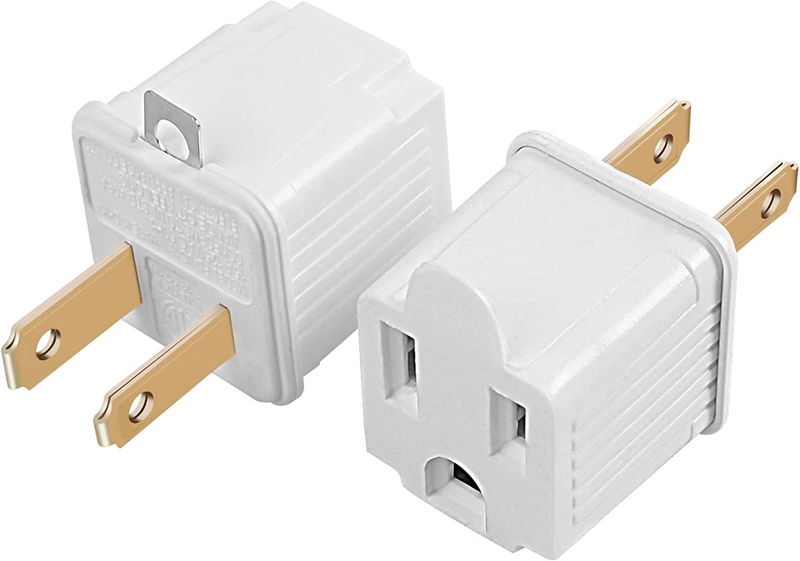

The global electrical plugs and sockets market is experiencing steady growth, driven by rising infrastructure development, expanding residential and commercial construction, and increasing demand for safe and reliable electrical connectivity solutions. According to Grand View Research, the global electrical plugs and sockets market size was valued at USD 17.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth trajectory underscores the importance of high-quality manufacturing in niche segments such as two prong electrical plugs, which remain widely used in portable electronics, household appliances, and low-voltage applications. As safety standards evolve and global electrification accelerates, manufacturers that combine innovation, regulatory compliance, and scalable production are gaining competitive advantage. In this landscape, identifying leading two prong plug producers becomes critical for OEMs, distributors, and procurement professionals aiming to source reliable components. Here, we present the top 10 two prong electrical plug manufacturers, evaluated based on production capacity, global reach, certifications, customer reviews, and market presence.

Top 10 Two Prong Electrical Plug Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Meltric

Domain Est. 1997

Website: meltric.com

Key Highlights: MELTRIC offers a full line of industrial plugs and receptacles, including our signature brand of UL-listed Switch-Rated devices with DECONTACTOR™ ……

#2 2 Pin Plugs and 3 Pin Plugs

Domain Est. 1993

Website: volex.com

Key Highlights: Volex 2-pin and 3-pin plug products are sold to manufacturers for a broad range of electrical and electronic device, equipment, and appliance applications….

#3 Marinco

Domain Est. 1996

Website: marinco.navico.com

Key Highlights: Marinco’s innovative power connections are engineered for safety, reliability and high performance in the toughest conditions – marine, RV and industrial….

#4 Leading Electrical Plug Manufacturers

Domain Est. 2001

Website: cordsets.org

Key Highlights: Save time and easily view the leading electrical plug manufacturers and suppliers in the USA who offer a wide selection of custom electrical plugs….

#5 Pass & Seymour Electrical Devices

Domain Est. 2004

Website: legrand.us

Key Highlights: Find innovation for commercial, residential and industrial electrical wiring. Explore Pass & Seymour switches, receptacles, GFCI outlets, USB chargers and ……

#6 China Two Prong Power Cord Suppliers, Manufacturers

Domain Est. 2021

Website: hongzhoucable.com

Key Highlights: We’re professional two prong power cord manufacturers and suppliers in China, specialized in providing high quality products….

#7 Types of Electrical Connectors and Wire Connectors

Domain Est. 1992

Website: te.com

Key Highlights: From USB connectors and RJ45 connectors to TE’s DEUTSCH connectors and AMP connectors, we design and manufacture the electrical connectors and wire connectors ……

#8 Products

Domain Est. 1999

Website: phino.com

Key Highlights: Hollands 2-Pin Wire Grounding, Angle Type AC Plug, 16A 250V. Plug P/No. PHP-206. Inquiry Cart. Hollands 2-Pin Wire Grounding, Straight AC Plug, 16A 250V.Missing: two prong…

#9 Smiths Interconnect Homepage

Domain Est. 2001

Website: smithsinterconnect.com

Key Highlights: It designs and manufactures technically differentiated electronic components, microwave, optical and radio frequency products and sub-systems that connect, ……

#10 World plugs

Website: iec.ch

Key Highlights: Select a location, electric potential or frequency to discover what plug type(s), voltage and frequency are used there….

