The global tungsten titanium alloy market is experiencing steady growth, driven by rising demand in aerospace, defense, medical, and industrial manufacturing sectors. According to Grand View Research, the global tungsten alloys market was valued at USD 5.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030, fueled by the need for high-density, wear-resistant materials in advanced engineering applications. Similarly, Mordor Intelligence projects continued expansion in specialty metal alloys, with increased R&D investments and technological advancements enhancing performance characteristics for extreme environments. As demand for lightweight yet high-strength materials rises, tungsten titanium alloys—known for their superior density, thermal stability, and corrosion resistance—are becoming critical in high-performance components. This growth trajectory underscores the importance of reliable, innovative manufacturers capable of meeting stringent industry standards. Below, we highlight the top 10 tungsten titanium alloy manufacturers leading the market through technological expertise, global supply chain reach, and consistent product quality.

Top 10 Tungsten Titanium Alloy Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tungsten Manufacturers

Domain Est. 2007

Website: tungstensuppliers.com

Key Highlights: Quickly locate the top tungsten manufacturers and suppliers who offer high quality tungsten made in the USA and custom quotes with easy online purchasing….

#2 Tungsten Titanium Alloy

Domain Est. 2022

Website: attelements.com

Key Highlights: ATT is a professional supplier of high-purity Tungsten Titanium Alloy. We also produce disc, granules, ingot, pellets, pieces, powder , rod, wire, sputtering ……

#3 What Are Tungsten Alloys?

Domain Est. 1995

Website: glemco.com

Key Highlights: Tungsten alloys are created to improve the material’s performance in specific applications. Tungsten on its own is a heavy dense metal known for its high ……

#4 Midwest Tungsten Service – Custom Parts or Order Online

Domain Est. 1997

Website: tungsten.com

Key Highlights: Midwest Tungsten offers the highest quality TIG Electrodes, Tungsten Bucking Bars, Tungsten Fine Wire, and more! Tungsten products & custom machining….

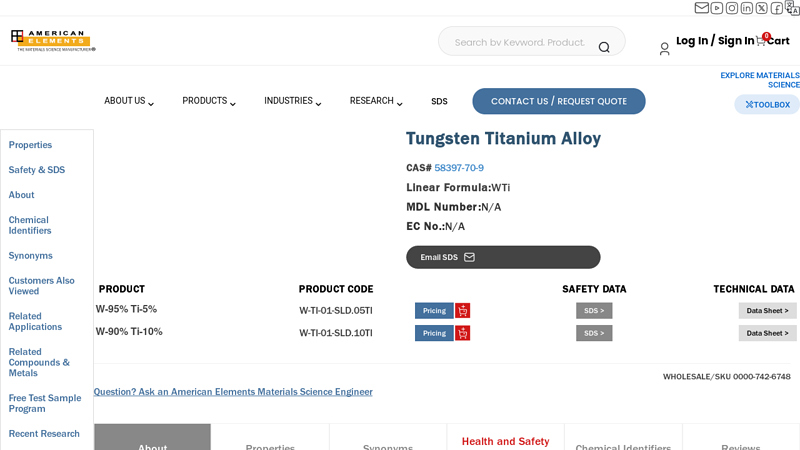

#5 Tungsten Titanium Alloy

Domain Est. 1998

Website: americanelements.com

Key Highlights: Tungsten Titanium Alloy qualified commercial & research quantity preferred supplier. Buy at competitive price & lead time. In-stock for immediate delivery….

#6 Tungsten Titanium Alloy

Domain Est. 2010

Website: tft-pneumatic.com

Key Highlights: Tungsten titanium alloys can display fatigue strength up to 500-800 MPa. This makes them an ideal choice for manufacturing the mentioned parts….

