The global turret machine market is experiencing steady growth, driven by rising demand for high-precision, high-efficiency metalworking solutions across automotive, aerospace, and industrial manufacturing sectors. According to a 2023 report by Mordor Intelligence, the CNC machine tools market—under which turret machines fall—is projected to grow at a CAGR of over 7.5% from 2023 to 2028, fueled by automation trends and advancements in smart manufacturing. Similarly, Grand View Research estimates that the global CNC machine market size was valued at USD 74.6 billion in 2022 and is expected to expand at a CAGR of 7.6% through 2030. Within this evolving landscape, turret machines remain a critical component for rapid tool indexing and repetitive machining tasks, especially in turning centers and punch presses. As industries prioritize throughput and accuracy, leading manufacturers continue to innovate with enhanced rigidity, faster indexing speeds, and IoT-enabled controls. Here’s a data-driven look at the top 10 turret machine manufacturers shaping the future of precision manufacturing.

Top 10 Turret Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Global CNC Industries Turret Tooling Technology

Domain Est. 1997

Website: globalcnc.com

Key Highlights: Global CNC is a U.S.-based manufacturer specializing in precision tool holders for CNC turning and mill-turn machines. Our product line includes Static and ……

#2 Turret Punch Press

Domain Est. 1997

Website: amada.com

Key Highlights: AMADA’s turret drive system combines the simplicity of clutch and brake technology with the high speeds of the fastest hydraulic ram driven systems….