Expert Sourcing Insights for Two Prong Electrical Plug

H2: Projected Market Trends for the Two-Prong Electrical Plug in 2026

By 2026, the market for two-prong electrical plugs is expected to experience moderate transformation driven by regional regulations, evolving safety standards, and shifts in consumer electronics design. While the two-prong plug remains prevalent in low-risk household devices, its market trajectory reflects both persistent demand and declining use in certain applications.

-

Continued Use in Low-Power Devices

Two-prong plugs will remain dominant in double-insulated, low-power consumer electronics such as phone chargers, lamps, and small kitchen appliances. Their simplicity, cost-effectiveness, and compatibility with ungrounded outlets ensure ongoing demand, particularly in mature markets like North America and parts of Asia. -

Regulatory and Safety Pressures

Strictening electrical safety regulations in regions like the European Union and parts of Southeast Asia may limit the expansion of two-prong plugs in higher-wattage appliances. Regulatory bodies are increasingly favoring grounded (three-prong) connections or requiring built-in safety features (e.g., insulated pins, child-safe outlets), indirectly pressuring manufacturers to reconsider two-prong designs. -

Impact of USB-C and Wireless Charging

The rise of USB-C power delivery and wireless charging technologies is reducing dependence on traditional AC plug designs. By 2026, more portable electronics will bypass two-prong adapters entirely, opting for universal DC power solutions. This shift may reduce long-term demand for two-prong plugs in consumer tech. -

Emerging Markets and Infrastructure Limitations

In developing economies, where electrical infrastructure often lacks grounding systems, two-prong plugs will continue to dominate. Urbanization and rising electrification rates in Africa, South Asia, and Latin America will sustain demand, especially for affordable appliances and lighting. -

Sustainability and Material Innovation

Environmental regulations will push manufacturers toward recyclable and flame-retardant materials in plug construction. Bioplastics and halogen-free components are expected to gain traction by 2026, aligning with broader ESG goals in the electronics supply chain. -

Smart Home Integration

While two-prong plugs themselves are not “smart,” they may increasingly serve as entry points for smart plugs and IoT devices. Retrofit smart outlets—often compatible with two-prong plugs—will drive a niche but growing segment focused on energy monitoring and remote control.

In summary, the two-prong electrical plug market in 2026 will be characterized by a dichotomy: steady demand in cost-sensitive and low-risk applications, countered by gradual displacement due to technological innovation and safety regulations. Manufacturers who adapt with safer designs, sustainable materials, and compatibility with smart ecosystems will maintain a competitive edge.

Common Pitfalls Sourcing a Two Prong Electrical Plug (Quality, IP Rating)

Sourcing two prong electrical plugs may seem straightforward, but overlooking key aspects like quality and Ingress Protection (IP) rating can lead to safety hazards, product failures, or non-compliance. Below are common pitfalls to avoid:

Overlooking Build Quality and Material Standards

Many low-cost suppliers offer two prong plugs made from substandard plastics or conductive materials that degrade quickly under heat or stress. Poor internal wiring connections, thin gauge conductors, or inadequate strain relief increase the risk of overheating, short circuits, or plug detachment. Always verify that plugs comply with recognized safety standards such as UL, CE, or IEC, and request material certifications to ensure durability and fire resistance.

Assuming IP Rating is Unnecessary for Simple Plugs

While two prong plugs are often used in dry indoor environments, assuming they don’t require any Ingress Protection (IP) rating can be a mistake—especially in environments with dust, moisture, or outdoor use. A plug without an appropriate IP rating (e.g., IP20 for basic finger protection or IP44 for splash resistance) may fail in humid conditions or industrial settings. Always match the plug’s IP rating to the intended operating environment to prevent corrosion, electrical leakage, or shock hazards.

Ignoring Compatibility with Cord Gauge and Appliance Load

Using a plug not rated for the current draw or wire gauge of the connected appliance leads to overheating and potential fire risks. A common pitfall is selecting a plug based solely on appearance or price without verifying its amperage and temperature ratings (e.g., 10A 125V). Always cross-reference the plug’s specifications with the appliance’s power requirements and the cord’s thickness (AWG) to ensure safe, long-term performance.

Falling for Counterfeit or Non-Certified Products

Markets, especially online platforms, are flooded with uncertified or counterfeit electrical components that mimic reputable brands. These plugs often lack proper testing and fail under stress. Always source from reputable suppliers, request compliance documentation, and look for authentic certification marks that are not easily forged.

Neglecting Regional Electrical and Regulatory Requirements

Two prong plugs vary by region (e.g., NEMA 1-15P in North America, Europlug in Europe), and using the wrong type can violate local regulations or create compatibility issues. Additionally, some countries require specific safety approvals even for simple plugs. Failing to verify regional standards can result in rejected shipments or legal liabilities.

Logistics & Compliance Guide for Two-Prong Electrical Plugs

This guide provides essential information on the logistics and regulatory compliance considerations for two-prong electrical plugs used in consumer electronics, appliances, and other low-voltage devices. Proper adherence ensures product safety, market access, and smooth international distribution.

