The global cabinet hinges market is experiencing steady expansion, driven by rising demand in residential, commercial, and modular furniture sectors. According to Grand View Research, the global kitchen cabinets market size was valued at USD 188.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth directly influences the demand for high-quality cabinet hinges, as advancements in kitchen design and the shift toward space-efficient, soft-close, and concealed hardware drive product innovation. Mordor Intelligence further projects the cabinet hardware market to grow at a CAGR of over 5.2% during the forecast period of 2023–2028, citing increased urbanization and renovation activities as key drivers. With evolving consumer preferences for durability, aesthetics, and silent operation, manufacturers are focusing on engineering precision, material quality, and ease of installation. In this competitive landscape, nine distinct types of hinge manufacturers—ranging from heavy-duty commercial suppliers to specialized European-style producers—have emerged as leaders, shaping the future of functional and stylish cabinetry.

Top 9 Type Of Cabinet Hinges Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hinge Outlet

Domain Est. 2004

Website: hingeoutlet.com

Key Highlights: Hinge Outlet, Inc. offers a wide range of spring hinges, residential door hinges, ball bearing hinges, and more. Find out more about our products today….

#2 Cabinet Hinge Suppliers

Domain Est. 2015

Website: hingemanufacturers.org

Key Highlights: Save time by selecting from a list of leading cabinet Hinge manufacturers, each of whom is offering top quality standard products, with no minimum order ……

#3 Cabinet Door Hinges

Domain Est. 2021

Website: keahardware.com

Key Highlights: KEAX is a professional furniture hardware manufacturer. We provide cabinet door hinges, drawer slides, gas springs, etc….

#4 Hinges for furniture & offices

Domain Est. 1996

Website: hettich.com

Key Highlights: Hettich hinges offer practical solutions for every application. Find out more about: ✓ Fast-assembly hinges ✓ Damping ✓ Opening systems….

#5 Hinges

Domain Est. 1997

Website: salice.com

Key Highlights: Innovation and continuous technical development: Salice hinges. An infinite range to suit every application….

#6 Motion in cabinetry

Domain Est. 1998

Website: blum.com

Key Highlights: They’re three-dimensional. All Blum hinges come with side, depth and height adjustment, giving you a perfectly precise gap layout every time….

#7 Adjustable Cabinet Hinges

Domain Est. 2000

Website: hardwareresources.com

Key Highlights: Hardware Resources offers a vast selection of cabinet hardware including: cabinet hardware hinges, soft close cabinet hinges, ……

