable standards. These include standards written or administered by the American ……

#4 Goods and services

Website: uspto.gov

Key Highlights: Your trademark application must include a list of the goods and services in use or have a bona fide intent to use with your trademark….

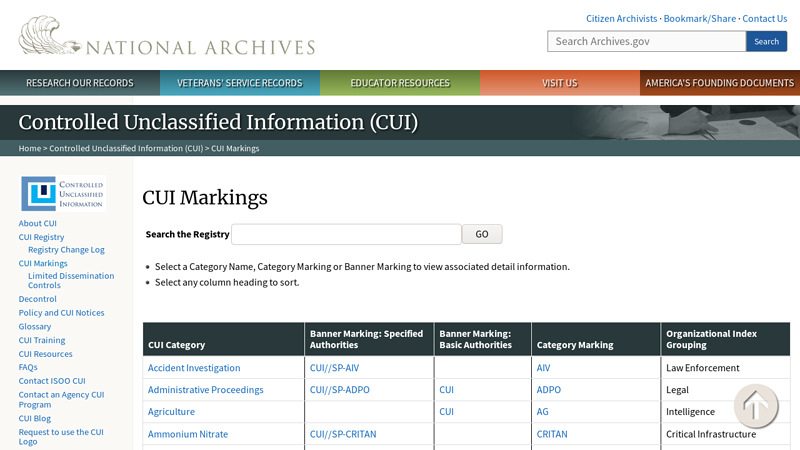

#5 CUI Markings

Website: archives.gov

Key Highlights: Select a Category Name, Category Marking or Banner Marking to view associated detail information. Select any column heading to sort….

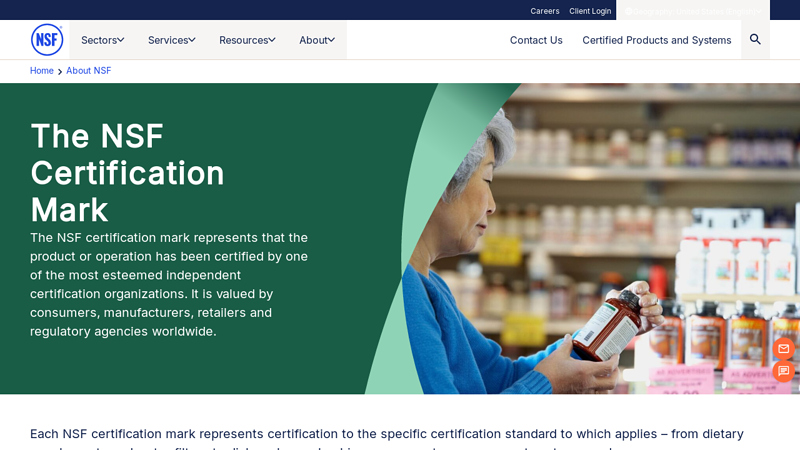

#6 The NSF Mark

Website: nsf.org

Key Highlights: The NSF certification mark represents that the product or operation has been certified by one of the most esteemed independent certification organizations….

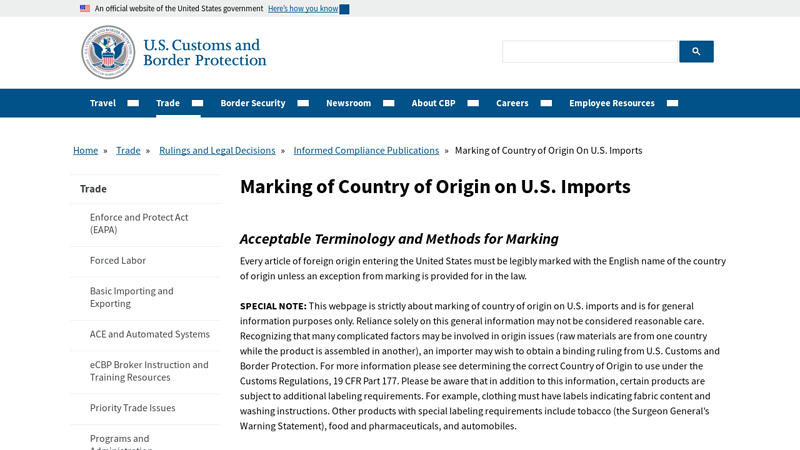

#7 Marking of Country of Origin on U.S. Imports

Website: cbp.gov

Key Highlights: Every article of foreign origin entering the United States must be legibly marked with the English name of the country of origin unless an exception from ……

