The global tube connectors market is experiencing steady growth, driven by increasing demand across industries such as construction, automotive, and industrial manufacturing. According to Grand View Research, the global tube and pipe fittings market size was valued at USD 43.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. The rise in infrastructure development and the need for durable, modular framing systems—especially those utilizing square tubing—are key factors propelling demand for high-performance tube connectors. As manufacturers seek reliable, efficient, and scalable joining solutions, the selection of appropriate connectors becomes critical. This list highlights the top 10 tube connectors engineered specifically for square tubing applications, evaluated based on load capacity, material quality, ease of assembly, corrosion resistance, and compatibility with industry standards.

Top 10 Tube Connectors For Square Tubing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

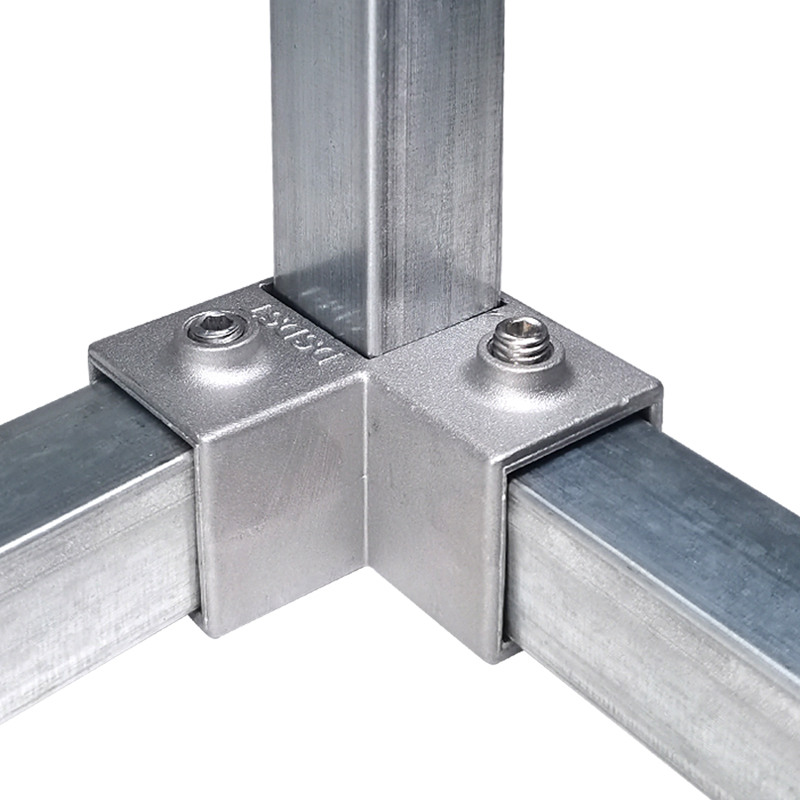

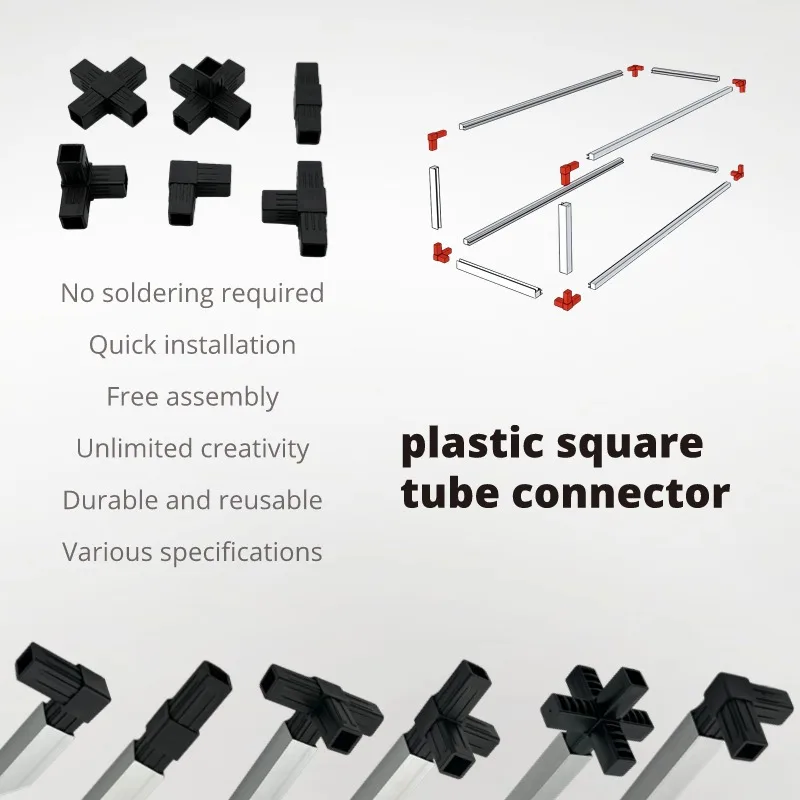

#1 Tube-end caps and connectors

Domain Est. 1996

Website: elesa.com

Key Highlights: Plastic square or round tub-end caps with threaded steel inserts. Available with one, two or three connecting legs, also with adjustable angles….

#2 Shop 80/20