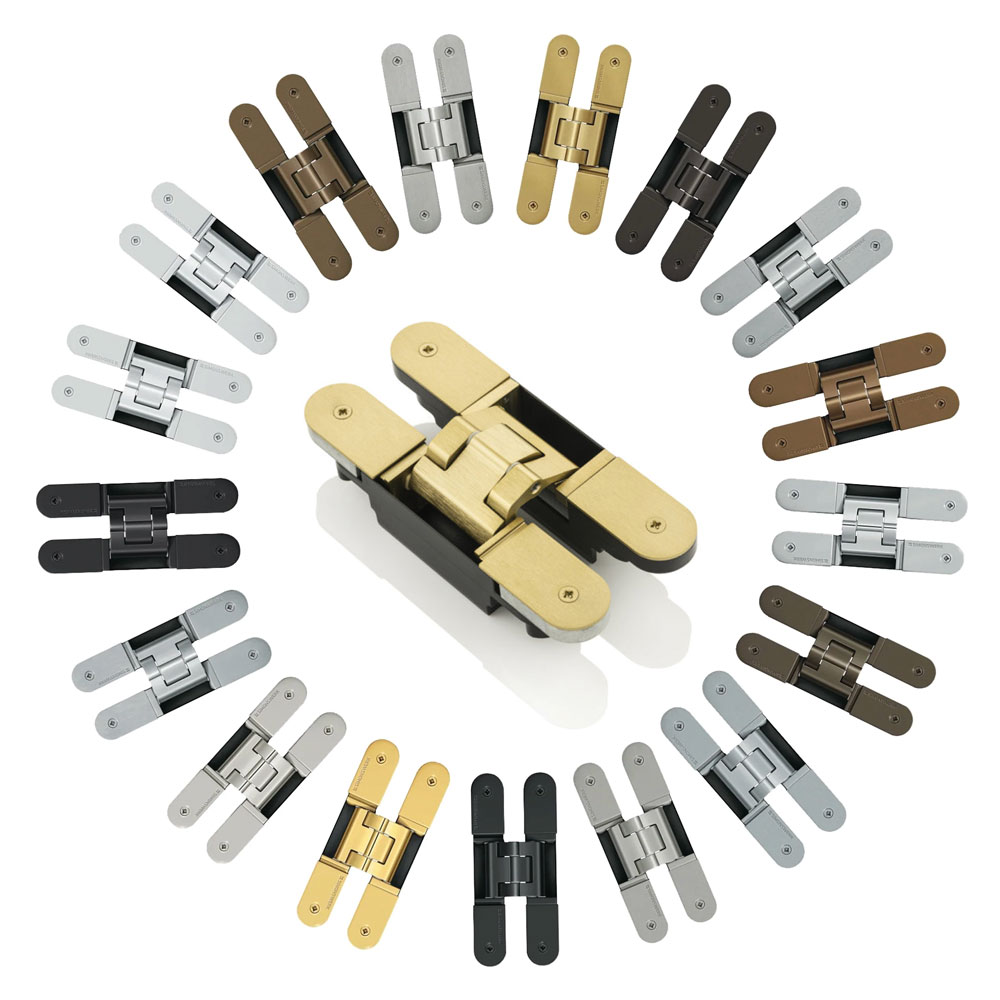

#8 Tectus Hinges

Domain Est. 2009

Website: tectushinges.com

Key Highlights: TECTUS is the most comprehensive concealed hinge system for premium flush doors. Easily adjustable in 3-Dimensions….

#9 soft close hinge cabinet door hinge kav furniture hardware,furniture …

Domain Est. 2010

Website: kavhinge.com

Key Highlights: Soft Close Hinges Non Soft Close Hinges 3D Adjustable Hinges Stainless Steel Hinges Special Hinges Heavy Duty Hinges Face Frame Hinges. Cabinet Hinges….

Expert Sourcing Insights for Type Of Cabinet Hinges

H2: 2026 Market Trends for Types of Cabinet Hinges

The global cabinet hinges market is poised for significant transformation by 2026, driven by evolving consumer preferences, advancements in materials and technology, and a growing emphasis on sustainable and smart home solutions. Below is an analysis of key trends shaping the demand and development of various types of cabinet hinges in the coming years.

-

Rise of Concealed (Euro-Style) Hinges

Concealed hinges, particularly the cup or Euro-style hinge, are expected to dominate the market by 2026 due to their sleek, minimalist appearance and compatibility with frameless cabinet designs, which are increasingly popular in modern kitchens. These hinges offer soft-close functionality, adjustability in three dimensions, and durability—features that align with high-end residential and commercial interior trends. The European design influence continues to expand globally, further boosting demand. -

Increased Demand for Soft-Close and Self-Closing Hinges

Consumers are prioritizing noise reduction, safety, and convenience, leading to a surge in demand for soft-close and self-closing hinges. These mechanisms prevent slamming, extend cabinet lifespan, and improve user experience. By 2026, soft-close technology is projected to become a standard feature even in mid-range cabinetry, supported by declining production costs and improved manufacturing efficiency. -

Growth in Smart Hinges for Smart Cabinets

Integration with smart home ecosystems is emerging as a niche but rapidly growing segment. Smart hinges equipped with sensors can detect cabinet usage, monitor inventory (e.g., in pantries), or trigger lighting systems. While currently limited to luxury homes and high-tech kitchens, advancements in IoT and declining sensor costs are expected to broaden adoption by 2026. -

Sustainability and Eco-Friendly Materials

Environmental concerns are influencing material choices across the hardware sector. By 2026, hinge manufacturers are likely to shift toward recyclable metals (e.g., aluminum, zinc alloys), water-based coatings, and reduced packaging waste. Certifications such as Cradle to Cradle or EPDs (Environmental Product Declarations) may become key differentiators in the market. -

Customization and Adjustable Hinges

Personalization remains a strong trend in home design. Adjustable hinges that allow precise alignment and easy installation are gaining favor among DIY consumers and professional installers alike. Modular hinge systems that support various door weights and thicknesses will see increased innovation to meet diverse design needs. -

Growth in Emerging Markets

Rising urbanization and disposable incomes in Asia-Pacific, Latin America, and parts of Africa are fueling demand for modern cabinetry. While traditional butt and pivot hinges still hold market share in these regions, there is a clear shift toward European-style concealed hinges as consumers adopt global design standards. -

Impact of E-Commerce and Direct-to-Consumer Models

Online retail platforms are making a wider variety of hinges accessible to end users. By 2026, digital marketplaces will play a crucial role in educating consumers about hinge types, compatibility, and installation—leading to more informed purchasing decisions and increased demand for user-friendly designs.