#8 Product Certification Marks for Safety, Quality, and Performance

Website: intertek.com

Key Highlights: Product Certification Marks are symbols or labels that indicate products have been tested and certified to meet specific standards or requirements….

Expert Sourcing Insights for Type Of Marking

2026 Market Trends for Types of Marking

As industries continue to evolve in response to technological advancements, regulatory demands, and sustainability goals, the landscape for product and material marking is undergoing significant transformation. By 2026, several key trends are expected to shape the adoption and development of different marking technologies. Below is an analysis of the major type-of-marking trends anticipated to dominate the market.

Laser Marking: Dominance Through Precision and Versatility

Laser marking is projected to maintain its leadership position in the global marking market by 2026. This growth is driven by its unmatched precision, permanence, and compatibility with a wide range of materials—including metals, plastics, ceramics, and composites. Increasing demand for traceability in regulated industries such as medical devices, automotive, and aerospace will fuel adoption. Fiber and UV lasers, in particular, are expected to see accelerated growth due to their ability to create high-contrast, non-contact marks without consumables. Additionally, advancements in ultrafast lasers will enable micro-marking for electronics and semiconductor applications, supporting miniaturization trends.

Inkjet Marking: Evolution in High-Speed and Sustainable Solutions

Inkjet marking, especially continuous inkjet (CIJ) and drop-on-demand (DOD) technologies, will remain essential for high-speed production lines in food & beverage, pharmaceuticals, and consumer goods. By 2026, the focus will shift toward eco-friendly inks and improved print resolution. Water-based and solvent-free inks are gaining traction as companies respond to environmental regulations and consumer demand for greener packaging. Integration with Industry 4.0 systems will allow real-time data marking, such as dynamic barcodes, batch numbers, and QR codes, enhancing supply chain transparency. Portable and smart inkjet systems are also expected to grow, catering to flexible manufacturing environments.

Thermal Transfer and Direct Thermal Marking: Growth in Logistics and Healthcare

Thermal transfer printing (TTP) and direct thermal marking are expected to experience steady growth, particularly in labeling applications across logistics, retail, and healthcare. The demand for durable, scannable labels for tracking shipments and medical supplies will drive adoption. By 2026, innovations in ribbon materials and printhead durability will improve print longevity and reduce maintenance costs. In healthcare, the need for compliant labeling of pharmaceuticals and medical devices under UDI (Unique Device Identification) regulations will further boost market demand for reliable thermal marking systems.

Dot Peen and Mechanical Marking: Resilience in Heavy Industry

Dot peen marking, a form of mechanical marking, will continue to serve niche but critical applications in heavy industries such as automotive, aerospace, and metal fabrication. Its ability to create deep, permanent marks on tough materials ensures ongoing relevance, especially for part traceability under harsh conditions. By 2026, integration with robotic systems and CNC machines will enhance automation and accuracy. However, growth will be moderate compared to non-contact technologies due to slower speeds and material limitations.

Emerging Trends Across Marking Technologies

Cross-cutting trends will influence all marking types by 2026. These include:

- Digital Integration: Marking systems will increasingly interface with MES (Manufacturing Execution Systems) and IoT platforms for real-time monitoring, quality control, and data traceability.

- Sustainability Focus: Reduced consumables, energy-efficient operation, and recyclable marking materials will become key selection criteria.

