The global chainsaw market is experiencing steady growth, driven by rising demand in forestry, agriculture, and landscaping sectors. According to Grand View Research, the global chainsaw market size was valued at USD 6.8 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2024 to 2030. This growth is fueled by increasing urbanization, infrastructure development, and a growing focus on efficient land management practices. As demand for high-performance, reliable cutting equipment rises, two-man chainsaws—known for their power and efficiency in large-scale operations—have gained prominence among professional logging and utility crews. These heavy-duty tools require coordinated operation and are often preferred in applications where precision and throughput are critical. In this evolving landscape, several manufacturers have emerged as leaders, combining innovative engineering with durability to meet the needs of industrial users. Based on market presence, product performance, and technological advancement, the following nine manufacturers represent the top players in the two-man chainsaw industry.

Top 9 Two Man Chain Saw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cordless & Electric Chainsaws

Domain Est. 1996

Website: mcculloch.com

Key Highlights: McCulloch has a range of electric, battery and petrol chainsaws with the power to get the job done. Whether cutting firewood or felling large trees.Missing: two manufacturer…

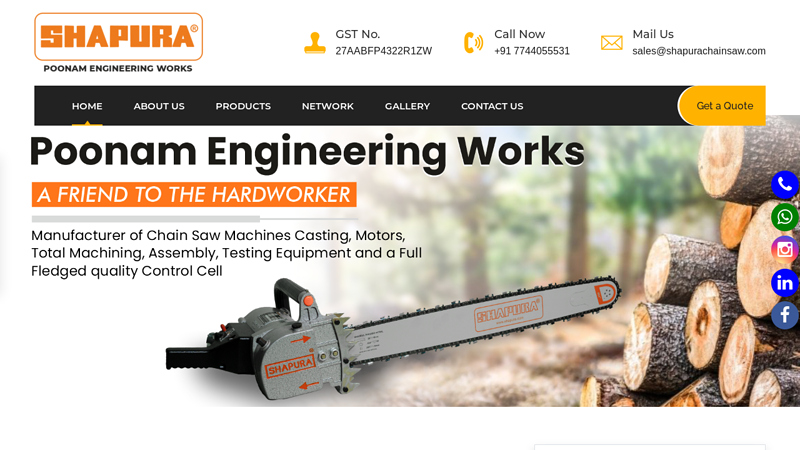

#2 SHAPURA Chain Saw

Domain Est. 2002

Website: shapura.com

Key Highlights: Two Man Chain Saw Machine · Plastic Body Chain Saw Machine · Petrol Chain Saw … Poonam Engineering is a chain saw manufacturer and Chainsaw Suppliers in India….

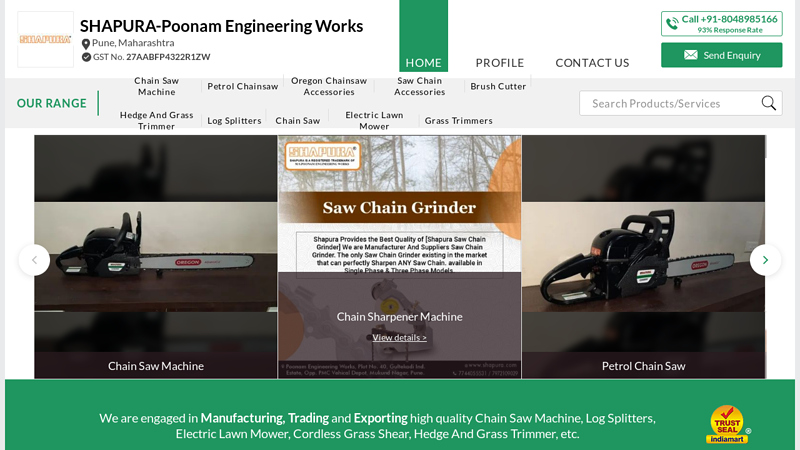

#3 Chain Saw Machine and Petrol Chainsaw Manufacturer

Domain Est. 2013

Website: shapurachainsaw.com

Key Highlights: Two Man Chain Saw Machine. Get Best Quote. Wood Breaker … We are engaged in Manufacturing, Trading and Exporting high quality Chain Saw ……