Domain Est. 1997

Website: 8020.net

Key Highlights: 60-day returnsReady Tube connectors for building 80/20 Ready Tube projects: standard tube inserts, extended tube inserts, insert kits, roll pins, and anti-rotation ……

#3 Tubing Connectors Archives

Domain Est. 1998

Website: brunnerent.com

Key Highlights: America’s Premier Distributor of Aluminum Extrusions. Nylon Connectors for 3/4″ and 1″ square tubing made of super-tough Zytel ST 801 HS….

#4 Affordable Structural Pipe Fittings

Domain Est. 2002

Website: easyfit.com

Key Highlights: Square tube is now available! Paired perfectly with our galvanized square fittings, our square tubing is a great product for indoor and outdoor applications….

#5 Telescoping Square Tubing & Fittings

Domain Est. 2002

#6 Carbon Fiber Tube Connector Systems

Domain Est. 2003

Website: dragonplate.com

Key Highlights: DragonPlate’s three tube connector systems make it easy to build carbon fiber tube structures, trusses and space frames….

#7 Tube Connectors For 1″ Square Tubing; “T” Intersection *Order 4 or …

Domain Est. 2003

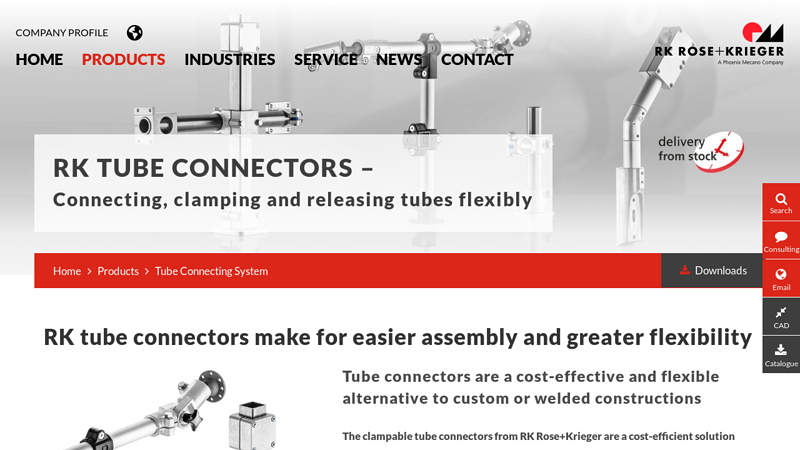

#8 Tube connectors

Domain Est. 2007

Website: rk-rose-krieger.com

Key Highlights: For connecting square and round tubes ✓ Plastic, aluminium & stainless steel ✓ Reusable & flexible ▻ Buy tube connectors online now!…

