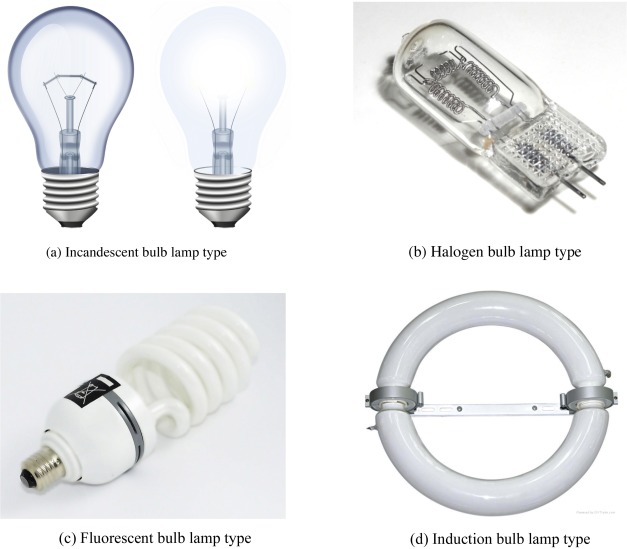

The global lighting market, driven by both legacy and niche applications, continues to see sustained demand for specialized components such as tungsten bulb filaments. Despite the widespread shift toward LED technology, tungsten filaments maintain a critical role in sectors requiring high-temperature stability, including industrial heating, aerospace, and specialty lighting. According to Mordor Intelligence, the global incandescent lamp market is projected to grow at a CAGR of approximately 1.8% from 2023 to 2028, supported by demand in developing regions and specific technical applications where alternatives are ineffective. Similarly, Grand View Research highlights ongoing use in filament-based vacuum and halogen lamps, particularly in medical and industrial equipment, where precision and heat output are paramount. This resilient demand has kept key manufacturers innovating in material science and filament efficiency. Below are the top 8 tungsten bulb filament manufacturers shaping the industry through technological expertise, production scale, and strategic R&D investments.

Top 8 Tungsten Bulb Filament Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Customized Tungsten Filament Suppliers, Manufacturers, Factory

Domain Est. 2013

Website: tdmfginc.com

Key Highlights: T&D is a producer of tungsten lamp filaments, wire filaments, and other specialty components for leading lighting manufacturers….

#2 Tungsten Filament Manufacturer And Supplier

Domain Est. 2001

Website: tungsten-bar.com

Key Highlights: Tungsten filament is used in bulbs, because of tungsten’s properties.Tungsten filament can be made in lots of shapes….

#3 Tungsten Filament

Domain Est. 2011

Website: siriaimpex.com

Key Highlights: Manufacturer of Tungsten Filament – Auto Lamp Filaments, Gls Lamp Filament, Automotive Halogen Filaments and Tungsten LED Filament offered by Siria Elemet ……

#4 Ultra

Domain Est. 2021

Website: en.dynaox.com.cn

Key Highlights: The average diameter of a hair strand is typically 80 μm, and we have the technical capability to manufacture filaments even thinner than that of a hair strand….

#5 Tungsten Lamp Filaments

Domain Est. 2021

Website: elfelectrolumech.com

Key Highlights: ELF Electrolumech manufactures 250 types of miniature and automotive lamp filaments and is one of the largest manufacturers in India. Download PDF Print Page…

#6 Illuminating Excellence

Website: tungstenwire.eu

Key Highlights: At Wiretech, a European manufacturer of high-quality tungsten fine wire, we take pride in supplying industries that rely on tungsten….

#7 Buffalo Tungsten LED Lighting Upgrade

Domain Est. 1999

Website: buffalotungsten.com

Key Highlights: Buffalo Tungsten has upgraded lighting in our facory to LED fixtures, making things brighter and saving a lot of energy at the same time….

#8 Tungsten Light Sources

Domain Est. 1997

Website: photonics.com

Key Highlights: Explore 9 top manufacturers and suppliers of Tungsten Light Sources in our comprehensive photonics buyers’ guide….