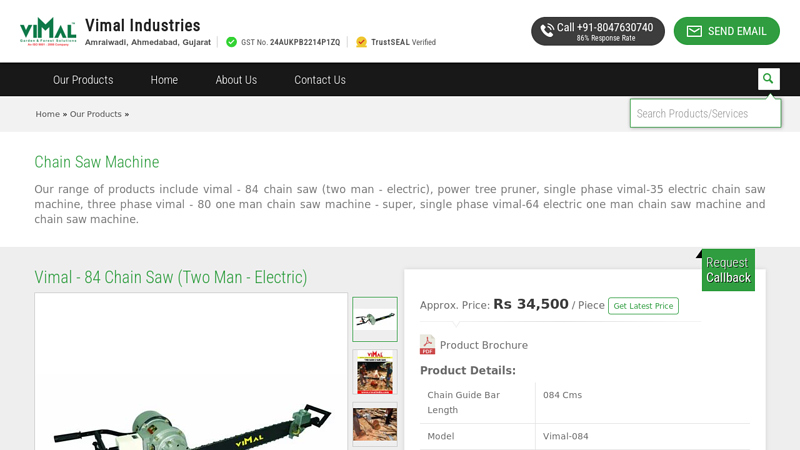

#4 Chain Saw Machine

Domain Est. 2016

Website: vimalindia.net

Key Highlights: Motor Power: 2 HP; Motor Speed: 2800 rpm. We are manufacturer of One Man Chain Saw Machine in ahmedabad, Gujarat. Kindly contcat us for further inquiry. know ……

#5 Husqvarna Forest & Garden

Domain Est. 1995

Website: husqvarna.com

Key Highlights: Husqvarna offers a full range of forest and gardening tools including lawn mowers, chainsaws, robotic mowers and more for both professionals and homeowners….

#6 About McCulloch

Domain Est. 2009

Website: mccullochsteam.com

Key Highlights: After a few years the company moved from Wisconsin to California, where McCulloch Motors produced its first chainsaw, a two-man model named 5-49. In 1949, ……

#7 Legendary STIHL chainsaw celebrates its 60th birthday

Domain Est. 2012

Website: corporate.stihl.rs

Key Highlights: The Contra, the first gearless STIHL one-man chainsaw, made it possible for STIHL to revolutionize forestry work in 1959 and set new standards in the field ……

#8 Premium Chainsaw Accessories

Domain Est. 2019

Website: westcoastsaw.com

Key Highlights: Free delivery over $125 · Free 90-day returnsBuilt for those who demand more, Westcoast Saw delivers precision chainsaw tools, parts, and performance upgrades—crafted in America, …

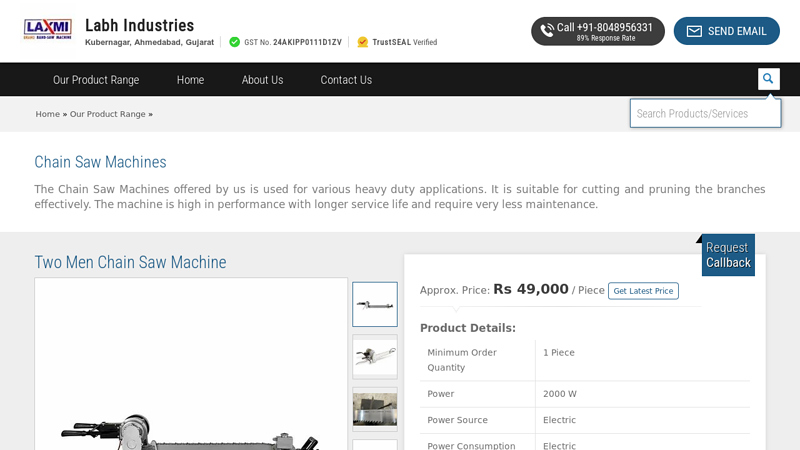

#9 Two Men Chain Saw Machine

Domain Est. 2023

Website: labhindustries.com

Key Highlights: Two Men Chain Saw Machine. Rs 49,000 / Piece ; Two Men Chain Saw Machine. Rs 42,500 / Piece ; One Man Chainsaw Machine Three Phase. Rs 22,500 / Unit….

Expert Sourcing Insights for Two Man Chain Saw

2026 Market Trends for Two-Man Chainsaws

As the demand for efficient, high-powered cutting tools continues to evolve, the two-man chainsaw market is poised for notable shifts by 2026. Driven by technological innovation, environmental regulations, and changing user preferences across forestry, land management, and emergency response sectors, several key trends are expected to shape the industry landscape.

Rising Demand in Professional and Emergency Applications

The two-man chainsaw, traditionally used in forestry and large-scale land clearing, is seeing growing adoption in emergency disaster response and wildfire mitigation. With climate change increasing the frequency and intensity of wildfires, government agencies and firefighting teams are investing in rugged, high-capacity tools capable of rapid tree felling and fuel reduction. By 2026, demand from public safety and land management agencies is projected to rise, particularly in regions prone to natural disasters such as North America, Australia, and Southern Europe.

