The global twine and cordage market has experienced steady growth, driven by increasing demand across agriculture, packaging, construction, and crafts. According to Mordor Intelligence, the global cordage and twine market was valued at USD 3.78 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2029. This expansion is fueled by rising agricultural activities in emerging economies, the resurgence of sustainable packaging solutions, and the growing popularity of DIY crafts and home improvement projects. As demand for durable, eco-friendly, and high-performance twine materials rises, manufacturers are innovating with natural fibers like jute, sisal, and cotton, as well as synthetic alternatives such as polypropylene and nylon. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining scalable production, material expertise, and sustainability initiatives to meet global needs. Below are the top 9 twine material manufacturers shaping the industry’s future.

Top 9 Twine Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Garware Technical Fibres

Domain Est. 2018

Website: garwarefibres.com

Key Highlights: Garware Technical Fibres is one stop solution for Top Quality Aquaculture Net & Ropes. a Go-To Solution for Fisheries, Aquaculture, and Industrial ……

#2 Category Product Twine

Domain Est. 1996

Website: frankwinne.com

Key Highlights: Frank Winne & Son, Inc.’s nylon seine twine is made from filament nylon. Our construction provides high tenacity, UV resistance, and very good stretch….

#3 Wholesale Twine String

Domain Est. 2014

Website: seacorope.com

Key Highlights: Seaco rope is a leading manufacturer and distributor of the finest twine in the world. For questions about twine or any of our premium products, call or email ……

#4 Twine Solutions: Dye Any Color of Thread or Yarn On

Domain Est. 2015

Website: twine-s.com

Key Highlights: Twine Solutions offers the textile industry sustainable, on-demand thread dyeing tech for yarn or twine with precision color matching technology & mass ……

#5 Mason Twine

Domain Est. 1997

Website: keson.com

Key Highlights: Keson’s Twisted Mason Twine is a time-tested construction staple, manufactured using traditional twisting methods that create strong, economical line perfect ……

#6 Twine, Rope & Strapping

Domain Est. 1998

Website: nyp-corp.com

Key Highlights: NYP Corp. offers an extensive line of tying products, from high grade center pull sisal twine and poly twines to super strong “mule tape” and seat belt ……

#7 Ashaway Line & Twine Manufacturing Company

Domain Est. 1999

Website: ashawayusa.com

Key Highlights: Welcome to Ashaway Line & Twine Manufacturing Company! Ashaway is a world leader in the production of bulk, non-sterile and non-absorbable suture threads….

#8 ShopAPT

Domain Est. 2000

Website: shopapt.com

Key Highlights: American Paper & Twine is the premier wholesale supplier and distributor of janitorial, packaging, disposable food service, safety and office products….

#9 Bridon USA

Domain Est. 2018 | Founded: 1975

Website: bridon-usa.com

Key Highlights: The Bridon USA company was founded in 1975 as an innovator in plastic agricultural baling twine. Continuous improvement, and a strong dealer network….

Expert Sourcing Insights for Twine Material

2026 Market Trends for Twine Material

The twine material market is poised for continued evolution by 2026, driven by sustainability mandates, technological innovation, and shifting demand across key end-use sectors. Here’s a detailed analysis of the primary trends expected to shape the industry:

Growing Dominance of Sustainable and Bio-Based Materials

Environmental concerns are reshaping consumer and industrial preferences, pushing demand toward eco-friendly alternatives. By 2026, bio-based twines—derived from materials like jute, hemp, organic cotton, and polylactic acid (PLA)—are expected to capture a significantly larger market share. Regulatory pressures in Europe and North America, coupled with corporate sustainability goals, are accelerating the phase-out of conventional polypropylene and polyethylene twines in favor of biodegradable or compostable options. Innovations in natural fiber processing are also enhancing durability and moisture resistance, closing the performance gap with synthetics.

Expansion in Agricultural and Horticultural Applications

The global push for efficient and sustainable agriculture continues to drive twine demand. Twine remains essential for crop binding, trellising in vineyards and orchards, and greenhouse applications. Precision farming techniques and vertical farming systems are creating new niches for specialized twines with enhanced UV resistance, tensile strength, and longevity. By 2026, smart twines embedded with sensors for moisture or nutrient monitoring may begin limited commercialization, particularly in high-value horticulture.