Expert Sourcing Insights for Tungsten Bulb Filament

H2: Projected 2026 Market Trends for Tungsten Bulb Filament

As of 2026, the market for tungsten bulb filaments is experiencing a continued decline, driven by technological advancements, regulatory shifts, and changing consumer preferences. Once a cornerstone of the global lighting industry, tungsten (incandescent) bulb filaments now occupy a shrinking niche due to the widespread adoption of energy-efficient alternatives.

-

Declining Market Demand

The demand for tungsten filament bulbs has significantly decreased by 2026. Many countries, including those in the European Union, the United States, and parts of Asia, have enforced bans or restrictions on incandescent lighting to meet energy efficiency and carbon reduction targets. As a result, manufacturing of traditional incandescent bulbs—dependent on tungsten filaments—has declined sharply. -

Shift Toward LED and Energy-Efficient Alternatives

The lighting sector has undergone a structural transformation, with Light Emitting Diodes (LEDs) dominating market share. LEDs consume up to 80–90% less energy than tungsten filament bulbs and offer lifespans exceeding 25,000 hours, compared to 1,000 hours for traditional incandescent bulbs. This shift has reduced the need for tungsten filament production and redirected investment toward semiconductor-based lighting technologies. -

Niche and Specialty Applications

Despite the overall decline, tungsten filaments retain relevance in niche markets. These include: - Specialty lighting: Applications in stage lighting, photography, and film production where high color rendering index (CRI) and precise light quality are critical.

- Industrial and scientific instruments: Use in furnaces, heating elements, and laboratory equipment due to tungsten’s high melting point (3,422°C).

-

Heritage and aesthetic lighting: Vintage-style bulbs used in decorative fixtures, restaurants, and retro design applications continue to support limited filament demand.

-

Raw Material and Supply Chain Dynamics

Tungsten mining and processing remain active, but the end-use demand in lighting has diminished. Major tungsten-producing countries—such as China, Vietnam, and Russia—have redirected supply toward high-tech industries, including aerospace, electronics, and tool manufacturing. The filament lighting segment now represents a small fraction of global tungsten consumption. -

Innovation and Hybrid Technologies

A few manufacturers are exploring hybrid solutions, such as halogen-incandescent bulbs with improved efficiency. While these still use tungsten filaments, they are designed to meet modern efficiency standards and are permitted under certain regulatory frameworks. However, even these hybrid products face stiff competition from smart lighting systems and adaptive LEDs. -

Environmental and Regulatory Pressures

Global climate initiatives, such as the Paris Agreement and national net-zero goals, continue to prioritize energy efficiency. Regulatory bodies are tightening standards, further marginalizing tungsten-based lighting. Recycling and responsible disposal of tungsten components are receiving attention, though the volume from lighting waste is relatively low compared to other e-waste streams.

Conclusion

By 2026, the tungsten bulb filament market is largely considered a legacy segment, with minimal growth prospects in mainstream lighting. While tungsten remains vital in other industrial applications, its role in consumer lighting has been overtaken by superior technologies. The filament lighting industry’s future lies in specialized, high-value applications rather than mass-market adoption. Companies involved in tungsten filament production are increasingly diversifying into advanced materials and alternative sectors to sustain growth.

Common Pitfalls in Sourcing Tungsten Bulb Filament: Quality and Intellectual Property Risks

Sourcing tungsten bulb filaments, while seemingly straightforward, presents significant challenges related to quality consistency and intellectual property (IP) protection. Overlooking these pitfalls can lead to product failures, legal disputes, and reputational damage.

Quality-Related Pitfalls

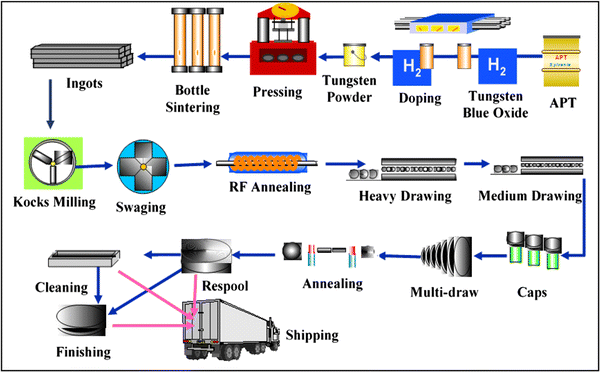

Inconsistent Material Purity and Grain Structure

Tungsten filaments require ultra-high purity (typically >99.95%) and controlled grain structure to ensure optimal ductility, high melting point performance, and longevity. Suppliers may cut costs by using lower-grade tungsten or inadequate sintering processes, resulting in brittle filaments prone to premature breakage during coiling or operation.