Shift Toward Fuel-Efficient and Low-Emission Engines

Environmental regulations, especially in the EU and North America, are pushing manufacturers to develop cleaner-burning two-man chainsaws. By 2026, compliance with Tier 5 and upcoming emissions standards will necessitate widespread adoption of advanced combustion technologies and catalytic converters. While electric models remain limited due to power and portability constraints, hybrid systems and improved two-stroke engines with reduced hydrocarbon emissions are expected to dominate the professional segment. This shift supports sustainability goals without compromising the high torque and durability required for heavy-duty tasks.

Integration of Smart Technology and Ergonomic Design

Innovation in user experience is becoming a differentiator. Leading manufacturers are incorporating smart features such as vibration reduction systems, anti-kickback mechanisms, and real-time engine diagnostics via Bluetooth connectivity. By 2026, expect wider integration of IoT-enabled sensors that monitor usage, maintenance needs, and operator fatigue—enhancing safety and prolonging equipment life. Additionally, ergonomic improvements, including weight distribution and handle customization, will address long-term operator health, a growing concern in labor-intensive fields.

Expansion in Emerging Markets and Rental Economies

Developing regions in Latin America, Southeast Asia, and Africa are witnessing increased infrastructure development and land use changes, boosting demand for heavy-duty equipment. While individual ownership remains limited by cost, the rise of equipment rental services and cooperative ownership models will expand access to two-man chainsaws. By 2026, rental and sharing platforms are expected to play a significant role, particularly among small landowners and agricultural contractors, driving market penetration without requiring large capital outlays.

Supply Chain Resilience and Localization

Ongoing global supply chain volatility is prompting manufacturers to localize production and secure alternative component sources. By 2026, companies that establish regional manufacturing hubs—particularly in North America and Eastern Europe—will gain competitive advantages in delivery speed and cost efficiency. This trend supports faster response to regional demand fluctuations and reduces dependency on single-source suppliers for critical parts like guide bars, chains, and engines.

In conclusion, the two-man chainsaw market in 2026 will be shaped by a convergence of environmental compliance, technological advancement, and evolving user needs. While traditional applications remain strong, growth will increasingly come from emergency response, sustainable forestry, and service-based access models. Manufacturers that innovate in efficiency, safety, and accessibility will lead the next phase of industry development.

Common Pitfalls When Sourcing a Two-Man Chainsaw (Quality and Intellectual Property)

Sourcing a two-man chainsaw—typically a heavy-duty, professional-grade tool used in forestry and logging—requires careful attention to both quality and intellectual property (IP) considerations. Failing to address these areas can lead to safety risks, operational inefficiencies, legal issues, and reputational damage. Below are common pitfalls to avoid:

Overlooking Build Quality and Safety Standards

Many buyers focus on price or availability while neglecting the mechanical integrity and safety certifications of the chainsaw. Low-quality models may use substandard steel for guide bars and chains, poorly engineered engines, or inadequate anti-vibration systems. This increases the risk of kickback, chain breakage, or component failure during operation. Always verify compliance with international safety standards such as ISO 11681 (for hand-held chain-saw safety) and CE or ANSI markings.

Ignoring Engine and Performance Specifications

Not all two-man chainsaws deliver consistent power or fuel efficiency. Some suppliers may exaggerate engine displacement (CC) or power output. Buyers should request performance test reports and verify specifications like torque, RPM, and fuel consumption. Poorly tuned engines or counterfeit carburetors can lead to overheating, stalling, or excessive emissions.

Failing to Evaluate After-Sales Support and Spare Parts Availability

High-quality chainsaws require regular maintenance and durable spare parts (e.g., chains, sprockets, ignition modules). Sourcing from manufacturers or suppliers without a reliable spare parts network—especially in remote logging areas—can result in costly downtime. Confirm the availability of consumables and technical support before finalizing procurement.

Procuring from Suppliers with Questionable IP Practices

A significant risk when sourcing from certain regions is the prevalence of counterfeit or “clone” chainsaws that infringe on established brands’ intellectual property. These replicas often mimic well-known models (e.g., Husqvarna, Stihl, or Echo) but lack licensed engineering, patents, or brand authorization. Using such equipment can expose your company to IP infringement claims, especially if used in commercial operations across international borders.

Assuming OEM Labels Indicate Authenticity

Some suppliers falsely label generic or imitation products with OEM branding or logos to imply legitimacy. Always verify authenticity through official distribution channels, request proof of licensing, and conduct factory audits if sourcing directly from manufacturers. Look for holograms, serial number traceability, and official distributor certifications.