Technological Advancements in Synthetic Twines

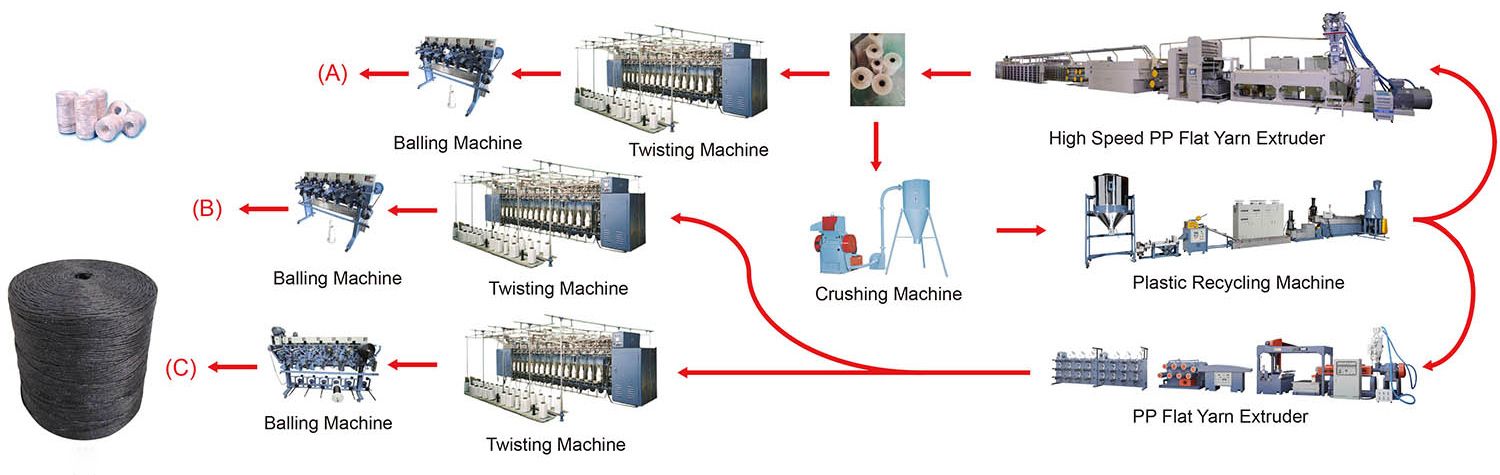

Despite the rise of bio-based materials, high-performance synthetic twines will maintain relevance in industrial applications requiring extreme durability. Innovations in polymer science are leading to the development of lighter, stronger, and more weather-resistant synthetic twines. Recycled content integration—such as rPP (recycled polypropylene) and rPET—is becoming standard among major producers, aligning with circular economy goals. Additionally, advancements in fiber extrusion and coating technologies are improving knot strength and abrasion resistance.

Regional Shifts and Supply Chain Localization

Asia-Pacific, particularly India and China, will remain dominant in natural fiber twine production due to abundant raw material access and established manufacturing infrastructure. However, by 2026, North America and Europe are expected to increase local production of specialty and sustainable twines to reduce import dependency and meet ESG (Environmental, Social, Governance) reporting requirements. Nearshoring trends and supply chain resilience concerns post-pandemic are encouraging investment in regional manufacturing facilities.

Rising Demand in Packaging and E-Commerce

The booming e-commerce sector is fueling demand for durable, lightweight, and recyclable packaging solutions. Twine—especially paper and biodegradable synthetic variants—is being adopted as an eco-conscious alternative to plastic tapes and adhesives in gift wrapping, parcel securing, and retail bundling. Brands emphasizing sustainable unboxing experiences are increasingly specifying natural twine for aesthetic and environmental appeal.

Price Volatility and Raw Material Challenges

The twine market will face ongoing price fluctuations due to volatility in both natural fiber crops (affected by climate change) and petrochemical feedstocks (linked to oil prices). By 2026, long-term contracts, forward purchasing, and strategic partnerships between twine manufacturers and raw material suppliers are expected to become more common as risk-mitigation strategies. Investments in alternative feedstocks, such as algae-based polymers, are in early development but could influence future supply dynamics.

Conclusion

By 2026, the twine material market will be characterized by a dual trajectory: rapid growth in sustainable, bio-based products and steady innovation in high-performance synthetics. Success for manufacturers will depend on agility in adopting green technologies, compliance with tightening environmental regulations, and responsiveness to sector-specific demands in agriculture, packaging, and retail. Companies that integrate circularity, transparency, and digital traceability into their value chains are likely to lead the next phase of market development.

Common Pitfalls Sourcing Twine Material (Quality, IP)

Sourcing twine material may appear straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to product failures, supply chain disruptions, or legal risks. Below are common pitfalls to avoid:

Inadequate Quality Control Standards

Suppliers may provide twine that varies significantly in tensile strength, thickness, or material composition. Relying on inconsistent quality can result in product breakage, customer complaints, or safety hazards—especially in industrial or agricultural applications. Always request material specifications (e.g., denier, breaking strength, UV resistance) and conduct batch testing.

Misrepresentation of Material Composition

Some suppliers may label twine as “natural” or “biodegradable” without proper certification. For example, synthetic fibers like polypropylene might be passed off as jute or cotton. Verify material claims through third-party testing or documentation such as certificates of analysis (COA) or sustainability certifications (e.g., FSC, GOTS).

Lack of Traceability and Supply Chain Transparency

Without a transparent supply chain, it becomes difficult to verify ethical sourcing, environmental compliance, or raw material origins. This increases the risk of reputational damage or non-compliance with regulations like the Uyghur Forced Labor Prevention Act (UFLPA). Require suppliers to provide traceability documentation.

