The global axial fan market is experiencing robust growth, driven by rising demand for efficient ventilation and cooling solutions across industrial, commercial, and residential sectors. According to Grand View Research, the global industrial fans market size was valued at USD 5.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. Similarly, Mordor Intelligence forecasts a CAGR of approximately 7.2% for the axial and centrifugal fans market over the same period, citing increased infrastructure development and heightened focus on energy efficiency as key growth catalysts. Within this expanding landscape, tube axial fans have emerged as a preferred solution for high-volume air movement in HVAC systems, industrial exhaust, and tunnel ventilation due to their streamlined design and superior airflow performance. As demand continues to rise, a select group of manufacturers have distinguished themselves through innovation, reliability, and global reach. Here are the top 9 tube axial fan manufacturers shaping the industry’s future.

Top 9 Tube Axial Fan Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tube Axial Fans

Domain Est. 1995

Website: greenheck.com

Key Highlights: Tube axial inline fans offer a lower cost option and are applied in ducted and unducted commercial or industrial applications….

#2 Tubeaxial Fixed Pitch Fans

Domain Est. 1996

Website: nyb.com

Key Highlights: Tubeaxial Fans are designed for ventilation and industrial-process applications. Uses include heat, smoke, and fume removal; process drying with ambient or ……

#3 Axial fans

Domain Est. 1998

Website: ebmpapst.com

Key Highlights: Axial fans from ebm-papst move air for heat or cold exchange. They impress with their low installation depth, low noise level and excellent efficiency….

#4 Axial Fans

Domain Est. 1998

Website: cincinnatifan.com

Key Highlights: Cincinnati Fan provides quality axial fans, tube fans, and exhaust fans at competitive prices, backed by dependable service….

#5 Tubeaxial Fans

Domain Est. 1998

Website: rotron.com

Key Highlights: Tubeaxial fans, which are integrated axial flow air moving devices, excel in aerospace and defense applications where space constraints are a critical ……

#6 Tubeaxial Fans

Domain Est. 1999

Website: continentalfan.com

Key Highlights: Continental Fan’s heavy duty Tubeaxial Fans feature welded steel construction with spark resistant, cast aluminum airfoil impellers….

#7 Tube Axial Fan

Domain Est. 1999

Website: knapeassociates.com

Key Highlights: Enhance airflow control, safety, and installation flexibility with essential accessories for tube axial fans. Each accessory supports efficient system operation ……

#8 Tube Axial Fans

Domain Est. 2015

Website: republic-mfg.com

Key Highlights: Republic Manufacturing offers a complete line of high flow tube axial fans which are low-maintenance and oil-free in design to provide continuous, ……

#9 Tube Axial Fans

Domain Est. 2020

Website: cookmfg.com

Key Highlights: Our tube axial fans are ideal for most intake and exhaust applications. We offer a wide range of standard sizes and air flow ratings. Manufactured in the USA ……

Expert Sourcing Insights for Tube Axial Fan

2026 Market Trends for Tube Axial Fans

The global tube axial fan market is poised for steady growth and transformation by 2026, driven by evolving industrial needs, technological advancements, and sustainability imperatives. Key trends shaping the market include:

1. Rising Demand Driven by Infrastructure and Industrial Expansion

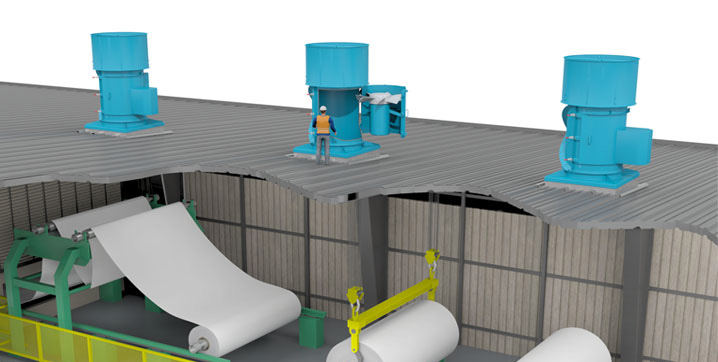

Continued investments in infrastructure development, particularly in emerging economies, are fueling demand for ventilation and cooling systems. Tube axial fans are extensively used in commercial buildings, tunnels, power plants, and manufacturing facilities. The expansion of data centers, urban transit systems, and industrial automation will further boost market growth through 2026.