Neglecting Warranty and Liability Coverage

Low-cost chainsaws often come with limited or voidable warranties. If an accident occurs due to equipment failure, lack of proper IP licensing may invalidate insurance claims or limit liability protection for the supplier. Ensure the product comes with a comprehensive warranty and that the supplier assumes responsibility for defects or safety-related failures.

Skipping On-Site Quality Inspections or Third-Party Testing

Relying solely on product photos or supplier claims is risky. Conduct pre-shipment inspections or use third-party quality control services to assess build quality, material integrity, and functional performance. Testing under load conditions can reveal hidden flaws not evident during visual checks.

By addressing these pitfalls proactively—prioritizing certified quality, verifying IP legitimacy, and ensuring long-term support—businesses can source reliable, safe, and legally compliant two-man chainsaws that meet professional demands.

Logistics & Compliance Guide for Two-Man Chainsaw

Product Classification and Regulatory Overview

A two-man chainsaw, typically used in forestry, logging, and utility operations, falls under heavy-duty power equipment regulations. It is subject to international, national, and regional safety, environmental, and transportation standards. Understanding classification under HS (Harmonized System) codes and applicable regulations is critical for compliance.

Harmonized System (HS) Code Classification

Two-man chainsaws are generally classified under HS Code 8467.21 – “Motorized saws; hand-held, self-propelled or mounted; circular saws: of the portable hand-held type.” This classification applies globally but may vary slightly by country. Confirm with local customs authorities to ensure accurate tariff designation and avoid delays.

Safety and Certification Requirements

Two-man chainsaws must comply with safety standards such as:

– EN 13236 (Europe): Personal protective equipment for forestry and logging work.

– ANSI B175.1 (USA): Safety requirements for gasoline-powered chain saws.

– ISO 11681-1: Safety for chain saws used in forestry.

Manufacturers must obtain CE marking (EU), UL listing (USA), or other regional certifications before distribution.

Environmental and Emissions Compliance

Due to internal combustion engines (typically two-stroke or four-stroke), emissions regulations apply:

– EPA Phase 3 (USA): Regulates exhaust emissions for non-road engines.

– EU Stage V (Europe): Sets limits on particulate matter and NOx emissions.

Ensure the chainsaw meets the applicable emissions standards in the destination market. Documentation such as EPA or EU type-approval certificates must accompany shipments.

Packaging and Transportation Logistics

- Packaging: Units must be securely packed in sturdy cardboard or wooden crates with protective foam to prevent damage. Include all accessories (bars, chains, tools) in clearly labeled compartments.

- Hazardous Materials: If shipped with fuel or oil, classify under UN 1202 (Gasoline) or UN 1203 (Motor Oil), requiring hazardous materials documentation, labeling, and special handling.

- Shipping Modes: Ocean freight (FCL/LCL), air freight (for urgent deliveries), or ground transport (domestic). Declare contents accurately on shipping manifests.

Import and Export Documentation

Required documentation includes:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Safety and Emissions Compliance Certificates (e.g., CE, EPA)

– Import licenses (if required by destination country)

Ensure all documents list the correct HS code, product description, and end-use.

Customs Clearance and Duties

- Pay applicable import duties and VAT based on the HS code and country-specific tariff schedules.

- Use an experienced customs broker familiar with power tools and forestry equipment.

- Provide technical specifications (engine displacement, power output, weight) to support classification.

End-User Compliance and Training

Two-man chainsaws require trained operators due to safety risks. Distributors should:

– Provide multilingual user manuals and safety warnings.

– Encourage operator certification (e.g., OSHA-compliant training in the U.S.).

– Ensure availability of personal protective equipment (PPE) such as helmets, chaps, and gloves.

Disposal and End-of-Life Considerations

Follow WEEE Directive (EU) or local e-waste regulations for decommissioned units. Recycle metal components, engines, and batteries responsibly. Maintain records of disposal to meet environmental compliance standards.

Summary

Compliance for two-man chainsaws involves accurate classification, adherence to safety and emissions standards, proper documentation, and safe handling during transport. Partner with certified suppliers and logistics providers to ensure seamless international distribution while meeting all regulatory requirements.

Conclusion: Sourcing Two Man Chainsaws

After a thorough evaluation of operational needs, safety requirements, and cost-efficiency, sourcing two-man chainsaws is a strategic decision that supports effective performance in heavy-duty cutting applications. These robust tools are essential for forestry, logging, and large-scale land clearing operations where efficiency, precision, and reliability are critical. By selecting reputable suppliers, ensuring equipment meets safety and environmental standards, and incorporating proper training and maintenance protocols, the investment in two-man chainsaws will enhance productivity, reduce operational downtime, and ensure the safety of personnel. Ultimately, sourcing these tools aligns with long-term operational goals, supporting sustainable and efficient workflow management in demanding environments.