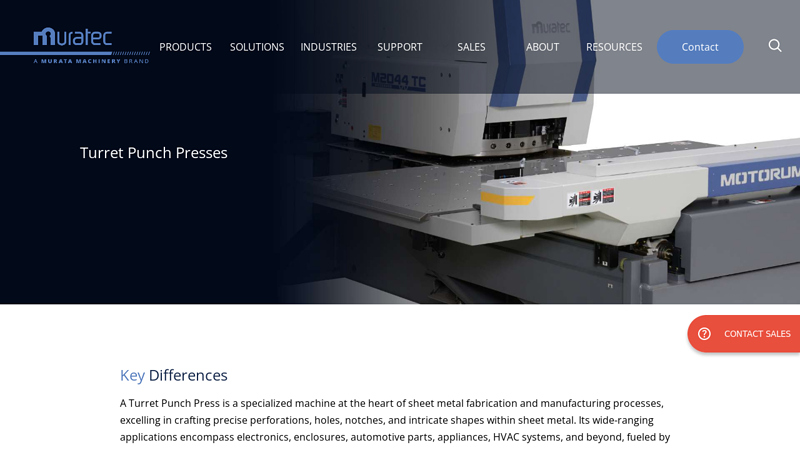

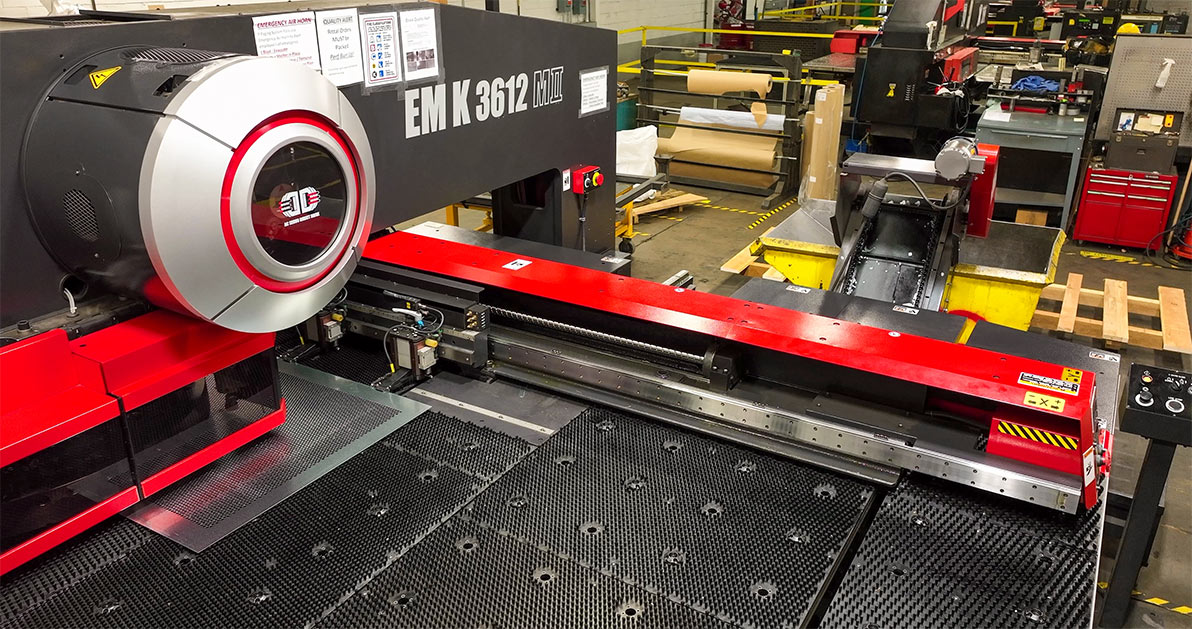

#3 Turret Punch Presses [M2044TC]

Domain Est. 2000

Website: muratec.net

Key Highlights: A new concept in ram drive technology, which incorporated a toggle mechanism driven by an AC servo motor. Hydraulic oil-less sheet metal processing….

#4 CNC turret manufacturer

Domain Est. 2002

Website: en.yaxingsk.com

Key Highlights: We have a complete product line of turrets including electric, hydraulic, servo, power, Y-axis and B-axis. We have a large group of experienced and professional ……

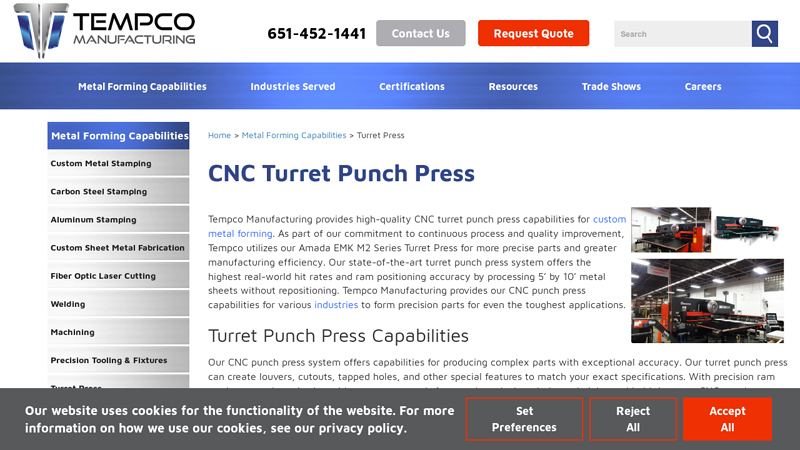

#5 CNC Turret Punch Press

Domain Est. 1996

Website: tempcomfg.com

Key Highlights: Our CNC turret punch press can produce high-quality components from metals such as aluminum, stainless steel, copper, or brass through precision and accuracy….

#6 Turret Punch Presses

Domain Est. 1997

Website: muratec-usa.com

Key Highlights: A Turret Punch Press is a specialized machine at the heart of sheet metal fabrication and manufacturing processes, excelling in crafting precise perforations….