Overlooking Intellectual Property in Twine Design or Branding

If your twine features a unique weave pattern, color scheme, or proprietary packaging, failing to secure IP protection (e.g., design patents, trademarks) can allow competitors to copy your product. Additionally, sourcing twine with branded elements from third parties may inadvertently infringe on existing trademarks or patents.

Assuming Generic Twine Has No IP Constraints

Even basic twine products can be covered by utility or design patents—especially if they include specialized coatings, twisted configurations, or performance-enhancing treatments. Conduct freedom-to-operate (FTO) searches before finalizing designs or large production runs.

Failure to Secure Proper Licensing for Branded or Specialty Twine

If sourcing twine with logos, licensed characters, or performance claims (e.g., “FDA-compliant”), confirm that the supplier holds the necessary rights or licenses. Unauthorized use can lead to cease-and-desist orders or litigation.

Ignoring Long-Term Supplier Reliability

Choosing a supplier solely based on low cost can compromise consistency. A vendor that cannot scale or maintain quality over time may disrupt operations. Evaluate supplier stability, production capacity, and past performance before committing.

By addressing these quality and IP-related pitfalls early, businesses can ensure reliable sourcing, maintain product integrity, and mitigate legal and operational risks.

Logistics & Compliance Guide for Twine Material

Twine, a lightweight and versatile material used across industries such as agriculture, packaging, construction, and crafts, requires careful handling and compliance with various regulatory standards during transportation and storage. This guide outlines key logistics considerations and regulatory compliance requirements to ensure safe, efficient, and lawful distribution of twine products.

Transportation & Packaging Requirements

Twine should be packaged to prevent tangling, moisture damage, and contamination during transit. Use moisture-resistant packaging such as polyethylene wraps or sealed cartons, especially for natural fiber twines like jute or cotton, which are susceptible to mold. Spools or coils must be securely bound and placed in sturdy outer packaging to resist crushing. When shipping in bulk, ensure loads are evenly distributed and secured within containers or trucks to prevent shifting. Consider using pallets with stretch wrap or shrink film for unitized loads.

Storage Conditions

Store twine in a dry, well-ventilated area, away from direct sunlight and sources of heat or moisture. High humidity can weaken natural fibers and promote mildew, while prolonged UV exposure can degrade synthetic twines like polypropylene or nylon. Maintain consistent temperatures between 10°C and 30°C (50°F to 86°F) and avoid storing near chemicals or combustible materials. Keep stock organized using a first-in, first-out (FIFO) system to prevent aging and deterioration.

Regulatory Compliance

Compliance varies depending on the twine composition and destination market:

- REACH & RoHS (EU): Ensure synthetic twines (e.g., polyester, polypropylene) do not contain restricted substances such as phthalates or heavy metals.

- Proposition 65 (California, USA): Provide warnings if twine contains chemicals known to cause cancer or reproductive harm.

- FDA Compliance (USA): Twine used in food packaging or agricultural applications must be food-grade and non-toxic. Avoid dyes or additives not approved for food contact.

- Customs & Import Regulations: Declare accurate HS codes (e.g., 5607.90 for other twine and cordage) and provide certificates of origin, material safety data sheets (MSDS), or test reports if requested.

- Environmental Regulations: Biodegradable twines (e.g., jute, hemp) may qualify for green certifications. Avoid non-recyclable composites unless properly labeled.

Safety & Handling

Provide handling guidelines to prevent injury—twine can pose entanglement or laceration risks. Use personal protective equipment (PPE) such as gloves when cutting or handling large volumes. Ensure proper disposal of waste twine, especially synthetic varieties, in accordance with local waste management regulations.

Documentation & Traceability

Maintain detailed records of material sourcing, manufacturing processes, test results, and shipping documentation. Implement batch tracking to support traceability in case of recalls or compliance audits. Include product labels with fiber content, weight, country of origin, and compliance marks (e.g., CE, USDA Organic if applicable).

By adhering to these logistics and compliance practices, businesses can ensure the safe and legal distribution of twine materials while minimizing environmental impact and maximizing customer trust.

Conclusion for Sourcing Twine Material:

After evaluating various suppliers, material types, cost considerations, and sustainability factors, it is clear that sourcing the right twine material requires a balanced approach that aligns with both operational needs and long-term business goals. Natural fibers such as jute, cotton, and sisal offer eco-friendly, biodegradable options ideal for applications demanding sustainability, while synthetic alternatives like polypropylene and nylon provide superior strength, durability, and resistance to environmental factors.

The optimal sourcing decision will depend on specific use cases—whether for agricultural binding, packaging, crafts, or industrial applications. Key factors such as tensile strength, environmental exposure, cost-efficiency, and environmental impact must be prioritized accordingly. Establishing relationships with reliable suppliers who adhere to ethical and sustainable practices further ensures consistent quality and supply chain resilience.

In conclusion, a strategic sourcing plan should leverage a mix of material options based on application requirements, supported by thorough supplier vetting and a commitment to sustainability. This approach not only meets current needs but also positions the organization for adaptability and responsibility in a rapidly evolving market.