Poor Dimensional Accuracy and Tolerance Control

Even minor deviations in wire diameter (often in the range of 10–50 micrometers) significantly affect resistance, brightness, and lifespan. Inconsistent drawing processes or inadequate quality control can lead to batch-to-batch variations, causing uneven light output and shortened bulb life.

Inadequate Ductility and Mechanical Strength

Filaments undergo extensive coiling and handling during bulb assembly. Filaments lacking sufficient ductility due to improper recrystallization or contamination may crack or break, increasing manufacturing waste and reducing yield.

Lack of Traceability and Certification

Many suppliers, especially in less-regulated markets, fail to provide proper material traceability or certifications (e.g., ISO, RoHS, REACH). Without documented quality assurance, buyers face risks of non-compliance and difficulty troubleshooting performance issues.

Intellectual Property-Related Pitfalls

Unauthorized Use of Proprietary Filament Designs

Advanced filament designs—such as coiled-coil (CC) or triple-coil (CCC) configurations—often involve patented geometries, manufacturing processes, or doping techniques (e.g., potassium-doped tungsten for sag resistance). Sourcing from suppliers who replicate these designs without licensing exposes buyers to IP infringement claims.

Reverse-Engineered or Counterfeit Products

Some suppliers offer filaments that mimic high-performance originals but are produced through reverse engineering. These may infringe on patents or trademarks, and their use can trigger legal action from original equipment manufacturers (OEMs) or IP holders, especially in export markets with strict enforcement.

Ambiguous Supply Chain Transparency

Complex or opaque supply chains can obscure the origin of filaments. A supplier might claim compliance while sourcing from downstream vendors using illicit or unlicensed technology. Without robust due diligence, buyers may unknowingly incorporate infringing components.

Inadequate IP Clauses in Contracts

Procurement agreements that lack clear IP indemnification, warranty of non-infringement, or audit rights leave buyers vulnerable. If litigation arises, the burden and cost may fall entirely on the buyer unless the contract explicitly shifts liability to the supplier.

Mitigation Strategies

- Conduct rigorous supplier qualification, including on-site audits and material testing.

- Require full documentation of material origin, processing methods, and compliance certifications.

- Perform independent lab testing for purity, tensile strength, and dimensional accuracy.

- Engage legal counsel to review supplier contracts for IP protections and indemnification.

- Source from reputable, licensed manufacturers and avoid suppliers offering unusually low prices, which may indicate IP or quality compromises.

By proactively addressing these quality and IP pitfalls, companies can ensure reliable performance, regulatory compliance, and freedom to operate in competitive lighting markets.

Logistics & Compliance Guide for Tungsten Bulb Filament

Overview

Tungsten bulb filament is a critical component in the manufacturing of incandescent and halogen light bulbs. Due to its high melting point and electrical resistance, tungsten is ideal for this application. However, transporting and handling tungsten filament requires careful attention to logistics, safety, and regulatory compliance. This guide outlines best practices and key requirements for the safe and compliant movement of tungsten bulb filament across the supply chain.

Classification & Regulatory Framework

Tungsten filament is generally classified as a non-hazardous solid under international transport regulations, such as the UN Model Regulations (UN 3089, Environmentally Hazardous Substance, Solid, Not Otherwise Specified, may apply if contaminated). However, compliance depends on form, packaging, and purity.

– UN Number: Typically UN 3089 (if classified as environmentally hazardous) or not regulated if in solid, pure filament form.

– IMDG Code (Maritime): Class 9 (Miscellaneous) if applicable; otherwise non-regulated.

– IATA DGR (Air): Generally not restricted, but must be declared if meeting criteria for Class 9.

– ADR (Road, Europe): Subject to ADR regulations only if classified as hazardous; otherwise standard cargo rules apply.

Always verify classification based on exact specifications and impurities.

Packaging Requirements

Proper packaging ensures filament integrity and prevents contamination or damage during transit.

– Use sealed, moisture-resistant packaging (e.g., vacuum-sealed bags or desiccant-lined containers).