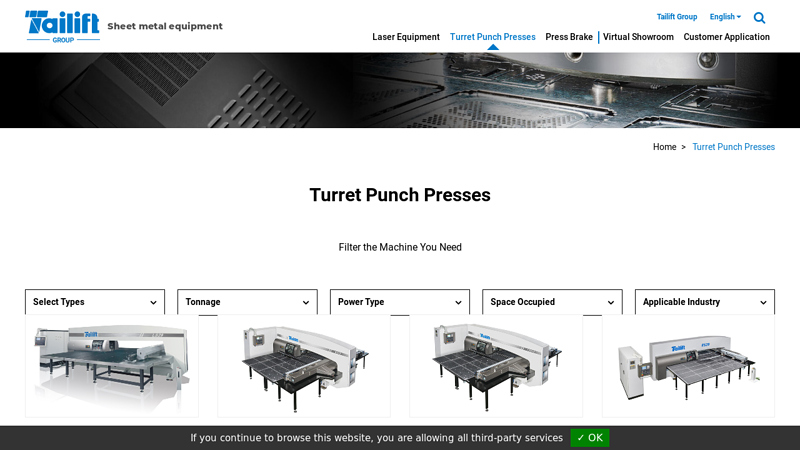

#7 Turret Punch Presses Machine

Domain Est. 2009

Website: sheet-metal.tailiftgroup.com

Key Highlights: Superior turret punch presses from Tailift Group are designed for precision and efficiency. Enhance your operations with our CNC turret punching machines, ……

#8 Tool Turret Systems

Domain Est. 2009

Website: duplomaticautomation.com

Key Highlights: Duplomatic Automation one of the world leaders in the production of a wide range of different kinds of static and driven tool turrets for Turning Centers….

#9 CNC Machine Shop Anaheim

Domain Est. 2019

Website: turretlathe.com

Key Highlights: Welcome to Turret Lathe Specialists, where precision, craftsmanship, and innovation come together. For over 50 years, we’ve been a trailblazer in precision CNC ……

#10 Nakamura

Domain Est. 2021

Website: nakamura-tome.com

Key Highlights: We offer various machines including Tool-Spindle Machines, Multi-Turret Machines, and Single-Turret Machines….

Expert Sourcing Insights for Turret Machine

H2: Projected Market Trends for Turret Machines in 2026

As the manufacturing landscape continues to evolve with advancements in automation, digitalization, and precision engineering, the turret machine market is poised for significant transformation by 2026. Turret machines—widely used in metalworking, automotive, aerospace, and general machining industries for their high-speed tool indexing and multi-operation capabilities—are expected to experience steady growth driven by technological innovation, rising demand for efficient production systems, and regional industrial expansion.

1. Increased Adoption of CNC and Hybrid Turret Systems

By 2026, Computer Numerical Control (CNC) turret machines will dominate the market, replacing traditional manual and semi-automatic models. The integration of advanced CNC controls enables greater precision, repeatability, and compatibility with Industry 4.0 frameworks. Hybrid turret lathes that combine turning with milling or drilling operations will gain traction, allowing manufacturers to reduce setup times and improve throughput. Expect enhanced software integration for real-time monitoring, predictive maintenance, and remote diagnostics.

2. Growth in Automation and Robotics Integration

Automation is a key driver shaping the turret machine market. In 2026, more turret machines will be equipped with robotic loading/unloading systems, automatic bar feeders, and pallet changers. This trend is fueled by labor shortages, the need for 24/7 operation, and the push for lights-out manufacturing. Smart factories will increasingly adopt turret machines as modular components of fully automated production cells.

3. Demand from Emerging Markets and Industrialization

Asia-Pacific, particularly China, India, and Southeast Asia, will remain the fastest-growing region for turret machine adoption. Rapid industrialization, government initiatives promoting manufacturing (e.g., “Make in India,” “Manufacturing Innovation in China 2025”), and expanding automotive and electronics sectors will drive demand. Latin America and Eastern Europe are also expected to show moderate growth due to localized production shifts and supply chain diversification.

4. Focus on Energy Efficiency and Sustainability

Environmental regulations and corporate sustainability goals will influence machine design. By 2026, manufacturers will prioritize energy-efficient motors, regenerative braking systems, and reduced coolant consumption in turret machines. Eco-friendly machining processes and recyclable machine components will become selling points, aligning with global green manufacturing standards.

5. Rise of Smart Manufacturing and IIoT Connectivity

Turret machines will increasingly feature Industrial Internet of Things (IIoT) capabilities, enabling seamless data exchange between machines, ERP systems, and cloud platforms. Real-time analytics will optimize tool life, detect wear patterns, and improve overall equipment effectiveness (OEE). Edge computing and AI-driven process optimization will begin to emerge in high-end turret systems.