#7 Tungsten Titanium (W/Ti) Evaporation Materials

Domain Est. 2013

Website: samaterials.com

Key Highlights: Starting from $100.00 In stockTungsten Titanium (W/Ti) Evaporation Material is generally evaporated in a vacuum for the purposes of wear and decorative, semiconductor, and optical …

#8 Titanium,Tantalum,Niobium,Molybdenum,Tungsten and alloy …

Domain Est. 2016

Website: giant-metals.com

Key Highlights: Welcome to Giant Metal official website! Weight Calculator | Request A Quote | Contact us. Giant Metal. [email protected]….

#9 Tungsten Tube & Pipe Supplier

Domain Est. 2018

Website: aemmetal.com

Key Highlights: AEM Metals offers custom-made tungsten tubes and tungsten pipes for high-temperature applications. Our products are designed with precision and tailored ……

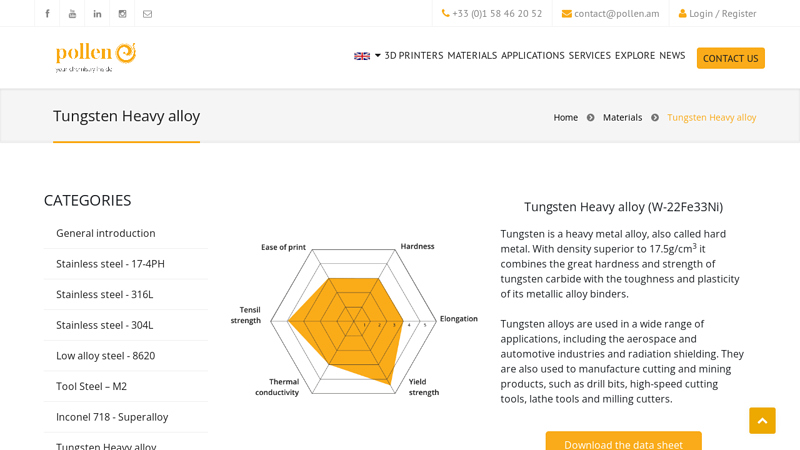

#10 Tungsten Heavy alloy

Website: pollen.am

Key Highlights: Tungsten is a heavy metal alloy, also called hard metal. With density superior to 17.5g/cm 3 it combines the great hardness and strength of tungsten carbide….

Expert Sourcing Insights for Tungsten Titanium Alloy

H2: Projected Market Trends for Tungsten Titanium Alloy in 2026

By 2026, the global market for Tungsten Titanium Alloy (W-Ti) is expected to experience steady growth driven by increasing demand across high-performance industrial sectors. This specialized refractory alloy, known for its exceptional hardness, thermal stability, and corrosion resistance, is anticipated to benefit from advancements in aerospace, defense, medical device manufacturing, and additive manufacturing technologies.

-

Aerospace and Defense Expansion

The aerospace and defense industries will remain the primary drivers of W-Ti alloy demand. With ongoing modernization of military platforms and the development of next-generation aircraft and hypersonic vehicles, the need for lightweight, high-strength materials capable of withstanding extreme temperatures will rise. Tungsten Titanium Alloys offer a favorable strength-to-density ratio and excellent resistance to thermal fatigue, making them suitable for turbine components, missile guidance systems, and armor applications. Geopolitical tensions and increased defense budgets in North America, Europe, and Asia-Pacific are expected to accelerate procurement of advanced materials, including W-Ti alloys. -

Growth in Medical and Biomedical Applications

The medical sector is projected to be a high-growth segment for W-Ti alloys. Their biocompatibility, radiopacity, and mechanical durability make them ideal for surgical instruments, radiation shielding components, and implantable devices such as bone screws and dental implants. As minimally invasive surgeries and personalized medical devices gain traction, demand for corrosion-resistant and non-toxic alloys will increase. Regulatory approvals and R&D investments in biocompatible metallic alloys are expected to support market expansion in this segment by 2026. -

Adoption in Additive Manufacturing (AM)

Advances in metal 3D printing technology are enabling the production of complex geometries with refractory metals. By 2026, additive manufacturing of Tungsten Titanium Alloys is expected to gain momentum, particularly in prototyping and low-volume production for aerospace and energy sectors. Innovations in powder bed fusion and laser-directed energy deposition techniques will improve the processability of W-Ti powders, reducing production costs and waste. This shift is likely to expand the application scope and attract new market entrants. -

