The global electric plug and socket market is experiencing steady growth, driven by rising electrification rates, infrastructure development, and increasing demand for residential and commercial electrical components. According to a report by Mordor Intelligence, the global electrical plugs and sockets market was valued at USD 28.6 billion in 2022 and is projected to grow at a CAGR of over 5.3% from 2023 to 2028. A significant portion of this demand comes from two-pin plug configurations, widely used in Europe, parts of Asia, and other regions adhering to specific regional standards such as the Europlug (Type C) or the Australian AS/NZS 3112. These plugs are favored for their simplicity, safety, and compatibility with low-power appliances. As urbanization accelerates and smart building technologies proliferate, manufacturers of two-pin plugs are expanding production capacity, enhancing materials for durability, and ensuring compliance with international safety certifications. In this competitive landscape, a select group of manufacturers has emerged as leaders in quality, innovation, and global distribution—shaping the present and future of two-pin plug supply chains.

Top 9 Two Pin Electric Plug Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Meltric

Domain Est. 1997

Website: meltric.com

Key Highlights: MELTRIC offers a full line of industrial plugs and receptacles, including our signature brand of UL-listed Switch-Rated devices with DECONTACTOR™ ……

#2 Power Cord Manufacturers

Domain Est. 2019

Website: powercordmanufacturers.com

Key Highlights: Cord sets are electrical cables designed to link an appliance or device to a primary power source, supplying it with electrical energy….

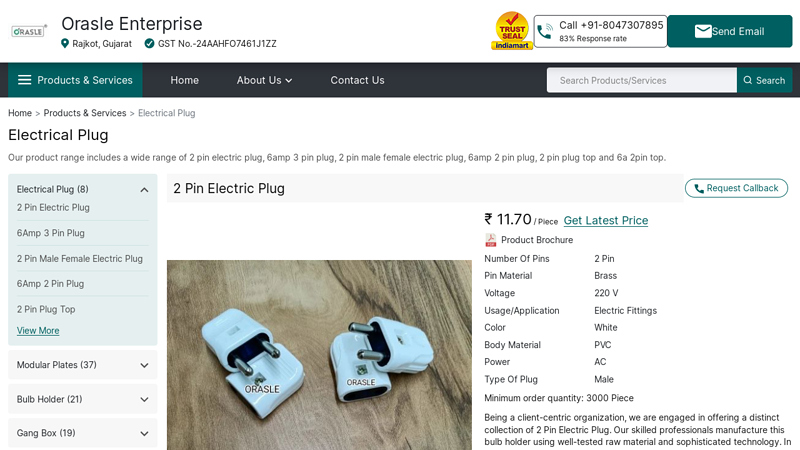

#3 2 Pin Electric Plug Manufacturer from Rajkot

Domain Est. 2023

Website: orasleenterprise.com

Key Highlights: 2 Pin Male Female Electric Plug · Minimum Order Quantity: 2000 Piece · Number Of Pins: 2 Pin · Pin Type: 2 Pin · Current Rating: 2Amp · Voltage: 240 V · Color: ……

#4 Types of Electrical Connectors and Wire Connectors

Domain Est. 1992

Website: te.com

Key Highlights: From USB connectors and RJ45 connectors to TE’s DEUTSCH connectors and AMP connectors, we design and manufacture the electrical connectors and wire connectors ……

#5 Connectors

Domain Est. 1994

Website: molex.com

Key Highlights: Molex offers a wide variety of Board-to-Board Connectors for microminiature, high-speed, high-density, and high-power applications….

#6 Connectors

Domain Est. 1996

Website: amphenol.com

Key Highlights: With 2 to 20 pin configurations, it features a magnetic safety latch, EMI/RFI shielding, and supports both low (<12V) and high (>5000V) ……

#7 Electrical and Electronic Connectors

Domain Est. 1996

Website: hirose.com

Key Highlights: Connector Selector Categories, Applications, Customer Support, Partners, Locations, Contact Us, Privacy Policy | Terms of Use | Membership Agreement…

#8 Fischer Connectors

Domain Est. 1997 | Founded: 1954

Website: fischerconnectors.com

Key Highlights: Founded in 1954, Fischer Connectors designs, develops and deploys end-to-end interconnect solutions for ecosystems requiring local transfer and management….

#9 LEMO – The Original Push-Pull Connector

Domain Est. 1998

Website: lemo.com

Key Highlights: LEMO offers complete connectivity services for high-performance solutions such as cable assembly, customised solutions and signal integrity services….