In conclusion, the 2026 cabinet hinge market will be shaped by innovation in functionality, aesthetics, and sustainability. Concealed and soft-close hinges will lead in volume and value, while smart and eco-conscious solutions will define the future frontier of growth. Manufacturers and suppliers who adapt to these trends will be best positioned to capture market share in an increasingly competitive landscape.

Common Pitfalls Sourcing Type of Cabinet Hinges (Quality, IP)

When sourcing cabinet hinges—especially those requiring specific performance characteristics like durability, finish quality, or Ingress Protection (IP) ratings—buyers often encounter several recurring issues. Understanding these pitfalls can help ensure you select the right hinge for your application while avoiding unnecessary costs, delays, or product failures.

Selecting Hinges Without Verifying Material Quality

One of the most common mistakes is assuming all hinges made from similar-looking materials perform the same. For example, stainless steel hinges may be labeled generically, but they can vary significantly in grade (e.g., 304 vs. 201), affecting corrosion resistance and longevity. Low-quality materials may lead to premature wear, rusting, or structural failure, especially in humid or high-use environments.

Overlooking Load Capacity and Duty Rating

Many purchasers focus on aesthetics or price without considering the hinge’s load-bearing capacity. Cabinet doors, especially large or heavy ones, require hinges rated for the appropriate weight. Using undersized hinges can lead to sagging doors, misalignment, and eventual failure.

Ignoring Ingress Protection (IP) Ratings for Environment Suitability

When sourcing hinges for use in wet, dusty, or outdoor environments, IP ratings are critical. However, many suppliers either omit this information or provide misleading claims. For example, a hinge advertised as “water-resistant” may not have a certified IP65 or IP67 rating. Always verify IP certifications through test reports or third-party documentation to ensure suitability.

Relying on Inconsistent or Unverified Supplier Claims

Especially when sourcing from online marketplaces or low-cost manufacturers, hinge specifications may be exaggerated or inaccurate. Terms like “heavy-duty,” “industrial-grade,” or “rust-proof” are often used without standardized definitions. Always request technical data sheets, material certifications, and—if possible—samples for testing before placing bulk orders.

Failing to Consider Finish and Corrosion Resistance

The finish of a hinge affects both appearance and performance. Electroplated finishes may wear off quickly in high-moisture areas, leading to corrosion. Powder-coated or passivated stainless steel finishes offer better longevity but may come at a higher cost. Not assessing the finish in the context of the intended environment can result in premature degradation.

Neglecting Compatibility with Cabinet Design and Installation

Some hinges are designed for specific cabinetry types (e.g., frameless vs. face-frame cabinets) or mounting methods (e.g., overlay, inset, full-wrap). Selecting the wrong hinge type can lead to improper fit, difficult installation, or compromised door function. Always confirm dimensional specifications and mounting requirements before sourcing.