Product Classification & Regulatory Overview

Two-prong electrical plugs, typically used in double-insulated devices without grounding requirements, are subject to various international standards and regulations based on region and application. These plugs are commonly found in Class II appliances and low-power electronics.

Key regulatory frameworks include:

– IEC 60884-1: International standard for plugs and socket-outlets for household and similar purposes.

– UL 498: Standard for attachment plugs and receptacles in the United States.

– CSA C22.2 No. 42: Canadian standard for plugs and receptacles.

– BS 1363 (UK) and AS/NZS 3112 (Australia/New Zealand): While these regions typically use three-pin systems, two-prong variants may be permitted for specific device types.

Manufacturers must ensure that plugs are rated for appropriate voltage (e.g., 125V or 250V) and current (e.g., 10A, 15A) based on intended use.

Electrical Safety & Certification Requirements

Electrical safety compliance is mandatory for market entry. Two-prong plugs must undergo testing and certification by accredited laboratories to verify they meet safety standards.

Critical safety requirements include:

– Dielectric strength and insulation resistance testing.

– Temperature rise under load.

– Mechanical strength (e.g., pin retention, cord anchorage).

– Flame resistance of housing materials (e.g., UL94 V-0 rating).

Certification marks such as UL Listed, CSA Certified, CE Marking (under LVD and RoHS), or UKCA must be applied based on the target market. For CE compliance, plugs must adhere to the Low Voltage Directive (2014/35/EU) and relevant harmonized standards.

Material & Environmental Compliance

Plugs must comply with environmental regulations governing hazardous substances:

– RoHS (EU): Restricts lead, mercury, cadmium, and other hazardous materials.

– REACH (EU): Requires disclosure of Substances of Very High Concern (SVHC).

– Proposition 65 (California, USA): Mandates warnings for chemicals known to cause cancer or reproductive harm.

– China RoHS: Similar restrictions on hazardous substances in electronic products.

Materials used (e.g., thermoplastics, copper alloys) should be recyclable and meet regional environmental standards. Flame-retardant, halogen-free materials are increasingly preferred.

Packaging, Labeling & Marking

Proper packaging and labeling are essential for compliance and consumer safety:

– Each plug must be permanently marked with:

– Manufacturer’s name or trademark.

– Model or type number.

– Voltage and current ratings (e.g., 125V~, 10A).

– Certification marks (e.g., UL, CSA, CE).

– Packaging must include:

– Safety warnings and usage instructions.

– Country of origin.

– Compliance statements (e.g., “Complies with UL 498”).

Labels must be durable, legible, and resistant to abrasion and environmental exposure.

Logistics & Distribution Considerations

Logistics planning must account for regional plug variations and import regulations:

– Regional Plug Types: Two-prong configurations vary by country (e.g., Type A in North America and Japan, Type C in Europe). Ensure product compatibility or include appropriate adapters.

– Import Documentation: Provide technical files, certificates of conformity, test reports, and product specifications to customs authorities.

– HS Codes: Use accurate Harmonized System codes (e.g., 8536.69 for electrical plugs and sockets) to determine tariffs and regulatory scrutiny.

– Warehousing & Handling: Store plugs in dry, temperature-controlled environments to prevent material degradation.

Market-Specific Compliance

Different markets have unique requirements:

– United States: UL certification is typically required; FCC compliance may apply if the plug is part of a device with radio frequency emissions.

– European Union: CE marking with compliance to LVD, RoHS, and REACH; notified body involvement may be required for certain product classes.

– Canada: CSA certification or recognized equivalency (e.g., cULus) is mandatory.

– Australia/NZ: SAA/RCM marking under AS/NZS 3112 standards.

– China: CCC certification may be required for certain plug-in products, even if the plug itself is not separately certified.

Always verify local regulations before market entry.

Quality Assurance & Conformity Maintenance

Ongoing compliance requires:

– Regular factory audits and production line inspections.

– Periodic retesting of samples to ensure continued conformity.

– Maintaining technical documentation (e.g., design drawings, test reports, risk assessments) for at least 10 years post-production.

– Implementing a corrective action process for non-conforming products or field complaints.

Partnering with accredited certification bodies and staying updated on regulatory changes ensures long-term market access and consumer trust.

In conclusion, sourcing a two-prong electrical plug requires careful consideration of safety standards, regional electrical requirements, device compatibility, and material quality. While two-prong plugs are commonly used for double-insulated devices that do not require grounding, it is essential to ensure that the plug meets relevant certifications (such as UL, CE, or other local standards) and is suitable for the intended voltage and current load. Sourcing from reputable suppliers or manufacturers helps guarantee product reliability and compliance with safety regulations. Additionally, evaluating factors such as cord attachment method, plug design (e.g., polarized vs. non-polarized), and environmental durability will contribute to optimal performance and user safety. Ultimately, selecting the right two-prong plug supports the safe and efficient operation of electronic devices across diverse applications.