2. Energy Efficiency and Regulatory Compliance

Stringent energy efficiency standards—such as those from the DOE (U.S. Department of Energy), EU Ecodesign Directive, and other regional regulations—are pushing manufacturers to develop high-efficiency tube axial fans. By 2026, fans equipped with EC (electronically commutated) motors and advanced aerodynamic designs will dominate new installations, reducing operational costs and carbon footprints.

3. Integration with Smart Building Systems

The trend toward smart buildings and Industry 4.0 is driving demand for intelligent ventilation solutions. Tube axial fans with integrated sensors, IoT connectivity, and variable speed controls are increasingly adopted for real-time monitoring, predictive maintenance, and optimized airflow management. This integration enhances performance and supports energy savings in dynamic environments.

4. Growth in HVAC and Tunnel Ventilation Applications

Heating, ventilation, and air conditioning (HVAC) systems remain a primary application area. Additionally, increased focus on safety and air quality in underground infrastructure—such as road and rail tunnels—will drive demand for reliable and high-capacity tube axial fans for emergency smoke extraction and routine ventilation.

5. Regional Market Shifts and Manufacturing Localization

Asia-Pacific is expected to lead market growth due to rapid industrialization and urbanization in countries like India, Vietnam, and Indonesia. At the same time, supply chain resilience concerns are prompting a shift toward regional manufacturing, reducing dependency on single-source suppliers and enabling faster customization.

6. Sustainability and Material Innovation

Environmental concerns are influencing material choices and lifecycle management. Manufacturers are exploring lightweight composites, recyclable materials, and corrosion-resistant coatings to extend product life and reduce environmental impact. By 2026, sustainability will be a key differentiator in procurement decisions.

In conclusion, the 2026 tube axial fan market will be characterized by innovation in efficiency, intelligence, and sustainability, with strong growth anchored in infrastructure development and regulatory trends. Companies that adapt to these dynamics will be best positioned to capture emerging opportunities.

Common Pitfalls Sourcing Tube Axial Fan (Quality, IP)

Sourcing Tube Axial Fans for industrial or commercial applications requires careful attention to quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to premature failure, safety hazards, or inefficient performance. Below are common pitfalls to avoid:

1. Ignoring IP Rating Requirements

One of the most frequent mistakes is selecting a fan with an inadequate IP rating for the operating environment. For example:

– Using an IP54-rated fan in a high-moisture or outdoor setting where IP65 or higher is needed.

– Assuming all “weatherproof” fans meet the required protection level without verifying the official IP classification.

Always match the IP rating to environmental conditions—dust, water exposure, and washdown requirements.

2. Prioritizing Low Cost Over Build Quality

Opting for cheaper fans may result in:

– Inferior materials (e.g., plastic housings that warp or corrode).

– Poor motor insulation leading to early burnout.

– Inconsistent blade balance causing vibration and noise.

Invest in reputable manufacturers with proven quality control to avoid frequent replacements and downtime.

3. Misunderstanding Airflow and Static Pressure Needs

Many buyers focus solely on maximum airflow (CFM or m³/h) without considering system resistance. A fan may have high airflow in free delivery but underperform if static pressure requirements are not met.

– Ensure the fan’s performance curve matches the system’s pressure demands.

– Verify testing standards used (e.g., AMCA certification) for reliable data.

4. Overlooking Motor Quality and Insulation Class

The motor is critical to longevity. Pitfalls include:

– Selecting motors without proper insulation (e.g., Class B instead of Class F or H in high-temperature environments).

– Ignoring motor protection features such as thermal overload protection.

Always confirm motor specifications align with operational temperature and duty cycle.

5. Assuming All “Industrial” Fans Are Suitable for Harsh Environments

Not all industrial-grade fans are built for corrosive, humid, or explosive atmospheres.

– Verify material compatibility (e.g., stainless steel or epoxy-coated components for corrosive settings).

– For hazardous locations, ensure compliance with ATEX or IECEx standards if applicable.

6. Skipping Verification of Certifications and Testing

Relying on supplier claims without documentation can be risky.

– Request test reports for airflow, noise, and efficiency.

– Confirm IP ratings are third-party certified, not self-declared.

– Look for compliance with standards like ISO, AMCA, or CE.

7. Poor Supplier Vetting and After-Sales Support

Choosing suppliers based solely on price or convenience can backfire.

– Lack of technical support or warranty service leads to operational delays.

– Risk of counterfeit or substandard products from unverified sources.

Work with established suppliers who provide documentation, warranties, and responsive support.

By addressing these pitfalls early, buyers can ensure reliable, efficient, and long-lasting performance from their Tube Axial Fan installations.

