The global market for power sockets, including Type E variants predominantly used across France, Belgium, and several Eastern European countries, is experiencing steady growth, driven by rising demand in residential, commercial, and industrial infrastructure. According to Grand View Research, the global electrical sockets and switches market was valued at USD 33.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.1% from 2023 to 2030. This growth is fueled by increasing urbanization, smart building initiatives, and the modernization of electrical infrastructure in both developed and emerging economies. As safety and standardization remain paramount—especially with Type E’s unique grounding pin design—manufacturers are investing heavily in compliance, durability, and innovation. In this evolving landscape, a select group of manufacturers have emerged as leaders in producing reliable, high-quality Type E sockets. Here’s a data-driven look at the top 9 Type E power socket manufacturers shaping the market today.

Top 9 Type E Power Socket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CUI Inc.

Domain Est. 1996

Website: belfuse.com

Key Highlights: The range of CUI products includes AC-DC power supplies and DC-DC converters, featuring desktop adapters, wall plug adapters, custom adapters, board mount, and ……

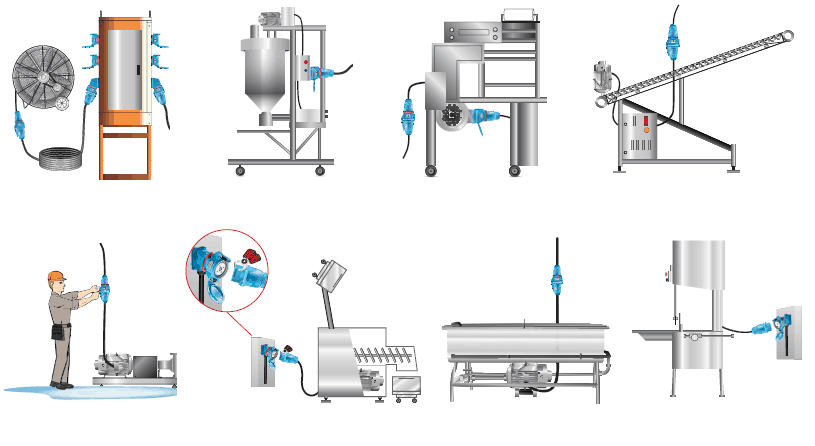

#2 MARECHAL ELECTRIC

Domain Est. 2003

Website: marechal.com

Key Highlights: World specialist in single-pole and multi-contact electrical outlets. High-performance sockets for industrial and ATEX environments….

#3 United Kingdom & Ireland Plugs and Sockets

Domain Est. 1996 | Founded: 1962

Website: interpower.com

Key Highlights: Interpower is the premier supplier of power system components worldwide. … The official plug standard in the United Kingdom since 1962 is the BS 1363 plug….

#4 Plugs and sockets

Domain Est. 2007

Website: r-stahl.com

Key Highlights: Innovative and versatile plugs and sockets from R. STAHL for hazardous areas: User friendly, safe without making compromises and suitable for worldwide use….