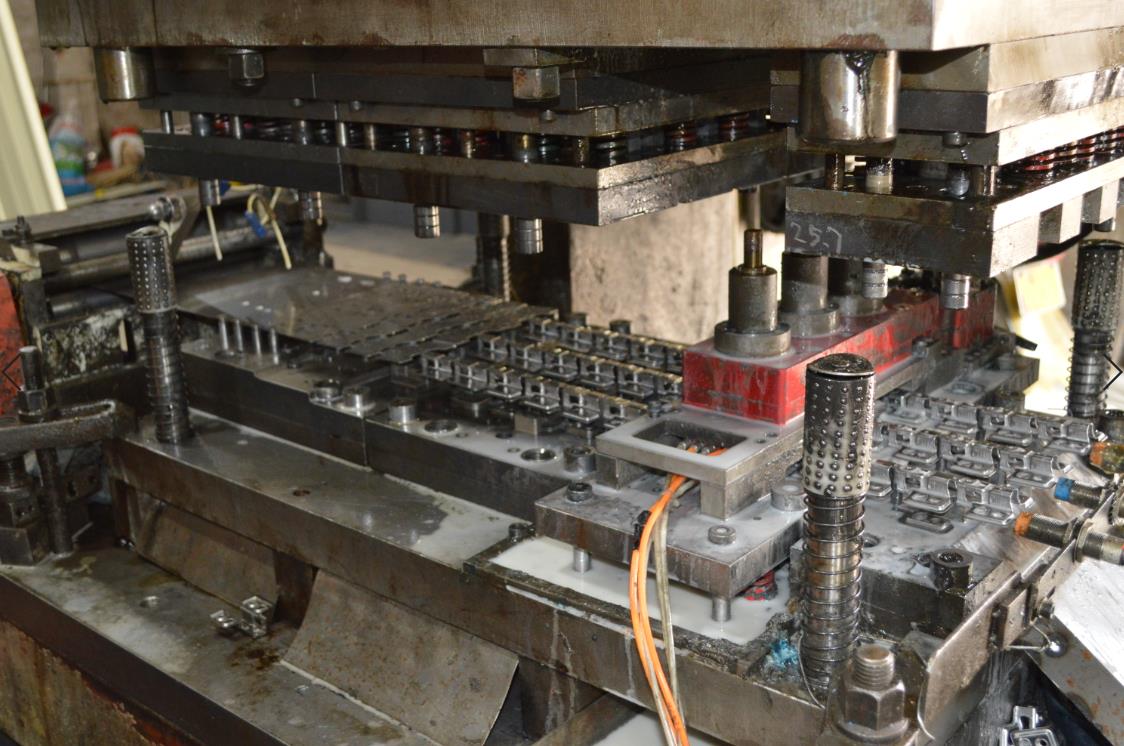

Skipping Sample Testing and Quality Audits

To save time or cost, buyers may skip evaluating physical samples or conducting factory audits. This increases the risk of receiving substandard products. Testing samples under real-world conditions—such as repeated opening cycles or exposure to humidity—can reveal durability issues early.

Assuming All “Stainless Steel” Hinges Are Non-Magnetic or Corrosion-Proof

Not all stainless steel hinges are created equal. Some lower grades contain magnetic properties and offer limited corrosion resistance. Buyers unfamiliar with metallurgy may be misled by visual appearance alone. Always verify the steel grade and request material test reports (MTRs) when corrosion resistance is critical.

Disregarding Long-Term Availability and Supplier Reliability

Even if a hinge meets all technical requirements initially, sourcing challenges can arise if the supplier discontinues the product or lacks consistent production capacity. Ensure your supplier can guarantee long-term availability and has a track record of reliable delivery.

By recognizing and addressing these common pitfalls, buyers can make more informed decisions when sourcing cabinet hinges—balancing quality, environmental resilience, and cost-effectiveness.

Logistics & Compliance Guide for Types of Cabinet Hinges

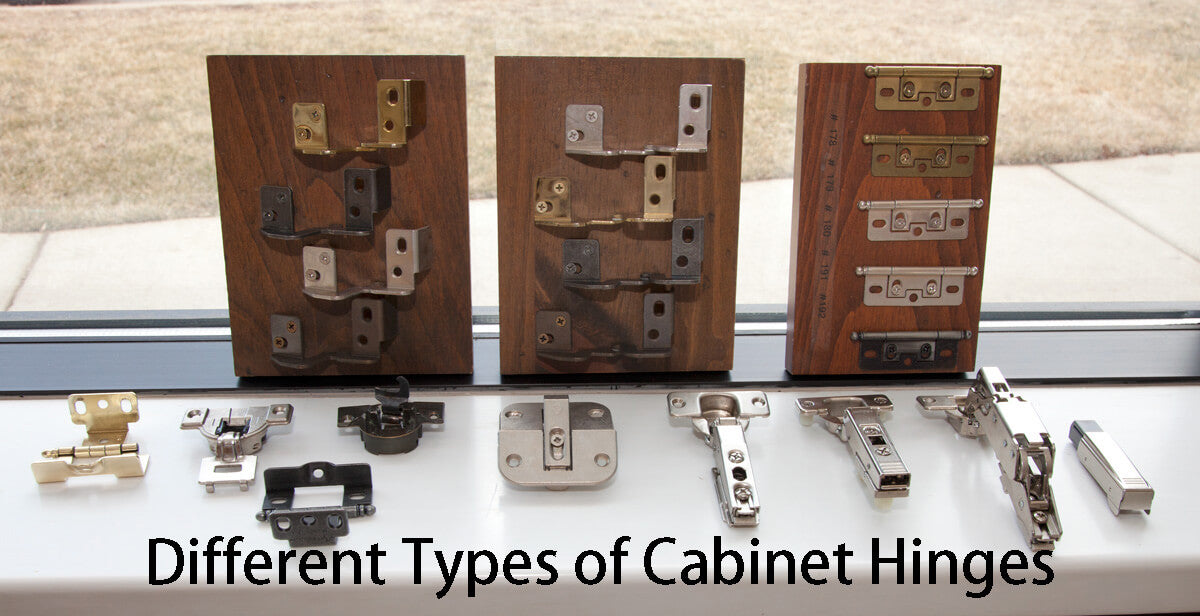

Overview of Common Cabinet Hinge Types

Understanding the various types of cabinet hinges is essential for proper logistics planning and regulatory compliance. The most common types include overlay hinges, inset hinges, full overlay hinges, concealed (cup) hinges, and pivot hinges. Each type has distinct dimensions, materials, and installation requirements, which influence packaging, shipping, and customs classification. Manufacturers and distributors must accurately classify these products to ensure smooth international and domestic transport.