6. Customization and Modular Design

To meet diverse industry needs, manufacturers will offer more modular and customizable turret solutions. Quick-change tooling, scalable configurations, and application-specific turrets (e.g., for medical device or aerospace components) will be in demand. This flexibility allows SMEs to adopt turret technology without significant capital investment.

7. Competitive Landscape and Innovation

Leading players such as DMG MORI, Doosan Machine Tools, Hardinge, and Okuma are expected to intensify R&D efforts, focusing on compact designs, improved rigidity, and faster tool indexing. New entrants from China and India will offer cost-competitive alternatives, increasing price pressure but also expanding market accessibility.

Conclusion:

By 2026, the turret machine market will be characterized by smart, connected, and highly automated systems tailored for efficient and flexible manufacturing. Growth will be underpinned by digital transformation, regional industrial expansion, and the ongoing need for high-precision, cost-effective machining solutions. Companies that embrace innovation, sustainability, and integration with broader smart manufacturing ecosystems will lead the market.

Common Pitfalls Sourcing Turret Machines (Quality, IP)

Sourcing turret machines—especially from overseas suppliers—can present significant challenges related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial to ensuring a successful procurement process and safeguarding your business interests.

Quality Inconsistencies and Lack of Standards

One of the most prevalent issues when sourcing turret machines is inconsistent quality. Suppliers, particularly in regions with less stringent manufacturing oversight, may deliver machines that do not meet promised performance specifications. Components such as the turret indexing mechanism, tool holders, or servo systems may be made with substandard materials or imprecise tolerances, leading to premature wear, reduced accuracy, and increased downtime. Buyers often discover discrepancies only after installation, when the machine fails to maintain required tolerances or suffers frequent mechanical failures.

Additionally, some suppliers may provide machines that appear identical to reputable OEM models but use inferior internal components or outdated control systems. Without proper vetting, on-site inspections, or third-party quality audits, these quality gaps may go unnoticed until it’s too late.

Intellectual Property Infringement Risks

Sourcing turret machines carries a significant risk of inadvertently acquiring equipment that violates intellectual property rights. Many low-cost suppliers produce machines that closely mimic patented designs, control software, or proprietary technologies from established manufacturers (e.g., turret layout, tool-changing mechanisms, or CNC interfaces). Purchasing such machines—even unknowingly—can expose your company to legal liability, especially if the equipment is used in a jurisdiction with strong IP enforcement.

Furthermore, cloned or counterfeit machines may come with pirated software licenses for CNC controls (e.g., Fanuc, Siemens, or Mitsubishi), which can result in compliance issues, lack of updates, and security vulnerabilities. Using such software not only breaches licensing agreements but may also compromise machine performance and create cybersecurity risks.

Inadequate After-Sales Support and Documentation

Even if the initial machine quality appears acceptable, many sourced turret machines come with limited technical support, spare parts availability, or comprehensive documentation. This lack of support becomes critical when maintenance is needed or production halts due to a malfunction. Without access to genuine spare parts or trained service personnel, downtime can escalate quickly, impacting productivity and return on investment.

Poorly translated or incomplete manuals also hinder proper operation and troubleshooting, increasing the risk of operator error and safety incidents.

Hidden Costs from Non-Compliance and Repairs

Initially attractive pricing can be misleading when hidden costs emerge from non-compliant machines. Turret machines that do not meet international safety standards (e.g., CE, UL, or ISO) may require costly retrofitting or fail regulatory inspections. Similarly, machines with IP-infringing components may need to be decommissioned or modified to avoid legal action, resulting in unplanned expenses and operational disruption.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct thorough due diligence on suppliers, including factory audits and reference checks.

– Require sample testing and performance validation before bulk orders.

– Verify compliance with relevant industry standards and certifications.

– Engage legal counsel to assess IP risks and include IP indemnity clauses in contracts.

– Ensure software licenses are legitimate and support agreements are in place.

By proactively addressing quality and IP concerns, businesses can reduce risk and ensure reliable, compliant, and legally sound procurement of turret machines.