Logistics & Compliance Guide for Tube Axial Fans

Product Overview

Tube axial fans are ventilation devices designed to move air efficiently through ducts and industrial systems. They are commonly used in HVAC, industrial processing, and building ventilation applications. Proper logistics and compliance management is essential to ensure safe handling, regulatory adherence, and timely delivery.

Packaging and Handling

Proper packaging is critical to prevent damage during transit. Tube axial fans should be securely crated or palletized with protective materials such as foam, edge protectors, and waterproof covers. Ensure fan blades and motors are immobilized to avoid internal damage. Handling instructions, including “This Side Up” and “Fragile” labels, must be clearly marked on all packaging.

Transportation Requirements

Transport via road, sea, or air must comply with carrier-specific regulations. For international shipments, fans must meet International Maritime Dangerous Goods (IMDG) Code standards if motor components contain restricted substances. Use climate-controlled containers when transporting to regions with extreme temperatures to protect electrical components.

Import and Export Compliance

Ensure compliance with export control regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation, especially if fans incorporate advanced motor control systems. Verify Harmonized System (HS) codes—typically 8414.59 for axial fans—for accurate customs declaration. Obtain necessary export licenses where required.

Electrical and Safety Standards

Tube axial fans must conform to regional electrical safety standards. Key certifications include:

– CE Marking (EU): Complies with Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

– UL/cUL (USA/Canada): Certified to UL 507 for electric fans.

– IEC 60335-2-80: International safety standard for fans.

Ensure documentation, including test reports and conformity certificates, is available for customs and end-user verification.

Environmental and RoHS Compliance

Fans and their components must comply with the Restriction of Hazardous Substances (RoHS) Directive (EU 2011/65/EU) and, where applicable, China RoHS. Confirm that materials such as lead, mercury, cadmium, and certain flame retardants are within permissible limits. Provide a RoHS compliance declaration upon request.

Documentation Requirements

Accurate documentation is essential for smooth logistics and customs clearance. Required documents include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Conformity (CE, UL, etc.)

– RoHS and REACH Compliance Statement

– Export License (if applicable)

Customs Clearance Procedures

Engage licensed customs brokers to facilitate clearance. Provide detailed product descriptions, including voltage, power rating, and intended use. Be prepared for inspections, particularly for electrical equipment entering regulated markets like the EU, USA, and Australia.

Labeling and Marking

All units must display permanent labels with:

– Manufacturer name and address

– Model and serial number

– Voltage and frequency (e.g., 230V~50Hz)

– Power rating (kW or HP)

– Safety certification marks (CE, UL, etc.)

– IP rating (e.g., IP55 for dust and water resistance)

Storage Guidelines

Store fans in dry, temperature-controlled environments away from direct sunlight and corrosive substances. Keep packaging intact until installation. Stack pallets no higher than recommended to prevent crushing.

End-of-Life and WEEE Compliance

For sales in the European Union, comply with the Waste Electrical and Electronic Equipment (WEEE) Directive. Register with national WEEE authorities and provide take-back options. Label products with the crossed-out wheeled bin symbol to indicate proper disposal requirements.

Supplier and Manufacturer Verification

Ensure all manufacturing partners are ISO 9001 certified and capable of providing traceable component sourcing. Conduct periodic audits to verify continued compliance with quality and environmental standards.

Incident Reporting and Recalls

Establish a process for reporting non-conformities, safety issues, or compliance failures. In the event of a product recall, follow regulatory procedures in affected regions and notify relevant authorities promptly.

Summary

Successful logistics and compliance for tube axial fans require attention to packaging, transportation safety, regulatory certification, and documentation. Adherence to international and regional standards ensures product acceptance, customer safety, and smooth global distribution.

Conclusion for Sourcing Tube Axial Fans

In conclusion, sourcing tube axial fans requires a comprehensive evaluation of technical specifications, application requirements, and supplier reliability. These fans are ideal for applications demanding high airflow at low static pressure, such as ventilation in commercial buildings, industrial exhaust systems, and cooling in HVAC setups. When selecting a supplier, key factors such as fan performance (airflow, pressure, efficiency), material quality, noise levels, energy consumption, and compliance with industry standards (e.g., AMCA, ISO) must be carefully assessed.

Additionally, considering total cost of ownership—factoring in energy efficiency and maintenance requirements—can lead to long-term savings despite higher initial investment. Building relationships with reputable manufacturers or distributors who offer technical support, warranties, and customization options ensures product suitability and operational reliability.

Ultimately, a strategic sourcing approach that balances performance, cost, and quality will result in the successful integration of tube axial fans into the intended system, enhancing overall efficiency and system longevity.