Packaging and Handling Requirements

Proper packaging is critical to prevent damage during transit. Cabinet hinges, especially those with delicate finishes (e.g., brushed nickel, chrome, or painted coatings), should be individually wrapped or compartmentalized in blister packs or partitioned boxes. Bulk shipments should use sturdy corrugated cartons with adequate cushioning. Labels must clearly indicate contents, weight, handling instructions (e.g., “Fragile,” “This Side Up”), and SKU numbers. For international shipments, packaging must comply with ISPM-15 standards if wood materials are used in pallets or crates.

Shipping and Transportation Considerations

Cabinet hinges are typically lightweight and compact, making them suitable for standard parcel and freight shipping. However, large-volume orders may require palletized LTL (Less Than Truckload) or FTL (Full Truckload) transport. Temperature and humidity control may be necessary for hinges with corrosion-prone finishes. Air freight should be reserved for urgent deliveries due to cost. Ensure proper documentation (e.g., bill of lading, packing list) is included for all shipments to avoid delays.

Regulatory Compliance and Product Standards

Cabinet hinges must comply with regional and international safety and quality standards. In the European Union, hinges may fall under the Construction Products Regulation (CPR) if part of a certified cabinet system. In the U.S., compliance with ANSI/BHMA standards (e.g., A156.5 for cabinet hinges) ensures durability and performance. Products containing certain metals (e.g., lead, cadmium) must meet RoHS (Restriction of Hazardous Substances) and REACH regulations in the EU. Accurate material declarations and testing certifications should be maintained.

Customs Classification and Tariff Codes

Correct HS (Harmonized System) code classification is vital for customs clearance. Cabinet hinges are generally classified under HS Code 8302.41 (butts and hinges, of base metal) or 8302.42 (fittings for doors, of base metal), depending on composition and design. Country-specific tariff rates and import duties vary—verify local customs requirements. Provide detailed product descriptions, including material (e.g., zinc alloy, stainless steel), finish, and intended use, to avoid misclassification and delays.

Environmental and Sustainability Compliance

Manufacturers and distributors must adhere to environmental regulations regarding production waste, emissions, and recyclability. Many hinges are made from recyclable metals, and companies should promote end-of-life recycling programs. Compliance with directives like WEEE (Waste Electrical and Electronic Equipment) may apply if hinges are part of larger electronic cabinetry systems. Sustainable sourcing of raw materials and reduction of packaging waste also support compliance with green building standards (e.g., LEED).

Documentation and Traceability

Maintain comprehensive records for each shipment, including certificates of conformity, material safety data sheets (MSDS), and test reports. Traceability systems (e.g., batch numbering) help manage recalls and quality control. Digital logistics platforms can streamline compliance by automatically generating required documentation and tracking regulatory updates across markets.

Final Recommendations

To ensure efficient logistics and full compliance, stakeholders should:

– Partner with certified suppliers who provide compliance documentation.

– Train logistics teams on product-specific handling and regulatory requirements.

– Conduct regular audits of packaging, labeling, and customs processes.

– Stay updated on changes in international trade regulations affecting hardware components.

Following this guide helps minimize risks, reduce delays, and ensure cabinet hinges reach customers in optimal condition, fully compliant with global standards.

In conclusion, selecting the appropriate sourcing type for cabinet hinges—whether local suppliers, international manufacturers, or direct-from-factory procurement—depends on several key factors including cost, quality requirements, lead times, volume needs, and long-term supply chain reliability. Local sourcing offers advantages in terms of faster delivery, easier communication, and reduced logistics complexity, making it ideal for small to medium operations or time-sensitive projects. On the other hand, international or offshore sourcing, particularly from large manufacturers in regions like Asia, often provides significant cost savings and scalability for high-volume buyers, though it may involve longer lead times and potential quality control challenges.

For optimal results, a hybrid sourcing strategy—leveraging local suppliers for urgent or custom needs and international partners for bulk, standardized hinges—can provide both flexibility and cost-efficiency. Additionally, building strong relationships with reliable suppliers, conducting regular quality audits, and staying informed about market trends will ensure consistent performance and long-term value. Ultimately, the best sourcing approach aligns with the specific operational, financial, and strategic goals of the cabinetry business or project.