Supply Chain and Raw Material Dynamics

Tungsten and titanium are critical raw materials subject to supply concentration risks—China dominates tungsten production, while titanium supply chains are influenced by major producers such as China, Japan, and Russia. Geopolitical factors and export controls could impact material availability and pricing. However, increased recycling efforts and development of alternative extraction technologies (e.g., urban mining and hydrometallurgical processing) are expected to mitigate supply disruptions and support sustainable growth. -

Regional Market Outlook

- Asia-Pacific will remain the largest consumer and producer of W-Ti alloys, driven by China’s industrial expansion, defense modernization, and growing high-tech manufacturing base.

- North America will see robust demand due to defense spending, aerospace innovation, and strong R&D ecosystems.

-

Europe will emphasize sustainability and high-value applications, particularly in medical and green energy technologies.

-

Price and Competitive Landscape

Prices for Tungsten Titanium Alloy are expected to remain volatile due to fluctuating raw material costs and energy-intensive production processes. However, economies of scale and improvements in processing efficiency may stabilize prices over time. The competitive landscape will likely consolidate, with key players investing in vertical integration, material innovation, and strategic partnerships to secure market share.

In conclusion, the 2026 market for Tungsten Titanium Alloy is poised for moderate to strong growth, underpinned by technological advancements and rising demand in mission-critical industries. Companies that innovate in production techniques, ensure supply chain resilience, and align with sustainability goals will be best positioned to capitalize on emerging opportunities.

Certainly. Below is a structured analysis of common pitfalls when sourcing Tungsten Titanium Alloy (also referred to as tungsten-titanium alloys or W-Ti alloys), under the header H2 as requested. These pitfalls primarily revolve around quality assurance and intellectual property (IP) risks.

H2: Common Pitfalls Sourcing Tungsten Titanium Alloy (Quality, IP)

Sourcing Tungsten Titanium Alloy—often used in high-performance applications such as aerospace, defense, and cutting tools—presents several challenges. Buyers must navigate both material quality inconsistencies and intellectual property (IP) concerns, especially when engaging with overseas suppliers or new vendors.

1. Quality-Related Pitfalls

a. Inconsistent Alloy Composition

Tungsten-titanium alloys require precise stoichiometric ratios (e.g., W-25Ti, W-30Ti) to achieve desired mechanical and thermal properties. A common pitfall is receiving material that deviates from specified compositions due to poor process control or lack of certified testing. This can lead to performance failures in critical applications.

b. Impurity Levels and Contamination

Impurities such as oxygen, carbon, or nitrogen can significantly degrade alloy performance, especially at high temperatures. Suppliers may not provide full traceability or certified mill test reports (MTRs), making it difficult to verify purity. Inadequate refining or sintering processes in low-cost manufacturing regions can exacerbate this risk.

c. Lack of Material Certification

Many suppliers, especially in emerging markets, fail to provide full certification per international standards (e.g., ASTM B760 for tungsten alloys). Without proper documentation (e.g., ISO 9001, AS9100 for aerospace), buyers cannot verify quality control procedures or batch traceability.

d. Inadequate Mechanical and Microstructural Testing

Buyers may assume standard testing is performed, but many vendors skip or falsify key tests (e.g., tensile strength, hardness, grain structure analysis). Without access to third-party validation, performance under stress, thermal cycling, or corrosion resistance remains uncertain.

e. Counterfeit or Recycled Material

There is a documented risk of receiving recycled or reprocessed scrap material misrepresented as virgin alloy. This is particularly common in gray-market supply chains and can compromise structural integrity.