Logistics & Compliance Guide for Turret Machine

Overview

This guide outlines the essential logistics considerations and compliance requirements for the safe and legal transportation, handling, and operation of a turret machine. Adhering to these guidelines ensures regulatory compliance, workplace safety, and equipment integrity.

Packaging & Handling Requirements

Turret machines must be securely packaged to prevent damage during transit. Use custom crating with shock-absorbing materials and ensure all moving parts are immobilized. Clearly label packages with “Fragile,” “This Side Up,” and handling instructions. Lift only using designated rigging points with appropriate slings or forklifts rated for the machine’s weight.

Transportation Specifications

Transport the turret machine using a flatbed or enclosed trailer with sufficient load capacity. Secure the machine with tie-down straps or chains meeting ISO or DOT standards. Confirm route compliance with local regulations regarding oversized loads if applicable. Avoid extreme temperature and humidity exposure during transit to protect electronic components.

Import/Export Compliance

Verify that the turret machine meets export control classifications (e.g., ECCN under the EAR or USML under ITAR, if applicable). Obtain necessary export licenses and documentation, including commercial invoices, packing lists, and certificates of origin. Comply with destination country import regulations, including CE marking (for EU), NRCan (Canada), or other regional certifications.

Safety & Regulatory Standards

Ensure the turret machine complies with relevant safety standards such as:

– ISO 12100:2010 (Safety of Machinery)

– ANSI B11.19 (Performance Requirements for Risk Reduction)

– OSHA 29 CFR 1910.212 (General Requirements for All Machines)

Install required safety guards, emergency stops, and warning labels. Provide machine-specific risk assessments and safety documentation.

Installation & Site Preparation

Prepare the installation site according to manufacturer specifications, including floor load capacity, power supply (voltage, phase, frequency), and clearance for operation and maintenance. Ensure proper grounding and compliance with NEC (NFPA 70) or IEC 60364 electrical standards. Verify local building and fire codes are met.

Operator Training & Documentation

Only trained personnel should operate the turret machine. Provide documented training covering startup, operation, shutdown, emergency procedures, and lockout/tagout (LOTO) compliance per OSHA 29 CFR 1910.147. Maintain training records and ensure operators have access to the machine’s user manual and safety instructions.

Maintenance & Environmental Compliance

Follow the manufacturer’s maintenance schedule to ensure safe and efficient operation. Dispose of waste materials (e.g., lubricants, metal shavings) in accordance with EPA or local environmental regulations. Use only approved replacement parts to maintain compliance and warranty validity.

Certification & Recordkeeping

Retain all compliance documentation, including CE declarations, conformity certificates, inspection reports, and maintenance logs. Conduct periodic safety audits and keep records for a minimum of five years or as required by local jurisdiction.

Emergency Procedures

Establish and communicate emergency response procedures for mechanical failure, fire, or operator injury. Equip the area with appropriate fire extinguishers and first aid supplies. Ensure emergency shutdown mechanisms are accessible and tested regularly.

Conclusion for Sourcing a Turret Machine:

After a thorough evaluation of technical requirements, production needs, supplier capabilities, and cost considerations, sourcing a turret machine represents a strategic investment to enhance manufacturing efficiency, precision, and throughput. The selected machine aligns with current production demands while offering scalability for future growth. Key factors such as machine rigidity, tooling capacity, automation compatibility, and after-sales support have been prioritized to ensure long-term reliability and minimal downtime.

Engaging with reputable suppliers offering strong service networks and warranty terms will further mitigate operational risks. Ultimately, integrating a suitable turret machine into the production line will optimize machining processes, reduce cycle times, and improve overall product quality, contributing significantly to operational competitiveness and cost-effectiveness in metal fabrication or turning operations. Continuous monitoring and maintenance post-installation will be essential to maximize ROI and sustain performance improvements.

![Turret Punch Presses [M2044TC]](https://www.sohoinchina.com/wp-content/uploads/2026/01/turret-punch-presses-m2044tc-152.jpg)