Expert Sourcing Insights for Two Pin Electric Plug

H2: 2026 Market Trends for Two-Pin Electric Plugs

The global market for two-pin electric plugs is expected to undergo notable shifts by 2026, driven by technological advancements, regulatory changes, and evolving consumer preferences. Below is an analysis of key trends shaping the market:

-

Increased Demand for Travel Adapters and Universal Compatibility

With the rise in international travel and expatriate lifestyles, demand for adaptable two-pin plug solutions—especially in universal travel adapters—is growing. Manufacturers are focusing on producing compact, multi-standard plugs that support two-pin configurations used in Europe, Asia, and Africa, making them essential accessories for global consumers. -

Growth in Consumer Electronics and Low-Voltage Devices

Two-pin plugs are commonly used in low-power devices such as phone chargers, laptops, lamps, and small kitchen appliances. The continued proliferation of portable electronics and IoT-enabled home devices is expected to sustain demand for two-pin connectors, particularly in regions where grounding is less critical. -

Regional Regulatory Shifts and Safety Standards

Regulatory bodies in Europe and parts of Asia are tightening electrical safety standards. While many two-pin plugs lack grounding, newer designs are incorporating safety shutters, insulation sleeves, and overload protection to meet updated EU directives and IEC standards. Compliance will be a key differentiator for manufacturers by 2026. -

Sustainability and Material Innovation

Environmental concerns are pushing manufacturers toward eco-friendly materials such as recycled plastics and biodegradable insulators. Additionally, energy-efficient plug designs that reduce phantom power draw are gaining traction, aligning with broader green energy initiatives. -

Shift Toward Type C (Europlug) Standardization

The Type C two-pin plug (Europlug) continues to gain dominance across Europe, parts of South America, and Africa. As harmonization efforts progress, the Europlug is likely to become the de facto two-pin standard, reducing regional fragmentation and enabling economies of scale for producers. -

Competition from Wireless Charging and Plugless Technologies

While two-pin plugs remain prevalent, emerging wireless charging solutions for consumer electronics could reduce reliance on physical connectors in the long term. However, for mains-powered appliances, two-pin plugs will retain relevance due to cost-effectiveness and reliability. -

Expansion in Emerging Markets

Rapid urbanization and electrification in Africa, Southeast Asia, and Latin America are increasing the demand for affordable electrical components. Two-pin plugs, being simpler and less expensive than grounded alternatives, are well-positioned to dominate in cost-sensitive markets.

Conclusion:

By 2026, the two-pin electric plug market will be shaped by standardization, safety enhancements, and regional growth dynamics. While technological disruptions loom on the horizon, the two-pin plug will remain a staple in low-voltage applications, especially where cost, simplicity, and compatibility are paramount. Manufacturers that innovate within regulatory frameworks and leverage global distribution networks will lead the market.

Common Pitfalls When Sourcing Two-Pin Electric Plugs (Quality and IP Rating)

Sourcing two-pin electric plugs may seem straightforward, but overlooking key factors related to quality and ingress protection (IP) can lead to safety hazards, product failures, and compliance issues. Below are common pitfalls to avoid:

Poor Material Quality

Using substandard plastics or low-grade metal contacts can result in premature wear, overheating, or electrical arcing. Cheap materials may not withstand repeated plugging/unplugging or higher current loads, increasing the risk of fire or electric shock.

Inconsistent Dimensional Tolerances

Inferior manufacturing processes often lead to inconsistent plug dimensions. This can cause loose connections, intermittent power supply, or difficulty inserting/removing the plug from sockets—especially problematic in high-use applications.

Misleading or Unverified IP Ratings

Many suppliers claim an IP rating (e.g., IP42 or IP67), but these may not be third-party tested or certified. A falsely rated plug may allow dust or water ingress in real-world conditions, compromising device safety and reliability, particularly in outdoor or wet environments.

Lack of Temperature and Flammability Certification

Low-quality plugs may not meet temperature rise or flammability standards (e.g., UL 94 V-0). Under load, they can overheat or catch fire. Always verify certifications such as UL, CE, or IEC compliance to ensure materials can handle specified electrical loads safely.

Inadequate Strain Relief

Poorly designed or missing strain relief mechanisms can lead to wire pull-out or internal wire breakage. This creates a shock hazard and reduces product lifespan, especially when the plug is frequently moved or pulled.