2. Intellectual Property (IP) Risks

a. Reverse Engineering and Technology Leakage

Tungsten titanium alloys may be part of proprietary formulations or patented manufacturing processes (e.g., specific sintering techniques or nanostructuring). Sourcing from regions with weak IP enforcement increases the risk that design specs or process know-how could be reverse-engineered or shared with competitors.

b. Unauthorized Production and Duplication

Suppliers may use provided technical drawings, compositions, or process parameters to produce and sell identical or similar alloys to third parties. This is particularly concerning when contracts lack robust confidentiality and non-compete clauses.

c. Lack of IP Ownership Clarity

In custom-developed alloys, ambiguity in contracts about who owns the IP (buyer vs. supplier) can lead to disputes. Suppliers may claim co-ownership or reuse developed formulations for other clients, undermining competitive advantage.

d. Export Control and Compliance Issues

Tungsten-titanium alloys may fall under dual-use export control regulations (e.g., ITAR, EAR) due to defense applications. Sourcing without proper compliance checks risks legal penalties and IP exposure, especially if materials are diverted through third-party intermediaries.

Recommendations to Mitigate Risks

- Require full material traceability and certified test reports (e.g., OES, LECO analysis).

- Engage third-party inspection agencies for pre-shipment quality audits.

- Use NDAs and IP clauses in supplier contracts to protect proprietary formulations.

- Source from certified manufacturers with recognized quality management systems.

- Conduct due diligence on supplier history, including site audits when feasible.

- Monitor export compliance and ensure proper licensing for sensitive alloys.

By proactively addressing these quality and IP pitfalls, organizations can secure reliable, high-integrity Tungsten Titanium Alloy supply chains while protecting innovation and operational performance.

H2: Logistics & Compliance Guide for Tungsten Titanium Alloy

Tungsten titanium alloy, typically a composite or alloy system involving tungsten (W) and titanium (Ti), is used in high-performance applications such as aerospace, defense, and industrial tooling due to its high strength, density, and heat resistance. Due to its composition and potential dual-use nature, shipping and handling these materials require strict adherence to international logistics and regulatory compliance standards.

This guide outlines key considerations for the safe, legal, and efficient logistics and compliance management of tungsten titanium alloy.

H2: 1. Classification and Identification

- Chemical Composition: Confirm exact composition (e.g., W-Ti binary alloy, % by weight, presence of other elements). This affects regulatory classification.

- UN Number & Proper Shipping Name: Tungsten and titanium alloys are generally not classified as hazardous under UN transport regulations unless in powder form or contaminated.

- Solid forms: Typically non-regulated for hazard (UN3089, Environmentally Hazardous Substance, may apply if in powder or dust form).

- Powders: May be classified as flammable solids (UN1309 – Metal powders, n.o.s.) if particle size and reactivity meet criteria.

- HS Code (Harmonized System):

- 8101.99 – Tungsten waste and scrap; other shapes (includes alloys).

- 8108.99 – Titanium waste and scrap; other forms.

- Final HS code depends on form (ingot, powder, fabricated part) and intended use.

H2: 2. Regulatory Compliance

- Export Controls:

- ITAR (International Traffic in Arms Regulations): May apply if alloy is used in defense articles (e.g., missile components, armor). Verify if product is on USML (U.S. Munitions List).

- EAR (Export Administration Regulations): Most tungsten-titanium alloys fall under EAR99 or may be listed on the CCL (Commerce Control List) under ECCN 1C009 (metal alloys for aerospace applications) or 1C350 (tungsten-based alloys exceeding certain thresholds).

- Key thresholds: Tungsten content >90% and density >16.5 g/cm³ may trigger controls.

-

Dual-Use Concerns: Due to applications in high-speed machining, armor-piercing rounds, or aerospace components, export licenses may be required for certain destinations (e.g., China, Russia, Iran).

-

Country-Specific Restrictions:

- China: Regulates exports of tungsten and titanium as strategic materials; import/export permits may be required.

- EU: Follows EU Dual-Use Regulation (Regulation (EU) 2021/821); check if alloy meets controlled specifications.

-

Russia & Sanctioned Jurisdictions: Strict export prohibitions apply; enhanced due diligence required.