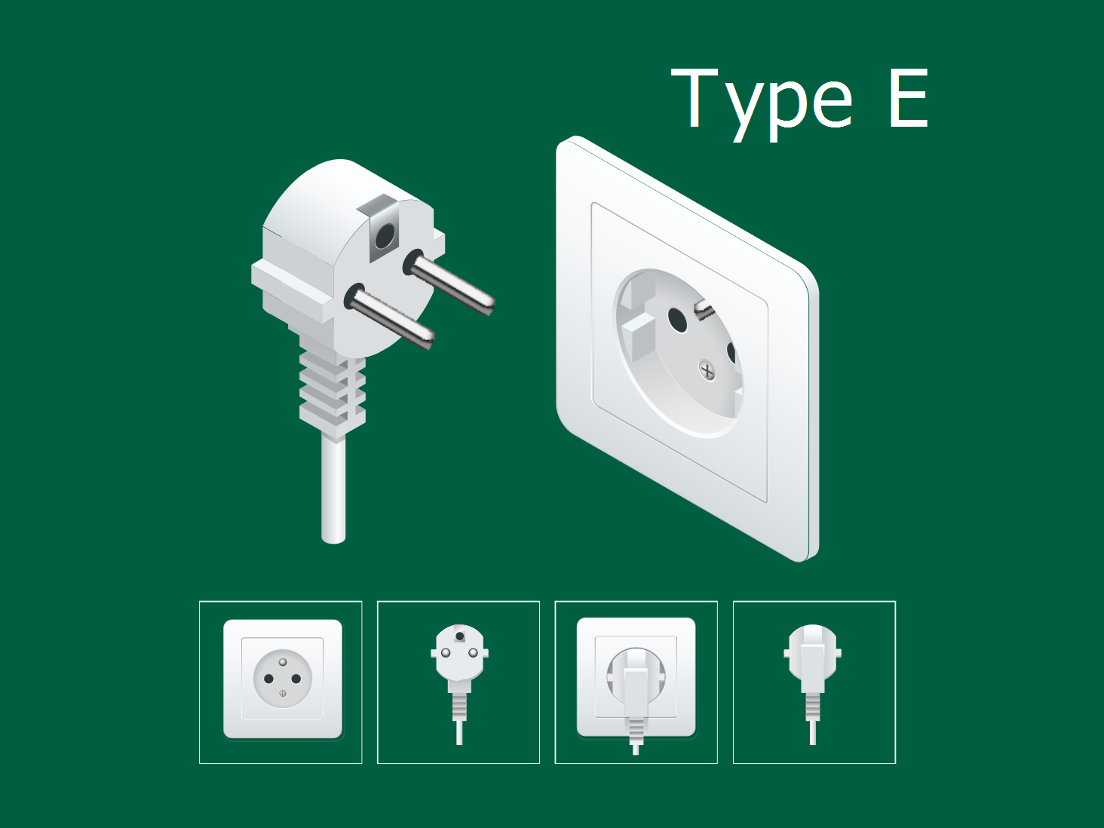

#5 Type E (FR electrical socket/electrical plug)

Domain Est. 2012

Website: netio-products.com

Key Highlights: The Type E plug is used for currents up to 16 A. Smart power sockets NETIO are available in DE/FR variants….

#6 BSEED Heritage Series EU Wall Sockets With Cover Waterproof …

Domain Est. 2012

Website: bseed.com

Key Highlights: 30-day returnsE-type plug: Suitable for FR standard sockets, mainly used in France, Bulgaria, Finland, Hungary, Iceland, Turkey and other regions. G-type plug: Suitable for ……

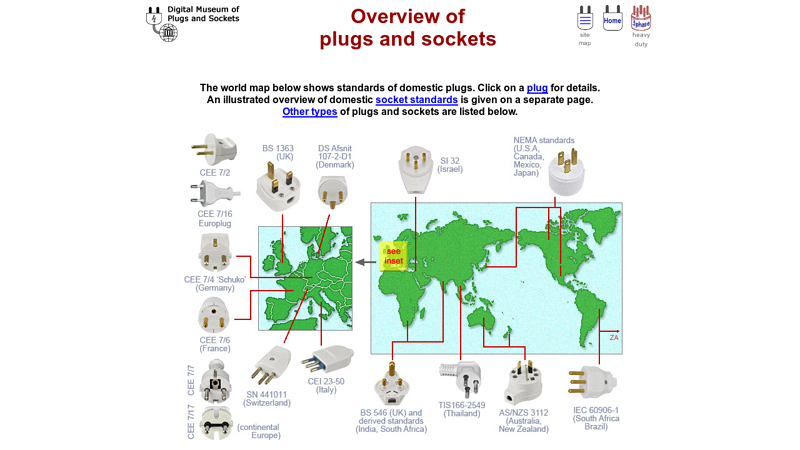

#7 Overview

Domain Est. 2015

Website: plugsocketmuseum.nl

Key Highlights: World map with links to photos and detailed descriptions of various types of domestic plugs and sockets….

#8 World plugs

Website: iec.ch

Key Highlights: The Type E electrical plug has two 4.8 mm round pins spaced 19 mm apart and a hole for the socket’s male earthing pin. The Type E plug has a rounded shape and ……

#9 Power plug & outlet Type E

Website: worldstandards.eu

Key Highlights: Type E is primarily used in France, Belgium, Poland, Slovakia, the Czech Republic, Tunisia and Morocco….

Expert Sourcing Insights for Type E Power Socket

H2: Projected 2026 Market Trends for Type E Power Sockets

While Type E power sockets (characterized by their two round pins and a central earth pin, primarily used in France, Belgium, Poland, Slovakia, and parts of the Middle East and North Africa) are a mature and standardized technology, several key trends are expected to shape their market landscape by 2026:

-

Steady Replacement & Renovation-Driven Demand:

- Core Driver: The primary market driver will remain the replacement of aging infrastructure and new residential/commercial construction within Type E countries. As buildings are renovated or new ones constructed, Type E sockets are installed as the national standard.

- 2026 Outlook: Demand will be stable but closely tied to regional construction and renovation rates. Economic fluctuations in key markets (e.g., France, Poland) will directly impact volume. Expect consistent, predictable replacement cycles in existing stock.

-

Enhanced Safety and Smart Features Integration:

- Core Driver: Increasing consumer and regulatory focus on electrical safety, energy efficiency, and smart home integration.

- 2026 Outlook: The market will see a significant shift towards sockets with advanced features:

- Built-in Safety: Shuttered sockets (mandatory in newer EU standards like Schuko, influencing Type E design), overload protection, surge protection, and child-safety mechanisms will become standard or highly preferred.