Non-Compliance with Regional Safety Standards

Two-pin plugs vary by region (e.g., Europlug vs. Australian Type I). Sourcing the wrong type or non-compliant version can lead to rejection in the target market or unsafe operation due to mismatched voltage/current ratings.

Overlooking Long-Term Durability Testing

Many suppliers provide no data on mechanical durability (e.g., number of insertion cycles). Plugs used in industrial or commercial settings require high cycle life (e.g., 5,000+ insertions), which low-cost options often fail to deliver.

Skipping Supplier Audits and Sample Validation

Relying solely on datasheets without physical testing or factory audits increases the risk of receiving non-conforming goods. Always test samples under real conditions, including thermal cycling and environmental exposure, to verify IP and performance claims.

Logistics & Compliance Guide for Two Pin Electric Plug

This guide outlines essential logistics and compliance considerations for the import, distribution, and sale of Two Pin Electric Plugs in global markets. Adhering to these requirements ensures safety, legal conformity, and smooth supply chain operations.

Regulatory Standards and Certifications

Two Pin Electric Plugs must comply with region-specific electrical safety standards. Key certifications include:

- European Union (EU): Must comply with the Low Voltage Directive (LVD) 2014/35/EU and carry the CE mark. Plugs should meet EN 50075 standards for dimension and safety.

- United Kingdom (UK): Requires UKCA marking (or CE until 2025) and compliance with BS 1363 or relevant BS EN standards, depending on plug type.

- United States (US): Although two-pin plugs are common, devices must be certified by a Nationally Recognized Testing Laboratory (NRTL) such as UL or ETL under standards like UL 498.

- Australia & New Zealand: Must meet AS/NZS 3112 standards and carry the Regulatory Compliance Mark (RCM).

- India: Compliance with Indian Standard IS 1293 and mandatory BIS (Bureau of Indian Standards) certification.

- China: Requires CCC (China Compulsory Certification) for applicable electrical products under GB 2099.1 standards.

Always verify local regulatory requirements before shipping.

Packaging and Labeling Requirements

Proper packaging and labeling are critical for compliance and logistics efficiency:

- Include safety warnings, voltage rating, current capacity, and manufacturer details on the product and packaging.

- Labels must be in the official language(s) of the destination country.

- Use durable, anti-static packaging to prevent damage during transit.

- Ensure packaging complies with environmental directives (e.g., EU Packaging Waste Directive).

Import and Customs Documentation

Prepare accurate documentation to avoid customs delays:

- Commercial Invoice

- Packing List

- Certificate of Conformity (CoC) or Test Report from accredited labs

- Bill of Lading or Air Waybill

- Import License (if required by destination country)

- Risk Assessment and Declaration of Conformity (DoC) for EU/UK markets

Verify Harmonized System (HS) Code (e.g., 8536.69 for plug connectors) for correct tariff classification.

Transportation and Handling

Ensure safe and efficient transportation:

- Classify plugs as non-hazardous goods; no special handling typically required.

- Use moisture-resistant packaging to avoid corrosion.

- Stack cartons properly in containers to avoid crushing.

- Maintain inventory in dry, temperature-controlled storage facilities.

Product Safety and Liability

Mitigate risks associated with electrical products:

- Conduct regular product safety testing and maintain records.

- Implement a product recall plan in case of non-compliance or defects.

- Ensure suppliers adhere to RoHS (Restriction of Hazardous Substances) and REACH regulations (EU), or equivalent local standards.

- Carry product liability insurance covering electrical safety incidents.

End-of-Life and Environmental Compliance

Comply with environmental regulations for electrical waste:

- Adhere to WEEE (Waste Electrical and Electronic Equipment) Directive in the EU.

- Support take-back programs where required.

- Use recyclable packaging materials and minimize plastic use.

Following these logistics and compliance protocols ensures that Two Pin Electric Plugs meet international safety standards, pass customs smoothly, and reach customers reliably and responsibly.

In conclusion, sourcing a two-pin electric plug requires careful consideration of safety standards, voltage and current ratings, regional electrical regulations, and the intended application. It is essential to select plugs that comply with relevant certifications (such as CE, UL, or ETL) to ensure user safety and product reliability. Additionally, evaluating factors like material quality, durability, cost, and supplier reputation will contribute to a successful sourcing decision. By aligning the plug specifications with both technical requirements and regulatory standards, businesses can ensure efficient, safe, and compliant electrical connections for their products.