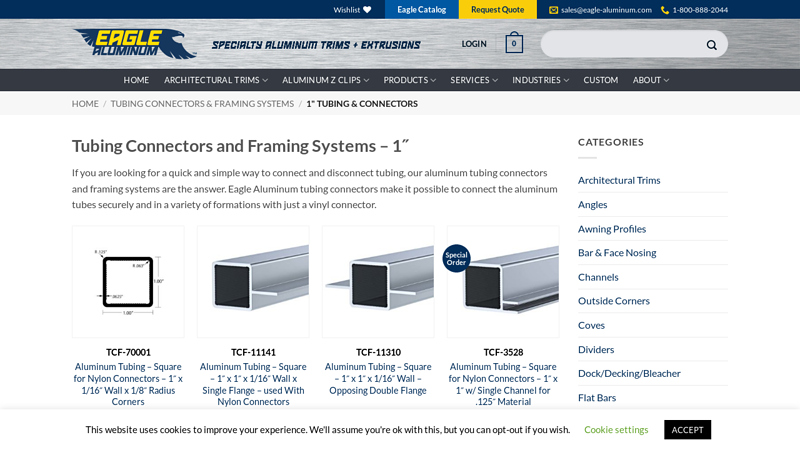

#9 1″ Aluminum Tubing and Connectors for Framing Systems

Domain Est. 2010

Website: eagle-aluminum.com

Key Highlights: $25 delivery 30-day returnsEagle Aluminum tubing connectors make it possible to connect the aluminum tubes securely and in a variety of formations with just a vinyl connector….

#10 Square tube connectors straight

Domain Est. 2012

Website: kippusa.com

Key Highlights: 3-day delivery 30-day returnsSquare tube connectors straight ✓ Made in Germany ✓ Highest quality ✓ Fast delivery ✓ Customer-specific solutions ✓ Download CAD data ✓ Wide range with…

Expert Sourcing Insights for Tube Connectors For Square Tubing

H2: Projected 2026 Market Trends for Tube Connecters for Square Tubing

The global market for tube connectors for square tubing is poised for significant evolution by 2026, driven by advancements in manufacturing, rising demand across key industries, and regional economic shifts. As infrastructure, industrial automation, and modular construction continue to expand, tube connectors—specifically those designed for square tubing—are experiencing increased demand due to their structural efficiency, ease of assembly, and adaptability.

One of the primary drivers shaping the 2026 landscape is the growing adoption of modular and prefabricated construction techniques, particularly in commercial, industrial, and renewable energy sectors. Square tubing, with its high strength-to-weight ratio and compatibility with standardized connectors, is becoming a preferred material for framing systems, solar panel mounts, and machine guarding. This trend is fueling demand for innovative, tool-free, and reusable tube connectors that streamline assembly and reduce labor costs.

Additionally, the industrial automation and robotics sector is expected to be a major end-user by 2026. The need for flexible, reconfigurable workstations and safety enclosures in smart factories is accelerating the use of aluminum extrusion systems, which rely heavily on precision tube connectors. As Industry 4.0 adoption grows, especially in North America, Europe, and parts of Asia-Pacific, the demand for high-tolerance, corrosion-resistant connectors will rise substantially.

Material innovation is another key trend. By 2026, manufacturers are anticipated to shift toward lightweight, high-strength composite connectors and improved aluminum alloys to meet sustainability goals and enhance product longevity. Eco-friendly production processes and recyclability will become critical differentiators in competitive markets.

Regionally, Asia-Pacific is expected to lead market growth due to rapid urbanization, infrastructure development, and expanding manufacturing bases in China, India, and Southeast Asia. Meanwhile, North America and Western Europe will focus on premium, technologically advanced connectors that support automation and green building standards.

In summary, the 2026 market for tube connectors for square tubing will be characterized by innovation in design and materials, expansion in automation and construction applications, and strong regional growth—particularly in emerging economies. Companies that invest in R&D, sustainability, and modular solutions are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Tube Connectors for Square Tubing

Sourcing the right tube connectors for square tubing is critical for structural integrity, safety, and project success. However, buyers often encounter several recurring pitfalls related to quality and intellectual property (IP). Being aware of these issues can help avoid costly mistakes.

Poor Material Quality and Durability

One of the most frequent problems is receiving connectors made from substandard materials. Low-quality steel or aluminum may lack the necessary strength, leading to deformation or failure under load. Some suppliers use inconsistent alloys or skip essential treatments like galvanization or anodizing, resulting in premature corrosion—especially in outdoor or industrial environments.

Inaccurate Dimensional Tolerances

Square tubing connectors must match the outer dimensions of the tubing precisely. Poorly manufactured connectors often have incorrect inner dimensions, leading to loose fits or difficulty during assembly. This can compromise structural stability and increase labor time. Variability between batches is another concern, especially when sourcing from manufacturers with lax quality control.