- Smart Integration: Sockets with integrated USB-C/USB-A charging ports (fast-charging capable) will dominate the premium segment. “Smart” Type E sockets with Wi-Fi/Bluetooth connectivity for remote control, energy monitoring, and integration into home automation systems (e.g., via Google Home, Apple HomeKit, Amazon Alexa) will gain substantial traction, moving beyond niche products.

-

Material and Aesthetic Evolution:

- Core Driver: Demand for durability, sustainability, and design flexibility in modern interiors.

- 2026 Outlook:

- Materials: Increased use of high-quality, durable thermoplastics, fire-retardant materials, and potentially recycled content. Focus on longevity and reduced environmental impact during manufacturing.

- Design: Wider availability of premium finishes (matte, metallic, colored faceplates) and modular designs allowing for customization (e.g., combining sockets, switches, USB, data ports in a single grid). Slimmer profiles and seamless integration into wall surfaces will be desirable.

-

Sustainability and Regulatory Pressure:

- Core Driver: EU Green Deal, Ecodesign directives, and the Ecodesign for Sustainable Products Regulation (ESPR).

- 2026 Outlook:

- Energy Efficiency: Regulations will increasingly target standby power consumption. Sockets, especially smart ones, will need to meet stricter energy efficiency standards.

- Circularity: Requirements for repairability (e.g., replaceable modules), recyclability of materials, and potentially product passports will influence design and manufacturing. This could favor modular socket systems.

- RoHS/REACH Compliance: Strict adherence to hazardous substance restrictions will remain paramount.

-

Competition from Universal and USB-C Focus:

- Core Driver: The rise of USB-C as a universal charging standard and consumer desire for fewer adapters.

- 2026 Outlook:

- USB-C Dominance: Dedicated USB-C charging sockets (potentially replacing some traditional AC outlets) may see growth in new builds, particularly in kitchens, bedrooms, and offices. However, the Type E AC socket itself will remain essential for high-power appliances.

- Travel Adapters: The demand for external Type E travel adapters will persist but may evolve towards multi-standard (e.g., EU/UK/US) and USB-C PD power delivery models, rather than impacting the fixed socket market directly.

-

Geopolitical and Supply Chain Considerations:

- Core Driver: Ongoing global supply chain dynamics, energy costs, and potential regional trade policies.

- 2026 Outlook: Manufacturing may see continued pressure to optimize costs, potentially influencing sourcing of components. Resilience in supply chains will remain a focus for major manufacturers. Regional conflicts could potentially impact demand in bordering areas.

Conclusion for 2026:

The Type E socket market in 2026 will be characterized by stable core demand driven by renovation and construction, overlaid by a strong shift towards value-added features. The key differentiators will be safety, smart functionality (especially USB-C integration and home automation), premium design, and adherence to evolving sustainability regulations. While the fundamental AC socket standard won’t change, the products on the market will be significantly more sophisticated, connected, and environmentally conscious than today. Competition will focus on innovation within the Type E framework rather than replacing the standard itself in its core markets.

Common Pitfalls When Sourcing Type E Power Sockets (Quality and IP Rating)

When sourcing Type E power sockets—commonly used in France, Belgium, and several other European countries—buyers often encounter challenges related to product quality and Ingress Protection (IP) ratings. Overlooking these aspects can lead to safety hazards, non-compliance, and costly replacements. Below are key pitfalls to avoid:

Poor Build Quality and Material Selection

Many low-cost Type E sockets use substandard materials such as brittle thermoplastics or undersized metal contacts. This compromises durability and increases the risk of overheating, arcing, or mechanical failure. Inferior spring mechanisms in the socket can result in loose plug connections, leading to intermittent power and potential fire hazards. Always verify compliance with relevant standards (e.g., NF C 61-314 in France) and request material certifications.

Misrepresentation of IP Ratings

Suppliers may advertise a specific IP rating (e.g., IP44 or IP66) without proper certification or testing. Type E sockets used in bathrooms, kitchens, or outdoor areas require adequate protection against dust and moisture. Beware of unverified claims—ensure third-party test reports from accredited labs support the stated IP rating. Counterfeit or self-declared ratings are common in low-cost supply chains.

Lack of Proper Earthing Contact Design

The Type E socket features a male earth pin that must align correctly with the plug’s female contact. Poorly designed or misaligned earth pins can result in unreliable grounding, increasing electric shock risks. Inspect the socket’s internal construction and verify compatibility with common plug types (e.g., CEE 7/5 and CEE 7/7).

Inadequate Strain Relief and Cable Glanding

Low-quality sockets often lack effective strain relief or IP-rated cable glands, which are essential for maintaining the enclosure’s integrity, especially in wet or industrial environments. Without proper sealing, moisture and dust can penetrate the wiring compartment, leading to short circuits or corrosion.