– Inner packaging should prevent movement and physical damage (e.g., foam inserts or spools).

– Outer packaging must be sturdy (corrugated fiberboard or wooden crates) and labeled appropriately.

– Mark packages with product name, batch number, net weight, manufacturer details, and handling instructions (e.g., “Fragile,” “Keep Dry”).

Storage Conditions

Tungsten filament is stable under normal conditions but sensitive to moisture and mechanical stress.

– Store in a dry, temperature-controlled environment (15–25°C; 40–60% relative humidity recommended).

– Avoid exposure to corrosive chemicals or conductive dust.

– Keep coils or spools upright and supported to prevent deformation.

– Segregate from incompatible materials (e.g., strong oxidizers).

Transportation Guidelines

- Mode Selection: Suitable for road, air, rail, and sea transport when properly packaged. Air freight is preferred for time-sensitive shipments due to filament value and low weight.

- Handling: Use manual or mechanical handling with care to avoid kinking or breaking filaments. Never drop or compress packages.

- Documentation: Include commercial invoice, packing list, certificate of analysis (CoA), and material safety data sheet (MSDS/SDS) even if non-hazardous.

- Customs Compliance: Declare under HS Code 8101.99 (Other unworked tungsten) or 8539.90 (Parts of electric filament lamps), depending on form and destination. Ensure export licenses if required by country (e.g., dual-use regulations).

Environmental & Safety Considerations

- Tungsten is not acutely toxic, but fine dust from broken filaments may pose inhalation risks.

- Provide SDS indicating no significant hazards under normal use.

- Avoid generating dust during handling; use PPE (gloves, safety glasses) as precaution.

- Recycle waste filament through approved metal recovery programs; do not dispose in regular waste.

Compliance with International Standards

- REACH (EU): Tungsten metal is registered; ensure downstream user compliance.

- RoHS: Tungsten filament is exempt from RoHS restrictions as a functional component.

- Conflict Minerals (U.S. SEC Rule 13p-1): Tungsten (3TG) reporting may be required if sourced from conflict-affected regions. Conduct due diligence on supply chain.

- EICC/RESponsible Business Alliance (RBA): Adhere to ethical sourcing and labor standards.

Quality Assurance & Traceability

- Maintain batch traceability from raw material to final filament.

- Conduct regular quality checks for diameter consistency, tensile strength, and purity (typically >99.95% W).

- Include lot numbers on packaging and shipping documents for full traceability.

Emergency Procedures

- Spill/Leak: Sweeping is sufficient; avoid creating dust. Use damp cloth if needed.

- Fire: Tungsten is non-combustible; use standard Class A extinguishers for surrounding materials.

- Exposure: If filament dust is inhaled, move to fresh air. Seek medical attention if irritation persists.

Conclusion

Tungsten bulb filament is generally low-risk in transport but requires careful handling and documentation to ensure product integrity and regulatory compliance. By adhering to this guide, manufacturers, logistics providers, and distributors can ensure safe, efficient, and legally sound operations across global markets. Regular audits and updates to comply with evolving regulations are strongly recommended.

Conclusion on Sourcing Tungsten for Bulb Filaments:

Sourcing tungsten for incandescent bulb filaments requires careful consideration of material purity, supply chain reliability, and cost-efficiency. Tungsten is the ideal material for filaments due to its exceptional melting point, tensile strength, and resistance to evaporation at high temperatures. However, as demand for traditional incandescent bulbs declines in favor of energy-efficient alternatives like LEDs, the market for tungsten filaments has diminished, leading to consolidation among suppliers.

Primary tungsten producers, particularly in China—which dominates global supply—remain key sources, but geopolitical factors, export controls, and environmental regulations can impact availability and pricing. Responsible sourcing must also account for ethical mining practices and environmental sustainability, especially given tungsten’s classification as a conflict mineral in certain regions.

For niche or specialized applications (e.g., specialty lighting, aerospace, or heritage lighting), long-term contracts with reputable suppliers, investment in recycling programs, and exploration of alternative materials or filament technologies may ensure continuity. In summary, while tungsten remains technically superior for filament use, successful sourcing depends on strategic supplier partnerships, adherence to ethical standards, and adaptation to evolving market and regulatory landscapes.