-

CITES & Environmental Regulations:

- Not applicable, as tungsten and titanium are not listed under CITES. However, mining and processing may be subject to environmental laws (e.g., REACH in EU for chemical safety).

H2: 3. Packaging and Handling

- Form-Based Requirements:

- Solid Forms (rods, sheets, ingots): Pack in wooden crates or steel containers with moisture barrier to prevent oxidation. Use anti-corrosive wrapping if needed.

- Powders or Fine Particulates: Pack in sealed, inert-gas-filled containers to prevent oxidation and dust dispersion. Label as flammable if applicable.

- Labeling:

- Include product name, composition, net weight, manufacturer, batch number, and handling instructions.

- If classified as hazardous: Apply GHS labels (flammable, health hazard) and transport hazard labels (Class 4.1 Flammable Solid, if applicable).

- Moisture Sensitivity: Titanium-containing alloys may be sensitive to moisture; use desiccants and vapor barrier packaging.

H2: 4. Transportation Guidelines

- Mode of Transport:

- Air (IATA): Follow IATA Dangerous Goods Regulations if material is classified as hazardous (e.g., metal powder). Otherwise, ship as general cargo.

- Sea (IMDG): Comply with IMDG Code for marine transport. Non-hazardous solid alloys typically do not require special handling.

- Land (ADR/RID): For EU/road and rail; apply only if hazardous classification applies.

- Documentation:

- Commercial Invoice

- Packing List

- Certificate of Origin

- Material Safety Data Sheet (MSDS/SDS)

- Export License (if required)

- End-Use Certificate (for sensitive destinations)

H2: 5. Customs Clearance and Duties

- Accurate Valuation and Description: Clearly describe goods as “Tungsten-Titanium Alloy in solid form, for industrial use” to avoid delays.

- Duty Rates: Vary by country. Check with local customs authority. Preferential rates may apply under trade agreements.

- Import Permits: Required in some countries (e.g., India, Brazil) for strategic metals.

- Customs Inspections: Be prepared for physical inspection, especially for high-value or dual-use materials.

H2: 6. Storage and Safety Precautions

- Storage Conditions:

- Dry, temperature-controlled environment.

- Separate from acids and oxidizing agents.

- For powders: Store in explosion-proof cabinets, away from ignition sources.

- Handling:

- Use PPE (gloves, safety glasses) when handling powders.

- Avoid generating dust; use ventilation if machining or grinding.

- Fire Safety:

- Metal fires involving titanium or tungsten require Class D fire extinguishers (dry powder).

- Never use water on burning metal powders.

H2: 7. Recordkeeping and Audit Readiness

- Maintain records for at least 5 years:

- Export licenses

- Shipping manifests

- Compliance certifications

- Due diligence on end-users (especially for dual-use items)

- Conduct internal audits to ensure adherence to export control laws.

H2: Conclusion

Tungsten titanium alloy logistics require a proactive compliance strategy due to its strategic and dual-use potential. Accurate classification, export licensing (where needed), proper packaging, and thorough documentation are essential. Engage with legal and trade compliance experts to ensure adherence to international regulations and prevent shipment delays or penalties.

Always verify the latest regulations with national authorities (e.g., BIS for U.S., DG Trade for EU) before shipping.

In conclusion, sourcing tungsten-titanium alloy requires a thorough evaluation of material specifications, supplier reliability, and cost-effectiveness to ensure optimal performance for intended applications such as cutting tools, aerospace components, or wear-resistant parts. Given the alloy’s high strength, hardness, and thermal stability, selecting a supplier with proven metallurgical expertise, consistent quality control, and compliance with industry standards is critical. Additionally, considerations such as lead times, geographic logistics, and the potential for long-term partnerships can enhance supply chain resilience. Sustainable and ethical sourcing practices should also be prioritized to align with environmental and regulatory expectations. Overall, a strategic and well-informed sourcing approach will ensure reliable access to high-quality tungsten-titanium alloy, supporting both performance and operational efficiency.