- Anti-Counterfeiting Features: Demand for covert and secure marking—such as microtext, invisible inks, and encrypted codes—will rise, particularly in luxury goods and pharmaceuticals.

- Customization and Personalization: Consumer demand for personalized products will drive flexible marking solutions capable of handling variable data at scale.

In conclusion, the 2026 marking market will be characterized by technological convergence, increased automation, and a strong emphasis on sustainability and traceability. While laser marking is poised to lead, each marking type will adapt to evolving industrial needs, ensuring a diversified and dynamic market landscape.

Common Pitfalls Sourcing Type of Marking (Quality, IP)

When sourcing components or products that require specific types of marking—such as quality certifications or Intellectual Property (IP) protection—organizations often encounter several recurring challenges. Overlooking these pitfalls can lead to compliance issues, reputational damage, or legal liabilities. Below are key mistakes to avoid:

1. Confusing Marking Types and Their Legal Implications

A frequent error is treating quality marks (e.g., ISO 9001, CE, UL) and IP marks (e.g., ™, ®, ©) as interchangeable or assuming they serve the same purpose. Quality marks indicate compliance with industry or safety standards, while IP marks signal ownership of intellectual property. Misunderstanding these distinctions can result in incorrect labeling, regulatory non-compliance, or infringement claims.

2. Relying on Unverified Supplier Claims

Suppliers may assert that their products carry certain certifications or IP protections without providing verifiable documentation. Sourcing based on unsupported claims exposes buyers to counterfeit goods, substandard quality, or unintentional IP violations. Always request up-to-date certificates, registration numbers, and independent verification.

3. Inadequate Due Diligence on IP Ownership

When sourcing products with branded elements or proprietary designs, failing to confirm the supplier’s legal right to use trademarks, patents, or copyrights is a major risk. Using unauthorized IP—even unknowingly—can lead to lawsuits, product seizures, and financial penalties. Conduct thorough IP audits and require proof of licensing or ownership.

4. Overlooking Regional Marking Requirements

Marking standards vary significantly by market. For example, CE marking is mandatory in the EU, while FCC certification is required in the U.S. Assuming that a product marked for one region is acceptable in another can result in shipment rejections or legal action. Ensure compliance with local regulations in each target market.

5. Neglecting Marking Durability and Legibility

Even if the correct marks are applied, poor implementation—such as using non-permanent inks or placing marks in hard-to-read locations—can invalidate compliance. Regulatory bodies often require that markings remain legible throughout the product’s lifecycle. Specify marking methods (e.g., laser etching, embossing) and placement during procurement.

6. Assuming Certification Equals Guaranteed Quality

Having a quality mark does not automatically mean the product meets your specific requirements. Certifications confirm adherence to baseline standards, but performance, materials, and build quality may still vary. Conduct independent testing and audits to validate product suitability.

7. Delaying Marking Integration in the Sourcing Process

Treating marking as an afterthought—rather than integrating it into initial sourcing criteria—can lead to last-minute compliance failures. Include marking requirements in RFQs and supplier contracts from the outset to ensure alignment and avoid costly redesigns or delays.

By recognizing and addressing these common pitfalls, organizations can source products with accurate, compliant, and legally sound quality and IP markings, minimizing risk and enhancing supply chain integrity.

Logistics & Compliance Guide for Type of Marking

When managing the transportation, storage, and handling of goods, proper marking is essential for ensuring regulatory compliance, operational efficiency, and supply chain transparency. The “Type of Marking” refers to specific labels, symbols, codes, or inscriptions applied to packaging, containers, or transport units to communicate critical information. This guide outlines key considerations for logistics and compliance related to different types of marking.

Understanding Types of Marking

Markings are categorized based on their purpose and regulatory requirements. Common types include:

- Shipping Marks: Identifiers such as consignee name, destination, purchase order number, or reference codes.

- Handling Marks: Pictorial symbols (e.g., “This Side Up,” “Fragile”) indicating how goods should be handled.