Lack of Load Rating Certification

Many generic or off-brand connectors do not come with verified load ratings, safety certifications, or engineering test data. Without this information, it’s impossible to ensure the connector will perform safely under expected loads. Relying on untested products increases liability risk and may violate building or safety codes.

Counterfeit or IP-Infringing Products

A significant IP-related pitfall is the proliferation of counterfeit connectors that mimic patented designs from reputable brands. These knock-offs often copy the appearance but not the engineering, using inferior materials and manufacturing processes. Purchasing such products can expose companies to legal risks, including contributory infringement claims, especially if the original design is protected by utility or design patents.

Inadequate Documentation and Traceability

Reputable suppliers provide material certifications (e.g., mill test reports), compliance documentation (e.g., ISO, CE), and traceability information. Many low-cost suppliers fail to offer these, making it difficult to verify quality or meet regulatory requirements in regulated industries like construction or aerospace.

Short-Term Cost vs. Long-Term Value

Focusing solely on upfront price often leads buyers to choose cheaper connectors that fail prematurely or require frequent maintenance. This false economy results in higher total cost of ownership due to repairs, downtime, or safety incidents. Investing in high-quality, IP-protected connectors from trusted manufacturers typically offers better performance and long-term savings.

Avoiding these pitfalls requires due diligence: vetting suppliers, requesting samples and certifications, verifying IP status, and prioritizing performance over initial cost.

Logistics & Compliance Guide for Tube Connectors for Square Tubing

This guide outlines the key logistics and compliance considerations for the transportation, storage, handling, and regulatory adherence of tube connectors designed for square tubing. Proper management in these areas ensures product integrity, supply chain efficiency, and legal compliance.

Product Classification & Handling

Tube connectors for square tubing are typically categorized as industrial hardware or structural fittings. They are commonly made from materials such as steel, stainless steel, aluminum, or plastic. Due to their rigid and often metallic construction, they require careful handling to prevent deformation, surface damage, or corrosion. Use protective packaging (e.g., corrugated boxes, pallet wraps, or anti-corrosion VCI paper) and handle with appropriate lifting equipment to avoid injury or product damage.

Packaging & Labeling Standards

All shipments must adhere to standardized packaging protocols to prevent transit damage. Connectors should be securely packed in unitized loads on wooden or plastic pallets, shrink-wrapped for stability. Labels must include:

– Product name and SKU/Part number

– Quantity per package

– Net weight and gross weight

– Handling symbols (e.g., “Fragile,” “This Side Up”)

– Manufacturer and supplier information

– Batch or lot numbers for traceability

Compliance with GS1 standards for barcoding is recommended for inventory and logistics tracking.

Transportation Requirements

Shipments must comply with domestic and international transport regulations, including:

– Road/Rail: Adherence to weight limits, load securement standards (e.g., EUMOS, ASTM D6055), and vehicle safety regulations.

– Air Freight: Compliance with IATA Dangerous Goods Regulations if applicable (e.g., for coated or treated metal fittings with volatile substances).

– Ocean Freight: Use of ISPM 15-compliant wooden pallets (heat-treated and stamped) to prevent pest spread. Waterproof wrapping is advised to protect against humidity.

Import/Export Compliance

For cross-border shipments, ensure compliance with relevant trade regulations:

– Accurate HS (Harmonized System) code classification – typically under 7326.90 (other articles of iron or steel) or 8302.50 (base metal mountings, fittings).

– Proper documentation including commercial invoice, packing list, bill of lading, and certificate of origin.

– Compliance with destination country standards (e.g., CE marking in the EU, ANSI/ASME standards in the U.S.).

– Screening against restricted party lists and adherence to export control regulations (e.g., EAR in the U.S.).

Regulatory & Safety Standards

Tube connectors must meet applicable industry and safety standards depending on region and application:

– North America: Conformance with ASTM or ANSI standards for structural integrity and dimensional accuracy.

– European Union: Compliance with CE marking requirements under the Construction Products Regulation (CPR) if used in load-bearing applications.