Non-Compliance with Local Regulations

Even if a socket meets basic electrical specs, it may not be certified for use in specific countries. For example, French installations require compliance with NF standards, and some regions mandate specific approvals. Always confirm local certification requirements and verify CE marking authenticity, including access to a valid EU Declaration of Conformity.

Supply Chain Transparency and Counterfeit Products

Sourcing from unknown suppliers, especially through online marketplaces, increases the risk of counterfeit or reconditioned products. Lack of traceability makes it difficult to verify quality or pursue recourse. Establish relationships with reputable manufacturers or authorized distributors and request batch testing data.

By addressing these pitfalls during the sourcing process—through rigorous vetting, testing, and compliance verification—buyers can ensure reliable, safe, and code-compliant Type E power socket installations.

Logistics & Compliance Guide for Type E Power Socket

Overview of Type E Power Socket

The Type E power socket, primarily used in France, Belgium, Poland, Slovakia, and some other European countries, features two round pins spaced 19 mm apart with a hole for the male earth pin. The socket includes a female earth contact in the form of a protruding metal contact, ensuring a secure grounding connection. Devices intended for use in these markets must comply with specific electrical safety and regulatory standards.

Regulatory Compliance Requirements

All Type E power sockets and associated electrical equipment must meet the European Union’s Low Voltage Directive (LVD) 2014/35/EU and the Electromagnetic Compatibility (EMC) Directive 2014/30/EU. Compliance with harmonized standards such as EN 50075 and EN 50065 is mandatory for socket outlets. Additionally, CE marking is required, indicating conformity with EU safety, health, and environmental protection standards. Manufacturers must also adhere to the RoHS (Restriction of Hazardous Substances) Directive 2011/65/EU and REACH regulations for material safety.

Certification and Testing Procedures

Products must undergo rigorous testing by accredited laboratories to verify electrical safety, insulation resistance, temperature rise, and mechanical durability. Third-party certification bodies may be required, especially for high-power or industrial-grade sockets. Test reports should be maintained as part of the technical file, supporting the EU Declaration of Conformity. Regular audits and production surveillance may be conducted to ensure ongoing compliance.

Packaging and Labeling Standards

Packaging for Type E sockets must include essential information such as voltage (230V), frequency (50Hz), current rating (e.g., 16A), CE marking, manufacturer details, and compliance symbols. Multilingual labeling is recommended for broader EU distribution. The packaging should also indicate compliance with relevant standards (e.g., “Conforms to EN 50075”) and include safety warnings in the local language(s) of the target market.

Import and Customs Documentation

When shipping Type E sockets into the EU, importers must provide a commercial invoice, packing list, bill of lading or airway bill, and the EU Declaration of Conformity. Customs authorities may request test reports or certificates from notified bodies. For non-EU manufacturers, an Authorized Representative within the EU may be required under the Market Surveillance Regulation (EU) 2019/1020 to facilitate compliance and communication with authorities.

Logistics and Distribution Considerations

Ensure temperature-controlled storage to prevent material degradation, especially in plastic components. Use anti-static and shock-resistant packaging to protect sensitive electrical parts during transit. Coordinate with distributors familiar with EU electrical product regulations to ensure proper handling and retail compliance. Maintain traceability through batch numbering and digital inventory systems to support recalls or audits if necessary.

Post-Market Surveillance and Reporting

Manufacturers and importers are responsible for monitoring product performance in the market. Any non-compliance or safety incidents must be reported to the relevant national authority via the Safety Gate (RAPEX) system. Regular reviews of customer feedback and field failures help ensure continued compliance and product improvement. Retain technical documentation for at least 10 years after the last product is placed on the market.

Conclusion for Sourcing Type E Power Sockets

In conclusion, sourcing Type E power sockets requires careful consideration of regulatory standards, compatibility, quality, and supplier reliability, particularly due to their specific design and safety requirements. Type E sockets, predominantly used in France, Belgium, and several other European countries, feature a female earth contact and are designed to accept 2-pin plugs with a male earth pin. Ensuring compliance with relevant certifications such as CE, NF, or other local standards is essential to guarantee safety and legal market access.

Sourcing options include direct procurement from manufacturers in regions with mature electrical manufacturing capabilities—such as the EU, China, or Southeast Asia—or through specialized electrical distributors and wholesalers. When evaluating suppliers, it is crucial to verify product quality, consistency, and adherence to regional standards. Additionally, factors such as cost-efficiency, lead times, and after-sales support should be balanced against quality and compliance requirements.

For projects requiring long-term reliability—especially in residential, commercial, or industrial installations—it is advisable to prioritize certified, high-quality components over cost savings. Ultimately, a well-informed sourcing strategy for Type E power sockets ensures safety, regulatory compliance, and the seamless integration of electrical systems in the target region.