- Hazardous Material Marks: Required for dangerous goods under regulations like IMDG (maritime), IATA (air), or ADR (road); includes UN numbers, hazard class labels, and warning symbols.

- Regulatory & Compliance Marks: Certifications such as CE, FCC, RoHS, or country-specific import/export labels.

- Barcodes & RFID Tags: Used for tracking and inventory management (e.g., UPC, EAN, SSCC).

- Country of Origin Marks: Legally required in many jurisdictions to inform consumers and customs authorities.

Regulatory Compliance Requirements

Compliance with international, national, and industry-specific regulations is mandatory. Key frameworks include:

- IMO & IMDG Code: For maritime transport of dangerous goods—markings must include proper shipping name, UN number, hazard class, and marine pollutant labels.

- IATA Dangerous Goods Regulations (DGR): Governs air freight; requires precise labeling of hazardous materials.

- OSHA & GHS: In the U.S., chemical containers must bear GHS-compliant labels with pictograms, signal words, and hazard statements.

- Customs Regulations: Marks indicating country of origin, tariff classification, and manufacturer details may be required for import clearance.

Failure to apply correct markings can result in shipment delays, fines, safety risks, or refusal of entry at borders.

Logistics Best Practices

To ensure smooth logistics operations:

-

Standardize Marking Procedures

Establish company-wide protocols for applying markings based on product type, destination, and mode of transport. -

Use Durable, Legible Materials

Ensure markings remain visible and intact under various conditions (e.g., moisture, temperature, handling). -

Position Markings Correctly

Place labels on two opposing sides of packages or as specified by regulations (e.g., hazard labels on hazardous material containers). -

Train Staff and Partners

Educate warehouse, logistics, and procurement teams on marking requirements and compliance standards. -

Conduct Regular Audits

Inspect packaging and shipments to verify marking accuracy and compliance before dispatch. -

Leverage Automation

Integrate barcode/RFID systems with warehouse management systems (WMS) and transportation management systems (TMS) for real-time tracking and compliance reporting.

Special Considerations

- Cross-Border Shipments: Ensure markings meet destination country requirements (e.g., bilingual labels, local certification marks).

- Temperature-Sensitive Goods: Use time-temperature indicators or cold chain monitoring labels where applicable.

- Sustainability & Reusability: For returnable packaging, use erasable or reprogrammable markings (e.g., RFID tags).

Conclusion

Proper “Type of Marking” is a cornerstone of compliant and efficient logistics operations. By aligning marking practices with regulatory standards and operational needs, organizations can reduce risks, enhance traceability, and ensure timely delivery across global supply chains. Regular review and adaptation to evolving regulations are essential for maintaining compliance and competitiveness.

Conclusion on the Sourcing Type of Marking:

The choice of marking method in sourcing depends heavily on the application, material type, durability requirements, regulatory compliance, and cost considerations. Common marking techniques such as laser marking, inkjet printing, dot peck marking, and embossing each offer distinct advantages and limitations. Laser marking provides high precision, permanence, and compatibility with a wide range of materials, making it ideal for industries requiring traceability and longevity, such as automotive and medical devices. Inkjet printing offers flexibility and speed, suitable for high-volume production and variable data marking, though it may lack durability in harsh environments. Dot peck marking is robust and cost-effective for metal parts, particularly in industrial settings, while embossing creates tactile, permanent marks ideal for branding or regulatory labels.

Ultimately, the sourcing decision should align with the product’s lifecycle, environmental exposure, and traceability needs. Evaluating total cost of ownership, maintenance requirements, and integration with existing production systems is crucial. As sustainability and digital traceability become increasingly important, investing in durable, eco-friendly, and digitally compatible marking solutions will enhance supply chain transparency and product quality. Therefore, a strategic approach to sourcing marking technology ensures not only operational efficiency but also long-term compliance and competitiveness in the market.