– RoHS & REACH: Ensure materials are free from restricted substances, especially for connectors used in sensitive environments.

– OSHA & WHMIS: Provide Safety Data Sheets (SDS) when required, particularly for metal components with surface treatments or coatings.

Storage Conditions

Store tube connectors in a dry, temperature-controlled environment to prevent corrosion, especially for carbon steel variants. Keep pallets off the floor and away from direct sunlight or moisture sources. Rotate stock using FIFO (First In, First Out) to minimize aging and ensure traceability. Maintain clean storage areas to avoid contamination.

Sustainability & End-of-Life Compliance

Support environmental compliance by:

– Using recyclable packaging materials.

– Providing take-back or recycling programs where feasible.

– Ensuring product materials are recyclable (e.g., metals can be reclaimed).

– Complying with WEEE or ELV directives if applicable to the end-use application.

Adhering to this logistics and compliance framework ensures that tube connectors for square tubing are delivered safely, legally, and sustainably across global supply chains.

Conclusion: Sourcing Tube Connectors for Square Tubing

In conclusion, sourcing tube connectors for square tubing requires careful consideration of several key factors to ensure compatibility, structural integrity, and ease of assembly. The selection process should begin with verifying dimensional accuracy—matching the outer diameter of the square tubing with appropriately sized connectors. Material compatibility, load requirements, and environmental conditions (such as exposure to moisture or corrosive elements) must also be evaluated to determine the optimal connector material, such as stainless steel, zinc-plated steel, or engineered polymers.

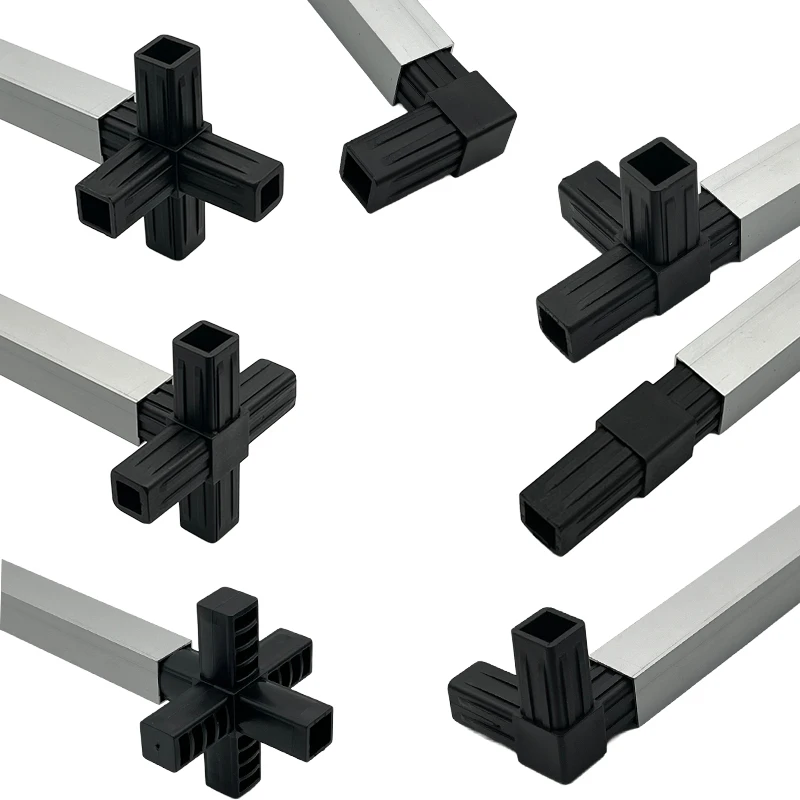

A variety of connector types—such as T-joints, elbow connectors, cross connectors, and flange adapters—offer flexibility in design and application, supporting uses ranging from structural frameworks to industrial fixtures and display systems. While off-the-shelf solutions are readily available from industrial suppliers and online vendors, custom or specialty connectors may be necessary for unique or high-performance applications.

Ultimately, prioritizing quality, precision, and suitability for the intended use will lead to reliable and durable assemblies. By partnering with reputable suppliers and utilizing detailed specifications during procurement, organizations can efficiently source the right tube connectors to meet both functional and economic objectives in their square tubing projects.